Documente Academic

Documente Profesional

Documente Cultură

Article On 'Pre-Engineered Building (PEB) Industry in India' by Chaitanya Raj Goyal

Încărcat de

Chaitanya Raj GoyalTitlu original

Drepturi de autor

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Article On 'Pre-Engineered Building (PEB) Industry in India' by Chaitanya Raj Goyal

Încărcat de

Chaitanya Raj GoyalDrepturi de autor:

Steel Buildings

Engineered to Succeed:

Chaitanya Raj Goyal

PEB Industry Slated to Revolutionize Construction in India

e're careering headlong into a new age of speed building an era where, in some cities, you could go away for the weekend and return to find a brand new skyscraper at the end of your garden. Imagine the relief when you suddenly realize that you have been spared the unnerving, yearlong noises of truck horns, pounding hammers, drilling machines and screaming laborers. You don't have to bother about road blocks either

because there are no heaps of sand, piles of rods, & bricks that have been dumped on your locality roads and you can also keep your windows open because there are no dust clouds to raid your home. And No! It's not an illusion. Relieved and happy, witnessing the construction of this miraculous building next door, you are reaping only its complementary benefits. The major advantages on the other hand are rolling into considerable profits for the in-

vestors, contractors and environment. We are talking about Pre-Engineered or Pre-Fabricated Buildings a sunrise industry which has already got the world talking with the major impact it has registered in the developed nations and is now all set to revolutionize the way India constructs! Industry Overview: Technology and Business PEB, as pre-engineered buildings

70

The Masterbuilder - March 2013 www.masterbuilder.co.in

Steel Buildings

are known in the industry jargon, have been around for a long time, but in India they have taken off only over the last few years. PEBs consist of a complete steel framed building system, with components pre-designed to fit together in a vast variety of combinations, to meet the unique requirements of specific end-users. PEB construction in factory environment is considered to be much stronger than the traditional structures thus ensuring superior product quality. Prefabricated structures also guarantee time minimization, architectural flexibility, low maintenance and operating costs, relatively low design and construction costs, option of single-source responsibility for building, etc. Demand for these buildings comprises warehouses, hospitals, factories, logistics, schools, stadiums, railway sheds, airplane hangars, offices, show rooms and residential buildings. Across India, the manufacturing sector especially has always preferred using PEBs in industrial construction. But over the time with turnaround period and scalability becoming important for construction across micro and macro projects for private, corporate and institutional use - the usage of PEBs has grown in construction projects across various other verticals as well. This is well certified by the fact that Indian PEB market earned revenues of INR 52,970 million in 2012 and the figure is estimated to reach INR 136,120 million by 2016, growing at a compound annual growth rate (CAGR) of 26.6 percent (Frost & Sullivan report). Currently 33% of the Indian construction industry is based on PEB while the remaining 67% is conventional construction. While this figure is lower than some European countries, it marks India's growing global market share at 9.5%, a step ahead of China's 8.5%. Also, the structural steel buildings market in India was around 5.0 to 5.5 million MT in 2011, of which around 9.510% i.e. 537,176 MT accounted for the PEB market in India. It is expected that the market in terms of volumes will reach

PEB Structures offer amazing architectural flexibility

900,000 MT by 2016, growing at a CAGR of 11.1% (Frost & Sullivan report). Growth Drivers: Opportunities are many Growing Recognition: In light of the recent news that PEB has been generating - awareness about their use in almost all the structures is changing the mass mindset for acceptance of PEBs over conventional buildings. Rapid Infrastructural Growth: The government is working to attract investments to the tune of $1 trillion as planned for the 12th FYP across key infra-

structure sectors. The Union Government and other State Governments are going full-ahead to set-up SEZs in exploring maximum opportunities from growing indus-trialization. Also the thermal power ca-pacity which currently stands at 140,976 MW is proposed to be increased by 50,000 MW. The commercial building sector in India, too, is estimated to reach a target of 20.44 billion square feet by 2030 from 7 billion square feet in 2010. It is expected that nearly 34% of 2030 target had already been constructed and

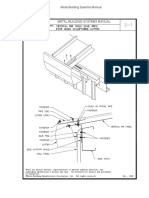

Interior Side Thermal break Recycled-steel Framing Waterproof membrane Gypsumboard

External cladding:

