Documente Academic

Documente Profesional

Documente Cultură

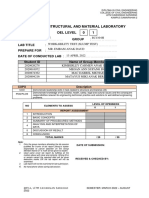

Concrete slump test measurement

Încărcat de

Marie Fe BermidoDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Concrete slump test measurement

Încărcat de

Marie Fe BermidoDrepturi de autor:

Formate disponibile

Concrete slump test

From Wikipedia, the free encyclopedia

A tester performing a concrete slump test.

The concrete slump test is an empirical test that measures the workability of fresh concrete. More specifically, it measures the consistency of the concrete in that specific batch. This test is performed to check the consistency of freshly made concrete. Consistency is a term very closely related to workability. It is a term which describes the state of fresh concrete. It refers to the ease with which the concrete flows. It is used to indicate the degree of wetness. Workability of concrete is mainly affected by consistency i.e. wetter mixes will be more workable than drier mixes, but concrete of the same consistency may vary in workability. It is also used to determine consistency between individual batches. The test is popular due to the simplicity of apparatus used and simple procedure. Unfortunately, the simplicity of the test often allows a wide variability in the manner that the test is performed. The slump test is used to ensure uniformity for different batches of similar concrete under field conditions,[1]:127,128and to ascertain the effects of plasticizers on their introduction.[1]:134 In India this test is conducted as per IS specification.

Apparatus

Metal mould, in the shape of the frustum of a cone, open at both ends, and provided with the handle, top internal diameter 102 mm, and bottom internal diameter 203 mm with a height of 305 mm. A 610 mm long [2] bullet nosed metal rod, 16 mm in diameter.

[edit]Procedure

Slump cone

Tamping procedure

Removing cone

Height measurement

The test is carried out using a mould known as a slump cone or Abrams cone. The cone is placed on a hard non-absorbent surface. This cone is filled with fresh concrete in three stages, each time it is tamped using a rod of standard dimensions. At the end of the third stage, concrete is struck off flush to the top of the mould. The mould is carefully lifted vertically upwards, so as not to disturb the concrete cone. [1]:128[3] Concrete subsides. This subsidence is termed as slump, and is measured in to the nearest 5 mm. [edit]Interpretation

of results

The slumped concrete takes various shapes, and according to the profile of slumped concrete, the slump is termed as true slump, shear slump or collapse slump. If a shear or collapse slump is achieved, a fresh

sample should be taken and the test repeated. A collapse slump is an indication of too wet a mix. Only a true slump is of any use in the test. A collapse slump will generally mean that the mix is too wet or that it [1]:128[3] is a high workability mix, for which slump test is not appropriate. Very dry mixes; having slump 0 25 mm are used in road making, low workability mixes; having slump 10 40 mm are used for foundations with light reinforcement, medium workability mixes; 50 - 90 for normal reinforced concrete [4]:68 placed with vibration, high workability concrete; > 100 mm.

Collapse

Shear

True

In a collapse slump the concrete collapses [3] completely. [edit]European

In a shear slump the top portion of the concrete shears off and slips [3] sideways.

In a true slump the concrete simply subsides, keeping more or less to [3] shape.

classes of slump

According to European Standard EN 206-1:2000 five classes of slump have been designated, as [4]:69 tabulated below.

Slump class Slump in mm

S1

10 - 40

S2

50 - 90

S3

100 - 150

S4

160-210

S5

220

[edit]Limitations

of the slump test

The slump test is suitable for slumps of medium to high workability, slump in the range of 25 125 mm, the test fails to determine the difference in workability in stiff mixes which have zero slump, or for wet mixes that give a collapse slump. It is limited to concrete formed of aggregates of less than 38 mm [1]:128 (1 inch). [edit]Differences

in standards

The slump test is referred to in several testing and building codes, with minor differences in the details of performing the test. [edit]United

States

In the United States, engineers use the ASTM standards and AASHTO specifications when referring to the concrete slump test. The American standards explicitly state that the slump cone should have a height of 12-in, a bottom diameter of 8-in and an upper diameter of 4-in. The ASTM standards also state in the procedure that when the cone is removed, it should be lifted up vertically, without any rotational [5] movement at all. The concrete slump test is known as "Standard Test Method for Slump of HydraulicCement Concrete" and carries the code (ASTM C 143) or (AASHTO T 119).

