Documente Academic

Documente Profesional

Documente Cultură

Types of Damages On Flexible Pavement For Malaysian Federal Road

Încărcat de

farahazuraDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Types of Damages On Flexible Pavement For Malaysian Federal Road

Încărcat de

farahazuraDrepturi de autor:

Formate disponibile

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010 (MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional.

ISBN 978-967-5770-08-1

TYPES OF DAMAGES ON FLEXIBLE PAVEMENT FOR MALAYSIAN FEDERAL ROAD Nurul Elma Kordi 1*, Intan Rohani Endut1,2, Bahardin Baharom1,2

ABSTRACT: Flexible pavements in Malaysia are designed until ten to fifteen years design life to support load. However, sometimes these roads not able to carry the load with the specified design life especially in industry areas because heavy lorries always using these road to move their goods. A lot of distress on the flexible pavement and it become uncomfortable feelings to the driver. A lot of factors contribute the problem of failure to flexible pavement either internal or external factors. Among the heavy trucks' operators, they want to raise the axle loads limit for all trucks to avoid delivery delays and meet higher storage chargers; in fact Road Transport Development (RTD) had given special permission to some 1000 lorries since August 2007 to carry the new maximum load. In order to quantify flexible pavement damages, the impacts of increase axle load on Federal road must identify and evaluate. This paper discusses a type of damages on the flexible pavement, causes of failure to flexible pavement and appropriate structural requirements for pavement performance that can carry the load on a routine basis. With the best understanding of the causes of failure and process to rehabilitation, the responsibilities' authorities will know well the key to proper maintenance of flexible pavement in order to design, manage and maintain the highways. Keywords: Axle Load, Distress, Flexible Pavement, Rehabilitation

1 2

Malaysia Institute of Transport (MITRANS), Universiti Teknologi MARA, 40450 Shah Alam, Selangor, MALAYSIA Faculty of Civil Engineering, Universiti Teknologi MARA, 40450 Shah Alam Selangor, MALAYSIA

* Correspondence Author: Nurul Elma Kordi, Malaysia Institute of Transport, Universiti Teknologi MARA, Malaysia. Tel: +6003 5521 1492, Fax: +603 5544 2344. E-mail: ema_nuelko@yahoo.com

421

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010 (MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

INTRODUCTION Road has played an important role in the trade and transportation system throughout the world, and it become rapid increase in the pavement infrastructure development in Malaysia. Gazette under Federal Roads Ordinance is usually roads linking the state capitals, airports, railway stations and ports. Currently, Malaysia has more than 80,300km roads. The road is divided into three main categories namely toll expressway (1,700km), federal roads (17,500km) and state roads (61,100km) and the life spans are between 10 to 15 years (Zakaria and Hassan, 2005). Local authority road (city mall, municipal or local council) or kampong (district office) road is depending upon jurisdiction and normally maintained by the responsibility local authority (Haron, 2004). In Malaysia, Federal road use the flexible pavement that constructed with asphaltic cement and aggregates and consist of several of layers with the lowest called the subgred which natural soil itself. The next layer is the subbase, which consist of crushed aggregate. The next layer is called road base, which can be made of crushed aggregates with a cementing material. The top layer is called surfacing layer. It is usually made of asphaltic concrete. The structural strength depends on individual material strength characteristic and thickness layer. Some form of deflection within the elastic limit is allowed. Surface readability is good but relatively less durable or susceptible to high temperature (Haron, 2004). Federal road at Malaysia almost used the flexible pavement compare to rigid pavement because flexible pavement more comfortable to the user. Furthermore, flexible pavement can be use by users once ready. Table 1 shows the differences between flexible and rigid pavement. With best design and proper construction method, adequate routine and periodic maintenance are necessary to achieve the determined design life spans and even beyond. The main factors of pavement deterioration due to increasing the number of vehicle and load traffic by the run which is five percent per annum. Table 1: The differences between flexible and rigid pavement No. 1 2 3 4 5 6 7 8 Flexible Last for 20 years High cost and schedule maintenance Cheap and easy to get the material Low initial cost Easy to upgrade / stage construction Rutting and potholes may occur Less economic for the long duration Can be used once ready Rigid Last for more than 40 years More economic maintenance, no schedule Material shortage problem always occurs Higher initial cost Cannot upgrade / no stage construction Free from rutting, potholes and corrugation More economical for the long duration Traffic disturbance, wait for maximum strength (28 days) (Source: Haron, 2004)

As a part of the study by research, this paper discusses on failure on flexible pavement, sources failure of flexible pavement and appropriate structural requirements for pavement performance that can carry the loads on a routine basis. This is a preliminary study before conduct the actual study which mapping all the damages along Federal road number one after this. TYPES OF DAMAGES According to Highway Research Board, 1970 cited by Pavement Interactive, 2010, pavement distress is "any indication of poor or unfavourable pavement performance or signs of impending failure;

422

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010 (MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