-Acoustic insulation -Ventilated Facade

Mechanical chase Exterior side

A typical wall panel

www.masterbuilder.co.in The Masterbuilder - March 2013

71

Steel Buildings

Massive investments in metro rail systems and other sectors will boost PEB industry

about 66% of the building stock is yet to be constructed. With such huge investments planned over the next four years in these and many other sectors like realty, ports, logistics, metros, airports, etc., PEB sector is witnessing a huge opportunity. The Green Touch: The environmentally friendly aspects of prefab structures - they create less waste, for example, they are often made from recycled materials (steel especially) and are highly energy efficient - continue to attract green-minded folks around the country. To increase energy-efficiency, many PEB manufacturers have developed high efficiency windows and insulation for roofs, walls, ceilings & floors. The use of sky lights and solar panels on rooftops will meet daylight and captive power requirements, while, at the same time, reducing emissions and gaining carbon credits under clean development mechanism. Technological innovations: The technology being used in modern construction has come a long way. BIM helps in organizing effective communi-

cation between Client, Architect, Engineer, Manufacturer and Erector. This technology is more economic, reduces error, and takes minimum time in conceptualizing and accomplishing any PEB project. Rise of Steel Sector: The Indian steel industry has made rapid progress over the past few years driven by the strong demand from manufacturing, housing and infrastructure sectors. The Indian steel industry's performance this year is regarded as one the best when pitted against global peers. While global steel production grew by a mere 0.9% in the first 11 months of 2012 and Chinese production rose by 2.9%, the Indian steel industry posted an impressive 4.2% growth. Easy availability of steel is going to smoother the growth drive for PEB sector. Affordable housing is need of the hour: India offers a huge market, (over $ 6 Billion for two million units), for affordable housing, which is highly correlated with the government's programmes for slum rehabilitation, for e.g. 'Rajiv Gandhi Aawas Yojana'. This market has a good latent de-

mand and offers a unique opportunity for prefab technology to reach masses. It is very clear therefore that large private sector developers who are eyeing this segment would resort to prefab technology, to ensure that there are faster returns on investment and that the project is completed within an economic cycle. The United Nations Population Division Report of 2007 predicted that the number of mega cities (those with over 10 million or more people) climbed from five in 1975 to 14 in 1995 and is projected to reach 26 by 2015. Naturally, the demand for affordable housing will leapfrog and this in turn will impact the growth of the PEB industry. Growth in Automobile Industry: The Auto industry in India is also on a growth ride and PEB manufacturers are getting enormous business opportunities in setting-up of automobile and auto ancillary facilities. Safe and Efficient: Deeper insight into PEB technology A PEB system in totality consists of a structural system, sandwich panels,

72

The Masterbuilder - March 2013 www.masterbuilder.co.in

Steel Buildings

'Instacon' was erected in 48 hours in Mohali, Punjab

roofing, exterior facade and accessories. The PEB concept based on a proper design usually involves a thorough project information data including complete details like building parameters, grade of steel, secondary member details, paint coat on steel members, welding, anchor bolts steel grade, roof & wall liner/ panel, insulation, sky light, gutters, facia, mezzanine, ridge ventilation to name a few. Following this input, the drawings for general arrangement, Anchor Bolt & Template Fabrication & Erection are prepared. Recently, a 10 storey residential building Instacon, was erected in a record shattering 48 hours from ground zero, in Mohali, Punjab by Synergy Thrislington. The walls of Instacon are made from polyurethane foaming (PUF) panels cast in a factory and screwed together at the site. 70% of the building was pre-fab-ricated and 30% was done at the site of construction. In China too, a succession of tall buildings are being erected in a flash. A Chinese company - Broad claims that it can prefabricate an incredible 93 %. It raised a 15-storey hotel in its home city of Changsha in six days last year and a $17m, 30-storey hotel, just outside Changsha in two weeks. But can a block of flats built in cou-

ple of days really be safe? Many questions are raised worldwide on the safety and efficiency of these structures primarily safety. It may be noted that these buildings are tested at some of the largest earthquake-testing platforms for Magnitude 9 seismic resistance. The economy safety tradeoff provided by PEBs is thus unparalleled and far better than conventional structures. Strategic Management: Existing Market players Started in 1999-2000 with a meager volume of less than 10,000 tons per annum, PEB construction is catching up fast. But despite good demand and due to excessive supply, the market scenario of PEB sector is changing. Suppliers from the unorganized segment of PEB are supplying material and services at an amazing low cost. This is ultimately reflected as a high compromise in quality and services. This is where the organized sector plays a crucial role in the form of technical competence and background because clients are always ready to pay good prices for quality jobs and big ticket projects. The existent Indian PEB segment is highly competitive with presence of established players like Kirby Building