Workability of Fresh Concrete by Slump Test

Posted in Civil Engineering Tests | WORKABILITY Slump test is used to determine the workability of fresh concrete. Slump test as per IS: 1199 1959 is followed.The apparatus used for doing slump test are Slump cone and Tamping rod. Procedure to determine workability of fresh concrete by slump test. i) The internal surface of the mould is thoroughly cleaned and applied with a light coat of oil. ii) The mould is placed on a smooth, horizontal, rigid and nonabsorbent surface. iii) The mould is then filled in four layers with freshly mixed concrete, each approximately to one-fourth distributed of evenly the over height the of the cross mould. section). iv) Each layer is tamped 25 times by the rounded end of the tamping rod (strokes are v) After the top layer is rodded, the concrete is struck off the level with a trowel. vi) The mould is removed from the concrete immediately by raising it slowly in the vertical direction. vii) The difference in level between the height of the mould and that of the highest point of Email This Post

the

subsided

concrete

is

measured.

viii) This difference in height in mm is the slump of the concrete.

Reporting

of

Results

The slump measured should be recorded in mm of subsidence of the specimen during the test. Any slump specimen, which collapses or shears off laterally gives incorrect result and if this occurs, the test should be repeated with another sample. If, in the repeat test also, the specimen shears, the slump should be measured and the fact that the specimen sheared, should be recorded. Typical Ques 1. What is the ideal value of Questions slump?

Answer 1 In case of a dry sample, slump will be in the range of 25-50 mm that is 1-2 inches. But in case of a wet concrete, the slump may vary from 150-175 mm or say 6-7 inches. So the value of slump is specifically mentioned along the mix design and thus it should be checked as per your location. Slump depends on many factors like properties of concrete ingredients aggregates etc. Also temperature has its effect on slump value. So all these parameters should be kept in mind when deciding the ideal slump Ques 2. How does a superplasticizer effect the slump of concrete?

Answer 2 Value of Slump can be increased by the addition of chemical admixtures like midrange or high-range water reducing agents (super-plasticizers) without changing the water/cement ratio.

Ques

3.

How

much

time

one

should

take

to

raise

the

cone?

Answer 3 Once the cone is filled and topped off [ excessive concrete from top is cleared ] raise the cone within 5-10 seconds. Ques Top Bottom Height 30cm 4. What are the dimensions of the cone used in Slump Test? are 10cm 20cm Answer 3 The Diameter Diameter dimensions

Sampling ProceduresSampling (or obtaining) concrete for theslump test shoul d be accomplished according to ASTM C 172. In this TRAMAN, onlythe procedure of sampling from a revolvingdrum truck mixer (TM) or agitator is discussed.If you should ever need to sample from a pavingmixer, opentop truck mixer, or other type ofequipment, be sure to refer to the most recent ASTM C 172.Samples taken for the test specimens mustbe representative of t

