Documente Academic

Documente Profesional

Documente Cultură

Determination of Coefficient of Discharge of A Venturi Meter

Încărcat de

Joffer GallamasoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Determination of Coefficient of Discharge of A Venturi Meter

Încărcat de

Joffer GallamasoDrepturi de autor:

Formate disponibile

College of Engineering Subject: CE 47 Hydraulics Experiment #: 1 Experiment Title: Determination of Coefficient of Discharge of a Venturi Meter Objectives: To determine the

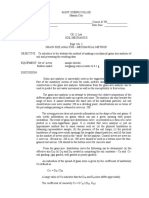

e coefficient of discharge of a given Venturi meter Apparatus: Venturi meter, Measuring tank, and Timer Procedure: 1. Examine the schematics of the Venturi meter. Draw its schematics and record its dimensions. 2. Turn on the pump beneath the Venturi meter. Make sure to fill the tank of with the pump higher than the elevation of the pump. 3. Simultaneously with operating the pump, open the gate valve. Set the discharge as maximum as possible. 4. Observe the flow and pressures at the pressure gauges. When the flow and pressures are steady, record the discharge with the measuring tank and timer. 5. Record the pressures indicated in the pressure gauges. Set the pressure of the pressure gauge at the inlet as P1 and at the throat as the P2. 6. Set Procedures 3-5 as Trial 1 and repeat the same procedures for the next two trials with the exception of the discharge being approximately three-quarters of the previous discharge by regulating the gate valve. Calculations: Use the equation below as derived from Bernoullis Equation and Continuity Equation of Discharge: Where: Q Cd HI HT AI AT

= discharge = coefficient of discharge = head at inlet section = head at throat section = area of pipe cross-section at inlet section = area of pipe cross-section at throat section

Additional calculations: With the same Venturi meter, compute the discharge if the coefficient of discharge is Cd = 0.955 Compute the percentage difference of the theoretical coefficient of discharge with the discharge from the three trials. Discussion: Derive and explain the given formula in the calculations. Note: The discussion is a separate part in your report. Do not mix it in your Data Analysis!

Drafted by: SJ, 11/14/12

S-ar putea să vă placă și

- Venturimeter LAB ReportDocument7 paginiVenturimeter LAB ReportJames Roy100% (1)

- Mapua Institute of Technology Experiment Validates Bernoulli's TheoremDocument16 paginiMapua Institute of Technology Experiment Validates Bernoulli's TheoremNadine Pascual100% (2)

- Pipe Friction ApparatusDocument6 paginiPipe Friction ApparatusShubham MauryaÎncă nu există evaluări

- Venturimeter (Discharge Coefficient)Document16 paginiVenturimeter (Discharge Coefficient)saleemdbg76% (21)

- Lab Report 3Document14 paginiLab Report 3Siti Syuhadah0% (1)

- Flow Meter Procedure: Rotameter, Venturi, OrificeDocument3 paginiFlow Meter Procedure: Rotameter, Venturi, OrificeZafirah Zaidi100% (1)

- Fluid Flow Measurement Lab: ObjectDocument9 paginiFluid Flow Measurement Lab: ObjectAboodÎncă nu există evaluări

- (Lab Report Operation Unit) Experiment 1 (A) Measuring Specific Gravity of A Liquid by Using Measuring Beaker, Eureka Can, Density Bottle and Hydrometer MethodDocument6 pagini(Lab Report Operation Unit) Experiment 1 (A) Measuring Specific Gravity of A Liquid by Using Measuring Beaker, Eureka Can, Density Bottle and Hydrometer MethodFazsroul100% (1)

- Flow Demonstration ExperimentDocument5 paginiFlow Demonstration ExperimentVictoria SooknananÎncă nu există evaluări

- Flowmeter DEMONSTRATIONDocument20 paginiFlowmeter DEMONSTRATIONAfiq IkhwanÎncă nu există evaluări

- Bernoulli'S Theorem Demonstration: Experiment No. 04Document3 paginiBernoulli'S Theorem Demonstration: Experiment No. 04ChristopherHiladoÎncă nu există evaluări

- Osborne Reynolds' Experiment Visualises Laminar and Turbulent FlowDocument9 paginiOsborne Reynolds' Experiment Visualises Laminar and Turbulent Flowwasiq999Încă nu există evaluări

- Bernoulli's Theorem ExperimentDocument4 paginiBernoulli's Theorem ExperimentT/ROX94% (18)

- Che486 l7 Osbourne Reynolds ApparatusDocument23 paginiChe486 l7 Osbourne Reynolds ApparatusEreen100% (1)