systems, Sintex Industries, Pennar EBSL, Era Buildsys, Tata BlueScope Steel, Interarch Building Products, Tiger Steel Engineering, Phenix Varco Pruden, Everest Industries, Zamil Steel, etc. Also, the sector is going international as companies move to tie up with multinationals for upgrading offerings to their customers. Technical association and JV's with leading PEB companies in Europe, USA and Middle-east are proving quite useful in terms of engineering excellence, product quality and superior products range for Indian firms. Major names that have linked up abroad are Tata BlueScope, Reliance Industries tie up with Mammut Group and JSW Building Systems bonding with Severfield Reeve Structures of UK, as also Phenix Varco Pruden, a JV between Gujarat's MB Group and Varco Pruden Buildings, USA. In such a competitive scenario, the ability of a company to retain its market share without any deterioration in its financial risk profile will prove critical in progress.

A 30 floor PEB building undergoing seismic testing in China

74

The Masterbuilder - March 2013 www.masterbuilder.co.in

Steel Buildings

Volatile nature of Steel Prices poses a huge challenge to the PEB industry

Preferred Alternative: Prefab vs. Conventional Construction Ideal for construction in remote and hilly areas, PEBs offer a complete building system of energy efficient, optimum weight and cost customized fitted requirement. They can be customized as per the climate/design requirements at the site. Since only the bolting needs to be done on the site a quicker construction speed compared to conventional construction is possible. The flexibility of PEBs to be casted even while the foundation is being laid also leads to saving on time. PEBs don't require curing time like concrete and mortar and boast of an immediate occupancy. The quality of the structure being controlled in the factory is superior to that achieved in masonry construction. They are much lighter in weight than normal steel buildings owing to their high proportion of recycled content. Their design flexibility is also a plus with wide ranges of available wall and roof sheeting (granite, stone cladding, brickwork, ACP's etc) and interface details between steel and other materials. These are low maintenance structures requiring only periodic cleaning of roofs, painting and annual washing of eave gutters. The ease of construction makes them hassle free and bestows

cleaner sites since the self-supporting components don't require shuttering or scaffolding. Future extensions/modifications or dismantling/relocating can also be accommodated easily. The Steel Saga: Impact of Fluctuating Price The usage of steel and especially in pre-engineered buildings is growing very rapidly in the Indian construction industry. Steel accounts for 65-75 % of the total raw material cost of a PEB. Thus availability and pricing of steel does make lot of difference to organized sector of PEB suppliers. The steel prices are volatile in nature and the same are driven by the global prices and are also dominated by the demand supply scenario prevailing on a particular day. Hence, profitability of the company can be impacted with adverse movement in raw material prices which it may not be able to pass on entirely to its clients, owing to competition pressure and lack of escalation clause in its contracts with clients. Off late, fluctuating steel prices has become a matter of concern which could affect the overall industry growth. Long-term rate contract is only possible if the steel purchaser is a very huge player. This is because the margins are higher in larger purchases with huge

players, so the steel manufacturer does not mind having long-term rate contracts. On the other hand, if the margins are slim, no steel manufacturer wants to enter into long-term contracts. Thus availability of steel in an affordable price is a big challenge. Speed Breakers and Way forward India is fast turning out to be a fertile ground for PEBs as the country is witnessing a boom in the construction sector. But there are still quite a few issues pertaining to the sector which are holding it back from exploiting its full potential. The lack of availability of international quality materials like quality fittings, insulation materials, wall claddings etc. is hampering growth because it makes the designers hesitant about opting for PEB structures. An Indian PEB manufactures association code of practice and PEB design institute need to be initiated. Such efforts will promote the merits and usage of PEBs in the country. To be competitive, this industry should look at investing into training of workmanship, R&D, manufacturing processes and also into latest software to optimize the design. It is essential that the industry focuses on these areas in coming times - to emerge as world players and to see a wider application of PEBs in India.