he entire batch. Thisis accomplished by taking the samples at twoor more reg ularly spaced intervals during discharge of the middle portion of the batch.Sample by repeatedly passing a s coop or pailthrough the entire discharge stream. Compositethese samples into one sample for testing purposes. Be sure that the first and last portions of the composite sample are taken asquickly as possible, but never excee ding 15min. If it is necessary to transport the samples away from the mixer to the place wherethe slump test is to be performed, combine thesamples and remix them with a shovel to ensureuniformity.Testing ProceduresFigure 15-40.Slump cone.to thetest loadis applied perpendicularlongitudinal axis of a standard size, premolded,andproperly cured concrete beam. From this test,the flexural strength, expressed in terms ofmodulus of rupture and given in psi, can bereadily calculated. As with the compression test,only the procedures to prepare the test beams correctly will be discussed in this TRAMAN.SLUMP TESTSThe slump test is performed on newly mixedconcrete. To perform the test, you need a slumpcone and a tamping rod. The slump cone (fig.15-40) should be made of galvanized steel, 12 in.in height, with a base opening 8 in. in diameterand the top opening 4 in. in diameter. Both thetop and bottom openings are perpendicular to thevertical axis of the cone. T he tamping rod is astraight, steel rod that is 5/8 in. in diameter andapproximately 24 in. in length. One end of therod is rounded to a diameter of 5/8 in. (Do notsubstitute a piece of rebar.)Perform the slump test according to ASTMC 143. Be sure to start the test within 5 minafter obtaining the fin al portion of the composite sample. In performing the test, firstdampen the slump cone and place i t on a flat,moist, nonabsorbent, rigid surface. From thecomposite sample obt ained and while standing onthe two foot pieces of the cone, fill the cone inthr ee layers, each approximately one third of thevolume of the cone. In placing each scoopful ofconcrete, rotate the scoop ar ound the top edgeof the cone as the concrete slides from it toensure even distr ibution of concrete within themold.Rod each layer with 25 strokes of thetampin g rod (using the rounded end), anduniformly distribute the strokes over the en-tire cross section of each layer. Rod the bottomlayer throughout its depth. Rod

the second layerand the top layer each throughout its depth sothat the strokes just penetrat e into the underlying layer. In filling and rodding the toplayer, heap the concrete above th e mold beforethe rodding is started. If the rodding results

ASTM C387 / C387M

Abstract This specification covers the production, properties, packaging, and testing of packaged, dry, combined materials for concrete and mortars. Concrete mixtures covered by this specification includes high-early strength concrete, normal strength concrete, normal weight concrete, high-strength mortar, and mortars for unit masonry. The purchaser shall specify the material desired as concrete, high strength mortar, or mortar for use with unit masonry, and the respective physical requirements. Materials used as ingredients in packaged, dry, combined materials for mortar and concrete shall be composed of aggregates, air-entraining admixtures, blended cement, chemical admixtures, fly ash, ground granulated blast-furnace slag, hydrated lime, latex and powder polymer modifiers, masonry cement, mortar cement, Portland cement, and silica fume. All aggregates shall be dried, without disintegration, to specific moisture content The proportions of cementitious material and aggregate shall be such that the strength requirements will be met. Packaged, dry, combined materials for concrete, high strength mortar and mortar for use with unit masonry shall conform to the respective compressive strength requirements. Scales conforming to the standards will be used for sampling concretes from a single batch using a sufficient quantity. A slump test will be performed to check if additional water is required. In sampling mortar, the contents of an entire package of dry, combined material for mortar for unit masonry or for concrete mortar shall be used. Mortar mixing equipment, which must be provided with a bowl positioning adapter, shall be used to ensure clearance for the largest size aggregate in the mix being tested. The specification includes the following testing methods for mortar: compressive strength, density and yield, air content, and water retention. This abstract is a brief summary of the referenced standard. It is informational only and not an official part of the standard; the full text of the standard itself must be referred to for its use and application. ASTM does not give any warranty express or implied or make any representation that the contents of this abstract are accurate, complete or up to date. 1. Scope 1.1 This specification covers the production, properties, packaging, and testing of packaged, dry, combined materials for concrete and high strength mortar. The classifications of concrete and mortar covered are defined in Section 3. NOTE 1The scope of this standard does not cover mortars for unit masonry. Dry preblended mortars for unit masonry are covered by Specification . 1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance

