Documente Academic

Documente Profesional

Documente Cultură

Effect of Wheel Geometry Parameters On Vehicle Steering

Încărcat de

Rudrendu ShekharDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Effect of Wheel Geometry Parameters On Vehicle Steering

Încărcat de

Rudrendu ShekharDrepturi de autor:

Formate disponibile

EFFECT OF WHEEL GEOMETRY PARAMETERS ON VEHICLE STEERING

R. P. Rajvardhan1, S. R. Shankapal2, S. M. Vijaykumar3 1 Student, M. Sc. [Engg.], 2Director, 3Assistant Professor M.S. Ramaiah School of Advanced Studies, Bangalore 560 054

Abstract

In modern era, steerability and handling characteristics of the vehicle have become major aspects. Providing comfort to the driver by reducing steering effort without any compromise in steerability and handling of the vehicle is a major concern for automakers. Evaluating handling and steering characteristics of a vehicle in a virtual environment with the help of multi-body system packages saves product development time and cost. The main intention is to improve the steerability and handling of the vehicle by avoiding the steering pull and wheel wandering problems. As per the specification of the selected vehicle Honda CR-V, a multi-body model of the SUV was built in ADAMS/CAR software. The SUV model was validated by comparing simulation results with the standard graphs from literature. Using this model, manoeuvres for different values of wheel geometry parameters, were simulated. The steering effort, steering wheel returnability and the lateral forces produced by the tires were obtained in order to predict the behaviour of the vehicle for different wheel geometry parameters. It can be seen from the results that positive caster angles improve the steering wheel returnability but increase the steering effort. Negative caster angles reduce the steering effort but create wheel wandering problems. Higher Steering Axle Inclination (SAI) angles help in improving the steering wheel returnability and decreasing the steering effort as well. Negative camber angles help in producing higher lateral forces to improve the cornerability of the vehicle. Toe-in angles help in improving the straight-line stability where as toe-out angles help in improving the cornering. Negative scrub radius seem to have stabilising effect on vehicle handling. Keywords: Vehicle Dynamics, Steering Geometry, Steering Drift, Vehicle Pull Nomenclature F Force, N K Stiffness, N/m R Turning radius, m W Weight, kg Steering angle, degrees Abbreviations CG Center of Gravity CRC Constant Radius Cornering DOF Degrees of Freedom KPIA Kingpin Inclination Angle SAI Steering Axis Inclination SLC Single Lane Change and moments which govern the control and stability of the vehicle. Interaction between tires and road generates tractive, braking and cornering forces for manoeuvring. Hence, proper alignment of the wheels help in achieving better grip and handling of the vehicle. 1.2 Wheel Geometry Parameters Affecting Vehicle Steering Wheel geometry is an important aspect which contributes a lot to the steerability of a vehicle. Even a slightest misalignment creates problems like steering pull and vehicle drift. The wheel geometry parameters that affect the steerability of the vehicle are camber, caster, Steering Axis Inclination (SAI), scrub radius and toe. Skip Essma has [1] discussed the methods used in evaluating and modifying steering effort for a cart series champ car racing on oval track. It was found that halving the camber reduced the steering effort by 30% but there was reduction in the peak lateral force capability also. Reduction in design trail also reduced the steering effort but resulted in wheel wandering problems. Hence, it was concluded that most of the design changes require trade-offs to maintain perfect balance. Younggun Cho and Unkoo Lee [2] discussed steering kickback and its effect on driver comfort. The study focused on the contribution of external force and inertial force responsible for the steering kickback when the vehicle approaches a bump. Initially front mount point of lower arm in the suspension system was raised as a remedy for the kickback. This showed 5% reduction in kickback. Further, the brake-caliper was moved from front to rear side of the wheel center. This produced inertial moment acting opposite to unbalanced

1. INTRODUCTION

1.1 Introduction to Vehicle Dynamics of a SUV Vehicle dynamics is the study concerned with the motion of vehicles on a road surface. The dynamic behaviour of a vehicle is determined by various kinds of forces, such as gravitational force, aerodynamic force and forces coming from the tires, acting on the vehicle. Vehicle dynamics constitutes the detailed study of all these forces imposed and their effect on stability and handling of the vehicle. For that purpose, approach used is to create approximate vehicle model and simulating different straight line course and cornering conditions in virtual environment for detailed study of the parameters contributing to handling and stability of the vehicle. Steering response, which plays an important role in the manoeuvrability and handling of the vehicle, is one of the important tasks in vehicle dynamics. Wheel geometry and tire behaviour are two major factors which aid thorough understanding of the vehicle steering. Tire is the primary source of different forces