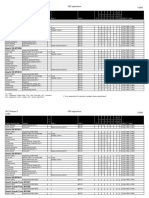

any unsatisfactory performance of a pavement short of failure". The causes of pavement failures are divided into two categories, which are an internal and external failure. Internal failures of pavement are usually because of the lack pavement mixture, weaknesses of component materials and poor construction. Meanwhile, external failures are due to overloading, diesel spillage, flooding, sink holes and other unforeseen cause such as earthquake, volcanoes and others. The failures of flexible pavement are divided into four categories, which are surface deformation, surface defects, cracking and patching and potholes (Rani, 2007). Tables 2, 3, 4 and 5 below shows the lists the pavement distress groups, possible causes, and the probable treatments that summarized by Rani, 2007 and PFI, 2010. Table 2: Surface deformation No. Possible Causes Shoving 1 Instability mixture of asphalt (course or fine aggregate too rounded or too smooth textured) 2 Low modulus bases course 3 Thin wearing course 4 Dragging of pavers during laying when bituminous mix temperatures were low 5 High stress due to braking and acceleration movements Corrugations 1 Inadequate stability of bituminous surface (excessive moisture) 2 Compaction of base in wave form 3 Faulty paver behaviour with some mixes (contamination caused by oil spillage) 4 Heavy traffic on steep downgrade or upgrade Stopping at intersection stop lights or roundabout 6 Inadequate stability of base course Rutting 1 Inadequate pavement thickness 2 Inadequate compaction of structural layers 3 Unstable bituminous mixes Unstable shoulder material which does not provide adequate lateral support 5 Overstressed subgrade which deforms permanently 6 Unstable granular bases or subbases Depression 1 Differential settlement of subgrade or base materials 2 Settlement of services and / or widening trenches 3 Volume change of subgrade due to environmental influences 4 Settlement due to instability of embankment 4 5 Probable Treatments Remove surface and base as necessary and replace with a more stable material Reconstruction of base Bituminous overlay Remove surface and base as necessary and replace with a more stable material Bituminous overlay with the stiffer mix or use the high compaction mix. Replace bituminous surface Base reconstruction Replace the faulty mixes and correct the faulty behaviour Mill off the corrugated surface and replace with the stiffer mix or use hot mix asphalt Mill off the corrugated surface and replace with the stiffer mix or use hot mix asphalt Base construction. Strengthening overlay or reconstruction Reconstruction Replace or recycle bituminous surfacing or use the stiffer mix Shoulder improvement and overlay rutted area with bituminous surfacing Reconstruction Base or sub base strengthening Subgrade or base reconstruction Reconstruction of services and/or widening trenches Improve sub-soil drainage and reconstruct Embankment stabilization

423

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010 (MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

(Source: Rani, 2007 and PFI, 2010) Table 3: Surface defect No. Possible Causes Bleeding / Flushing 1 Excessive asphalt in the surface layer. On hot days the binder expands into air voids; if the volume of air voids is too low, continued expansion results in lower stability of the mix with the consequence that traffic will force out excess binder to the surface. 2 Paving over flushed surfaces. The excess bitumen on the old surface may be pumped up through the new paving over period of time. 3 Paving over excessively primed surfaces 4 Lack of proper rolling during placement 5 Failure to protect a newly constructed surface from traffic until the asphalt cured sufficiently. Ravelling 1 Insufficient bitumen content 2 Poor adhesion of bitumen binder to aggregate particles due to wet aggregate 3 Inadequate compaction or construction during wet weather 4 Deterioration of binder and/or aggregate Polishing 1 Inadequate resistance to polishing of surface aggregates particularly in areas of heavy traffic movements or where high stresses are developed between surface and tyres 2 Use of naturally smooth uncrushed aggregates Delimitation / Surface Lifting /Seal Break 1 Inadequate cleaning or inadequate tack cot before placement of upper layers 2 Seepage of water through asphalt, especially in cracks, to break the bond between surface and lower layers. 3 Weak, loose layer immediately underlying seal 4 Adhesion of surface binder to vehicle tyres Probable Treatments Apply hot sand to blot up the excess binder to the stone size.

Apply hot sand or aggregate seal coat.

Apply hot sand Resurfacing the asphalt Resurfacing the asphalt

Thin bituminous overlay Thin bituminous overlay Thin bituminous overlay Thin bituminous overlay The bituminous overlay of use of stiffer mix

Thin bituminous overlay. Mill off and re-lay upper layers. Replace wearing course or thin bituminous overlay Reconstruction of weak layers Thin bituminous overlay (Source: Rani, 2007 and PFI, 2010)

424

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010 (MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

Table 4: Cracking crack No. Possible Causes Fatigue (alligator/crocodile) crack 1 Inadequate pavement thickness 2 Low modulus base 3 Brittle base 4 Poor base drainage 5 Brittle wearing course Block cracking 1 Joints in underlying layer 2 Shrinkage and fatigue of underlying cemented materials 3 Shrinkage cracks (due to bitumen hardening) in bituminous surfacing 4 Fatigue cracks in embrittled bituminous wearing course Longitudinal cracking 1 Reflection of shrinkage cracks 2 Poorly Constructed paving lane in bituminous surfacing 3 Displacement of joints at pavement widening 4 Differential settlement between cut and fill Transverse (Thermal) Crack 1 Reflection of shrinkage cracks 2 Construction joint in bituminous surfacing 3 Structural failure of Portland Cement 4 Shrinkage crack bituminous surfacing 5 Reflection of joints in the underlying base Edge cracks 1 Excessive traffic loading at the pavement edge 2 Poor drainage at pavement edge and shoulder 3 Inadequate pavement width which forces traffic too close to the pavement edge 4 Insufficient bearing support Edge breaks 1 Inadequate pavement width 2 Alignment which encourages drivers to travel on the pavement edge. 3 Inadequate edge support 4 Edge drop-off 5 Loss of a adhesion to base Edge drop-offs 1 Inadequate pavement width 2 Shoulder material with inadequate resistance Probable Treatments Strengthen the pavement or reconstruction Strengthen the base or reconstruction Base recycling or reconstruction Improve the drainage and reconstruct Replace or treat wearing course Crushed aggregate overlay Replace underlying cemented materials Seal cracks or replace bituminous surfacing Cut and patch or crushed aggregate overlay

Cut and patch Replace bituminous surfacing Reconstruction of joints Crushed aggregate overlay or reconstruction of joints. Cut and patch Crack sealant Reconstruction of base Seal cracks or replace bituminous surfacing Crushed aggregate overlay or reconstruction of joints Widen the pavement or strengthen the pavement edge Improve drainage and shoulder Widen treatment Reconstruction Widen the pavement Pavement widening and realignment Shoulder strengthening Strengthening and leveling of shoulder with road surface Cut and patch or bituminous overlay. Widen the pavement Replace shoulder material and reconstruct