76

The Masterbuilder - March 2013 www.masterbuilder.co.in

S-ar putea să vă placă și

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDe la EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionÎncă nu există evaluări

- PEB Article Engineered To SucceedDocument5 paginiPEB Article Engineered To SucceedBennoDsouzaÎncă nu există evaluări

- Pre-Engineered Building Design and AnalysisDocument73 paginiPre-Engineered Building Design and Analysissrinivasa raghavanÎncă nu există evaluări

- Sustainable Steel Buildings: A Practical Guide for Structures and EnvelopesDe la EverandSustainable Steel Buildings: A Practical Guide for Structures and EnvelopesBernhard HaukeÎncă nu există evaluări

- Rhino Pre-Engineered Buildings GuideDocument6 paginiRhino Pre-Engineered Buildings GuideHaris MustafaÎncă nu există evaluări

- Zamil Steel Vietnam (ZSV) : Total Steel Building SolutionsDocument80 paginiZamil Steel Vietnam (ZSV) : Total Steel Building SolutionsTuan Hung TrinhÎncă nu există evaluări

- A Review On Comparative Study Between The Pre-Engineered Building and Conventional Steel BuildingDocument7 paginiA Review On Comparative Study Between The Pre-Engineered Building and Conventional Steel BuildingIJRASETPublicationsÎncă nu există evaluări

- TMDocument471 paginiTMAhmed KhanÎncă nu există evaluări

- Zamil Steel PDFDocument12 paginiZamil Steel PDFAshishÎncă nu există evaluări

- Pre-Engineered Building Design ComparisonDocument11 paginiPre-Engineered Building Design ComparisonKulal SwapnilÎncă nu există evaluări

- Cellular BeamsDocument4 paginiCellular BeamsSeifeldin Ali MarzoukÎncă nu există evaluări

- PEB 2D Vs 3D ModelDocument5 paginiPEB 2D Vs 3D ModelGautam PaulÎncă nu există evaluări

- Project Report On Pre Engineered BuildingsDocument7 paginiProject Report On Pre Engineered BuildingsEIRI Board of Consultants and PublishersÎncă nu există evaluări

- Seismic Evaluation of Pre-Engineering and Conventional Steel Structure-A ReviewDocument6 paginiSeismic Evaluation of Pre-Engineering and Conventional Steel Structure-A ReviewIJRASETPublicationsÎncă nu există evaluări

- A Comparative Study of Conventional Steel Building and Pre-Engineered Steel Building Structure Using STAAD PRODocument7 paginiA Comparative Study of Conventional Steel Building and Pre-Engineered Steel Building Structure Using STAAD PROIJRASETPublicationsÎncă nu există evaluări

- PebDocument12 paginiPebazharuddin1100Încă nu există evaluări

- (DM) Implementing The New Building Code For Earthquake Proof BldgsDocument14 pagini(DM) Implementing The New Building Code For Earthquake Proof BldgsJose Leo MissionÎncă nu există evaluări

- Bridge Building Design Thinking ProcessDocument12 paginiBridge Building Design Thinking Processapi-262592867100% (1)

- Everest PEB Brochure - Leader in PEB StructuresDocument28 paginiEverest PEB Brochure - Leader in PEB StructuresBikramdevPadhiÎncă nu există evaluări

- Cfsei 2015 Award Winners - CemcoDocument3 paginiCfsei 2015 Award Winners - CemcokrlosÎncă nu există evaluări

- Pre-Engineered Structure ResearchDocument9 paginiPre-Engineered Structure Researchya gurl shainnaÎncă nu există evaluări

- Solar Panel Installations on Existing StructuresDocument6 paginiSolar Panel Installations on Existing StructuresPhani ArvapalliÎncă nu există evaluări

- A Study On Pre-Engineered Building (PEB) Sector of Bangladesh - Challenges & OpportunitiesDocument46 paginiA Study On Pre-Engineered Building (PEB) Sector of Bangladesh - Challenges & Opportunitiesrahivilla100% (3)

- Basement Modeling and The Backstay Effect - Sanya LeviDocument20 paginiBasement Modeling and The Backstay Effect - Sanya Levisyl29100% (2)

- Corrugated Sheets Design GuideDocument12 paginiCorrugated Sheets Design GuideRama KrishnaÎncă nu există evaluări

- References PDFDocument42 paginiReferences PDFSalik Tramboo100% (1)

- Brochure Combined Wall Systems - 2019 - Digital - SingleDocument40 paginiBrochure Combined Wall Systems - 2019 - Digital - SinglelazcanoÎncă nu există evaluări

- Peb Brochure SteelDocument40 paginiPeb Brochure SteelChamila RajapakshaÎncă nu există evaluări