with the standard. Some values have only SI units because the inch-pound equivalents are not used in practice. 1.3 The following safety hazards caveat pertains only to the test method portion of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. 2. Referenced Documents (purchase separately) ASTM Standards C33 Specification for Concrete Aggregates C39/C39M Test Method for Compressive Strength of Cylindrical Concrete Specimens C91 Specification for Masonry Cement C109/C109M Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50mm] Cube Specimens) C125 Terminology Relating to Concrete and Concrete Aggregates C138/C138M Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete C143/C143M Test Method for Slump of Hydraulic-Cement Concrete C144 Specification for Aggregate for Masonry Mortar C150 Specification for Portland Cement C173/C173M Test Method for Air Content of Freshly Mixed Concrete by the Volumetric Method C185 Test Method for Air Content of Hydraulic Cement Mortar C192/C192M Practice for Making and Curing Concrete Test Specimens in the Laboratory C207 Specification for Hydrated Lime for Masonry Purposes C231 Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method C260 Specification for Air-Entraining Admixtures for Concrete C270 Specification for Mortar for Unit Masonry C305 Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency C330 Specification for Lightweight Aggregates for Structural Concrete C494/C494M Specification for Chemical Admixtures for Concrete C566 Test Method for Total Evaporable Moisture Content of Aggregate by Drying C595 Specification for Blended Hydraulic Cements C618 Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete C702 Practice for Reducing Samples of Aggregate to Testing Size C989 Specification for Slag Cement for Use in Concrete and Mortars C1116 Specification for Fiber-Reinforced Concrete and Shotcrete C1157 Performance Specification for Hydraulic Cement C1240 Specification for Silica Fume Used in Cementitious Mixtures C1329 Specification for Mortar Cement C1437 Test Method for Flow of Hydraulic Cement Mortar C1438 Specification for Latex and Powder Polymer Modifiers in Hydraulic Cement Concrete and Mortar C1600/C1600M Specification for Rapid Hardening Hydraulic Cement C1714/C1714M Specification for Preblended Dry Mortar Mix for Unit Masonry

Keywords

aggregate-cement aggregate combinations; cement mortars; combined concrete/mortar materials; concrete admixtures; concrete, packaged; concrete specifications; dry combined concrete/mortar materials; mortar-cement mortar; mortar, packaged; packaged dry combined materials; packaged concrete/mortar materials; Aggregate--specifications; Cement mortars--specifications; Combined concrete/mortar materials; Concrete admixtures--specifications; Concrete construction materials/applications--specifications; Dry combined concrete/mortar materials; Mortar-specifications; Packaged dry combined materials

The slump test is the most well-known and widely used test method to characterize the workability of fresh concrete. The inexpensive test, which measures consistency, is used on job sites to determine rapidly whether a concrete batch should be accepted or rejected. The test method is widely standardized throughout the world, including in ASTM C143 in the United States and EN 12350-2 in Europe. The apparatus consists of a mold in the shape of a frustum of a cone with a base diameter of 8 inches, a top diameter of 4 inches, and a height of 12 inches. The mold is filled with concrete in three layers of equal volume. Each layer is compacted with 25 strokes of a tamping rod. The slump cone mold is lifted vertically upward and the change in height of the concrete is measured. Four types of slumps are commonly encountered, as shown in Figure 3. The only type of slump permissible under ASTM C143 is frequently referred to as the true slump, where the concrete remains intact and retains a symmetric shape. A zero slump and a collapsed slump are both outside the range of workability that can be measured with the slump test. Specifically, ASTM C143 advises caution in interpreting test results less than inch and greater than 9 inches. If part of the concrete shears from the mass, the test must be repeated with a different sample of concrete. A concrete that exhibits a shear slump in a second test is not sufficiently cohesive and should be rejected.

The slump test is not considered applicable for concretes with a maximum coarse aggregate size greater than 1.5 inches. For concrete with aggregate greater than 1.5 inches in size, such larger particles can be removed by wet sieving. Additional qualitative information on the mobility of fresh concrete can be obtained after reading the slump measurement. Concretes with the same slump can exhibit different behavior when tapped with a tamping rod. A harsh concrete with few fines will tend to fall apart when tapped and be appropriate only for applications such as pavements or mass concrete. Alternatively, the concrete may be very cohesive when tapped, and thus be suitable for difficult placement conditions. Slump is influenced by both yield stress and plastic viscosity; however, for most cases the effect of plastic viscosity on slump is negligible. Equations have been developed for calculating yield stress in terms of slump, based on either analytical or experimental analyses. Since different rheometers measure different absolute values for the yield stress of identical samples of concrete, the experimental equations are largely depended on the specific device used to measure yield stress.

