Documente Academic

Documente Profesional

Documente Cultură

Scheuerle SPTM English Brochure PDF

Încărcat de

Jonp4ul_MiddletonDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Scheuerle SPTM English Brochure PDF

Încărcat de

Jonp4ul_MiddletonDrepturi de autor:

Formate disponibile

Technical data

1.0140.2E MT3/3.04_05.1 - We reserve the right to change construction and design

axle lines

Combination

Total weight

Payload max

Tractive force

Gradient

Brake force

160 t

143,5 t

240 kN

13 %

220 kN

240 t

216 t

240 kN

7,5 %

330 kN

14

560 t

503 t

720 kN

10,4 %

770 kN

20

800 t

719 t

960 kN

9,5 %

1100 kN

30

1200 t

1078,5 t

1440 kN

9,5 %

1650 kN

40

1600 t

1438 t

1920 kN

9,5 %

2200 kN

www.hettenbach.de

48

1920 t

1726,5 t

2160 kN

8,8 %

2640 kN

* Data based on following figures: Speed 1 km/h rolling resistance 0.025 acceleration 0.005 m/s2

4axle module type PKEZ 140.8.4 6axle module type PKEZ 210.12.4

Dead weight 16.5 t Dead weight 24.0 t

Drive positions: Normal drive F Transversal drive F B F B B Rotation point on front axle left side

F = forward; B = backward Diagonal drive F B

Circular drive

Front-/Rear drive

F B

Member of TII Group

SCHEUERLE Fahrzeugfabrik GmbH hringer Strae 16 74629 Pfedelbach Germany Phone ++49(0)7941/691-0 Fax 691-333 info@scheuerle.com www.scheuerle.com

Transporter Industry International GmbH

Module Transporter 3 generation

rd

Transport of a generator in Arizona, summer 2003

Self-propelled modular transporter for moving huge plants of any size and dimension

Highlights Computer optimised design, new platform concept, no torsion, sandwich platform, high tensile steel STE 690V, closed platform top Payload to dead weight ratio of 9:1 Max. driving speed unloaden 12 km/h Fully compatible with 2nd generation The heaviest loads in the world, weighing more than 15,000 tons such as plant modules for power and sea water desalination plants, oil rigs and off-shore platforms are transported safely and reliably to the operation site. Power pack unit (PPU) Hydrostatic Drive Engine power 98 -350 kW Max. oil pressure 420 bar Euro pollutant emission class I + II PPU liftable up to max. 12 Overspeed protection and ASR-System Load dependent drive control Synchronised pump control Steering Freely programmable electronically controlled multidirectional steering Selectable steering modes, standard-, crab-, transverse-, circular plus pole rotational on long axis Exact positioning of entire plants to the millimetre Open compound synchronised steering for up to a distance of 1.000 m between the modules Portable remote control with clear instrumentation for one man operation Radio remote control available

Pendulum axle Hydraulic lifting and lowering by Power Pack Unit 3- or 4-point support, axle support system is symmetrical, asymmetrical or freely selectable, axle by axle Complete electronics developed by SCHEUERLE Digital electronics with integrated self-diagnosis, error code and text report in combination with a trouble shooting manual Transportable on open flat racks and suitable for Ro-Ro operation Homologation for road transport Hydraulic axle support system, suspension range 700 mm Hydraulically operated brake system Steering through rack gear, turning angle 130 (100) Cabin 2 doors, 2 seats, heating/cooling, Mounting frame, towing eye 50 t, Control elements via remote control Accessoires/combination elements Long material transport bolster Remote control with pre-selection of driving speed and brake power COG-System (Center of gravity System) Lighting system as for road regulations Coupling adapter platform vehicles/SPMT Accessoires upon request

Pendulum axles positioned for circular drive

S-ar putea să vă placă și

- Scheuerle SPMT 3000 IC BrochureDocument4 paginiScheuerle SPMT 3000 IC BrochureJanuÎncă nu există evaluări

- Datasheet Conventional TrailersDocument11 paginiDatasheet Conventional TrailersMohamed Metwalli100% (1)

- SPMT - Module Weight EstimationDocument4 paginiSPMT - Module Weight EstimationShreyas RautÎncă nu există evaluări