- Prestressed Concrete StructuresDocument32 paginiPrestressed Concrete StructuresMâjñù MâjñúÎncă nu există evaluări

- CFSEI Tech Note X Bracing L001-09Document8 paginiCFSEI Tech Note X Bracing L001-09Jane EyreÎncă nu există evaluări

- Star Building Systems - 2 - 1Document27 paginiStar Building Systems - 2 - 1NiranjanAryanÎncă nu există evaluări

- High Rise Buildings and The Role of Construction ManagementDocument3 paginiHigh Rise Buildings and The Role of Construction ManagementIJIERT-International Journal of Innovations in Engineering Research and TechnologyÎncă nu există evaluări

- Zamil Steel Brochures English 68 PagesDocument35 paginiZamil Steel Brochures English 68 PagesAmr El-ShorbagyÎncă nu există evaluări

- PEB CodesDocument8 paginiPEB CodesMahmood MuftiÎncă nu există evaluări

- Suitability of Fixed Base and Pinned Base PEB Structure With Pile FoundationDocument4 paginiSuitability of Fixed Base and Pinned Base PEB Structure With Pile FoundationKarthik SgÎncă nu există evaluări

- Offer Steel Building FormatDocument16 paginiOffer Steel Building FormatShamsul IslamÎncă nu există evaluări

- Revit To Advance Steel Collaboration Method AULON18281-AU2018 - JB - Powerpoint - Show - V2Document48 paginiRevit To Advance Steel Collaboration Method AULON18281-AU2018 - JB - Powerpoint - Show - V2Fongho Eric SinclairÎncă nu există evaluări

- Analysis and Design of High-Rise Building (G+30) Using Staad - ProDocument5 paginiAnalysis and Design of High-Rise Building (G+30) Using Staad - ProআকাশআহসানÎncă nu există evaluări

- Chhatrapati Shivaji International Airport Integrated Terminal BuildingDocument6 paginiChhatrapati Shivaji International Airport Integrated Terminal BuildingRiddhi PatelÎncă nu există evaluări

- Book SummaryDocument33 paginiBook SummaryhabteeÎncă nu există evaluări

- CCL PT Slabs Brochure Eng PDFDocument15 paginiCCL PT Slabs Brochure Eng PDFSharad BornarkarÎncă nu există evaluări

- Zamil PEB BrochureDocument40 paginiZamil PEB BrochureAlbert Ericson DelfinoÎncă nu există evaluări

- Post Tension StructuresDocument10 paginiPost Tension Structurestwinkle4545Încă nu există evaluări

- Roof Details Section 2.pdf MBMADocument31 paginiRoof Details Section 2.pdf MBMASilvanaÎncă nu există evaluări

- Fischer THB INT 110640 082013Document445 paginiFischer THB INT 110640 082013arunks4uÎncă nu există evaluări

- 05450-Pre Engineered Metal TrussesDocument4 pagini05450-Pre Engineered Metal TrussesRamsey RasmeyÎncă nu există evaluări

- Pre-Engineered Building Solutions - FUXIN Steel Buildings Co., Ltd. 2015Document28 paginiPre-Engineered Building Solutions - FUXIN Steel Buildings Co., Ltd. 2015vannethny100% (2)

- Pre-Engineered Metal Buildings GuideDocument20 paginiPre-Engineered Metal Buildings GuideAbhishek GandhiÎncă nu există evaluări

- MIVAN SeminarDocument57 paginiMIVAN SeminarSarinÎncă nu există evaluări

- Indian Structural Hand BookDocument209 paginiIndian Structural Hand BookNaliniRanjanMuduliÎncă nu există evaluări

- Long Paper Nicmar - Peb HangarDocument88 paginiLong Paper Nicmar - Peb HangarZuber Ahmed100% (2)

- ADMIN Building Calculation SheetDocument95 paginiADMIN Building Calculation Sheetorode franklynÎncă nu există evaluări

- Project 2 ReportDocument26 paginiProject 2 Reportarjun kumarÎncă nu există evaluări

- AISI tn-d100-13Document4 paginiAISI tn-d100-13Edison BecerraÎncă nu există evaluări

- Night School 23 Session 2Document41 paginiNight School 23 Session 2Luis CortesÎncă nu există evaluări

- I.S 5624-1993 Foundation BoltsDocument8 paginiI.S 5624-1993 Foundation Boltssandeepgupta202Încă nu există evaluări