- CE 410 Hydraulics: Venturi MeterDocument4 paginiCE 410 Hydraulics: Venturi MeterJENNIFER ARELLANOÎncă nu există evaluări

- Hydraulic Bench Flow RateDocument9 paginiHydraulic Bench Flow RateJudith LacapÎncă nu există evaluări

- Demonstration of Bernoulli's EquationDocument27 paginiDemonstration of Bernoulli's Equationmahbub1332100% (5)

- Lab06rotating VesselDocument3 paginiLab06rotating VesselJQÎncă nu există evaluări

- Bernoulli Theorem DemonstrationDocument27 paginiBernoulli Theorem DemonstrationmanzahuhuÎncă nu există evaluări

- Hydrostatic forces on immersed plane surfacesDocument9 paginiHydrostatic forces on immersed plane surfacesEssam Ahmed Abd MeguidÎncă nu există evaluări

- Conclusion & Recomendation Thermo Exp 4Document2 paginiConclusion & Recomendation Thermo Exp 4Zoltar JRÎncă nu există evaluări

- Specific Gravity Determination Using U-Tube ManometerDocument8 paginiSpecific Gravity Determination Using U-Tube ManometerOliver LoridoÎncă nu există evaluări

- Application of WeirDocument10 paginiApplication of Weirdanial 96Încă nu există evaluări

- Determination of The Coefficient of Discharge of A Trapezoidal WeirDocument1 paginăDetermination of The Coefficient of Discharge of A Trapezoidal WeirJoffer Gallamaso100% (2)

- CC501 - Lab - 1 HydraulicDocument11 paginiCC501 - Lab - 1 HydraulicMuhammad Azizul100% (1)

- FM Dec - 2009Document20 paginiFM Dec - 2009Divyesh Morabiya80% (5)

- Fluid FrictionDocument18 paginiFluid Frictioncakhoa100% (2)

- Slump Test Determines Concrete WorkabilityDocument3 paginiSlump Test Determines Concrete WorkabilityKevin P MendozaÎncă nu există evaluări

- The Two Peg TestDocument22 paginiThe Two Peg TestCJLara75% (4)

- Table of Content DocDocument17 paginiTable of Content DocjjÎncă nu există evaluări

- Measurement of Density, Specific Gravity and Viscosity of LiquidsDocument10 paginiMeasurement of Density, Specific Gravity and Viscosity of LiquidsSaid Ahmed Ali100% (2)

- Bernoulli S Principle Demonstration Lab ReportDocument18 paginiBernoulli S Principle Demonstration Lab ReportHasan RabyÎncă nu există evaluări

- Doe Hydraulics EngineeringDocument30 paginiDoe Hydraulics EngineeringMaster Pits100% (1)

- Lab Manual-Manomety Lab Experiment PDFDocument12 paginiLab Manual-Manomety Lab Experiment PDFcheeball100% (1)

- Lecture 4 (Hydrostatic Force On Plane Surfaces) - 1077388911Document2 paginiLecture 4 (Hydrostatic Force On Plane Surfaces) - 1077388911jose rufino ygbuhayÎncă nu există evaluări

- Experiment no. 4 Hydrostatic Force on Submerged and Semi ʹ submerged Rectangular Area 1. bjectiveDocument6 paginiExperiment no. 4 Hydrostatic Force on Submerged and Semi ʹ submerged Rectangular Area 1. bjectiveGien Lim100% (1)

- Theory and Introduction Multi Pump Test RigDocument6 paginiTheory and Introduction Multi Pump Test RigIkhwhanif KhalidÎncă nu există evaluări

- Axially Loaded Members: Changes in Lengths and EffectsDocument59 paginiAxially Loaded Members: Changes in Lengths and EffectsAshok Dargar67% (3)

- Exp 5 Head Loss Due To FrictionDocument17 paginiExp 5 Head Loss Due To FrictionnileshÎncă nu există evaluări

- Lab 3 - Hydrostatic Forces On Plane and Curved SurfacesDocument5 paginiLab 3 - Hydrostatic Forces On Plane and Curved SurfacesAlyssa Suzanne TafallaÎncă nu există evaluări

- Experiment No. 1 Performance Test of Centrifugal PumpDocument24 paginiExperiment No. 1 Performance Test of Centrifugal PumpAli Requiso MahmudÎncă nu există evaluări

- Hydraulic Bench Parts DemoDocument4 paginiHydraulic Bench Parts DemoAliya A KhanÎncă nu există evaluări