- 4.1 SPMT Loading DiagramsDocument167 pagini4.1 SPMT Loading DiagramsDaniel Varvara0% (1)

- The SPMT Trailer1Document38 paginiThe SPMT Trailer1Anwar ShanÎncă nu există evaluări

- Scheuerle SPMT SpecDocument17 paginiScheuerle SPMT SpecBoy100% (2)

- 13 Barnhart Moving TierneyDocument42 pagini13 Barnhart Moving TierneyhiyeonÎncă nu există evaluări

- Goldhofer Spec For ProcedureDocument6 paginiGoldhofer Spec For ProcedureBoyÎncă nu există evaluări

- 1.1 General Information SPMT'sDocument4 pagini1.1 General Information SPMT'sSky MoonÎncă nu există evaluări

- Tractive Force Prime MoverDocument1 paginăTractive Force Prime MoverBHAUMIK SOLANKI0% (1)

- SPMT Loading Diagrams X24 Doku 20130305Document56 paginiSPMT Loading Diagrams X24 Doku 20130305BoyÎncă nu există evaluări

- TP Mammoet Trailers Stability&Lashing - Rev03-2Document88 paginiTP Mammoet Trailers Stability&Lashing - Rev03-2paramarthasom197490% (10)

- Self Propelled Modular TransportersDocument5 paginiSelf Propelled Modular TransportersHimanshu Purohit100% (1)

- 4.2 - Information To Loading DiagramsDocument7 pagini4.2 - Information To Loading DiagramsDaniel Varvara0% (1)

- Cometto SYV6 Modular Trailer+SPMTDocument11 paginiCometto SYV6 Modular Trailer+SPMTAllen RenÎncă nu există evaluări

- Mammoet 2002 PDFDocument20 paginiMammoet 2002 PDFCuong Dinh100% (1)

- 5 Technical Data PST-SL-E 4-08x04Document1 pagină5 Technical Data PST-SL-E 4-08x04Anwar Shan100% (2)

- 02 Technical DataDocument17 pagini02 Technical DataDaniel VarvaraÎncă nu există evaluări

- TLash22 ManualDocument35 paginiTLash22 ManualEkwak Zcelebre100% (2)

- Sarens SPMTDocument2 paginiSarens SPMTheavytransport100% (1)

- Guidelines On Trailer Stability Needed or Not?? RULES On Trailer Stability Are Needed!!Document32 paginiGuidelines On Trailer Stability Needed or Not?? RULES On Trailer Stability Are Needed!!Anonymous UebIaD8A8C80% (5)

- Lashing Project CargoDocument1 paginăLashing Project CargoBHAUMIK SOLANKIÎncă nu există evaluări

- Roro Ramp CalDocument2 paginiRoro Ramp CalBoyÎncă nu există evaluări

- Project 7Document56 paginiProject 7Ravi Sharma100% (2)

- Modular TrailerHydraulic Multi Axle ChinaheavyliftDocument6 paginiModular TrailerHydraulic Multi Axle ChinaheavyliftSulaim Al KautsarÎncă nu există evaluări

- Tractive Force SPMTDocument1 paginăTractive Force SPMTBHAUMIK SOLANKI0% (2)

- THT-FAGIOLI-BAPCO - NAPHTHA SPLITTER-019C0010-TP For PermitDocument1 paginăTHT-FAGIOLI-BAPCO - NAPHTHA SPLITTER-019C0010-TP For PermitEdward CelebreÎncă nu există evaluări

- SPMT Description Incl DrawingsDocument10 paginiSPMT Description Incl DrawingssefazÎncă nu există evaluări

- Goldhofer THP SLDocument8 paginiGoldhofer THP SLCHRISTIAN LOPEZ FLOREZÎncă nu există evaluări

- 6.5.1 - Service and Maintenance Schedule For Brake Axles - 10 - 2016Document16 pagini6.5.1 - Service and Maintenance Schedule For Brake Axles - 10 - 2016Daniel VarvaraÎncă nu există evaluări

- Mammoet SPMT BrochureDocument19 paginiMammoet SPMT BrochurehcurmudgeonÎncă nu există evaluări

- SPMT Stability of Hydraulic EngDocument4 paginiSPMT Stability of Hydraulic Engparamarthasom1974Încă nu există evaluări