SAS

TECH Journal

11

Volume 9, Issue 2, September 2010

moment producing kick-back. This design change reduced kick-back by 8%. Klaps and Day [3] investigated the causes for steering drift during straight-line braking. Different static and dynamic tests were carried out to find out the variation in the wheel alignment during braking. It was observed that the caster angle became slightly negative and aligning torque started acting in opposite direction due to suspension compression during braking. Also, suspension compression altered the steering offset and was different at both the sides. The difference in the steering offset at both the side created imbalance because of the difference in steering arm forces generated. These factors were found to be the sole factors responsible for drift in the vehicle during braking. Sang-Hyun Oh et al [4] studied the parameters responsible for vehicle pull mechanism. Their work concentrated on PRAT (Ply-steer Residual Aligning Torque), VRAT (Vehicle Residual Aligning Torque), cross camber, cross caster and road crown. It was seen that the reduction in cross camber and cross caster values resulted in reduction in steering pull. According to the authors, collaboration between vehicle and tire manufacturers is necessary in order to match the characteristics of the vehicle and the tires. VRAT is usually designed according to the road crown, and PRAT has to be properly produced by adjusting the tire design in order to suit VRAT. Marcelo Prado et al [5] have described the procedure for modelling, testing and validation of a bus. The tests carried out were ISO lane change at 80 km/h and sweep steer test at 40 km/h. For comparison, only steering wheel angle, lateral acceleration, and yaw rate were selected. In all the cases, a close correlation was found between the experimental results and simulation results. March and Shim [6] developed an integrated control system of active front control and normal force control to enhance vehicle handling. Fuzzy reasoning was used in the integration of the control systems for achieving better handling performance. The developed yaw rate control system automatically adjusts the normal force and the additional steering angle to achieve the desired yaw rate. Integration of normal force control and active front steering system showed better handling. Ragnar Ledesma and Shan Shih [7] studied the effect of Kingpin Inclination Angle (KPIA) and wheel offset on vehicle performance metrics such as steering effort, vehicle handling and steering system vibration. Kingpin inclination was varied from 6.25 to 9.25 and wheel offset was varied from 63.5 mm (2.5 in) to 114.3 mm (4.5 in) in order to study the variation in performance metrics. The results obtained were summarised and listed in a table to observe the impact of design changes on total vehicle performance. Table 1, shows the summary of other performance metrics and contributing factors. Renuka Avachat et al [8] developed a methodology for improving steering wheel returnability. Instead of altering the steering geometry of the vehicle, investigation was carried out to find the reasons for

frictional resistance. It was found that the losses in steering universal joint, intermediate bearing and clamping bush cause the frictional resistance. The bearing design was improved, greasing procedure was implemented in the manufacturing process and the central support bush alignment procedure was implemented with respect to column and bracket in order to reduce frictional resistance.

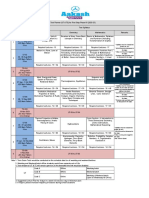

Table 1. Summary of vehicle performance metrics [7]

Scenario High turn angle Steady State Cornering Steady State Cornering Steady State Cornering Driver side bump Rough road Side force disturbance Constant- braking Split- braking Braking in turn Braking in turn Performance Metric Camber angle change Tire slip angle Lateral stability Steering effort Steering vibration Steering vibration Directional stability Directional stability Directional stability Directional stability Steering effort Major Contributing Factor KPIA KPIA KPIA KPIA Wheel offset Wheel offset Wheel offset Wheel offset Scrub radius Scrub radius Scrub radius Max. % change from reference 32% 3% 0% 7% 27% 33% 4% 5% 10% 2% 4%

Implementation of all the corrective actions, not only improved steering returnability by 40% but also helped in reducing the cycle time in design and validation by 80%. Wade Allen et al [9] have discussed the effect of inertial properties on vehicle handling stability. In this study, carried out on small and medium sized SUVs, at high speeds, the yaw rates were seen to be more in case of small SUVs compared to medium sized SUVs. The authors concluded that the inertial properties are strongly correlated with the length, width and the height of the vehicle. And these inertial properties affect the handling and stability of the vehicle. Smaller vehicles respond more quickly and hence they cannot be controlled easily in emergency manoeuvres. It has been also concluded that small vehicles tip-up more quickly due to their small ratio of roll moment of inertia to mass. Klaus Rompe and Edmund Donges [10] investigated variation of handling characteristics of 15 of todays passenger cars. They found that the driving conditions become more difficult when the vehicles approach their handling limits in the tests like power-off and braking during cornering. It was also observed that handling characteristic of only a few vehicles was affected by changes in loading conditions. Other

SAS

TECH Journal

12

Volume 9, Issue 2, September 2010

vehicles retained their handling characteristics for different loading and for different test procedures.

Three major steps involved in the construction of multi-body model of SUV are Creation of templates Creation of sub-systems Creation of full vehicle assembly

2. PROBLEM DEFINITION

Based on the literature survey, various problems related to steering, like steerability under limit handling condition, steering drift because of improper alignment, have be identified. The work reported in this paper concerns the effect of different wheel parameters on steerability and development of a computer model and carrying out virtual simulations to study the effect of different wheel geometry parameters on vehicle steering.