425

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010 (MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

to erosion and abrasion. Resurfacing of pavement without Leveling of shoulder with road surface resurfacing of shoulder Crescent shaped cracks / parabolic / slippage / shear cracks 1 Lack of bond between wearing course and Cut and patch the underlying layers 2 Low modulus bases course Reconstruction of Reconstruction of base base 3 Thin wearing course Bituminous overlay 4 Dragging of pavers during laying when Cut and patch bituminous mix temperatures were low 5 High stress due to braking and acceleration Bituminous overlay with the stiffer mix or use movements the high compaction mix. (Source: Rani, 2007 and PFI, 2010) 3

Table 5: Patching and Potholes No. Possible Causes Patch/Patch Deterioration 1 Inadequate cleaning or inadequate tack cot before placement of upper layers 2 Seepage of water through asphalt, especially in cracks, to break the bond between surface and lower layers. 3 Weak, loose layer immediately underlying seal Pothole 1 Loss of surface course 2 Moisture entry to base course through a cracked pavement surface 3 Load associated disintegration of base Probable Treatments Mill off and re-lay upper layers. Replace wearing course or thin bituminous overlay Reconstruction of weak layers Patching Cut and patch Base reconstruction (Source: Rani, 2007 and PFI, 2010)

From the table, it shows most of the possible causes damages of pavement are due to of imperfection during construction. This failure will give uncomfortable to the users during their driving. Either responsibility contractor does their work perfectly or not during construction of the road need to investigate.

CHARACTERISTICS EFFECTING FAILURE OF PAVEMENT Truck factors Most comment from the users of the road about the vehicle that carries the heavy load that makes the pavement damage. On behalf of heavy truck operators, they want to increase the axle load limit to avoid delivery delays and meet higher storage chargers. Table 6 below shows the comparison weight limit of the truck among various countries.

426

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010 (MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

Table 6: Comparison Weight Limit of Truck among Various Countries Country Malaysia Type Two-axle-fixed truck Three-axle-fixed truck Four-axle-fixed truck Two-axle-fixed truck Three-axle-fixed truck Five-axle-fixed truck Two-axle-fixed truck Three- axle-fixed truck Four-axle-fixed truck Articulated truck Two-axle-fixed truck Three-axle-fixed truck Four-axle-fixed truck Articulated truck (load+vehicle) Weight limit (maximum) 16 tons 21 tons 25 tons 12 tons 21 tons 39 tons 16 tons 24 tons 24 tons 16 tons 21 tons 38 tons (Source: MRTV3, 2010)

Thailand

Singapore

ASEAN Standard

Table 7 show the comparison of axle load among various countries. Axle load and total truck load limits are also an important factor, which can determine the efficiency of the road system and competitiveness of the countrys logistics system. Thailands maximum axle load limit is 8.2 tons while the truck limit had increased to 25 tons from 21 tons in 2006. Thailands axle load limit is lower than other countries. Truck load limit and axle load limit will have impact on Thailands long-run freight transport cost and road maintenance cost, which need to be balanced. Different load limits among Thailand and neighboring countries might also cause problems for transshipment of goods across national borders and complicate international trade negotiations (Transport Sector, 2008).

Table 7: Comparison of Axle Load among Various Countries Country Axle Load Limit (Ton) Malaysia 12 Thailand 8.2 Singapore 10 Japan 11 Europe 10-13 The Peoples Republic of China 10 ASEAN member countries 10 (Source: Transport Sector, 2008)

427

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010 (MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

Heavy vehicle also contributed to deterioration of the road, there were 19.3 million registered vehicles on the Malaysias road, and the government spent RM5 billion between 2001 and 2010 to keep sustaining all the Federal roads (New Strait Times, June 2010). Heavy vehicle has been banned during morning peak hours started 2 August 2010 from certain stretches to avoid traffic congestion on the NorthSouth Expressway. Federation of Malaysian Manufacturer presidents, Tan Sri Mustafa Mansur (2010) said the move would not cause much impact as lorries could still use other alternative roads to get their destination. This rule is applied after investigations have been done. The result shows the total of heavy vehicle breakdown three times more than light vehicles and this situation will give big impact on traffic congestion (Berita Harian, 2010). However, Pan Malaysia Lorry Drivers Association president, Er Sui See, unhappy with the ban because it unfair and absurd to expect them apply for temporary permits each time they need to use the highway during the ban time (The Star, July 2010). Pavement and environmental factors The other factor of pavement damages is due to extra ordinary weather such as heavy rain and flooding. It is bringing on water absorption to pavement and weakened the structural pavement base. The pavement will weaken and fail due to increasing moisture content of the subgrade. Therefore, drainage is very important in the roads' system to keep the low water table. In Malaysia, RM220 million was spent every year on repairing road damages by rains and floods (New Strait Times, 2010). In general, conventional asphalt easy to damage when exposed to water and high incidences of flooding. The used less quality of material, non effective construction, construction procedure without control and overweight commercial transports also as sources of failure pavement. Tolled expressways are better maintained than Federal roads because government has to take care of more roads, which are 16,500km of federal roads compared only 1,360km that managed by private highway concessionaires (The Star, 2010).