- 0013-Nd Rev 8.1 28-Jun-16 Guidelines For Load-OutsDocument16 pagini0013-Nd Rev 8.1 28-Jun-16 Guidelines For Load-OutsJanuÎncă nu există evaluări

- 03 HeavyTransport 2day UK 50 Pages - KeyDocument25 pagini03 HeavyTransport 2day UK 50 Pages - KeyJavier Páez100% (5)

- SPMT and Pump Data PDFDocument5 paginiSPMT and Pump Data PDFlipanzyÎncă nu există evaluări

- GET - Basics - EngineeringDocument23 paginiGET - Basics - EngineeringAustin Mathew100% (1)

- Mammoet SPMT Incident in Thailand On Nov.16,2008Document7 paginiMammoet SPMT Incident in Thailand On Nov.16,2008egy pureÎncă nu există evaluări

- Engine Transport For Power Plant: Commercial ProposalDocument16 paginiEngine Transport For Power Plant: Commercial ProposalJanu100% (1)

- S PMT Best Practice GuideDocument29 paginiS PMT Best Practice Guidejuriesk100% (1)

- Mod TransDocument1 paginăMod TransmrmerajÎncă nu există evaluări

- Scheuerle SPMT 3000 IC Brochure PDFDocument13 paginiScheuerle SPMT 3000 IC Brochure PDFRuben Bartolome GarciaÎncă nu există evaluări

- 2014-06 PP Heavy-Duty Modules THP-PST enDocument60 pagini2014-06 PP Heavy-Duty Modules THP-PST enTh Nattapong100% (1)

- SPMT Double 2430 Wide Unlimited 3P SuspDocument1 paginăSPMT Double 2430 Wide Unlimited 3P SuspBHAUMIK SOLANKIÎncă nu există evaluări

- Skidding System Data SheetDocument1 paginăSkidding System Data Sheetm4l4ysiaÎncă nu există evaluări

- VSL Heavy LiftingDocument16 paginiVSL Heavy LiftingDrPadipat ChaemmangkangÎncă nu există evaluări

- Heavy LiftDocument31 paginiHeavy LiftFachrurrazi100% (2)

- Introduction To HeavyliftDocument30 paginiIntroduction To HeavyliftAnonymous qT66pyKÎncă nu există evaluări

- 6-Achs SPMT 210.12.4 G4 6-Axle SPMT 210.12.4 G4: Scheuerle-Fahrzeugfabrik GMBHDocument22 pagini6-Achs SPMT 210.12.4 G4 6-Axle SPMT 210.12.4 G4: Scheuerle-Fahrzeugfabrik GMBHsrikanthc8550% (2)

- 08 Heavy Lifting and Heavy TransportDocument10 pagini08 Heavy Lifting and Heavy TransporttrungscrÎncă nu există evaluări

- US FHWA Manual On Use of SPMTs 06-2007 PDFDocument118 paginiUS FHWA Manual On Use of SPMTs 06-2007 PDFenviroswÎncă nu există evaluări

- Simulation and Structural Analysis of Modules During Land TransportationDocument6 paginiSimulation and Structural Analysis of Modules During Land TransportationRay Lee100% (1)

- SPMT Modular Trailer Ultimate GuideDocument61 paginiSPMT Modular Trailer Ultimate Guidefcesar1986100% (1)

- ALE Capabilities Brochure FVDocument64 paginiALE Capabilities Brochure FVNatree TeeÎncă nu există evaluări

- 2D TRansformer 640 Ton + 73.2 PDFDocument5 pagini2D TRansformer 640 Ton + 73.2 PDFHaGun GantryÎncă nu există evaluări

- 1.different LIFTING and TRANSPORT Types: 1. Rolling MaterialDocument8 pagini1.different LIFTING and TRANSPORT Types: 1. Rolling MaterialSalah SalahÎncă nu există evaluări

- SPMTDocument5 paginiSPMTLinhNguyenViet100% (2)

- AS 90tele: The Loader SpecialistDocument8 paginiAS 90tele: The Loader Specialistdm1680Încă nu există evaluări

- Unimog Techdata u4000 Euro5 1209 en PDF Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdfDocument2 paginiUnimog Techdata u4000 Euro5 1209 en PDF Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdfIvana Ilic67% (3)

