Documente Academic

Documente Profesional

Documente Cultură

10d Slickline Operations PDF

Încărcat de

gandalf the grayTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

10d Slickline Operations PDF

Încărcat de

gandalf the grayDrepturi de autor:

Formate disponibile

Taylormade Training Consultants

www.TaylormadeTC.com contact@TaylormadeTC.com

ABN # 77 653 296 426

Slickline Operations Course : 10 Days

Learning Objectives

Provide a full understanding of slickline operations. Highlight the critical aspects of slickline and the pressure control. Learn the function and use of a wide range of wireline tools. Utilise a hand-on approach to learning in a workshop. Use cutaway tools to ensure a complete understanding of downhole operation. Become proficient in the operation of the wireline unit. Learn the job planning aspects of a successful wireline operation. Provide a venue for questions and discussion.

Who should attend

Personnel who will be carrying out slickline operations. Well Service personnel with a need to know more about wireline operations. Managers with a need to know more about wireline operations. Logistics and support personnel.

Venue : Vause Training Centre New Plymouth, NZ (VTC) or clients choice of location Pre-requisites : Some field exposure to wireline and well service operations and a prior knowledge of well completions is an advantage. Support material Course presented in .ppt with multi media animations, video clips and movies. VTC: Fully equipped workshop, cutaway tool demonstrator and 1000 ft well. Course description While similar to the 5 day Supervisors course, this training involved a greater degree of tool stripping/redress and of the setting up of tools, along with their repair and essential maintenance requirements. The theory of pressure control equipment and surface component operation are taught, then carried out on a well. The function and use of the downhole tools is presented in class, then the tools are handled in a workshop before being demonstrated as surface cutaways. Wireline operations are planned and executed in a 1000 ft well, with each participant becoming the lead operator for the duration of each planned activity. The use of pressure and flow can be used to create realistic, but safe conditions. Participants consolidate the classroom theory with practical sessions in a fully equipped workshop. Knowledge gained is then applied to set up actual cutaway tools operated by a surface hand winch. The final stage of learning is carried out using a wireline unit and surface pressure control equipment rigged up to run tools into a completed 1000 ft well. Refer to course details overleaf:

Slickline Operations Course - Detailed Contents (continued)

While similar in scope to the 5 day supervisory course, each topic below is expanded to a greater depth to ensure full understanding of the tool operation, redress and maintenace. Well Completions Brief description of down hole components as related to wireline, to ensure a good overall understanding of the wellbore and completion components Xmas Trees Types of trees; single, dual, composite, solid block. Wireline History and development Use and limitations of wireline. Wire types and strengths. Wireline Units Design, function and operating procedures Surface Equipment Pressure control equipment. Stuffing boxes, lubricators, BOPs Braided Line Equipment Grease Injection systems for braided line operations Pressure Testing Test Procedures and safety precautions Toolstring Components Rope sockets - knot, no knot and braided Stem - sizes, selecting correct amount. Jars - mechanical, hydraulic, spring, accelerators Knuckle joints, swivels. Rig-up Procedures Lifting options: Ginpole, crane, (onshore/offshore) Use of masts Basic Service Tools Gauge cutters, Blind boxes, Lead Impression Blocks Running / Pulling tools Otis (HES) type R, S, G series Camco JD, JU series Lock Mandrels / Plugs Slip and collar locks Selective systems No go locks Plugs and Flow controls Running and pulling procedures Sliding Side Doors Description and use in the well. Types eg: XO, XD, XA, Baker CMD, CMU Shifting tools and procedures