- Grain Size Analysis - Mechanical MethodDocument3 paginiGrain Size Analysis - Mechanical MethodRian BernanteÎncă nu există evaluări

- Particle Size Analysis Using a HydrometerDocument13 paginiParticle Size Analysis Using a HydrometerShubhrajit MaitraÎncă nu există evaluări

- Experiment1 Orifice and Jet Flow Group1 A03Document6 paginiExperiment1 Orifice and Jet Flow Group1 A03Francis Aeron PabalanÎncă nu există evaluări

- Calibrating Bourdon Pressure GaugeDocument6 paginiCalibrating Bourdon Pressure GaugeKhairil IkramÎncă nu există evaluări

- Lab Report 01Document3 paginiLab Report 01Rao MaazÎncă nu există evaluări

- Manometers Practice Problem - Continue - SolutionsDocument6 paginiManometers Practice Problem - Continue - SolutionsAli Al Abdullah100% (2)

- Spot Speed StudyDocument18 paginiSpot Speed Studymmorvin89Încă nu există evaluări

- NCESQ 2018 QuestionsDocument3 paginiNCESQ 2018 QuestionsMelanio VillaverdeÎncă nu există evaluări

- Che Lab Report On Flow Over WeirsDocument14 paginiChe Lab Report On Flow Over WeirsJonelou Cusipag100% (1)

- Centrifugal Pump Test RigDocument4 paginiCentrifugal Pump Test RigVaidish Sumaria100% (1)

- 3.5.2 Two Envelope System Inguillo and ZoletsDocument1 pagină3.5.2 Two Envelope System Inguillo and ZoletsXyrile ß IngilloÎncă nu există evaluări

- Hydraulics Problem SetDocument17 paginiHydraulics Problem SetJebone Stein Web JuarbalÎncă nu există evaluări

- Water Flow Experiment: Head Losses in Pipe FittingsDocument8 paginiWater Flow Experiment: Head Losses in Pipe Fittingssaad_arif_10Încă nu există evaluări

- 2 Nozzle Pressure DistributionDocument4 pagini2 Nozzle Pressure DistributionKonul AlizadehÎncă nu există evaluări

- Energy Loss Factors for Pipe FittingsDocument5 paginiEnergy Loss Factors for Pipe FittingsChristine Joyce A. CortezÎncă nu există evaluări

- Laboratory Manual MEC 212Document43 paginiLaboratory Manual MEC 212Kirandeep GandhamÎncă nu există evaluări

- Experiment No 7Document7 paginiExperiment No 7Faizan Ahmed67% (3)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDe la EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGÎncă nu există evaluări

- CE 41 Lab Report FormatDocument2 paginiCE 41 Lab Report FormatJoffer GallamasoÎncă nu există evaluări

- Determination of Pump EfficiencyDocument1 paginăDetermination of Pump EfficiencyJoffer GallamasoÎncă nu există evaluări

- Determination of Discharge by Use of The Pitot TubeDocument2 paginiDetermination of Discharge by Use of The Pitot TubeJoffer Gallamaso100% (4)

- Determination of The Coefficient of Discharge of A Trapezoidal WeirDocument1 paginăDetermination of The Coefficient of Discharge of A Trapezoidal WeirJoffer Gallamaso100% (2)

- Determination of The Coefficient of Discharge of A Trapezoidal WeirDocument1 paginăDetermination of The Coefficient of Discharge of A Trapezoidal WeirJoffer Gallamaso100% (2)

- Laboratory Manual Subject: Experiment #: Experiment Title: Objectives: Apparatus: ProcedureDocument2 paginiLaboratory Manual Subject: Experiment #: Experiment Title: Objectives: Apparatus: ProcedureJoffer GallamasoÎncă nu există evaluări

- Determination of Coefficient of Discharge of A Submerged OrificeDocument1 paginăDetermination of Coefficient of Discharge of A Submerged OrificeJoffer GallamasoÎncă nu există evaluări

- Ce 47Document1 paginăCe 47Joffer GallamasoÎncă nu există evaluări

- XUERC Leaflet (2011)Document2 paginiXUERC Leaflet (2011)Dex LoÎncă nu există evaluări

- Pump Sizing Calculation: Tag No. Description Date by Checalc P-101 Feed Pump 28-Jan-15Document2 paginiPump Sizing Calculation: Tag No. Description Date by Checalc P-101 Feed Pump 28-Jan-15anto3harrish3fdoÎncă nu există evaluări

- Eurobrass 146: Pressure Reducing ValveDocument5 paginiEurobrass 146: Pressure Reducing ValveNicolas Fuentes Von KieslingÎncă nu există evaluări