- Matt Gombeda - Job Application PackageDocument10 paginiMatt Gombeda - Job Application Packageapi-253274604Încă nu există evaluări

- Project Presentation On "Tuned Mass Dampers and Their Application in Structures" by Chaitanya Raj GoyalDocument34 paginiProject Presentation On "Tuned Mass Dampers and Their Application in Structures" by Chaitanya Raj GoyalChaitanya Raj Goyal100% (13)

- EQTip 17Document2 paginiEQTip 17Arnav Anuj KasarÎncă nu există evaluări

- Article On 'Integrated Townships' by Chaitanya Raj GoyalDocument6 paginiArticle On 'Integrated Townships' by Chaitanya Raj GoyalChaitanya Raj GoyalÎncă nu există evaluări

- India Kids Project Research Internship JDDocument1 paginăIndia Kids Project Research Internship JDChaitanya Raj GoyalÎncă nu există evaluări

- Article On 'Life Cycle of Indian Concrete Industry' by Chaitanya Raj GoyalDocument7 paginiArticle On 'Life Cycle of Indian Concrete Industry' by Chaitanya Raj GoyalChaitanya Raj GoyalÎncă nu există evaluări

- The Masterbuilder - February 2013 - Construction Equipment SpecialDocument196 paginiThe Masterbuilder - February 2013 - Construction Equipment SpecialChaitanya Raj GoyalÎncă nu există evaluări

- Article On 'Indian Precast Concrete Building Industry' by Chaitanya Raj GoyalDocument7 paginiArticle On 'Indian Precast Concrete Building Industry' by Chaitanya Raj GoyalChaitanya Raj GoyalÎncă nu există evaluări

- The Masterbuilder - July 2013 - Concrete SpecialDocument286 paginiThe Masterbuilder - July 2013 - Concrete SpecialChaitanya Raj GoyalÎncă nu există evaluări

- Project Presentation On "Foundation in Collapsible Soils" by Chaitanya Raj GoyalDocument47 paginiProject Presentation On "Foundation in Collapsible Soils" by Chaitanya Raj GoyalChaitanya Raj Goyal92% (12)

- Project Presentation On "Comprehensive Study of Chhatrapati Shivaji International Airport, Mumbai' by Chaitanya Raj GoyalDocument86 paginiProject Presentation On "Comprehensive Study of Chhatrapati Shivaji International Airport, Mumbai' by Chaitanya Raj GoyalChaitanya Raj Goyal90% (21)

- Article On 'Indian Construction Equipment Industry' by Chaitanya Raj GoyalDocument7 paginiArticle On 'Indian Construction Equipment Industry' by Chaitanya Raj GoyalChaitanya Raj GoyalÎncă nu există evaluări

- Article On 'Bauma Conexpo, India - 2013' by Chaitanya Raj GoyalDocument7 paginiArticle On 'Bauma Conexpo, India - 2013' by Chaitanya Raj GoyalChaitanya Raj Goyal0% (1)

- Article On 'Indian Contribution To Sri Lankan Infrastructure' by Chaitanya Raj GoyalDocument4 paginiArticle On 'Indian Contribution To Sri Lankan Infrastructure' by Chaitanya Raj GoyalChaitanya Raj GoyalÎncă nu există evaluări

- Interview: Chairman, Structwel Designers and ConsultantsDocument3 paginiInterview: Chairman, Structwel Designers and ConsultantsChaitanya Raj GoyalÎncă nu există evaluări

- Article On 'Life Cycle Assesment Concrete Structures' by Chaitanya Raj GoyalDocument5 paginiArticle On 'Life Cycle Assesment Concrete Structures' by Chaitanya Raj GoyalChaitanya Raj GoyalÎncă nu există evaluări

- Article On 'Coolest Buildings of 2012' by Chaitanya Raj GoyalDocument10 paginiArticle On 'Coolest Buildings of 2012' by Chaitanya Raj GoyalChaitanya Raj GoyalÎncă nu există evaluări

- Seminar Presentation On "Applications of GIS in Civil Engineering: Case Studies" by Chaitanya Raj GoyalDocument51 paginiSeminar Presentation On "Applications of GIS in Civil Engineering: Case Studies" by Chaitanya Raj GoyalChaitanya Raj Goyal89% (18)

- The Masterbuilder - September 2012 - Flooring SpecialDocument224 paginiThe Masterbuilder - September 2012 - Flooring SpecialChaitanya Raj Goyal100% (1)