Contact condition and configuration of tire The consensus is clear which the details of the contact conditions such as the exact area, pressure and pressure distribution, effect stresses and strains near to the surface of the pavement, whereas the response in the lower layers depends mainly on the overall load. Haas and Papagiannakis, 1986 (as cited in Cole & Cebon, 1997) showed that increasing the tyre inflation (contact) pressure from 415 kPa to 830 kPa at constant load will increase the theoretical vertical compressive strain near to the surface of a 200mm thick asphalt layer by up to a factor of eight, but hardly affected the strain at the bottom of the layer. In 1963, Zube and Forsyth (as cited in Cole & Cebon, 1997) performed an experimental comparison of the vertical deflections and transverse strains of a flexible pavement surface, to wide-base single tyres and dual wheels. Their results indicated that pavement deflection was equivalent to 27 kN carried on a single tyre or 40 kN carried on a dual pair. Cole and Cebon, 1997, conclude that fatigue cracking failed due to wide single tyres cause up to seven times more damage than dual tyres carrying the same total load for the relatively thin asphalt pavements (minor roads). For thicker pavements, where permanent deformation is the main mode of failure, wide single tyres are likely to cause one and half to two times more damage than dual tyres. Dadoo and Thorpe (2005) identify the main factors responsible for pavement damage caused by heavy vehicle such as dynamic axle load, number and type of axles (e.g. single, tandem), tyre properties (e.g. wide-base, dual) and pavement properties (e.g. pavement type, thickness, temperature and roughness). This research will discover which these factors have the greatest influence on pavement response. Marshek et al. (1986) lists of the possible damage or defect on the pavement are shown in Table 8. It can be concluded that, pavement damage will be increased due to less of contact area of tires to road. The higher pressure of tires is one of the factor's pavement damages because small of contact area between tires and pavement.

428

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010 (MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

Table 8: Summary of characteristics influencing pavement damage Characteristic Decrease in Pavement Damage More Tires per Axle (Tandem Axle) Less Load per Tire Less Load per Unit Contact Area Decrease in Pavement Damage More Axles Less Load per Axle Less Load per Unit Contact Area Decrease in Pavement Damage Load Distributed Evenly Among Axle Less Load for the Most Heavily Loaded Axle Group Decrease in Pavement Damage Higher Speeds Decrease in Load Duration Decrease in Pavement Damage Lower Tire Pressure Greater Surface Contact Area between Tire and Pavement Less Load per Unit Contact Area Decrease in Pavement Damage Increase in Pavement Damage Fewer Tires per Axle Greater Load per Tire Greater Load per Unit Contact Area Increase in Pavement Damage Fewer Axles Greater in Load per Axle Greater Load per Unit Contact Area Increase in Pavement Damage Load Not Distributed Evenly Among Axles Greater Load for the Most Heavily Loaded Axle Group Increase in Pavement Damage Lower Speeds Greater Load Distribution Increased Pavement Damage Higher Tire Pressure Smaller Surface Contact Area between Tire and Pavement Greater Load per Unit Area Increase in Pavement Damage

No. of Tires per Axle

No. of Axles

Load Distribution

Speed / Congestion

Tire Pressure

EFFECTS OF INCREASED LEGAL LOAD LIMITS Studies of the effect of increasing the legal load limit from 18,000 to 20,000 pounds for single axles and from 32,000 to 36,000 pounds tandem axles were made by the California Transportation Department. According to a study by Smith (1973) cited by Matthews and Baumeister (1976), if half load trucks which hauled legal limit loads were to increase axle loads to the proposed limits, the decrease in fatigue life of existing pavements is predicted to be between 20 and 25%. The effect of this decrease in pavement life will be to increase maintenance costs on existing pavements considerably over what they have been in the past and require reconstruction and rehabilitation at an earlier date. Findings from the study indicate that an 11% increase in legal load limits appears to reduce service life in years approximately 20% (Matthews and Baumeister, 1976). Jarviss (2008) opinion the increasing of truck Gross Vehicle Weights (GVW) on the federal highway system, while keeping individual axle weight limits at the current level, will improve productivity, fuel conservation, air quality, infrastructure conservation, and public safety, while reducing carbon emissions and traffic congestion. While Eason and Greene (2008) explained by providing fuel-cost savings, increasing the allowable GVW also would streamline trucking across national borders. Current maximum GVWs allowed by Mexico and Canada are 106,920 pounds and 95,900 pounds, respectively. According to the Americans for Safe and Efficient Transportation (ASET), the payload increase would make trade more parallel and obtain $14.5 billion of potential savings in shipping costs. For an individual truck, ASET also states that tractor-trailers (with six axles rather than five) can reduce vehicle miles

429

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010 (MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

travelled (VMT) by 11% and reduce fuel usage by 6%. Accidents would decrease as well, as fewer trucks driven by a smaller pool of more highly qualified drivers would be on the road. With the increasing prices of fuel, the haulier needs to improve their trucking system because fuel costs will reduce the profit margins on every industry in the economy, and logging is certainly no exception.

APPROPRIATE STRUCTURAL REQUIREMENT The rehabilitation of flexible pavements encompasses a broad range of activities, which could be grouped into three categories namely; restoration, resurfacing (structural) and reconstruction (Caltrans, 2000). In order to prevent failure flexible pavement, the polymer-modified asphaltic (PMA) concrete has started used in several project road upgrading by Work Ministry. The National Economic Action Council had agreed that PMA be used on five per cent of new projects as a part of the 10th Malaysia plan. PMA is a mixture of natural or synthetic polymer materials with conventional bitumen. Their rubberlike surfaces are highly resistant against rutting and cracking and absorb little water, which is the cause of cracks in roads. PMA has a lower life cycle cost and can admit the higher axle load, also, with using PMA it can save until RM200,000 for every kilometer of the road in yearly maintenance work, although the cost PMA is 1.7 times more than conventional (New Strait Times, 2010). A study was completed for the Affiliate Committee of the Asphalt Institute on the use of PMA for reducing distress in flexible pavements and hot mix asphalt (HMA) overlays. The results from that study found that the use of PMA reduced pavement distress and increased the life of flexible pavements by two to ten years (Asphalt Institute IS-215, 2005). Figure 1 below illustrates the alternatives of pavement maintenance and rehabilitation. This figure is helpful in understanding the aim for which a given treatment.