Additional Equipment Pack-offs, Calliper surveys - brief overview TCP guns - wireline release options. Safety Valves SSV Surface tree actuators and lock out SCSSV wireline and tubing retrievable TRSSV Tubing Retrievable DCSSV back up downhole valves Gaslift Theory of gaslift operations Side Pocket mandrels Gaslift valves - design and function. Running and pulling procedures. Additional uses of SPMs - Well kill, water flood, chemical injection. Extreme Deviation Use of rolling systems for deviated wells. Wireline Fishing Avoidance by due care and good job planning. Fishing Job Planning Line/force/pressure considerations Lubricator length calculations Use of appropriate equipment Rig up height considerations Site constraints Fishing Tools Presentation of tools available, their design, function and operation. HD Jarring Activity Use of braided lines (3/16, 7/32) and grease injection systems Spring jars setting, calibration and redressing Accelerators use and matching to jar operations Use of HD fishing tools Fishing Scenarios and Calculations Various part fishing situations, requiring calculation of wire end depth etc. Final Written Exam Final discussion and review of course and revisiting initial objectives Issue of course certificates General : Each day will start with discussion of prior days activities, question and answers, then written test on topics covered. Questions are encouraged at all times

S-ar putea să vă placă și

- Well Control for Completions and InterventionsDe la EverandWell Control for Completions and InterventionsEvaluare: 4 din 5 stele4/5 (10)

- The Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbDe la EverandThe Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbEvaluare: 4.5 din 5 stele4.5/5 (11)

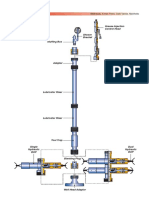

- SWiPS Manual SwipsDocument107 paginiSWiPS Manual SwipsElkin Casas HÎncă nu există evaluări

- Travelling Block (760TB-750-8C) User ManualDocument27 paginiTravelling Block (760TB-750-8C) User ManualTony100% (1)

- Well Integrity for Workovers and RecompletionsDe la EverandWell Integrity for Workovers and RecompletionsEvaluare: 5 din 5 stele5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsDe la EverandWell Testing Project Management: Onshore and Offshore OperationsÎncă nu există evaluări

- Slickline CalculationsDocument0 paginiSlickline CalculationsKHALEDFEKAIR100% (2)

- Wireline ManualDocument307 paginiWireline ManualJorge Rodriguez100% (14)

- Slickline PresentationDocument90 paginiSlickline PresentationRangga DraAp100% (3)

- Drilling Supervisor: Passbooks Study GuideDe la EverandDrilling Supervisor: Passbooks Study GuideÎncă nu există evaluări

- Wireline Operation Course - Mahmoud F. RadwanDocument184 paginiWireline Operation Course - Mahmoud F. RadwanSaeed Vaezian100% (9)

- Wireline OperationDocument90 paginiWireline Operationjarbas.otoni88% (8)

- Wire Line Pressure Control EquipmentDocument39 paginiWire Line Pressure Control EquipmentStan Andrei100% (1)

- Thru Tubing Electronic CatalogDocument77 paginiThru Tubing Electronic CatalogEduardo Oyarzun100% (2)

- Dowhole Tools - SlicklineDocument34 paginiDowhole Tools - SlicklineAdonis Saidler100% (8)

- Chapter 3 The Equipment of Naturally Flowing Wells-1Document24 paginiChapter 3 The Equipment of Naturally Flowing Wells-1stanlnleybuduka100% (1)

- Emergency Procedures For Coiled TubingDocument19 paginiEmergency Procedures For Coiled TubingGreg AndersonÎncă nu există evaluări

- Wireline Equipment Standard-Norsok PDFDocument14 paginiWireline Equipment Standard-Norsok PDFRio de Mario100% (2)

- Cabeza de Inyeccion de GrasaDocument100 paginiCabeza de Inyeccion de GrasaPierre MejiaÎncă nu există evaluări

- Slickline TallybookDocument29 paginiSlickline Tallybookpitia100% (3)

- Wireline Slickline Training ProgramDocument1 paginăWireline Slickline Training ProgramPurwanto Pur100% (4)

- RT100300 - Rev01 - Wireline Advanced Practical (Locked) PDFDocument219 paginiRT100300 - Rev01 - Wireline Advanced Practical (Locked) PDFazze bouzÎncă nu există evaluări

- 010 Wireline LoggingDocument23 pagini010 Wireline LoggingKami Oey100% (1)

- Depth Control PDFDocument11 paginiDepth Control PDFKhalid Zaeem100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!De la EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Evaluare: 5 din 5 stele5/5 (2)