3.1 Creation of Templates In the simulation software, a template is the basic level multi-body model that contains the geometry and topological data. Template defines the geometric parts, joints (to enable the connection between different geometric parts), forces and other modelling elements that constitute an aggregate sub-assembly of a vehicle. It also includes how the parts connect together through the joints and how the force will be transmitted from one part to another and so on. The template also contains communicators to achieve the communication between different sub-assemblies of the vehicle. To create the simulation model of the selected SUV, the coordinates of hard points were changed to match those in the selected vehicle. Similarly, the templates of steering, front and rear suspension, front and rear wheels, powertrain and brakes were modified according to the specification of selected SUV and saved in the database. 3.2 Creation of Subsystems A subsystem is a mechanical model which references the template and tailors it by supplying the parameters, including properties of the components like spring, tire etc. Subsystems also allow new point positions can be defined. The respective templates from the database were imported and all the subsystems required for the SUV were created. 3.3 Full-Vehicle Assembly To create the full vehicle model, the subsystems were imported in a single environment and assembled properly.

3. MODELING OF SUV IN ADAMS/CAR

To study the behaviour of an SUV for different wheel geometry parameter, a multi-body model of Honda-CRV, the vehicle selected for this study, was built in ADAMS/CAR. Different sub-systems of an SUV, such as suspension system, steering system, wheels, brakes and chassis were built according to the specification and assembled together to carry out the simulations. The data used to build the model is shown in the Table 2.

Table 2. Specification of the selected SUV

Front suspension Rear suspension Steering system Brakes Tire size Wheel Base Track Width CG Location (X, Y, Z) Kerb Weight Weight Distribution(%, Front/Rear) Turning radius Macpherson strut Double Wishbone Rack and pinion type Four wheel Disc brakes 225/65 R 17 102 T 2620 mm 1565 mm 1180, 0, 650 mm 1565 mm 58/42 5.54 m

Fig. 1 Full vehicle assembly

SAS

TECH Journal

13

Volume 9, Issue 2, September 2010

After assembling, the subsystems were translated from the default positions to suit the parameters such as wheelbase and other vehicle specification. Figure 1 shows the full vehicle assembly of Honda-CRV consisting of the following subsystems Front suspension subsystem Rear suspension subsystem Steering subsystem Front wheel subsystem Rear wheel subsystem Body subsystem Brake subsystem Powertrain subsystem

Fig. 3 Time variation of aligning torque for different caster angles

For negative caster angles, the aligning torque, instead of trying to push the wheels to straight ahead position, pushes the wheels farther away from it. This destabilises the wheel path, giving rise to wheel wandering problems. Hence, it is preferred to have positive caster angles.

4. RESULTS AND DISCUSSIONS

The SUV modelled in ADAMS/CAR was used to study the steering wheel returnability, steering effort and other steering related parameters in a SLC test with vehicle speed of 80 km/h. For lane change, steering angle of 20 was given as an input to steering wheel. Simulations of this test for different wheel geometry parameters were carried out to study their effect on steering effort, handling behaviour and steering wheel returnability. 4.1 Effect of Caster Angles on Vehicle Behaviour Figure 2 shows the variation of pinion torque acting at the pinion of rack and pinion steering system for different values of caster angles. The caster angle was varied from +5 to -5 to observe its effect on the variation of steering effort. It can be seen that the torque acting at the pinion, a measure of steering effort, is lower for negative caster angle and increases as the caster angle is changed from maximum negative to maximum positive.

Fig. 4 Time variation of steering assistance angle for different caster angles

Figure 4 shows the variation of steering assistance angle, a measure of returnability of the steering wheel back to its initial position after the lane changeover, with caster angle. After changing the lane the steering angle remains constant as the vehicle starts moving in the straight path.

Fig. 2 Time variation of pinion torque for different caster angles

A completely reverse trend is observed for aligning torque. Aligning torque, a moment generated at the road-tire interface, tends to align the wheels back to the straight ahead position without any effort from the driver. This is higher for positive caster and decreases as the caster angle reduces to zero and goes to negative (Fig. 3). Higher aligning torque aids steering returnability. SAS

Fig. 5 Time variation of steering assistance angle for different caster angles

Details of the variation in the encircled area is shown in Fig. 5. It can be seen that a vehicle with positive caster angle of 5 returns back to the initial position faster than vehicles with lower positive or

TECH Journal

14

Volume 9, Issue 2, September 2010

negative camber. This observation corroborates the variation of self-aligning torque shown in Fig. 3. 4.2 Effect of SAI Angles on Vehicle Behaviour Figure 6 shows the variation of the torque acting at the pinion for different values of SAI angles in an SLC manoeuvre. The SAI angle is varied from +10 to +15 to observe the variation of steering effort. From the results it can be observed that the torque acting at the pinion, and hence, drivers effort to steer, decreases with increasing SAI angle.

forces at tires increase. With moment arm remaining the same, this results in increase in aligning torque. Higher aligning torque improves steering returnability and the wheels align to straight ahead position faster. Figure 8 shows the variation of steering assistance angle for different SAI angles for an SLC manoeuvre. After changing the lane the steering angle remains constant as the vehicle starts moving in the straight path. Details of the variation in the encircled area is shown in Fig. 9. There, it can be seen that a vehicle with SAI angle of 15 returns back to the initial position faster than venicles with lower SAI angle. This observation corroborates the variation of self-aligning torque shown in Fig. 7. Another way to interpret this result is as follows. SAI angle causes the front end of the car to rise as the wheels are steered. This lifting increases steering returnability. Larger the SAI angle, more is the lift, and more is the self-centring effect, as seen from Figure 9.

