Documente Academic

Documente Profesional

Documente Cultură

Trip Oil

Încărcat de

chdeepak96Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Trip Oil

Încărcat de

chdeepak96Drepturi de autor:

Formate disponibile

Gas Turbine Training Manual

TRIP OIL SYSTEM The hydraulic trip oil system is the primary protection interface between turbine control panel and the components on the turbine which admit or shut off fuel to the turbine. Lube oil (oil) from the turbine bearing header is used for trip functions (abnormal and emergency shutdown of the turbine) as well as the hydraulic signal to the fuel stop valve for normal startup and shutdown. See the schematic diagram FUNCTIONAL DESCRIPTION The low-pressure lube oil (oil) functions in this system as trip oil to cause component devices to trip. Lube oil is passed through a piping orifice to become the trip oil (OLT). This orifice is sized to limit the flow of lube oil into the trip oil system and ensure an adequate capacity for all tripping device operations without causing starvation of the lube system when the trip oil system is activated. The resultant low-pressure oil (OLT) is then at proper capacity for the trip functions. This low pressure trip oil is supplied to the inlet guide vane trip device, 20TV-1, and passes through the flow limiting parallel check valve/orifice arrangement to the turbine over speed trip device. Trip oil then flows through a second flow limiting parallel check valve/orifice piping arrangement to the turbine fuel system (fuel stop valve arrangement) parallel to the trip system solenoid operated fuel dump valve 20FG-1. Operation of the solenoid valve permits use of the fuel system for turbine operation and turbine stop action when required. The system also provides a direct connection to the 12 HA over speed trip device for turbine shutdown whenever an over speed condition occurs. A fuel system trip or an over speed trip will not trip the inlet guide vane system. The IGVs will close under normal control under these conditions. The devices that cause a turbine shutdown through the trip system do so by dumping fluid pressure from the system either directly or indirectly through solenoidoperated dump valves 20FG-1 or 20FL-1. When oil in the trip oil line is dumped, fuel stop valves close by spring return action. When the turbine is started, the dump valve is energized to reset at the desire point in the starting sequence, permitting oil pressure to open the fuel stop valves. The fuel stop valves remain open until some trip action occurs or until the unit is shut down.

Bharat Heavy Electricals Limited

GTATO Page 1 of 3

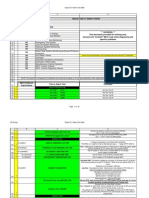

Scheme For Trip Oil System

Pressure switches 63HG-1,-2 and -3 are also installed in the low pressure trip and fuel control systems to provide redundant pressure monitoring and feedback to the turbine control system insuring required trip oil pressure levels for turbine operations. If the pressure levels for turbine operations. If the pressure of the fuel system becomes too low for reliable operation, one or more switches will trip ;the unit and cause an alarm indication of Low trip oil pressure. A direct reading pressure gauge and test valves are installed with the pressure switches to facilitate required inspection and maintenance.

Gas Turbine Training Manual

TRIP DEVICES Over Speed Trip Mechanism ( for FR-5 only)

Bharat Heavy Electricals Limited

GTATO Page 2 of 3

Gas Turbine Training Manual

An over speed trip mechanism, mounted on the Accessory gear, is the second trip device in the system. This totally mechanical device, located in the Accessory gear, is Actuated automatically by the over speed bolt should the turbine speed exceed the bolt setting . As a result, a rapid decay of trip oil pressure(OLT) occurs, ultimately stopping the flow of fuel to the turbine by action of the fuel oil stop valve. When activated, the over speed bolt assembly trips the latching trip fingers of the over speed trip mechanism. The action release the trip valve in the mechanism and dumps the OLT trip system pressure to atmosphere. In turn, this causes the oil in the fuel stop valve cylinder to return to atmosphere pressure, thus allowing spring pressure to close the valve. An additional feature included in the over speed trip mechanism is a limit switch (12HA) which signals an alarm and trips the turbine and a manual trip push. Once the trip is actuated, the system remains open and drains until it is reset manually by pulling the reset rod. Hydraulic Dump Solenoid Valves 20 FL-1 and 20FG-1 Solenoid-operated spring return hydraulic dump valves 20FL-1 for Liquid Fuel and 20 FG-1 for gas fuel are used to trip the system operation by a signal form the master control and protection circuit. The valves are energized when the turbine is running depending upon the fuel currently in use. Fuel Stop solenoid (dump) valve 20 FG-1 relieves trip oil pressure going to the gas fuel stop valve. By dumping the trip oil to the gas fuel stop valve, it causes the fuel system to shut down. This solenoid valve is spring biased to trip and, therefore protects the turbine during all normal situations as well as for loss of DC power. 20 FG-1 is shown in its de-energized state in the schematic diagram. Similarly , 20 FL-1 valve is used to relieve trip oil pressure going to Liquid Fuel stop valve. The stop valve , based on the spring tension , closes upon dumping of the trip oil and thus causes fuel system to shut down. Hydraulic Dump Valve for IGV - 20TV-1 Functionally it dumps trip oil pressure to the inlet guide vane dump valve, VH3-1, and stops the flow in a manner similar to the over speed trips mentioned above.