- Cap.5 547705 High Pressure Cleaner HPW Manual ENGDocument20 paginiCap.5 547705 High Pressure Cleaner HPW Manual ENGJoaquin CardenasÎncă nu există evaluări

- Pages From 112006967-PRV-Sizing-for-Exchanger-Tube-RuptureDocument1 paginăPages From 112006967-PRV-Sizing-for-Exchanger-Tube-RuptureGhasem BashiriÎncă nu există evaluări

- Oils & Lubricants ManufacturersDocument4 paginiOils & Lubricants ManufacturersnagamabhishekÎncă nu există evaluări

- DewateringDocument6 paginiDewateringDrishti Jain100% (1)

- Twin Peaks Pumping Plant Model TestsDocument25 paginiTwin Peaks Pumping Plant Model TestsJerry PellerÎncă nu există evaluări

- Diagram Hydraulic Power PackDocument1 paginăDiagram Hydraulic Power PackYuri SetiadiÎncă nu există evaluări

- 3M3 Drag On A Sphere F18!08!2007Document9 pagini3M3 Drag On A Sphere F18!08!2007Valentin MoldovanÎncă nu există evaluări

- Discussion Conclusion Report FluidDocument5 paginiDiscussion Conclusion Report Fluidnurlisa khaleeda100% (2)

- Volvo GearDocument1 paginăVolvo GearIvan Horak0% (1)

- Liquid Penetrant Inspection Guide - Detect Surface FlawsDocument29 paginiLiquid Penetrant Inspection Guide - Detect Surface FlawsSrivathsa SharmaÎncă nu există evaluări

- r5220303 Mechanics of FluidsDocument1 paginăr5220303 Mechanics of FluidssivabharathamurthyÎncă nu există evaluări

- SHELL AND TUBE HEAT EXCHANGER DESIGNDocument60 paginiSHELL AND TUBE HEAT EXCHANGER DESIGNniaaparamita100% (1)

- Procedimiento de Diseño de GLCC PDFDocument9 paginiProcedimiento de Diseño de GLCC PDFjoellopezzÎncă nu există evaluări

- How Coriolis Flow Meters WorkDocument4 paginiHow Coriolis Flow Meters WorkIsares PodkohÎncă nu există evaluări

- Practice Problems - Groundwater Permeability and Seepage Part 1Document2 paginiPractice Problems - Groundwater Permeability and Seepage Part 1Kok Soon ChongÎncă nu există evaluări

- Analysis of Pipe NetworksDocument14 paginiAnalysis of Pipe NetworksAhmad Sana100% (2)

- Lecture Notes 13-1Document82 paginiLecture Notes 13-1ahmad zaini100% (1)

- AC Pocket Guide Adhesive Bonding EN WebDocument23 paginiAC Pocket Guide Adhesive Bonding EN WebDong HungÎncă nu există evaluări

- Gas/Steam Gas/Steam Medium MediumDocument7 paginiGas/Steam Gas/Steam Medium MediumAaron BirhanuÎncă nu există evaluări

- De Report Sem3rdDocument32 paginiDe Report Sem3rdPrabhat Singh83% (6)

- Worksheet - Pressure Losses and Pump Performance WorksheetDocument10 paginiWorksheet - Pressure Losses and Pump Performance WorksheetUmair AnwarÎncă nu există evaluări

- Master Plumber Review Random PDFDocument48 paginiMaster Plumber Review Random PDFGilven MedinaÎncă nu există evaluări

- Canal DesignDocument34 paginiCanal Designniranjan100% (2)

- Sheet 8 (Cha (7,8) )Document2 paginiSheet 8 (Cha (7,8) )chemicalengineering321Încă nu există evaluări

- FFODocument31 paginiFFOBhakti Mahbubani0% (1)

- 1-SEVO 1230 Technical Data Sheets - NozzlesDocument2 pagini1-SEVO 1230 Technical Data Sheets - NozzlesAndres Rodriguez ArevaloÎncă nu există evaluări

- Inter-Discipline Check Routing Sheet: PEC-EN-FRM-X-2387 Rev 2Document1 paginăInter-Discipline Check Routing Sheet: PEC-EN-FRM-X-2387 Rev 2sathishÎncă nu există evaluări

- Flow of Fluid and Bernoulli's Equation: 2005 Pearson Education South Asia Pte LTDDocument123 paginiFlow of Fluid and Bernoulli's Equation: 2005 Pearson Education South Asia Pte LTDDickson LeongÎncă nu există evaluări