Fig. 6 Time variation of pinion torque for different SAI angles

Fig. 9 Time variation of steering assistance angle for different SAI angles

4.3 Effect of Toe Angles on Vehicle Behaviour Figure 10 shows the lateral forces acting at the tires for different toe-in angles in an SLC manoeuvre. In this case, the lateral force increases with the increase in toein angles but the range of variation of the force decreases. The variation of lateral force is more for zero toe-in (~3500 N) compared to when the toe-in is 3 (~700 N). Since larger variation indicates better steering response, vehicles with higher toe-in will have more tendency to understeer. However, with increasing steering response comes the tendency of the vehicle to enter a turn. This compromises the straight line stability of the vehicle. So, even though non-zero toe-in vehicles have steering response inferior to zero toe-in vehicles, some toe-in must be kept to ensure straight line stability. Figure 11 shows the lateral forces acting at the tires for different toe-out angles in an SLC manoeuvre. Unlike the case of toe-in angle, for toe-out angle the range of variation of force is not much different for different toe-out angles. For zero toe-out case, it is about 3150 N and for 3 toe-out it is about 3300 N. This will result in good steering response. The vehicle will have a tendency to exhibit neutral steer characteristics. It will have good corenerability because of its tendency to enter a turn but at the expense of straight line stability.

Fig. 7 Time variation of aligning torque for different SAI angles

Fig. 8 Time variation of steering assistance angle for different SAI angles

Figure 7 shows the variation of aligning torque for different SAI angles. The aligning torque about the steering axis is higher for 10 SAI the angle and decreases as the SAI angle increases. This pattern of variation is because as SAI angle increases the lateral SAS

TECH Journal

15

Volume 9, Issue 2, September 2010

forces decrease as the camber angle increases because of higher camber thrust produced by the positive camber angles.

Fig. 10 Lateral forces for different toe-in angles

For vehicles with toe-out, the slip angle is less for zero toe-out angle and increases with the increasing toeout angles (Fig. 12). This is an undesirable situation as higher slip angle will result in more sliding, and hence more wear, of the tire.

Fig. 13 Time variation of lateral force for positive camber angles

Reduction in the net lateral force at the tires increases vehicles tendency to understeer. To reduce this tendency, lower positive camber should be used.

Fig. 11 Lateral forces for different toe-out angles

Fig. 14 Time variation of lateral force for negative camber angles

Variation of lateral forces for different values of negative camber angles in a CRC test is shown in Fig. 14. Unlike for the positive camber, in this case, the lateral force increases with the increase of absolute value of the camber as camber thrust adds to the other dynamic loads produced during cornering. Hence, higher negative camber will provide better cornering characteristics and manoeuverability.

Fig. 12 Slip angles for different toe-out angles

4.4 Effect of Camber Angles on Vehicle Behaviour Constant Radius Cornering (CRC) simulations, for different camber angles, were carried out to study the effect of camber thrust and slip angles on handling behaviour of a vehicle and tire wear. For this study, vehicle travelling at 20 km/h initially and gradually accelerating to 80 km/h on circular test track of 3.5 meters radius was simulated. The camber angle was varied from 0 to 4 in steps of 1. Figure 13 shows the variation of lateral forces in CRC test for different positive camber angles. Lateral

Fig. 15 Variation of lateral force with respect to slip angle for different camber angles

SAS

TECH Journal

16

Volume 9, Issue 2, September 2010

Figure 15 shows the variation of lateral force as a function of slip angle for different values of camber angles in a CRC test simulation. The maximum lateral force increases as the camber increases from negative to zero to positive. From Fig. 15, it is also seen that the slip angle produced by positive camber is highest and reduces as camber reduces to zero and then goes to negative. This explains why wheels with positive cambers wear out faster. Generally a negative camber is preferred as it provides better cornering and manoeuvrability and also less slip and tire wear. 4.5 Simulation of the Vehicle Going Over Hump to Study the Effect of Scrub Radius In order to study the effect of scrub radius on the stability of a vehicle, the vehicle moving at 40 km/h going over a hump was simulated and the result, steering kickback, was analysed. The analysis was repeated for different scrub radii, and the results were compared to assess the stability of the vehicle.

Physically, when the vehicle hits the hump, the force acting on the wheels from the hump produces steering torque proportional to the scrub radius. To counteract this unbalanced steering torque, the driver has to apply steering correction to keep the vehicle moving in straight direction. For zero scrub radius unbalanced steering torque is eliminated, but the driver loses the feel of steering. Hence it is preferred to have negative scrub radius.

Fig. 18 Time variation of steering assistance angle for different scrub radii

4.6 Simulation of Brake-in-turn Analysis to Study the Effect Scrub Radius In brake-in-turn analysis, the vehicle was made to run on the circular test track of 3.5 m radius with lateral acceleration of 0.35 g and then the brakes were applied. Through brakes, 3 g deceleration was applied to the wheels for a period of 2 sec to stop the vehicle.

Fig. 16 Time variation of steering assistance angle for different scrub radii

Figure 16 shows the time variation of steering assistance angle for three different, positive, zero and negative, values of scrub radii. Few peaks in steering assistance angle, which indicate steering disturbance caused when the vehicle moves over a hump, can be seen in Fig. 16.