Advantages: The slump test is the most widely used device worldwide. In fact, the test is so well known that often the terms workability and slump are used interchangeably, even though they have different meanings. Specifications are typically written in terms of slump. The slump test is simple, rugged, and inexpensive to perform. Results are obtained immediately. The results of the slump test can be converted to yield stress in fundamental units based on various analytical treatments and experimental studies of the slump test. Compared to other commonly used concrete tests, such as for air content and compressive strength, the slump test provides acceptable precision. Disadvantages: The slump test does not give an indication of plastic viscosity. The slump test is a static, not dynamic, test; therefore, results are influenced by concrete thixotropy. The test does not provide an indication of the ease with which concrete can be moved under dynamic placing conditions, such as vibration. The slump test is less relevant for newer advanced concrete mixes than for more conventional mixes.

S-ar putea să vă placă și

- Flexural Test On Concrete Based On The ASTM Standards Are ExplainedDocument9 paginiFlexural Test On Concrete Based On The ASTM Standards Are ExplainedTesfayeÎncă nu există evaluări

- LAB REPORT Rebound Hammer TestDocument24 paginiLAB REPORT Rebound Hammer TestZahidahÎncă nu există evaluări

- Determination of Consistency of Standard Cement PasteDocument3 paginiDetermination of Consistency of Standard Cement PasteAfifah FauziÎncă nu există evaluări

- TEST PROCEDURES FOR CONCRETE PAVING UNITSDocument5 paginiTEST PROCEDURES FOR CONCRETE PAVING UNITSLan CorpuzÎncă nu există evaluări

- Hyper CreteDocument2 paginiHyper CretedjgiumixÎncă nu există evaluări

- FINENESS OF HYDRAULIC CEMENT - Group - 7Document5 paginiFINENESS OF HYDRAULIC CEMENT - Group - 7K PrinceÎncă nu există evaluări

- BEAMDocument114 paginiBEAMPaul Macharia Ndungu100% (1)

- 1.15 Destructive Test For Hardened ConcreteDocument17 pagini1.15 Destructive Test For Hardened Concretesilswal1988Încă nu există evaluări

- Conrete Mix Design & Making and Curing of Test SpecimenDocument15 paginiConrete Mix Design & Making and Curing of Test SpecimenBlesÎncă nu există evaluări

- Compressive Strength ConcreteDocument5 paginiCompressive Strength ConcreteMuhammad Sufian Sarwar100% (1)

- DETERMINING INITIAL & FINAL SETTING TIMESDocument4 paginiDETERMINING INITIAL & FINAL SETTING TIMESHamza MughalÎncă nu există evaluări

- Experiment No 1Document20 paginiExperiment No 1Israr MuhammadÎncă nu există evaluări

- Construction Material Lab Manual2Document44 paginiConstruction Material Lab Manual2VitoPascasioÎncă nu există evaluări

- Sand Cone Test PDFDocument11 paginiSand Cone Test PDFDinush SenanayakeÎncă nu există evaluări

- Fresh Concrete Vebe TestDocument2 paginiFresh Concrete Vebe TestMarilyn Camenzuli100% (1)

- Quantitative Extraction of Bitumen From Bituminous Paving MixturesDocument12 paginiQuantitative Extraction of Bitumen From Bituminous Paving Mixturessebastian novoa0% (1)

- Split Tensile Strength of ConcreteDocument9 paginiSplit Tensile Strength of Concreteabhineet srivastavaÎncă nu există evaluări

- Effect of Curing Methods On Strength and Durability of Concrete Under Hot Weather Conditions 2013 Cement and Concrete CompositesDocument10 paginiEffect of Curing Methods On Strength and Durability of Concrete Under Hot Weather Conditions 2013 Cement and Concrete CompositesWilliam GossÎncă nu există evaluări

- CE 121 LAB REPORT DENSITY & SPECIFIC GRAVITYDocument14 paginiCE 121 LAB REPORT DENSITY & SPECIFIC GRAVITYNatsu RefilÎncă nu există evaluări