- Working Guide to Drilling Equipment and OperationsDe la EverandWorking Guide to Drilling Equipment and OperationsEvaluare: 5 din 5 stele5/5 (9)

- Shale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementDe la EverandShale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementEvaluare: 4.5 din 5 stele4.5/5 (2)

- Fundamentals and Applications of Bionic Drilling FluidsDe la EverandFundamentals and Applications of Bionic Drilling FluidsÎncă nu există evaluări

- Wireline Technologies-Riggup Equipment PDFDocument18 paginiWireline Technologies-Riggup Equipment PDFDoniÎncă nu există evaluări

- Catalog Ge Oil and GasDocument146 paginiCatalog Ge Oil and GasLászló Lós50% (2)

- Storm Choke K Safety ValveDocument2 paginiStorm Choke K Safety ValveHIPAP100% (5)

- Slickline TenderDocument10 paginiSlickline Tender李四江Încă nu există evaluări

- Wireline (Cabling) - WikipediaDocument9 paginiWireline (Cabling) - Wikipediaharshpatel18100% (2)

- Wireline OperationsDocument132 paginiWireline OperationsJude80% (5)

- Slickline BasicsDocument86 paginiSlickline BasicsAmiromaan100% (7)

- Wireline Surface EquipmentDocument14 paginiWireline Surface EquipmentAdenta Hadi Aranto75% (4)

- Slickline Vs Wilreline (HTTP://WWW - Rigzone.com)Document3 paginiSlickline Vs Wilreline (HTTP://WWW - Rigzone.com)krylancelotÎncă nu există evaluări

- Slickline Basics 71-80Document10 paginiSlickline Basics 71-80Rio de MarioÎncă nu există evaluări

- Standard Slickline Tools 6Document7 paginiStandard Slickline Tools 6eng200720070% (1)

- Winch Operators Slickline Cased Hole Analog PanelDocument2 paginiWinch Operators Slickline Cased Hole Analog PanelHenry FuentesÎncă nu există evaluări

- SPE 35236 Low Cost Solutions For Well Interventions Through Advanced Slickline ServicesDocument16 paginiSPE 35236 Low Cost Solutions For Well Interventions Through Advanced Slickline ServicesDen YogaÎncă nu există evaluări

- Nigeria Slickline Operations ManualDocument226 paginiNigeria Slickline Operations ManualWilliam Evans100% (1)

- Field Engineering - Wireline 2014Document31 paginiField Engineering - Wireline 2014Bharat Bhattarai100% (1)

- SLB Production LoggingDocument9 paginiSLB Production LoggingPondok Huda100% (1)

- Slickline PerforatingDocument2 paginiSlickline PerforatingDavid Kusuma100% (1)

- Wire LineDocument54 paginiWire LineAbid Ali88% (8)

- Grease Injection Control Head: ParveenDocument46 paginiGrease Injection Control Head: ParveenKedai KopiÎncă nu există evaluări

- Slickline Basics.61 70Document10 paginiSlickline Basics.61 70Rio de MarioÎncă nu există evaluări

- Slickline: Slickline Refers To A Single Strand WireDocument40 paginiSlickline: Slickline Refers To A Single Strand Wirewilliam MadingÎncă nu există evaluări

- Wireline Awereness Training2Document28 paginiWireline Awereness Training2JennyÎncă nu există evaluări

- Depth ControlDocument11 paginiDepth ControlledlouÎncă nu există evaluări

- Chapter 10 Slick WirelineDocument24 paginiChapter 10 Slick WirelineMohamed Yousry100% (1)

- Wireline FishingDocument28 paginiWireline Fishingwasayraza100% (2)

- Wireline Services and EquipmentDocument62 paginiWireline Services and EquipmentTamer Hesham AhmedÎncă nu există evaluări

- Wireline NotesDocument46 paginiWireline NotesDavide Boreaneze100% (15)

- K-WINCH SmartHead II Measuring HeadDocument1 paginăK-WINCH SmartHead II Measuring Headu2006262918Încă nu există evaluări