Pavement maintenance and Rehabilitation

Maintenance

Rehabilitation

Surface

Subsurface

Reconstruction

Recycling

- Preventive - Corrective

Overlays Combination of recycling and overlays

Figure 1: Alternatives of Pavement Maintenance and Rehabilitation (Source: Monismith, 1979)

430

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010 (MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

There are differentiated between preventive and corrective approaches preventive strategies for pavement surface include fog-seal asphalt, rejuvenators, joint sealing, seal coat (with aggregate) and thin blanket. For surface corrective there are patching, crack filling, joint sealing, seal coat, friction course, grooving, thin blanket, surface recycling, cold planning and drainage. For subsurface, there have drainage for preventive maintenance and sub-sealing, in-situ stabilization and drainage for corrective maintenance.

CONCLUSSION The failures of pavement have increased significantly over the year. The effect of axle load plays an important role in the deterioration of flexible pavements. Although the Association of Malaysia Hauliers (AMH) and truck operators want to raise the lorry load limit for all as similar size vehicles have been transporting heavier loads at overseas, the responsibilities' authority still needs to investigate carefully the effect to the road and users. Damaged roads need to repair immediately as they can cause accidents and traffic congestion. The study that was conducted and discussed in this paper show that the possible causes of flexible damages mostly did not cause by heavy truck. Therefore, the further research needs to conduct to check whether the responsible contractor done their work properly or not and the other factor of flexible pavement easy to damage need to consider and investigate. New road construction will involve big investment. Therefore, to ensure life span of the road that constructed more durable, comfortable and safe to the user, construction and maintained of the road need to be done effectively.

REFERENCES

Asphalt Institute, (2005). Quantifying the Effects of PMA for Reducing Pavement Distress, Asphalt Institute Information Series 215.

Berita Harian. (2010, July 30). Tiada Kompromi Lori 6 Tayar Masuk Lebuhraya, pp. 2. Caltrans, S. L. (2000). Maintenance Technical Advisory Guide (TAG). American Concrete Pavement Association. Dodoo, N. A. & Thorpe, N. (2005). New Approach for Allocating Pavement Damage between Heavy Good Vehicles for Road-user Charging. School of Civil Engineering and Geosciences, University of Newcastle Tyne, pp. 419-430. Eason, K. & Greene, D. (2008), Potential Impact of 97,000-Gvw on Logging Costs. Retrieved from Agricultural Transportation Efficiency Coalition website: http://ag-haul.org/resources/ multimedia/PDF/ AgTEC-GVWstatement.pdf. Haas, R. C. G. & Papagiannakis, A. T. (1986). Understanding Pavement Rutting. Special Workshop on Rutting in Asphalt Pavements, Toronto, Roads and Transport Association of Canada. Haron, S. (2004). Highway and Traffic Engineering (1st ed.). Universiti Teknologi MARA, Perlis. Jarvis, S. (2008). Increase Truck Weight Limits For Agricultural Transportation from 80,000 to 97,000 Pounds. Retrieved from Agricultural Transportation Efficiency Coalition website: http://aghaul.org/resources/ multimedia/PDF/ AgTEC-GVWstatement.pdf.

431

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010 (MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

John, S. M. & William, Y. B. (2003). Distress Identification Manual for the Long-Term Pavement Performance Program (4th revised ed.). U.S. Department of Transportation, Federal Highway Administration, 6300 Georgetown Pike. Marshek, K. M., Chen, H. H., Connell, R. B. & Saraf, C. L. (1986). Effect of Truck Tire Inflation Pressure and Axle Load on Flexible and Rigid Pavement Performance. Transportation Research Record N1070, Transportation Research Board, Washington DC. Matthews, J. A. & Baumeister, K. L. (1976). Damage to Pavement due to Axle Load. Technical Report Document Page, California Department of Transportation, Sacramento, California 95807. Monismith, C. L. (1979). Pavement Evaluation and Overlay Design Summary of Methods. Transportation Research Record No. 700, Transportation Research Board, National Research Council, Washington, D.C. New Strait Times. (2010, June 22). Fewer Potholes with New Type of Asphalt, pp. 14.

Nicholas, J. G. & Lester, A. H. (2002). Traffic and Highway Engineering (3rd ed.). University of Virginia, United States: Thomson Learning. Pavement Failure Identification, PFI (2010). Retrieved from http://www.apai.net/cmdocs/apai/ designguide/Appendix_A-B.pdf Pavement Interactive (2010). Pavement Distress. Retrieved from http://pavementinteractive .org/index.php?title=Surface_Distress

Quintus, H. L. & Mallela, P. E. (2005). Reducing Flexible Pavement Distress in Colorado Through the Use of PMA Mixtures. Final Report No. 16729.1/1 (prepared for the Asphalt Institute), Applied Research Associates, Inc., Round Rock, Texas.

Rani, O. A. (2007). The Effectiveness of Pavement Rehabilitation at Kuala Lumpur Karak Highway. Master thesis, Universiti Teknologi Malaysia.

Thailand Infrastructure Annual Report (2008) Retrieved on 12 April 2010 from http://siteresources.worldbank.org/INTTHAILAND/Resources/333200-1177475763598/37142751234408023295/5826366-1234408105311/chapter2-transport-sector.pdf The Star. (2010, May 5). Tolled Roads are Better Maintained, pp 11. The Star. (2010, July 27). Heavy Vehicle Banned, pp. 12.

Vehicles of today and motor ways in Myanmar (4). Retrieved

http://www.mrtv3.net.mm/open6/230909for1.html

on 16 August 2010 from

Zakaria, S. & Hasan, M. Z. (2005). Data Collection Strategies in Malaysia, Public Work Department Malaysia.