Bharat Heavy Electricals Limited

GTATO Page 3 of 3

S-ar putea să vă placă și

- Jacking Oil SystemDocument15 paginiJacking Oil SystemSarah Frazier100% (1)

- Write Up On Interlock SchemesDocument3 paginiWrite Up On Interlock SchemesSatyaKrishna PallaÎncă nu există evaluări

- Gek 116328 9fa Water Injection SystemDocument12 paginiGek 116328 9fa Water Injection SystemZaki nouiÎncă nu există evaluări

- Variable Inlet Guide Vane System: GE Power SystemsDocument4 paginiVariable Inlet Guide Vane System: GE Power Systemsanggita gigih wahyu iriawan100% (1)

- GE 9FA Water Wash PROCEDURE FinalDocument43 paginiGE 9FA Water Wash PROCEDURE FinalAbdelaziz EldeebÎncă nu există evaluări

- To System & Barring GearDocument22 paginiTo System & Barring GearPrudhvi RajÎncă nu există evaluări

- GT 5-8 Alarm Trip ListDocument3 paginiGT 5-8 Alarm Trip Listmuddasirmasood100% (1)

- Seal Oil Systems Stage - 1Document34 paginiSeal Oil Systems Stage - 1raghavendran raghu100% (1)

- Turbine Trip LogicDocument2 paginiTurbine Trip Logicdilbagh_scribd50% (2)

- DLN Controls Code Development 9fa+ EnhancedDocument28 paginiDLN Controls Code Development 9fa+ Enhancednabil160874Încă nu există evaluări

- Limiting The Gas Turbine Load and Operating at Base LoadDocument6 paginiLimiting The Gas Turbine Load and Operating at Base Loadramkrishna100% (1)

- C&I WriteupDocument137 paginiC&I WriteupSayan AichÎncă nu există evaluări

- Turbine and AuxiliariesDocument65 paginiTurbine and AuxiliariesSwadhin Kumar Das100% (1)

- GFA - GT Exhaust Spread ProblemDocument5 paginiGFA - GT Exhaust Spread Problemأمير معروف100% (1)

- Seal Oil and Hydrogen SystemDocument34 paginiSeal Oil and Hydrogen Systemashish_ntpcÎncă nu există evaluări

- Ms9001E Starting System: GeneralDocument2 paginiMs9001E Starting System: Generalferas_elnggarÎncă nu există evaluări

- Turbine Systems GuideDocument22 paginiTurbine Systems Guidelavpandey8719100% (2)

- GE's 330MW Digital Electro-Hydraulic Control System for Steam TurbinesDocument22 paginiGE's 330MW Digital Electro-Hydraulic Control System for Steam Turbineskeerthi dayarathnaÎncă nu există evaluări

- Check The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001Document5 paginiCheck The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001jose Alberto uribe Minier100% (1)

- Ge Ms5001pDocument14 paginiGe Ms5001pMohamed Hamed100% (1)

- 9fa PDFDocument3 pagini9fa PDFsujiv_sujiv1278Încă nu există evaluări

- Gas Turbine Questions and AnswersDocument10 paginiGas Turbine Questions and AnswersJêmš Navik100% (1)

- Terms and Abbreviation For GE Gas TurbinesDocument3 paginiTerms and Abbreviation For GE Gas TurbinesFazalur Rehman Babar100% (1)

- Control Valve Data SheetsDocument150 paginiControl Valve Data SheetsAnonymous ZnuMEWN1Încă nu există evaluări

- Turbine Performance Assesment - BHELDocument36 paginiTurbine Performance Assesment - BHELscribd free100% (2)

- Stator CW SOP-2Document12 paginiStator CW SOP-2SonratÎncă nu există evaluări

- Barring StallingDocument6 paginiBarring Stallingnetygen1100% (3)

- 500MW Starting ProceduresDocument38 pagini500MW Starting Proceduresthangarajm1984Încă nu există evaluări

- Overview of Start-Up of Gas TurbineDocument38 paginiOverview of Start-Up of Gas TurbineJulio Cesar Barajas Aguilar100% (1)