- Vicat ApparatusDocument5 paginiVicat ApparatusFeras TemimiÎncă nu există evaluări

- AGGREGATE ABRASION TEST VALUESDocument6 paginiAGGREGATE ABRASION TEST VALUESAbdur RazzakÎncă nu există evaluări

- Screenshot 2022-10-17 at 18.52.41Document41 paginiScreenshot 2022-10-17 at 18.52.41Rod VincentÎncă nu există evaluări

- Workability Test (Slump Test) Lab ReportDocument10 paginiWorkability Test (Slump Test) Lab ReportMAC DARREL MICHAEL MAC DARREL MICHAELÎncă nu există evaluări

- CMT Prelim-Reviewer PDFDocument11 paginiCMT Prelim-Reviewer PDFCONFI DENTIALÎncă nu există evaluări

- Fracture Energy of Concrete BeamsDocument37 paginiFracture Energy of Concrete Beamsphyrexio100% (1)

- Tut 1 - Port, Air & RailDocument81 paginiTut 1 - Port, Air & RailJia SingÎncă nu există evaluări

- Hardened ConcreteDocument50 paginiHardened ConcreteMayank KapriÎncă nu există evaluări

- Determination of Angularity Number For The Given Aggregate SampleDocument4 paginiDetermination of Angularity Number For The Given Aggregate SampleEngr Muhammad TariqÎncă nu există evaluări

- Compressive Strength Test ProcedureDocument9 paginiCompressive Strength Test ProcedureAnique Ur RehmanÎncă nu există evaluări

- Slump Test Procedure and SheetDocument3 paginiSlump Test Procedure and SheetB R Paul FortinÎncă nu există evaluări

- Concrete Mix Design - (Part 1 & Part 2) PPT7Document39 paginiConcrete Mix Design - (Part 1 & Part 2) PPT7JuliaÎncă nu există evaluări

- Early Cracking of Concrete PavementDocument25 paginiEarly Cracking of Concrete PavementRajesh KhadkaÎncă nu există evaluări

- Civil Engineering Material Lab ReportDocument13 paginiCivil Engineering Material Lab Reportsharrmaa100% (1)

- Specific Gravity of SoilsDocument8 paginiSpecific Gravity of Soilsradi_ashrafÎncă nu există evaluări

- Determine Cement Setting TimesDocument2 paginiDetermine Cement Setting TimesMastani Bajirao100% (1)

- Concrete TestDocument9 paginiConcrete TestVelmurugan BalasubramanianÎncă nu există evaluări

- Test of AggregateDocument24 paginiTest of AggregatePriyank BhimaniÎncă nu există evaluări

- CMT Laboratory 11 Concrete Mix ProportionsDocument9 paginiCMT Laboratory 11 Concrete Mix ProportionsLyka BalacdaoÎncă nu există evaluări

- Physical and Mechanical Properties of Some Common Nigerian Timber Species Based On Limit State Design ApproachDocument8 paginiPhysical and Mechanical Properties of Some Common Nigerian Timber Species Based On Limit State Design ApproachSEP-PublisherÎncă nu există evaluări

- Flexural TestDocument13 paginiFlexural TestAliaÎncă nu există evaluări

- Name: Yanik Lubin CVNG 3009 - Marshall Mix Design Lab I.D.#: 809100024Document17 paginiName: Yanik Lubin CVNG 3009 - Marshall Mix Design Lab I.D.#: 809100024Deoraj ToolsieÎncă nu există evaluări

- Shear Strength of Soil ExplainedDocument31 paginiShear Strength of Soil ExplainedAhmad Rizal AliasÎncă nu există evaluări

- Experimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Document6 paginiExperimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Siddhesh Kamat Mhamai100% (2)

- Compressive Strength TestDocument17 paginiCompressive Strength TestKushal Dagli100% (1)

- Standard Test Method For Splitting Tensile Strength of Cylindrical Concrete Specimens1Document5 paginiStandard Test Method For Splitting Tensile Strength of Cylindrical Concrete Specimens1Lupita RamirezÎncă nu există evaluări