432

S-ar putea să vă placă și

- Spec Cold FormedDocument43 paginiSpec Cold Formedfarahazura88% (8)

- JKR Inspection and Testing Plan Version 1Document80 paginiJKR Inspection and Testing Plan Version 1Azmi Ashari100% (2)

- JKR Inspection and Testing Plan Version 1Document80 paginiJKR Inspection and Testing Plan Version 1Azmi Ashari100% (2)

- Specification For Structural Steelworks PDFDocument58 paginiSpecification For Structural Steelworks PDFfarahazura80% (5)

- Curve RangingDocument10 paginiCurve Rangingshersherine30% (40)

- Zenith 35-40 InatDocument15 paginiZenith 35-40 InatSinanToklucu67% (3)

- Unit 6 ( CONSTRUCTION OF THE FLEXIBLE PAVEMENT )Document19 paginiUnit 6 ( CONSTRUCTION OF THE FLEXIBLE PAVEMENT )Zara Nabilah87% (15)

- Mackintosh Probe TestDocument3 paginiMackintosh Probe Testeidalin50% (2)

- Uniform Building by Law PDFDocument196 paginiUniform Building by Law PDFfarahazuraÎncă nu există evaluări

- Example MACKINTOSH PROBE TESTDocument10 paginiExample MACKINTOSH PROBE TESTAmy Nazmi100% (1)

- Probe Mackintosh TestDocument2 paginiProbe Mackintosh Testsalljuraij83% (18)

- Traffic Junction Capacity and SidraDocument15 paginiTraffic Junction Capacity and SidraMohamad NazranÎncă nu există evaluări

- Chapter 7 Junction DesignDocument49 paginiChapter 7 Junction DesignMuhd Fareez100% (6)

- Mackintoch Probe TestDocument20 paginiMackintoch Probe TestMuhammad Yusoff Zakaria50% (2)

- Slip Form and Fixed Form PaversDocument63 paginiSlip Form and Fixed Form PaversShubham Pawar100% (1)

- Lab Skid ResistanceDocument1 paginăLab Skid ResistanceMohamad Zahir Razak83% (6)

- Discussion: Geomatics Engineering (BFC 20703)Document4 paginiDiscussion: Geomatics Engineering (BFC 20703)Hani BarjokÎncă nu există evaluări

- SPJ S4 2008 PDFDocument202 paginiSPJ S4 2008 PDFfarahazura100% (4)

- Microsoft PowerPoint - Instrumentations-JDDocument39 paginiMicrosoft PowerPoint - Instrumentations-JDfarahazuraÎncă nu există evaluări

- Specification Pre Fabricated Timber Roof Trusses 1 PDFDocument47 paginiSpecification Pre Fabricated Timber Roof Trusses 1 PDFAin Hanina100% (5)

- List of RDSO Coaching DrawingsDocument21 paginiList of RDSO Coaching DrawingsDisability Rights AllianceÎncă nu există evaluări

- Maintenance 05.2017Document236 paginiMaintenance 05.2017Laios Alberto NicolaÎncă nu există evaluări

- Project Pavement Condition Survey at Parit Jelutong, Batu Pahat, JohorDocument73 paginiProject Pavement Condition Survey at Parit Jelutong, Batu Pahat, JohorMoganraj100% (3)

- Road Coring TestDocument2 paginiRoad Coring TestAmree Deaf50% (2)

- Calculation PCI METHODDocument5 paginiCalculation PCI METHODSiti Nurfatin67% (3)

- 3.1 DCC30103 - Chapter 3.1 Construction of Flexible PavementDocument56 pagini3.1 DCC30103 - Chapter 3.1 Construction of Flexible PavementFATIN NABILA100% (1)

- Introduction To Highway Pavement-1Document60 paginiIntroduction To Highway Pavement-1Sagni Oo ChambÎncă nu există evaluări

- Flakiness IndexDocument6 paginiFlakiness IndexEagleLordÎncă nu există evaluări

- Highway MaintenanceDocument13 paginiHighway MaintenancePia CajayonÎncă nu există evaluări

- Skid ResistanceDocument5 paginiSkid ResistanceMoyashi Desu100% (2)

- Spot Speed StudyDocument8 paginiSpot Speed StudyMuhammad AimiÎncă nu există evaluări

- Full Report HighwayDocument19 paginiFull Report HighwayShahrel Bin Salleh100% (1)

- 2 Literature ReviewDocument11 pagini2 Literature Reviewsantkabir100% (1)

- Chapter - 5-Intersection, Interchanges, Traffic Rotary, Channelization, Road Mark and Traffic SignsDocument43 paginiChapter - 5-Intersection, Interchanges, Traffic Rotary, Channelization, Road Mark and Traffic SignsTewodros Abate100% (1)

- Highway and Traffic Engineering ReportDocument24 paginiHighway and Traffic Engineering Reportnurhaslizana0% (2)

- 1 (85) - ARAHAN TEKNIK Barrier & Guard RailDocument20 pagini1 (85) - ARAHAN TEKNIK Barrier & Guard RailAllen Neoh100% (2)

- Discussion Flakiness & Elongation IndexDocument2 paginiDiscussion Flakiness & Elongation IndexAidi RedzaÎncă nu există evaluări

- Discussion LevellingDocument1 paginăDiscussion LevellingMuhammad Faiz bin Ahmad Shafi100% (2)

- DCC30122 QUESTION PALT Set ADocument6 paginiDCC30122 QUESTION PALT Set ANazrul IzdhamÎncă nu există evaluări

- Report Politeknik Concrete Sieve Analysis of Fine Aggregates (Sand)Document10 paginiReport Politeknik Concrete Sieve Analysis of Fine Aggregates (Sand)Muhammad MuazzamÎncă nu există evaluări

- Taking Off Project (Contract and Estimation)Document16 paginiTaking Off Project (Contract and Estimation)muhammad alifÎncă nu există evaluări

- Tension Coefficient MethodDocument9 paginiTension Coefficient Methodpeipei33% (6)

- C4008 - Geotechnic 2 (Kertas Soalan Politeknik-Politeknik Malaysia Kejuruteraan Awam)Document7 paginiC4008 - Geotechnic 2 (Kertas Soalan Politeknik-Politeknik Malaysia Kejuruteraan Awam)Azil14100% (1)