Figure 18 shows the plot of time variation of steering angle for three different, positive, zero and negative, values of scrub radii. The steering input used is to maintain the vehicle on course on road after the brakes are applied.

Fig. 19 Time variation of steering assistance angle for different Scrub radii

To provide more details of the steering input, enlarged view of the encircled portion in Fig. 18 is shown in Fig.19. It shows that when scrub radius is positive, maximum steering input is required to keep the vehicle on course. This effort is less for zero and negative scrub radii, but only marginally. This means the unbalanced steering torque produced is less for the negative scrub radius during braking. Hence, the steering input given by the driver to maintain the vehicle on desired path is also less. Therefore, negative scrub radius is preferable. Though the zero scrub radius

Fig. 17 Time variation of steering assistance angle for different scrub radii

To provide more details of the variation in that region, enlarged view of the encircled portion in Fig. 16 is shown in Fig. 17. Most severe steering disturbance steering kickback, is observed for positive scrub radius of 30 mm. The peak value comes down as scrub radius reduces to zero and then changes to -30 mm.

SAS

TECH Journal

17

Volume 9, Issue 2, September 2010

produces least steering disturbance, it is not preferred because the driver will not have the steering feel.

ADAMS/CAR, Debis humaita IT Services Ltd, 2005. [6] C March and T Shim, Integrated Control of Suspension and Front Steering to Enhance Vehicle, Date published: 11 December 2006 [7] Ragnar Ledesma and Shan Shih. 2001, The Effect of Kingpin Inclination angle and Wheel Offset on Medium-Duty Truck Handling, SAE technical paper series, Paper number 2001-01-2732. [8] Renuka Avachat, J. S. Mahajan and K. Gopalakrishna., Development of methodology for Improvement in Steering Returnability, SAE technical paper series, Paper number 2008-010494. [9] R. Wade Allen, David H. Klyde, Theodore J. Rosenthal and David M. Smith, Estimation of Passenger Vehicle Inertial Properties and Their Effect on Stability and Handling, SAE technical paper series, ISSN 0148-7191, 2003. [10] Klaus Rompe and Edmund Donges, Variation Ranges for the Handling Characteristics of Todays Passenger Cars, SAE Inc, 1985.

5. CONCLUSIONS

Based on the simulation results of SUV for different values of wheel geometry parameters, the following conclusions are drawn: Increasing positive caster angle increases the mechanical trail, and this trail increases the self aligning torque which improves the steering wheel returnability. As the self-aligning torque acts in the direction opposite to the steering torque, the steering effort of the driver increases. Negative caster angle reduces the steering effort due to the absence of sufficient aligning torque, but it leads to the wheel wandering problem. Higher Steering Axis Inclination (SAI) angle improves the steering wheel returnability and reduces the steering effort as well. Positive camber angle reduces the net lateral force generated at the tires because of the counter-acting camber thrust and hence increases the tendency of a vehicle to exhibit understeer characteristics. Negative camber angle increases the net lateral force at the tires, the camber thrust acts in the same direction as the tire lateral force. Hence, the negative camber angle increases the handling behaviour of the vehicle and enables sharp cornering. Toe-in increases the straight-line stability by sacrificing sharp cornering ability. Toe-out increases the cornerabilty of the vehicle at the cost of straight line stability. Though the zero scrub radius eliminates the generation of unbalanced steering torque, it is not preferred. The driver loses the steering feel if the scrub radius is zero. Negative scrub radius produces less steering disturbance and has a stabilising effect.

6. REFERENCES

[1] Skip Essma, Steering Effort Analysis of an Oval Racing Track Setup Champ Car, International ADAMS User Conference, 2002. [2] Younggun Cho and Unkoo Lee, Simulation of Steering Kickback Using Component Load Method, SAE technical paper series, Paper number 200401-1097. [3] J Klaps and A J Day, Steering drift and wheel movement during braking static and dynamic measurements, DOI: 10.1243/095440705X5975, 2004. [4] Sang-Hyun Oh, Young-Hee Cho and Gwanghun Gim, Identification of a Vehicle Pull Mechanism, FISITA World Automotive Congress, 2004. [5] Marcelo Prado, Rodivaldo H. Cunha and Alvaro C. Neto, Bus Handling Validation and Analysis Using

SAS

TECH Journal

18

Volume 9, Issue 2, September 2010

S-ar putea să vă placă și

- Senior Project ReportDocument6 paginiSenior Project ReportRoss Bunnell100% (1)

- JOSAMDocument4 paginiJOSAMStefan Cristea100% (1)

- Calibracion de Motores Cummins 1Document2 paginiCalibracion de Motores Cummins 1joseÎncă nu există evaluări

- Automotive Business Review November 2009Document100 paginiAutomotive Business Review November 2009MadhouseEnterprisesÎncă nu există evaluări

- Chassis: Axles and SuspensionDocument19 paginiChassis: Axles and Suspensionali100% (1)

- Trakindo Lifting-Jacking-BlockingDocument80 paginiTrakindo Lifting-Jacking-BlockingEnan YayankÎncă nu există evaluări