- Article On 'Backhoe Loader Industry in India' by Chaitanya Raj GoyalDocument10 paginiArticle On 'Backhoe Loader Industry in India' by Chaitanya Raj GoyalChaitanya Raj GoyalÎncă nu există evaluări

- Article On 'Robotics in High Rise Construction' by Chaitanya Raj GoyalDocument5 paginiArticle On 'Robotics in High Rise Construction' by Chaitanya Raj GoyalChaitanya Raj Goyal100% (1)

- The Masterbuilder - November 2012Document228 paginiThe Masterbuilder - November 2012Chaitanya Raj GoyalÎncă nu există evaluări

- Article On 'Fire Safety in High Rise Buildings' by Chaitanya Raj GoyalDocument4 paginiArticle On 'Fire Safety in High Rise Buildings' by Chaitanya Raj GoyalChaitanya Raj GoyalÎncă nu există evaluări

- Article On 'Surface Preparation For Industrial Flooring' by Chaitanya Raj GoyalDocument5 paginiArticle On 'Surface Preparation For Industrial Flooring' by Chaitanya Raj GoyalChaitanya Raj GoyalÎncă nu există evaluări

- Article On 'Solar Energy: Off Grid Applications' by Chaitanya Raj GoyalDocument4 paginiArticle On 'Solar Energy: Off Grid Applications' by Chaitanya Raj GoyalChaitanya Raj GoyalÎncă nu există evaluări

- The Masterbuilder - October 2012 - Geotech SpecialDocument230 paginiThe Masterbuilder - October 2012 - Geotech SpecialChaitanya Raj GoyalÎncă nu există evaluări

- Article On 'Concrete Floor Coatings' by Chaitanya Raj GoyalDocument5 paginiArticle On 'Concrete Floor Coatings' by Chaitanya Raj GoyalChaitanya Raj GoyalÎncă nu există evaluări

- Interview: 'JCB India VP Marketing"Document2 paginiInterview: 'JCB India VP Marketing"Chaitanya Raj GoyalÎncă nu există evaluări

- EQTip 08Document2 paginiEQTip 08raj_ferrariÎncă nu există evaluări

- How Buildings Twist During Earthquakes - Understanding Torsional BehaviorDocument2 paginiHow Buildings Twist During Earthquakes - Understanding Torsional Behaviormdkml2Încă nu există evaluări

- AZURFLEXDocument16 paginiAZURFLEXtitaÎncă nu există evaluări

- Bistra AnnouncementDocument55 paginiBistra AnnouncementMohammed Al-samarraeÎncă nu există evaluări

- EE6604 UwDocument131 paginiEE6604 UwVengatesh VelusamyÎncă nu există evaluări

- What Is A Passive HouseDocument2 paginiWhat Is A Passive HouseLeontin LeonÎncă nu există evaluări

- Manual Técnico y de Aplicación PROMAT® - Particiones y Muros Externos PDFDocument118 paginiManual Técnico y de Aplicación PROMAT® - Particiones y Muros Externos PDFJorge ValeroÎncă nu există evaluări

- Basement WaterproofingDocument22 paginiBasement WaterproofinglallanasaintsÎncă nu există evaluări

- Mortarless CMU SystemsDocument10 paginiMortarless CMU Systemsomisla100% (1)

- Circularity in The Built Environment: Case StudiesDocument72 paginiCircularity in The Built Environment: Case StudiesMargarita KianidouÎncă nu există evaluări

- 00 Me SPC 0004 ADocument18 pagini00 Me SPC 0004 Aandmar2011Încă nu există evaluări

- 2017 Technical Data Guide For Precast, Prestressed Concrete Hollow-Core PlankDocument40 pagini2017 Technical Data Guide For Precast, Prestressed Concrete Hollow-Core PlankAdam JonesÎncă nu există evaluări

- Quality Guidelines For Doors and WindowsDocument9 paginiQuality Guidelines For Doors and WindowsPavan BurraÎncă nu există evaluări

- ATENA Studio & DEA StudioDocument94 paginiATENA Studio & DEA StudioAtelier AlbaniaÎncă nu există evaluări

- Astm C335Document11 paginiAstm C335deivisbtsÎncă nu există evaluări

- Measurement of The Noise Production in Drainage Pipes: W.G. Van Der ScheeDocument14 paginiMeasurement of The Noise Production in Drainage Pipes: W.G. Van Der Scheecuongg;Încă nu există evaluări