- Spot Speed Study Lab ReportDocument8 paginiSpot Speed Study Lab ReportMuhammad ArbainÎncă nu există evaluări

- Lab Report U1 (Workability)Document11 paginiLab Report U1 (Workability)SYaz WAniÎncă nu există evaluări

- Labsheet Curve (Survey 2)Document38 paginiLabsheet Curve (Survey 2)Mohd Amirul Najmie67% (9)

- Water Treatment Plant in Politeknik Kota BharuDocument11 paginiWater Treatment Plant in Politeknik Kota BharuLidiah ImzaÎncă nu există evaluări

- Traffic Junction - Highway Lab ReportDocument9 paginiTraffic Junction - Highway Lab ReportMuzhafar Akmal NorAzlan86% (7)

- Discussion Highway Penetration of BituminousDocument5 paginiDiscussion Highway Penetration of BituminousU Mad BRoÎncă nu există evaluări

- Road Safety Audit Campus ReportDocument7 paginiRoad Safety Audit Campus Reportsiddharthsmp100% (3)

- Highway Report 2Document30 paginiHighway Report 2Kerol Kerol Kerol100% (1)

- MACKINTOSH PROBE Test ReportDocument8 paginiMACKINTOSH PROBE Test ReportKrisyen Murali Tharan100% (1)

- Discussion (Levelling)Document1 paginăDiscussion (Levelling)Haritah HakimiÎncă nu există evaluări

- 4.0 Structural Design of Flexible PavementDocument16 pagini4.0 Structural Design of Flexible PavementAK47100% (2)

- Skid-Sand-Outflow ReportDocument11 paginiSkid-Sand-Outflow ReportAthirah Dinata100% (1)

- Multilane Highway Capacity AnalysisDocument9 paginiMultilane Highway Capacity AnalysisIkhwan Z.100% (1)

- Unit 1 (INTRODUCTION OF HIGHWAY ENGINEERING) - JLN RayaDocument21 paginiUnit 1 (INTRODUCTION OF HIGHWAY ENGINEERING) - JLN RayaZara Nabilah83% (6)

- Sand Patch TestDocument5 paginiSand Patch TestgreatpicÎncă nu există evaluări

- Example of Traffic Flow StudyDocument2 paginiExample of Traffic Flow Studysyah123Încă nu există evaluări

- Cc206 - Bab 4 Ibs Score NewDocument27 paginiCc206 - Bab 4 Ibs Score NewAdron LimÎncă nu există evaluări

- Case Study HydroDocument12 paginiCase Study Hydronurlisa khaleedaÎncă nu există evaluări

- Full ReportDocument25 paginiFull ReportMuhammad Asyraf Bin RusliÎncă nu există evaluări

- Rsa Stage 5 PDFDocument56 paginiRsa Stage 5 PDFwan roselanÎncă nu există evaluări

- Map 3 Introduction To True & Apparent Dip and Thickness of BedDocument1 paginăMap 3 Introduction To True & Apparent Dip and Thickness of BedSyazli EimranÎncă nu există evaluări

- 2nd AssignmentDocument14 pagini2nd AssignmentSyed Faizan KhalidÎncă nu există evaluări

- ThesisDocument13 paginiThesisRebuild ManagementÎncă nu există evaluări

- Chapter 1. Introduction: 1.1. OverviewDocument49 paginiChapter 1. Introduction: 1.1. OverviewFrank Diaz LuqueÎncă nu există evaluări

- A Comparative Study On Rigid and Flexible PavementDocument6 paginiA Comparative Study On Rigid and Flexible PavementKristophe WatsonÎncă nu există evaluări

- A Comparative Study On Rigid and Flexible Pavement: A ReviewDocument6 paginiA Comparative Study On Rigid and Flexible Pavement: A ReviewosichristoÎncă nu există evaluări

- Investigation On Causes of Pavement Failure and Its Remedial Measures Ijariie16932Document7 paginiInvestigation On Causes of Pavement Failure and Its Remedial Measures Ijariie16932Abraham OluwasolaÎncă nu există evaluări

- Guide for Planning, Construction and Maintenance of Forest RoadsDe la EverandGuide for Planning, Construction and Maintenance of Forest RoadsÎncă nu există evaluări

- Design of TiesDocument26 paginiDesign of TiesfarahazuraÎncă nu există evaluări

- M&E & Arch CoordinationDocument29 paginiM&E & Arch CoordinationfarahazuraÎncă nu există evaluări

- Planning To PrecastDocument29 paginiPlanning To PrecastfarahazuraÎncă nu există evaluări

- Design of Wall StructureDocument21 paginiDesign of Wall StructurefarahazuraÎncă nu există evaluări

- Design of Composite Precast BeamDocument47 paginiDesign of Composite Precast BeamfarahazuraÎncă nu există evaluări

- Analysis and Design of Precast FramesDocument37 paginiAnalysis and Design of Precast Framesfarahazura100% (1)

- Design of Precast Column PDFDocument54 paginiDesign of Precast Column PDFfarahazura100% (1)

- 1.precast Concrete Framed System 2Document87 pagini1.precast Concrete Framed System 2farahazura100% (1)

- Proof Load Test On Jambatan Jalan Kompleks Waterfront FL 745-000-45 Wilayah Persekutuan LabuanDocument82 paginiProof Load Test On Jambatan Jalan Kompleks Waterfront FL 745-000-45 Wilayah Persekutuan Labuanfarahazura100% (1)

- Adv Geotech Forensic Eng CompileWebDocument277 paginiAdv Geotech Forensic Eng CompileWebfarahazuraÎncă nu există evaluări

- Current Compaction Practices For JKR Projects 2005 PPT Presentation PDFDocument33 paginiCurrent Compaction Practices For JKR Projects 2005 PPT Presentation PDFfarahazuraÎncă nu există evaluări