- Introduction To Contracts, Sales, and Product Liability - AttributedDocument952 paginiIntroduction To Contracts, Sales, and Product Liability - AttributedAlfonso J Sintjago100% (1)

- Arai IndiaDocument175 paginiArai Indiaamity2kok100% (1)

- Suspension Design by Ravi DeshmukhDocument11 paginiSuspension Design by Ravi DeshmukhsonirocksÎncă nu există evaluări

- Brake Report 2015Document38 paginiBrake Report 2015Pratyush NagareÎncă nu există evaluări

- Alignment BasicsDocument11 paginiAlignment BasicshelakaraaÎncă nu există evaluări

- 2022 TRA Base BEMM Publishable 25-07-2022Document135 pagini2022 TRA Base BEMM Publishable 25-07-2022Jack Norhy100% (1)

- Simplex Air Cam Drum Brake: February 2012Document19 paginiSimplex Air Cam Drum Brake: February 2012Anonymous gTerattFpQ100% (1)

- Clutch Release BearingDocument3 paginiClutch Release BearingSunil DeshpandeÎncă nu există evaluări

- Air Brake ModuleDocument80 paginiAir Brake ModuleShahzad ahamadÎncă nu există evaluări

- Steering Ackerman4Document13 paginiSteering Ackerman4Ankit GoratelaÎncă nu există evaluări

- Toyota Vehicle Glossary TermsDocument31 paginiToyota Vehicle Glossary TermsEdward Ugochukwu AdighibeÎncă nu există evaluări

- Wheel Alignment SpecificationsDocument15 paginiWheel Alignment SpecificationsBAla0% (1)

- Steering GeometryDocument4 paginiSteering GeometryAnanya BhardwajÎncă nu există evaluări

- Vehicle Roll EstimatorDocument10 paginiVehicle Roll EstimatorRaja Amer AzimÎncă nu există evaluări

- Transient Characteristics of A Hydraulically Interconnected Suspension System PDFDocument12 paginiTransient Characteristics of A Hydraulically Interconnected Suspension System PDFmanteghÎncă nu există evaluări

- Modeling and Validation of Off-Road Vehicle Ride DynamicsDocument17 paginiModeling and Validation of Off-Road Vehicle Ride DynamicsAnderson MoribeÎncă nu există evaluări

- Half Bike Suspension Model SolidworksDocument59 paginiHalf Bike Suspension Model SolidworksRavi Kiran MeesalaÎncă nu există evaluări

- Drive Trains Serve The Following FunctionsDocument49 paginiDrive Trains Serve The Following FunctionsRakesh PanigrahiÎncă nu există evaluări

- Vehicle Dynamics ProDocument15 paginiVehicle Dynamics ProChirag D PatelÎncă nu există evaluări

- Sae Technical Paper Series: Chinar Ghike and Taehyun ShimDocument12 paginiSae Technical Paper Series: Chinar Ghike and Taehyun ShimSteven SullivanÎncă nu există evaluări

- Castor Camber KingpinDocument7 paginiCastor Camber KingpinahamedÎncă nu există evaluări

- Facts About Brakes: After Sales ServicesDocument24 paginiFacts About Brakes: After Sales ServicesNovie RizkyÎncă nu există evaluări

- Drive ShaftDocument8 paginiDrive ShaftAkshat SharmaÎncă nu există evaluări

- Development of Torque Vectoring Differential Control ECU PDFDocument6 paginiDevelopment of Torque Vectoring Differential Control ECU PDFcerÎncă nu există evaluări

- Bump SteerDocument5 paginiBump SteerHimanshu RajputÎncă nu există evaluări

- Coupling: This Article Is About A Mechanical Connection Between Two Objects. For Other Uses, SeeDocument24 paginiCoupling: This Article Is About A Mechanical Connection Between Two Objects. For Other Uses, Seerupesh8989Încă nu există evaluări

- Draft He SisDocument31 paginiDraft He SisASIM RIAZÎncă nu există evaluări

- 995-T System Alignament HunterDocument12 pagini995-T System Alignament HunterArturo Zavala UrquidesÎncă nu există evaluări

- Suspension and Steering Systems PDFDocument15 paginiSuspension and Steering Systems PDFVijay SotaniÎncă nu există evaluări

- Design of An Energy Efficient High Performance Drive Train: Loek MarquenieDocument116 paginiDesign of An Energy Efficient High Performance Drive Train: Loek MarqueniePratik PrakashÎncă nu există evaluări

- AlignmentDocument5 paginiAlignmentVarshasonawane962100% (1)

- Bearing PreloadDocument1 paginăBearing PreloadvinayakÎncă nu există evaluări

- Chassis Newsletter 2010.8Document3 paginiChassis Newsletter 2010.8Ganesh ShanmugamÎncă nu există evaluări

- Baja'18 Problem Statements 1Document2 paginiBaja'18 Problem Statements 1Shubham GuptaÎncă nu există evaluări

- Lecture 2 Tire FundamentalsDocument17 paginiLecture 2 Tire FundamentalsabasÎncă nu există evaluări

- Electro-Hydraulic Brake (EHB) System.Document18 paginiElectro-Hydraulic Brake (EHB) System.prasathramaiah100% (1)