- 0000062374Document22 pagini0000062374George AniborÎncă nu există evaluări

- I.G.V Openning and Closing CurveDocument3 paginiI.G.V Openning and Closing CurveHussam Baiee100% (3)

- Turning Gear An Operation Point of ViewDocument22 paginiTurning Gear An Operation Point of ViewAshwin Narayan100% (1)

- Turbine & Its Governing and Turbo Generator AlokDocument143 paginiTurbine & Its Governing and Turbo Generator AlokSHAMSIK2002100% (3)

- Governing System Steam Turbine PDFDocument3 paginiGoverning System Steam Turbine PDFPaulina100% (2)

- Effect of H2 Purity in Large Turbo GeneratorDocument7 paginiEffect of H2 Purity in Large Turbo Generatorkumar_ranjan_3Încă nu există evaluări

- C7 5-16-2010 Rev-01 Commented Trips, Alarms, Events, HoldsDocument34 paginiC7 5-16-2010 Rev-01 Commented Trips, Alarms, Events, HoldsbalumuriashokÎncă nu există evaluări

- GT Mtc. PracticesDocument59 paginiGT Mtc. PracticesAbhishek Prakash SrivastavaÎncă nu există evaluări

- Gas Turbine - Traning Report Bhel - 14 PageDocument14 paginiGas Turbine - Traning Report Bhel - 14 PageVivek PatelÎncă nu există evaluări

- Steam Turbine Seal Oil Operation & Controls ConsultingDocument2 paginiSteam Turbine Seal Oil Operation & Controls ConsultingManoj Upadhyay100% (1)

- Dry Low NoxDocument10 paginiDry Low NoxIvan Poma Montes100% (1)

- 210 MW Seal Oil SystemDocument6 pagini210 MW Seal Oil Systemmag_ktps20021520Încă nu există evaluări

- Turbine ShutdownDocument12 paginiTurbine ShutdownRaja RamÎncă nu există evaluări

- REPORT ON 500 MW TG WITH PROPORTIONAL VALVE SYSTEMDocument13 paginiREPORT ON 500 MW TG WITH PROPORTIONAL VALVE SYSTEMMohammad Ibnul Hossain100% (1)

- Generator & Auxillaries (Stator Water, Seal Oil and Hydrogen Gas System)Document32 paginiGenerator & Auxillaries (Stator Water, Seal Oil and Hydrogen Gas System)Praveen Jagadev100% (1)

- STG820 - Steam Turbine Governor: ALSPA P320 System - Technical Data Sheet P-TP09-A49052Document3 paginiSTG820 - Steam Turbine Governor: ALSPA P320 System - Technical Data Sheet P-TP09-A49052hudson100% (2)

- Gas Turbine Protection and InterlockDocument2 paginiGas Turbine Protection and Interlockld_ganesh75% (4)

- Gas Turbine Startup Per Missives For GeDocument5 paginiGas Turbine Startup Per Missives For Gejeromejoe100% (4)

- Hydrogen Seal Oil SystemDocument6 paginiHydrogen Seal Oil SystemamitÎncă nu există evaluări

- h2 Dew PointDocument4 paginih2 Dew Pointgeddam0610882592% (12)

- Instrument GEDocument42 paginiInstrument GEnabil160874100% (1)

- GE Power Systems Gas Turbine Speed Control Constant Settable DroopDocument9 paginiGE Power Systems Gas Turbine Speed Control Constant Settable DroopZaki nouiÎncă nu există evaluări

- CcOLD STARTUPDocument15 paginiCcOLD STARTUPAnonymous ICKtnYvC100% (1)

- Relocating Emergency DPR Valve Overcomes High Head IssueDocument4 paginiRelocating Emergency DPR Valve Overcomes High Head IssueAdnan Habib Khan100% (2)

- Gas Turbine StartupDocument9 paginiGas Turbine Startuppawangwl100% (2)

- Hydraulic Clearance Optimization TrainingDocument9 paginiHydraulic Clearance Optimization Trainingasodiyamech100% (1)

- Trip Oil SystemDocument6 paginiTrip Oil Systemsmart_eng2009100% (3)

- Hydraulic turning gear operation and logicsDocument5 paginiHydraulic turning gear operation and logicsSai Swaroop50% (2)

- Gas Turbine Training Manual: Trip Oil SystemDocument3 paginiGas Turbine Training Manual: Trip Oil SystemsambhuÎncă nu există evaluări