- Proof Load Test On Jambatan Jalan Kompleks Waterfront FL 745-000-45 Wilayah Persekutuan LabuanDocument82 paginiProof Load Test On Jambatan Jalan Kompleks Waterfront FL 745-000-45 Wilayah Persekutuan Labuanfarahazura100% (1)

- 2.1 VMBOK - VM Study Process - BLP - Ogos - 2015 PDFDocument43 pagini2.1 VMBOK - VM Study Process - BLP - Ogos - 2015 PDFfarahazuraÎncă nu există evaluări

- 1.1 Introduction Background of VM - BLP - Ogos - 2015Document41 pagini1.1 Introduction Background of VM - BLP - Ogos - 2015farahazuraÎncă nu există evaluări

- 2.1 VMBOK - VM Study Process - BLP - Ogos - 2015 PDFDocument43 pagini2.1 VMBOK - VM Study Process - BLP - Ogos - 2015 PDFfarahazuraÎncă nu există evaluări

- 3a. Design of Connection - 2 EC3Document82 pagini3a. Design of Connection - 2 EC3farahazura75% (4)

- Gerbang Nilai Training Presentation PDFDocument62 paginiGerbang Nilai Training Presentation PDFfarahazuraÎncă nu există evaluări

- 1.precast Concrete Framed System 2Document87 pagini1.precast Concrete Framed System 2farahazura100% (1)

- The Effect of Particle Size and Concentration ofDocument15 paginiThe Effect of Particle Size and Concentration offarahazuraÎncă nu există evaluări

- RSA IssuesDocument5 paginiRSA IssuesfarahazuraÎncă nu există evaluări

- Uniform-Building-by-Law 1984 (UBBL) PDFDocument196 paginiUniform-Building-by-Law 1984 (UBBL) PDFWilliam Ball96% (72)

- Parts Catalog: 2011/2 (Feb.) PublishedDocument21 paginiParts Catalog: 2011/2 (Feb.) PublishedhalonsoÎncă nu există evaluări

- Automobile EngineeringDocument5 paginiAutomobile EngineeringINAMUL HASANÎncă nu există evaluări

- Owners Manual FUSO 2006 FE FGDocument309 paginiOwners Manual FUSO 2006 FE FGReynolds WilliamsÎncă nu există evaluări

- Manual HD605-8Document3.100 paginiManual HD605-8draganvranes100% (2)

- Incab InspectionDocument2 paginiIncab InspectionDispatchÎncă nu există evaluări

- 1 Pavement Design: 1.1 Subgrade PropertiesDocument31 pagini1 Pavement Design: 1.1 Subgrade PropertieshaumbamilÎncă nu există evaluări

- Especificaciones Excavadora Sany 465C (Folleto)Document8 paginiEspecificaciones Excavadora Sany 465C (Folleto)prueba100% (1)

- Subaru Normal Maintenance Schedule PDFDocument4 paginiSubaru Normal Maintenance Schedule PDFPatrick AveryÎncă nu există evaluări

- Heavy Vehicle Road Safety PDFDocument111 paginiHeavy Vehicle Road Safety PDFv53Încă nu există evaluări

- Highlander Hibrido 2009Document7 paginiHighlander Hibrido 2009Daniel Castillo PeñaÎncă nu există evaluări

- AT-20 S3 OPERATORS MANUAL COMPLETE FOR PRINTING v3Document239 paginiAT-20 S3 OPERATORS MANUAL COMPLETE FOR PRINTING v3le mefÎncă nu există evaluări

- Engine Performance Query Manager 24 HDocument4 paginiEngine Performance Query Manager 24 HTyler GoodwinÎncă nu există evaluări

- 0116 Mass and Dimension LimitsDocument10 pagini0116 Mass and Dimension LimitstriÎncă nu există evaluări

- Catalogo Freno EngDocument4 paginiCatalogo Freno EngjhonÎncă nu există evaluări

- Delphi Car AppsDocument2.645 paginiDelphi Car AppsFigueredoÎncă nu există evaluări

- 900A ProductGuideDocument16 pagini900A ProductGuideEdson EscobedoÎncă nu există evaluări

- FR8 WP4 D Ac2 022 03 - FR8 WP4 D KTH - DLR - TVP 021 03Document186 paginiFR8 WP4 D Ac2 022 03 - FR8 WP4 D KTH - DLR - TVP 021 03Gabriel CaraveteanuÎncă nu există evaluări

- SW4S enDocument4 paginiSW4S engolden-eagleÎncă nu există evaluări

- SRCDocument88 paginiSRCHector Moises Fredes PadillaÎncă nu există evaluări

- Dmax V3.5 Coverage ChartDocument16 paginiDmax V3.5 Coverage ChartSeun AlhassanÎncă nu există evaluări

- Traffic Management & Road SafetyDocument72 paginiTraffic Management & Road SafetytingÎncă nu există evaluări

- Kawasaki Jet SkiDocument6 paginiKawasaki Jet SkiMeor Amri100% (3)

- Ecus 4E-FTEDocument0 paginiEcus 4E-FTELuis Lezama67% (3)

- Difference Between Toyota Hilux Vigo G and Toyota Hilux Vigo eDocument37 paginiDifference Between Toyota Hilux Vigo G and Toyota Hilux Vigo eDavide Boreaneze100% (1)

- SD7N 推土机操作指南 Operating Guide for the SD7N Bulldozer: Please do the following checks before you operate this bulldozerDocument3 paginiSD7N 推土机操作指南 Operating Guide for the SD7N Bulldozer: Please do the following checks before you operate this bulldozerHassan BilaliÎncă nu există evaluări

- P13303EN Opticruise tcm40-358169 PDFDocument6 paginiP13303EN Opticruise tcm40-358169 PDFWin Min TunÎncă nu există evaluări

- Grupo Volvo Penta PDFDocument2 paginiGrupo Volvo Penta PDFjuanÎncă nu există evaluări