- EAGLE IV4x4Document2 paginiEAGLE IV4x4Cristián IvesÎncă nu există evaluări

- The Loader Specialist: System 180Document8 paginiThe Loader Specialist: System 180dm1680Încă nu există evaluări

- AC50-1 Data SheetDocument18 paginiAC50-1 Data SheetJonp4ul_MiddletonÎncă nu există evaluări

- LR11350 Technical Data SheetDocument70 paginiLR11350 Technical Data SheetJonp4ul_MiddletonÎncă nu există evaluări

- LTM 1750-9.1 BrochureDocument134 paginiLTM 1750-9.1 BrochureJonp4ul_MiddletonÎncă nu există evaluări

- Steel Desing To Eurocode 3Document2 paginiSteel Desing To Eurocode 3Jonp4ul_MiddletonÎncă nu există evaluări

- 08GroundPressuresC PDFDocument2 pagini08GroundPressuresC PDFJonp4ul_MiddletonÎncă nu există evaluări

- Microsome S9 Prep ProtocolDocument22 paginiMicrosome S9 Prep ProtocolSAN912Încă nu există evaluări

- QAI Golden Pass Fact SheetDocument2 paginiQAI Golden Pass Fact SheetQatar-America InstituteÎncă nu există evaluări

- Nails Care: Word Search: Name: - DateDocument1 paginăNails Care: Word Search: Name: - DateDeverly Hernandez Balba-AmplayoÎncă nu există evaluări

- Chapter 6 Strategy Analysis and Choice: Strategic Management: A Competitive Advantage Approach, 16e (David)Document27 paginiChapter 6 Strategy Analysis and Choice: Strategic Management: A Competitive Advantage Approach, 16e (David)Masum ZamanÎncă nu există evaluări

- Uniden PowerMax 5.8Ghz-DSS5865 - 5855 User Manual PDFDocument64 paginiUniden PowerMax 5.8Ghz-DSS5865 - 5855 User Manual PDFtradosevic4091Încă nu există evaluări

- ENSC1001 Unit Outline 2014Document12 paginiENSC1001 Unit Outline 2014TheColonel999Încă nu există evaluări

- Maskote WB Zinc Stop-OffDocument7 paginiMaskote WB Zinc Stop-OffbondsivamaniÎncă nu există evaluări

- NCERT Solutions For Class 10 Maths Chapter 5 Arithmetic Progression (Ex 5.1) Exercise 5.1Document8 paginiNCERT Solutions For Class 10 Maths Chapter 5 Arithmetic Progression (Ex 5.1) Exercise 5.1Akash DasÎncă nu există evaluări

- Economics - Economics - Cheat - SheetDocument1 paginăEconomics - Economics - Cheat - SheetranaurÎncă nu există evaluări

- Project Analysis - M5 - MotorwayDocument6 paginiProject Analysis - M5 - MotorwayMuhammad Haroon ArshadÎncă nu există evaluări

- Reinforced Concrete Design PDFDocument1 paginăReinforced Concrete Design PDFhallelÎncă nu există evaluări

- 00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentDocument4 pagini00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentFaizal AbdullahÎncă nu există evaluări

- HPSC HCS Exam 2021: Important DatesDocument6 paginiHPSC HCS Exam 2021: Important DatesTejaswi SaxenaÎncă nu există evaluări

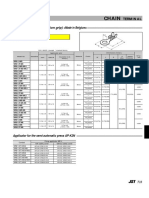

- Chain: SRB Series (With Insulation Grip)Document1 paginăChain: SRB Series (With Insulation Grip)shankarÎncă nu există evaluări

- (Ebook - Antroposofia - EnG) - Rudolf Steiner - Fundamentals of TheraphyDocument58 pagini(Ebook - Antroposofia - EnG) - Rudolf Steiner - Fundamentals of Theraphyblueyes247Încă nu există evaluări

- MSDS Leadframe (16 Items)Document8 paginiMSDS Leadframe (16 Items)bennisg8Încă nu există evaluări

- Bassoon (FAGOT) : See AlsoDocument36 paginiBassoon (FAGOT) : See Alsocarlos tarancón0% (1)