- ShutoffDocument27 paginiShutoffSergio Andrés ArizaÎncă nu există evaluări

- KWU Text GoverningDocument43 paginiKWU Text GoverningSam100% (2)

- Misc. GK 3 Ch. 29 Sobrequets Beliefs Awards Sports Etc.Document12 paginiMisc. GK 3 Ch. 29 Sobrequets Beliefs Awards Sports Etc.chdeepak96Încă nu există evaluări

- Big Data Hadoop StackDocument52 paginiBig Data Hadoop StackYaser Ali TariqÎncă nu există evaluări

- Misc. GK 4 Ch. 30 Defence Security Space Disaster Etc.Document9 paginiMisc. GK 4 Ch. 30 Defence Security Space Disaster Etc.chdeepak96Încă nu există evaluări

- Misc. GK 4 Ch. 30 Defence Security Space Disaster Etc.Document9 paginiMisc. GK 4 Ch. 30 Defence Security Space Disaster Etc.chdeepak96Încă nu există evaluări

- 8 Ways Power BI Falls ShortDocument11 pagini8 Ways Power BI Falls Shortchdeepak96Încă nu există evaluări

- Real Python Part 2Document656 paginiReal Python Part 2kimÎncă nu există evaluări

- Chapter 3 MODERN HISTORY OF INDIA 2 PDFDocument12 paginiChapter 3 MODERN HISTORY OF INDIA 2 PDFATUL ROSHANÎncă nu există evaluări

- Misc. GK 2 Ch. 28 Books Authors Etc.Document18 paginiMisc. GK 2 Ch. 28 Books Authors Etc.chdeepak96Încă nu există evaluări

- Misc. GK 1 Ch. 27 UN and Other Organztions Copy 2Document9 paginiMisc. GK 1 Ch. 27 UN and Other Organztions Copy 2chdeepak96Încă nu există evaluări

- Jeremy Johnson - Real Python Part 3 - Advanced Web Development With Django PDFDocument593 paginiJeremy Johnson - Real Python Part 3 - Advanced Web Development With Django PDFjorgefÎncă nu există evaluări

- Chapter 4 INDIAN NATIONAL MOVEMENT 2 PDFDocument16 paginiChapter 4 INDIAN NATIONAL MOVEMENT 2 PDFATUL ROSHANÎncă nu există evaluări

- Designing Efficient Workbooks v10.0Document88 paginiDesigning Efficient Workbooks v10.0borjaghÎncă nu există evaluări

- CH 24 Banking and Financial Institution in IndiaDocument6 paginiCH 24 Banking and Financial Institution in Indiachdeepak96Încă nu există evaluări

- Python Data Science Cheat SheetDocument1 paginăPython Data Science Cheat SheetMaisarah Mohd PauziÎncă nu există evaluări

- Real Python 2-4Document214 paginiReal Python 2-4wentaozhang150% (2)

- Real Python Part 1 PDFDocument234 paginiReal Python Part 1 PDFKiran ReddyÎncă nu există evaluări

- Cbs Esp 006 Notes PDFDocument11 paginiCbs Esp 006 Notes PDFchdeepak96Încă nu există evaluări

- Data Science ContentsDocument3 paginiData Science Contentschdeepak96Încă nu există evaluări

- Real Python 2-4Document214 paginiReal Python 2-4wentaozhang150% (2)

- Learn Common Spoken TamilDocument225 paginiLearn Common Spoken TamilThirunavukkarasuÎncă nu există evaluări

- Complete Phrasal Verbs ListDocument137 paginiComplete Phrasal Verbs ListHermes®Încă nu există evaluări

- Synonyms - BriefDocument4 paginiSynonyms - Briefchdeepak96Încă nu există evaluări

- Python Data Science Cheat SheetDocument1 paginăPython Data Science Cheat SheetMaisarah Mohd PauziÎncă nu există evaluări

- Cbs Esp 006 Notes PDFDocument11 paginiCbs Esp 006 Notes PDFchdeepak96Încă nu există evaluări

- Lanco Kondapalli power plant failures and best practicesDocument4 paginiLanco Kondapalli power plant failures and best practiceschdeepak96Încă nu există evaluări

- Dasar Dasar PLCDocument65 paginiDasar Dasar PLCAgie FernandezÎncă nu există evaluări

- NTPC Questionaire BlankDocument6 paginiNTPC Questionaire Blankchdeepak96Încă nu există evaluări

- Training TopicsDocument2 paginiTraining Topicschdeepak96Încă nu există evaluări

- BOE Examination AdmittedDocument28 paginiBOE Examination Admittedchdeepak96Încă nu există evaluări