- Time of Setting of Hydraulic Cement by Vicat Needle: Standard Test Method ForDocument6 paginiTime of Setting of Hydraulic Cement by Vicat Needle: Standard Test Method ForAhmed AbidÎncă nu există evaluări

- WorkabilityDocument3 paginiWorkabilityyay94rebuildÎncă nu există evaluări

- Concrete TestsDocument198 paginiConcrete Tests'Sayed AsadullahÎncă nu există evaluări

- Water Cement Ratio (Gate60 Short Notes)Document4 paginiWater Cement Ratio (Gate60 Short Notes)akash rathodÎncă nu există evaluări

- 2 - Normal Consistency of Hydraulic CementDocument9 pagini2 - Normal Consistency of Hydraulic CementJayHatÎncă nu există evaluări

- Survey Camp Report (Mars Nepal Engineering Survey Camp)Document225 paginiSurvey Camp Report (Mars Nepal Engineering Survey Camp)Sudip Khadka100% (1)

- BS - SlumpDocument10 paginiBS - SlumpAna FarÎncă nu există evaluări

- Strength of Materials Laboratory ManualDocument33 paginiStrength of Materials Laboratory ManualRock Man100% (1)

- Concrete: KARDAN UniversityDocument49 paginiConcrete: KARDAN UniversityBibek BhattaraiÎncă nu există evaluări

- Soil Mechanics Lab ManualDocument64 paginiSoil Mechanics Lab ManualSathya Narayanan100% (1)

- Concrete Lab Manual - Standard Consistency TestDocument3 paginiConcrete Lab Manual - Standard Consistency TestMazharYasin100% (1)

- Temperature problems in concretingDocument4 paginiTemperature problems in concretingMirosha NavaratnaÎncă nu există evaluări

- Concrete Slump TestDocument19 paginiConcrete Slump TestGhayas Ud-din DarÎncă nu există evaluări

- Different Standards of ConcreteDocument23 paginiDifferent Standards of ConcreteShubham FulsoundarÎncă nu există evaluări

- Testing of Concrete BlocksDocument6 paginiTesting of Concrete BlocksMarie Fe BermidoÎncă nu există evaluări

- Soil KindsDocument3 paginiSoil KindsMarie Fe BermidoÎncă nu există evaluări

- Compressive Strength Is The Capacity of A Material or Structure ToDocument5 paginiCompressive Strength Is The Capacity of A Material or Structure ToMarie Fe BermidoÎncă nu există evaluări

- RiprapDocument2 paginiRiprapMarie Fe BermidoÎncă nu există evaluări

- Cement SpecificationsDocument2 paginiCement SpecificationsMarie Fe BermidoÎncă nu există evaluări

- GrainDocument3 paginiGrainMarie Fe BermidoÎncă nu există evaluări

- Mechanical Properties of BambooDocument11 paginiMechanical Properties of BambooPedro Rodriguez RosalesÎncă nu există evaluări

- RiprapDocument2 paginiRiprapMarie Fe BermidoÎncă nu există evaluări

- When Is The Best Time To SealcoatDocument9 paginiWhen Is The Best Time To SealcoatMarie Fe BermidoÎncă nu există evaluări

- The UfoDocument35 paginiThe UfoMarie Fe BermidoÎncă nu există evaluări

- Soil Compaction TestsDocument26 paginiSoil Compaction TestsMarie Fe BermidoÎncă nu există evaluări

- Flexural StrengthDocument38 paginiFlexural StrengthMarie Fe BermidoÎncă nu există evaluări

- WEIRSDocument29 paginiWEIRSMarie Fe BermidoÎncă nu există evaluări

- Water ContentDocument8 paginiWater ContentMarie Fe BermidoÎncă nu există evaluări

- Beam Deflection FormulaeDocument2 paginiBeam Deflection Formulae7575757575100% (6)

- Code of Ethics Report!!!Document33 paginiCode of Ethics Report!!!Marie Fe BermidoÎncă nu există evaluări

- Intersection Ass.Document15 paginiIntersection Ass.Marie Fe BermidoÎncă nu există evaluări