- Corner Weights 4 PagesDocument4 paginiCorner Weights 4 PagesTeresa HollidayÎncă nu există evaluări

- Hastings PDFDocument220 paginiHastings PDFEmily BullockÎncă nu există evaluări

- Roll Center MysteryDocument7 paginiRoll Center MysteryMrudula Amar WardeÎncă nu există evaluări

- Meritor T 226 Transfer Case Parts ManualDocument71 paginiMeritor T 226 Transfer Case Parts ManualBlack SampaÎncă nu există evaluări

- Baja SAE Auburn Design Report Cleveland State University 16Document10 paginiBaja SAE Auburn Design Report Cleveland State University 16Noel Mahung Melendez100% (1)

- Fabrication of Four Wheel Steering SystemDocument14 paginiFabrication of Four Wheel Steering SystemRenju PaulÎncă nu există evaluări

- This Lesson Discussed Different Methods of Brake EngagementDocument18 paginiThis Lesson Discussed Different Methods of Brake EngagementSteven LincolnÎncă nu există evaluări

- Electronic Stability ProgramDocument21 paginiElectronic Stability ProgramVinay GirdharÎncă nu există evaluări

- SAE 2002-01-3105 (Screen)Document14 paginiSAE 2002-01-3105 (Screen)rajdrklÎncă nu există evaluări

- Lecture 1 Tire or TyreDocument15 paginiLecture 1 Tire or TyreabasÎncă nu există evaluări

- Editors' Perspectives:: Road Vehicle Suspension Design, Dynamics, and ControlDocument34 paginiEditors' Perspectives:: Road Vehicle Suspension Design, Dynamics, and ControlTech DudeÎncă nu există evaluări

- Winalign Software: Quick Reference GuideDocument89 paginiWinalign Software: Quick Reference GuideValuador CjaÎncă nu există evaluări

- Torque Vectoring With A Feedback and Feed Forward Controller-Applied To A Through The Road Hybrid Electric VehicleDocument6 paginiTorque Vectoring With A Feedback and Feed Forward Controller-Applied To A Through The Road Hybrid Electric Vehiclesmmj2010Încă nu există evaluări

- LV06 - Engines - Issue 1Document72 paginiLV06 - Engines - Issue 1Valentin Silvan Valentin SilvanÎncă nu există evaluări

- Design and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainDe la EverandDesign and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainÎncă nu există evaluări

- Course PM Mechatronincs MF2030 HT14Document3 paginiCourse PM Mechatronincs MF2030 HT14Rudrendu ShekharÎncă nu există evaluări

- Element Young'S Modulus (Gpa) Proof or Yield Stress (Mpa) Ultimate Strength (Mpa)Document3 paginiElement Young'S Modulus (Gpa) Proof or Yield Stress (Mpa) Ultimate Strength (Mpa)Rudrendu ShekharÎncă nu există evaluări

- Task 2: We Started Having A Voltaje Controlled DC MotorDocument4 paginiTask 2: We Started Having A Voltaje Controlled DC MotorRudrendu ShekharÎncă nu există evaluări

- EU Regulation1Document10 paginiEU Regulation1Rudrendu ShekharÎncă nu există evaluări

- Divo LeafletDocument2 paginiDivo LeafletRudrendu ShekharÎncă nu există evaluări

- Astm D 2270Document7 paginiAstm D 2270Rudrendu Shekhar100% (1)

- Ka Vaada: ZyaadaDocument4 paginiKa Vaada: ZyaadaRudrendu ShekharÎncă nu există evaluări

- Journal Bearing Paper PDFDocument36 paginiJournal Bearing Paper PDFRudrendu ShekharÎncă nu există evaluări

- Brake: This Article Is About The Vehicle Component. For Other Uses, SeeDocument5 paginiBrake: This Article Is About The Vehicle Component. For Other Uses, SeeRudrendu ShekharÎncă nu există evaluări

- 100Cr6 PropertiesDocument1 pagină100Cr6 PropertiesRudrendu ShekharÎncă nu există evaluări

- Aisi SteelDocument11 paginiAisi SteelIlham SetiadiÎncă nu există evaluări

- ASTM Product ListDocument33 paginiASTM Product ListRudrendu ShekharÎncă nu există evaluări

- AckermannDocument40 paginiAckermannRudrendu ShekharÎncă nu există evaluări

- Automotive 130910Document1 paginăAutomotive 130910Rudrendu ShekharÎncă nu există evaluări

- Complex GreasesDocument2 paginiComplex GreasesRudrendu ShekharÎncă nu există evaluări

- FAG Lubrication BasicsDocument228 paginiFAG Lubrication BasicsRudrendu Shekhar100% (2)

- Basic Oxygen Furnace For Steel MakingDocument3 paginiBasic Oxygen Furnace For Steel MakingRudrendu ShekharÎncă nu există evaluări

- Astm D 2270Document7 paginiAstm D 2270Rudrendu Shekhar100% (1)

- Ranthambore Travel GuideDocument3 paginiRanthambore Travel GuideRudrendu ShekharÎncă nu există evaluări

- ASTM Product ListDocument33 paginiASTM Product ListRudrendu ShekharÎncă nu există evaluări