- Mcs 021 Heat Emitter Guide For Domestic Heat Pumps Issue 21Document11 paginiMcs 021 Heat Emitter Guide For Domestic Heat Pumps Issue 21Denis DillaneÎncă nu există evaluări

- Miyasato Catalogo Policarbonato DanpalonDocument64 paginiMiyasato Catalogo Policarbonato DanpalonDiego Angeles QuesquenÎncă nu există evaluări

- FM Approval Standards For Sandwich Panels:: Colin Hill FM Approvals EuropeDocument60 paginiFM Approval Standards For Sandwich Panels:: Colin Hill FM Approvals EuropeHaroon AhmedÎncă nu există evaluări

- Meeting Passive House Standards with SIPsDocument2 paginiMeeting Passive House Standards with SIPsBrit YongeÎncă nu există evaluări

- Kodumaja Modulos The TreetDocument13 paginiKodumaja Modulos The TreetYanina GobbiÎncă nu există evaluări

- Oisd STD 177Document26 paginiOisd STD 177yandiÎncă nu există evaluări

- U Value CalculationsDocument18 paginiU Value Calculationsskywalker_handsomeÎncă nu există evaluări

- Bollettino Tecnico 004 - 05Document2 paginiBollettino Tecnico 004 - 05Emanuele CallegaroÎncă nu există evaluări

- Construction Systems: With Unlimited DesignDocument60 paginiConstruction Systems: With Unlimited DesignTamás NAGY-GYÖRGYÎncă nu există evaluări

- Recycled Aggregate-Thermal PropertiesDocument9 paginiRecycled Aggregate-Thermal PropertiesShakeel WaseemÎncă nu există evaluări

- Vitoplex 100 Oil/Gas Boiler Service InstructionsDocument28 paginiVitoplex 100 Oil/Gas Boiler Service InstructionsSorin CiuculanÎncă nu există evaluări

- Vacuum Tray DryerDocument3 paginiVacuum Tray DryerAllen Henry Cena AlcantaraÎncă nu există evaluări

- MIMOA Guide KSA Netherlands AmsterdamDocument17 paginiMIMOA Guide KSA Netherlands AmsterdamFll Wright De RadaÎncă nu există evaluări

- Wall PDFDocument87 paginiWall PDFEmil SánchezÎncă nu există evaluări

- Advanced GlazingDocument58 paginiAdvanced GlazingEros BellioÎncă nu există evaluări

- NBK TA Brochure 2016-EmailDocument11 paginiNBK TA Brochure 2016-EmailPietrus NimbusÎncă nu există evaluări

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDe la EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetEvaluare: 4.5 din 5 stele4.5/5 (10)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDe la EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationEvaluare: 4 din 5 stele4/5 (18)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDe la EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansÎncă nu există evaluări

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (137)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeDe la EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeEvaluare: 4.5 din 5 stele4.5/5 (59)

- Summary of Neil Postman's Amusing Ourselves to DeathDe la EverandSummary of Neil Postman's Amusing Ourselves to DeathEvaluare: 4 din 5 stele4/5 (2)

- Cable Supported Bridges: Concept and DesignDe la EverandCable Supported Bridges: Concept and DesignEvaluare: 5 din 5 stele5/5 (1)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDe la EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansEvaluare: 4.5 din 5 stele4.5/5 (21)

- Methodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaDe la EverandMethodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Shallow Foundations: Discussions and Problem SolvingDe la EverandShallow Foundations: Discussions and Problem SolvingEvaluare: 5 din 5 stele5/5 (1)

- Transportation Engineering: Theory, Practice, and ModelingDe la EverandTransportation Engineering: Theory, Practice, and ModelingÎncă nu există evaluări

- Principles of Forensic Engineering Applied to Industrial AccidentsDe la EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsÎncă nu există evaluări

- Introducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureDe la EverandIntroducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureEvaluare: 4.5 din 5 stele4.5/5 (11)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingDe la EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingÎncă nu există evaluări

- Professional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionDe la EverandProfessional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionÎncă nu există evaluări

- Ground Improvement Case Histories: Embankments with Special Reference to Consolidation and Other Physical MethodsDe la EverandGround Improvement Case Histories: Embankments with Special Reference to Consolidation and Other Physical MethodsÎncă nu există evaluări