- Assistant Slickline Operator 001Document3 paginiAssistant Slickline Operator 001Muhammad shehryar KhanÎncă nu există evaluări

- Prakarsa-Iliadi - Slickline - Rigless Application 20180307Document90 paginiPrakarsa-Iliadi - Slickline - Rigless Application 20180307AsfanÎncă nu există evaluări

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsDe la EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsÎncă nu există evaluări

- Formulas and Calculations for Drilling OperationsDe la EverandFormulas and Calculations for Drilling OperationsÎncă nu există evaluări

- Christensen CT14Document2 paginiChristensen CT14LeónÎncă nu există evaluări

- Superior Hydraulic Fishing Jar Manual R3Document22 paginiSuperior Hydraulic Fishing Jar Manual R3Aritra MahapatraÎncă nu există evaluări

- GuibersonCatalog PDFDocument66 paginiGuibersonCatalog PDFtictacal100% (2)

- Wire Line EquipmentDocument70 paginiWire Line EquipmentwelshinÎncă nu există evaluări

- Link JarDocument2 paginiLink Jarjainendra_ismÎncă nu există evaluări

- INTERWELL Product Sheet Insert Valve CarrierDocument2 paginiINTERWELL Product Sheet Insert Valve CarrierDavid Pit FermiereÎncă nu există evaluări

- Checkvalve PDFDocument10 paginiCheckvalve PDFCARLOS MORENOÎncă nu există evaluări

- BK-7 Recompletion Program 2023Document27 paginiBK-7 Recompletion Program 2023s.agus.ntoÎncă nu există evaluări

- Altachem LTD.: Acid Cap Stick TreatmentsDocument2 paginiAltachem LTD.: Acid Cap Stick Treatmentscv sabiraÎncă nu există evaluări

- Goebor S Operating InstructionsDocument12 paginiGoebor S Operating InstructionsElgi Zacky ZachryÎncă nu există evaluări

- Equipment Workover & Completion Operation RevDocument21 paginiEquipment Workover & Completion Operation RevHaries SeptiyawanÎncă nu există evaluări

- 1 Oilfield EquipmentDocument87 pagini1 Oilfield Equipmentmuhammad_alsaleem5884Încă nu există evaluări

- Gas Lift EquipmentDocument23 paginiGas Lift EquipmentJose JassoÎncă nu există evaluări

- Operations and Maintenance Manual Asep Elmar Hydraulic Wireline Tool Catcher AssemblyDocument54 paginiOperations and Maintenance Manual Asep Elmar Hydraulic Wireline Tool Catcher AssemblyAbhinav Kumar100% (1)

- Selective Lateral Re-Entry SystemDocument2 paginiSelective Lateral Re-Entry SystemJorge FernandoÎncă nu există evaluări

- Wireline ExerciseDocument21 paginiWireline Exerciseomar shahat0% (1)

- PGFT Fishing Course: S/L Fishing Page 1Document57 paginiPGFT Fishing Course: S/L Fishing Page 1Slbcar Looging100% (1)

- 7 Conductor Procedimiento de Rehead Manual - D00667626 - 1Document31 pagini7 Conductor Procedimiento de Rehead Manual - D00667626 - 1felipeÎncă nu există evaluări

- SPE 35236 Low Cost Solutions For Well Interventions Through Advanced Slickline ServicesDocument16 paginiSPE 35236 Low Cost Solutions For Well Interventions Through Advanced Slickline ServicesDen YogaÎncă nu există evaluări

- Dump Bailer PDFDocument1 paginăDump Bailer PDFDaniex VillalobosÎncă nu există evaluări

- Half Mule Shoe Guide 88050307Document2 paginiHalf Mule Shoe Guide 88050307satyendraÎncă nu există evaluări

- Casing Inspection LogDocument11 paginiCasing Inspection LogDeepesh Khandelwal100% (1)

- WL - TopicsDocument22 paginiWL - TopicsMohamed100% (1)

- Sub Surface Flow Control SlideDocument29 paginiSub Surface Flow Control SlideAshley England100% (1)