- Formula Sae Italy 2012: How To RegisterDocument4 paginiFormula Sae Italy 2012: How To RegisterRudrendu ShekharÎncă nu există evaluări

- Ackerman AnalysisDocument47 paginiAckerman AnalysisRudrendu Shekhar100% (1)

- Ranthambore Trip SuggestionsDocument2 paginiRanthambore Trip SuggestionsRudrendu ShekharÎncă nu există evaluări

- AASW Code of Ethics-2004Document36 paginiAASW Code of Ethics-2004Steven TanÎncă nu există evaluări

- Problem ManagementDocument33 paginiProblem Managementdhirajsatyam98982285Încă nu există evaluări

- Work Teams and GroupsDocument6 paginiWork Teams and GroupsFides AvendanÎncă nu există evaluări

- Simulation of Channel Estimation and Equalization For WiMAX PHY Layer in Simulink PDFDocument6 paginiSimulation of Channel Estimation and Equalization For WiMAX PHY Layer in Simulink PDFayadmanÎncă nu există evaluări

- Lista Verbelor Regulate - EnglezaDocument5 paginiLista Verbelor Regulate - Englezaflopalan100% (1)

- Pentecostal HealingDocument28 paginiPentecostal Healinggodlvr100% (1)

- ID2b8b72671-2013 Apush Exam Answer KeyDocument2 paginiID2b8b72671-2013 Apush Exam Answer KeyAnonymous ajlhvocÎncă nu există evaluări

- Syllabus/Course Specifics - Fall 2009: TLT 480: Curricular Design and InnovationDocument12 paginiSyllabus/Course Specifics - Fall 2009: TLT 480: Curricular Design and InnovationJonel BarrugaÎncă nu există evaluări

- Druze ScriptureDocument15 paginiDruze ScriptureChristopher DeMott100% (2)

- Awareness and Usage of Internet Banking Facilities in Sri LankaDocument18 paginiAwareness and Usage of Internet Banking Facilities in Sri LankaTharindu Thathsarana RajapakshaÎncă nu există evaluări

- VtDA - The Ashen Cults (Vampire Dark Ages) PDFDocument94 paginiVtDA - The Ashen Cults (Vampire Dark Ages) PDFRafãoAraujo100% (1)

- 619Document3 pagini619elektron2010Încă nu există evaluări

- Lead Workplace CommunicationDocument55 paginiLead Workplace CommunicationAbu Huzheyfa Bin100% (1)

- Policarpio Vs Manila Times - Unprotected Speech LibelDocument3 paginiPolicarpio Vs Manila Times - Unprotected Speech LibelStef BernardoÎncă nu există evaluări

- Final Presentation BANK OF BARODA 1Document8 paginiFinal Presentation BANK OF BARODA 1Pooja GoyalÎncă nu există evaluări

- UT & TE Planner - AY 2023-24 - Phase-01Document1 paginăUT & TE Planner - AY 2023-24 - Phase-01Atharv KumarÎncă nu există evaluări

- Need You Now Lyrics: Charles Scott, HillaryDocument3 paginiNeed You Now Lyrics: Charles Scott, HillaryAl UsadÎncă nu există evaluări

- Focus Charting of FDocument12 paginiFocus Charting of FRobert Rivas0% (2)

- 1E Star Trek Customizable Card Game - 6 First Contact Rule SupplementDocument11 pagini1E Star Trek Customizable Card Game - 6 First Contact Rule Supplementmrtibbles100% (1)

- The Changeling by Thomas MiddletonDocument47 paginiThe Changeling by Thomas MiddletonPaulinaOdeth RothÎncă nu există evaluări

- Welcome LetterDocument2 paginiWelcome Letterapi-348364586Încă nu există evaluări

- 206f8JD-Tech MahindraDocument9 pagini206f8JD-Tech MahindraHarshit AggarwalÎncă nu există evaluări

- Old San Agustin NHS MSISAR Sept 2021Document2 paginiOld San Agustin NHS MSISAR Sept 2021ERICSON SABANGANÎncă nu există evaluări

- Leg Res Cases 4Document97 paginiLeg Res Cases 4acheron_pÎncă nu există evaluări

- Re CrystallizationDocument25 paginiRe CrystallizationMarol CerdaÎncă nu există evaluări

- Validator in JSFDocument5 paginiValidator in JSFvinh_kakaÎncă nu există evaluări

- PMS Past Paper Pakistan Studies 2019Document3 paginiPMS Past Paper Pakistan Studies 2019AsmaMaryamÎncă nu există evaluări

- Producto Académico #2: Inglés Profesional 2Document2 paginiProducto Académico #2: Inglés Profesional 2fredy carpioÎncă nu există evaluări

- United States Court of Appeals, Third CircuitDocument1 paginăUnited States Court of Appeals, Third CircuitScribd Government DocsÎncă nu există evaluări

- How To Develop Innovators: Lessons From Nobel Laureates and Great Entrepreneurs. Innovation EducationDocument19 paginiHow To Develop Innovators: Lessons From Nobel Laureates and Great Entrepreneurs. Innovation Educationmauricio gómezÎncă nu există evaluări