- Geometry Formulas - Gr8AmbitionZDocument1 paginăGeometry Formulas - Gr8AmbitionZMurthy KethaÎncă nu există evaluări

- Ic2401 Digital Control System SyllabusDocument1 paginăIc2401 Digital Control System SyllabusSharmila83Încă nu există evaluări

- FlameDocument6 paginiFlameFadzil NorÎncă nu există evaluări

- Smart Wireless Water Level Monitoring & Pump Controlling SystemDocument11 paginiSmart Wireless Water Level Monitoring & Pump Controlling Systemsumanth reddyÎncă nu există evaluări

- UF MAE Schedule Fall 2016Document2 paginiUF MAE Schedule Fall 2016salil91Încă nu există evaluări

- 2.15 Model-Free Adaptive (MFA) Control: G. S. ChengDocument10 pagini2.15 Model-Free Adaptive (MFA) Control: G. S. ChengkangsungjinÎncă nu există evaluări

- Chapter 8Document31 paginiChapter 8fosterÎncă nu există evaluări

- Optimal Control System Based EPASDocument8 paginiOptimal Control System Based EPASNarender KumarÎncă nu există evaluări

- Distributed Control Systems: Emad Ali Chemical Engineering Department King SAUD UniversityDocument24 paginiDistributed Control Systems: Emad Ali Chemical Engineering Department King SAUD Universityessakkirajm19902116Încă nu există evaluări

- 50hz - gcs16lrg - 0700 LennoxDocument16 pagini50hz - gcs16lrg - 0700 Lennoxnvr735iÎncă nu există evaluări

- Block Diagram Representation of A Simple Electronic System: Main DefinitionsDocument9 paginiBlock Diagram Representation of A Simple Electronic System: Main DefinitionsCansu ElizadeÎncă nu există evaluări

- FFBL Internship ReportDocument27 paginiFFBL Internship ReportMaliha Ashraf0% (1)

- Automotive Acronyms and AbbreviationsDocument20 paginiAutomotive Acronyms and Abbreviationssampapa33% (3)

- Control SystemDocument8 paginiControl SystemEire SimanjuntakÎncă nu există evaluări

- Conveyor BrakesDocument16 paginiConveyor BrakesFabian Eduardo Tapia Cisternas100% (2)

- Fisher FIELDVUE DVC6200 Series Digital Valve Controllers PDFDocument72 paginiFisher FIELDVUE DVC6200 Series Digital Valve Controllers PDFARMANDO0% (1)

- Boiler Instrumentation and ControlDocument54 paginiBoiler Instrumentation and ControlSunny Gupta100% (2)

- R 001 PDFDocument152 paginiR 001 PDFleekiangyenÎncă nu există evaluări

- Training Servo Hydraulic Drive Systems 36Document61 paginiTraining Servo Hydraulic Drive Systems 36Gary Jenkins100% (4)

- GA-Optimized PID Speed Control for Marine Diesel EnginesDocument5 paginiGA-Optimized PID Speed Control for Marine Diesel EngineshoangductuanÎncă nu există evaluări

- Robots in Computer Integrated ManufacturingDocument33 paginiRobots in Computer Integrated ManufacturingLuis David SanchezÎncă nu există evaluări

- Z-Peller Zp31 Niigata 6l26hlxDocument4 paginiZ-Peller Zp31 Niigata 6l26hlxDon Cupertino León Osuna83% (6)

- Control System PresentationDocument10 paginiControl System PresentationVikneshwaran Keluan SinghÎncă nu există evaluări

- LENTON Furnaces BrochureDocument20 paginiLENTON Furnaces Brochureantho_lombokÎncă nu există evaluări

- Boiler Three Element Controller PhilosophyDocument3 paginiBoiler Three Element Controller PhilosophysandystaysÎncă nu există evaluări

- Temperature Control and Data Acquisition Method For Factory Using LabviewDocument14 paginiTemperature Control and Data Acquisition Method For Factory Using LabviewIAEME PublicationÎncă nu există evaluări

- Fisher HF340 Filter HARTDocument4 paginiFisher HF340 Filter HARTpgarces86Încă nu există evaluări

- Practical Tuning of Industrial Control LoopsDocument2 paginiPractical Tuning of Industrial Control LoopsPrabakaran Thambusamy0% (1)

- 17 ProcessInstrumentationDocument66 pagini17 ProcessInstrumentationnewnse2008Încă nu există evaluări

- PVG32Document80 paginiPVG32Carlos PaezÎncă nu există evaluări

- 07 GRP07 All EnginesDocument20 pagini07 GRP07 All Engineseurospeed2Încă nu există evaluări