- ING C1 CO JUN2016 CorrectorDocument6 paginiING C1 CO JUN2016 CorrectoraciameÎncă nu există evaluări

- Corrosion Performance of Mild Steel and GalvanizedDocument18 paginiCorrosion Performance of Mild Steel and GalvanizedNarasimha DvlÎncă nu există evaluări

- Module 5Document14 paginiModule 5shin roseÎncă nu există evaluări

- Linux and The Unix PhilosophyDocument182 paginiLinux and The Unix PhilosophyTran Nam100% (1)

- Unit 1 Building A Professional Relationship Across CulturesDocument16 paginiUnit 1 Building A Professional Relationship Across CulturesAlex0% (1)

- Half Yearly Examination, 2017-18: MathematicsDocument7 paginiHalf Yearly Examination, 2017-18: MathematicsSusanket DuttaÎncă nu există evaluări

- DatuinMA (Activity #5 - NSTP 10)Document2 paginiDatuinMA (Activity #5 - NSTP 10)Marc Alen Porlaje DatuinÎncă nu există evaluări

- Banin Cawu 1: Panitia Ujian Perguruan Islam Mathali'Ul FalahDocument4 paginiBanin Cawu 1: Panitia Ujian Perguruan Islam Mathali'Ul FalahKajen PatiÎncă nu există evaluări

- Citrus Information Kit-Update: Reprint - Information Current in 1998Document53 paginiCitrus Information Kit-Update: Reprint - Information Current in 1998hamsa sewakÎncă nu există evaluări

- PretestDocument8 paginiPretestAlmonte Aira LynÎncă nu există evaluări

- Anykycaccount Com Product Payoneer Bank Account PDFDocument2 paginiAnykycaccount Com Product Payoneer Bank Account PDFAnykycaccountÎncă nu există evaluări

- Furniture AnnexDocument6 paginiFurniture AnnexAlaa HusseinÎncă nu există evaluări

- X Lube Bushes PDFDocument8 paginiX Lube Bushes PDFDavid TurnerÎncă nu există evaluări

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDe la EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterÎncă nu există evaluări

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVDe la EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVEvaluare: 5 din 5 stele5/5 (2)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceDe la EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceÎncă nu există evaluări

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDe la EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestEvaluare: 4 din 5 stele4/5 (28)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDe la EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerEvaluare: 4.5 din 5 stele4.5/5 (54)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDe la EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesEvaluare: 4.5 din 5 stele4.5/5 (21)

- Introduction to Power System ProtectionDe la EverandIntroduction to Power System ProtectionEvaluare: 5 din 5 stele5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridDe la EverandShorting the Grid: The Hidden Fragility of Our Electric GridEvaluare: 4.5 din 5 stele4.5/5 (2)

- CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]De la EverandCDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]Evaluare: 5 din 5 stele5/5 (2)

- Automotive Electronic Diagnostics (Course 1)De la EverandAutomotive Electronic Diagnostics (Course 1)Evaluare: 5 din 5 stele5/5 (6)

- Why We Drive: Toward a Philosophy of the Open RoadDe la EverandWhy We Drive: Toward a Philosophy of the Open RoadEvaluare: 4 din 5 stele4/5 (6)

- A Pathway to Decarbonise the Shipping Sector by 2050De la EverandA Pathway to Decarbonise the Shipping Sector by 2050Încă nu există evaluări

- AR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualDe la EverandAR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualEvaluare: 4.5 din 5 stele4.5/5 (2)

- Tips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)De la EverandTips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)Încă nu există evaluări

- Why We Drive: Toward a Philosophy of the Open RoadDe la EverandWhy We Drive: Toward a Philosophy of the Open RoadEvaluare: 4.5 din 5 stele4.5/5 (21)

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!De la EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Încă nu există evaluări

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceDe la EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceÎncă nu există evaluări

- Building Honda K-Series Engine PerformanceDe la EverandBuilding Honda K-Series Engine PerformanceEvaluare: 5 din 5 stele5/5 (2)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDe la EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsEvaluare: 4.5 din 5 stele4.5/5 (2)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsDe la EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsÎncă nu există evaluări

![CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/710834945/198x198/00b81cbbd3/1714482720?v=1)