- Add Item N N°Document268 paginiAdd Item N N°Bilel MahjoubÎncă nu există evaluări

- Abb CatDocument9 paginiAbb CatMukesh Kumar MeenaÎncă nu există evaluări

- TENDERSCHEDULE309532Document2 paginiTENDERSCHEDULE309532heavens indiaÎncă nu există evaluări

- Class XII Computer Science: HOTS (High Order Thinking Skill)Document14 paginiClass XII Computer Science: HOTS (High Order Thinking Skill)JanakiÎncă nu există evaluări

- Orace Rac TafDocument4 paginiOrace Rac TafNst TnagarÎncă nu există evaluări

- Bs1030 BrochureDocument2 paginiBs1030 BrochuremgvuleÎncă nu există evaluări

- Rajib Mall Lecture NotesDocument97 paginiRajib Mall Lecture NotesAnuj Nagpal100% (1)

- DehumidificationDocument9 paginiDehumidificationRafael Echano AcederaÎncă nu există evaluări

- DesuperheatersDocument8 paginiDesuperheatersmuhdrijasmÎncă nu există evaluări

- An Introduction To Marketing Research by SmithDocument448 paginiAn Introduction To Marketing Research by SmithKali Das100% (1)

- S4L1D-D41 Wdg.311 - Technical Data Sheet - StamfordDocument10 paginiS4L1D-D41 Wdg.311 - Technical Data Sheet - Stamfordscribbles_buddyÎncă nu există evaluări

- DemarcationDocument4 paginiDemarcationpradz4Încă nu există evaluări

- NV 24 Globe ActuatorDocument12 paginiNV 24 Globe ActuatorRodrigo AlvesÎncă nu există evaluări

- GENRE DocumentaryDocument10 paginiGENRE Documentaryemilyweal123Încă nu există evaluări

- Bod User ManualDocument2 paginiBod User ManualAshish VermaÎncă nu există evaluări

- Nuke 9.0v1 ReleaseNotesDocument32 paginiNuke 9.0v1 ReleaseNotesFlavioÎncă nu există evaluări

- Barrera BANNER 2 PDFDocument10 paginiBarrera BANNER 2 PDFrollinga2013Încă nu există evaluări

- DPD Catalog 05 PDFDocument36 paginiDPD Catalog 05 PDFRuth D.Încă nu există evaluări

- PGCB ReportDocument36 paginiPGCB ReportNayemul Hasan NayemÎncă nu există evaluări

- Pid Handbook 1002-02 PDFDocument94 paginiPid Handbook 1002-02 PDFMUHAMMAD TAUFEEQÎncă nu există evaluări

- Flow Chart Fixed Column BasesDocument4 paginiFlow Chart Fixed Column BasesstycnikÎncă nu există evaluări

- NATO Tactical Nuclear Weapons in EuropeDocument35 paginiNATO Tactical Nuclear Weapons in EuropeMaria Mont' SerratÎncă nu există evaluări

- The 717Document2 paginiThe 717An LeÎncă nu există evaluări

- Merkava Siman 3 Merkava MK 3 in IDF Service PaDocument80 paginiMerkava Siman 3 Merkava MK 3 in IDF Service Pasacripal95% (20)

- Bitsler DicebotDocument4 paginiBitsler DicebotShinsÎncă nu există evaluări

- Iphone 6 Full schematic+IC BoardDocument86 paginiIphone 6 Full schematic+IC BoardSIDNEY TABOADAÎncă nu există evaluări

- Fault Database - Flat TVDocument3 paginiFault Database - Flat TVZu AhmadÎncă nu există evaluări

- Telepo SDK Develop Guide (Linux For TPS300) - v1.0Document10 paginiTelepo SDK Develop Guide (Linux For TPS300) - v1.0VKM2013Încă nu există evaluări

- Checklist For BrickworkDocument2 paginiChecklist For Brickworkइंजि कौस्तुभ पवारÎncă nu există evaluări

- Environmental Management Plan - MatrixDocument6 paginiEnvironmental Management Plan - Matrixplokhande47100% (1)