Documente Academic

Documente Profesional

Documente Cultură

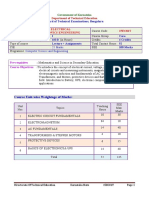

Notes Tee604 Transformer Design

Încărcat de

Anonymous sAmJfcVDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Notes Tee604 Transformer Design

Încărcat de

Anonymous sAmJfcVDrepturi de autor:

Formate disponibile

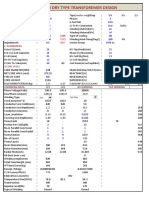

Transformer Design

OUTPUT EQUATION: - It gives the relationship between electrical rating and physical dimensions

of the machines.

Let

V

1

= Primary voltage say LV

V

2

= Secondary voltage say HV

I

1

= Primary current

I

2

= Secondary current

N

1

= Primary no of turns

N

2

= Secondary no of turns

a

1

= Sectional area of LV conductors (m

2

)

=

1

I

a

1

= Sectional area of HV conductors (m

2

)

=

2

I

= Permissible current density (A/m

2

)

Q = Rating in KVA

We place first half of LV on one limb and rest half of LV on other limb to reduce leakage flux.

So arrangement is LV insulation then half LV turns then HV insulation and then half HV turns.

(1) For 1-phase core type transformer

Rating is given by

Q =

3

1 1

10

I V KVA

= ( )

3

1 1

10 44 . 4

I N f

m

KVA

( )

1 1

44 . 4 N f V

m

= ( )

3

1 1

10 44 . 4

I N B fA

m i

KVA -----------(1)

) (

m i m

B A

Where

f = frequency

m

= Maximum flux in the core

i

A

= Sectional area of core

m

B

= Maximum flux density in the core

Window Space Factor

) (

w

w

A Area Window

Window in Windings of Area Section Cu Actual

K

w

A

N a N a

2 2 1 1

+

) / & / (

) / ( ) / (

2 2 1 1

2 2 1 1

I a I a

A

N I N I

w

+

w

A

N I N I

2 2 1 1

+

So

http://eed.dit.googlepages.com, Prepared by: Nafees Ahmed

1

L

V

L

V

L

V

L

V

H

V

H

V

H

V

H

V

1-phase core type transformer with

concentric windings

Window

) (

2

2 2 1 1

1 1

N I N I r Transforme Ideal For

A

N I

w

) 2 (

2

1 1

1

]

1

w w

A K

I N

Put equation value of N

1

I

1

form equation (2) to equation (1)

KVA

A K

B A f Q

w w

m i

3

10

2

44 . 4

) 3 ( 10 22 . 2

3

KVA A K B A f Q

w w m i

(2) For 1- phase shell type transformer

Window Space Factor

K

w

w

A

N a N a

2 2 1 1

+

) / & / (

) / ( ) / (

2 2 1 1

2 2 1 1

I a I a

A

N I N I

w

+

w

A

N I N I

2 2 1 1

+

) (

2

2 2 1 1

1 1

N I N I r Transforme Ideal For

A

N I

w

So

) 4 (

2

1 1

w w

A K

I N

Put equation value of N

1

I

1

form equation (4) to equation (1)

KVA

A K

B A f Q

w w

m i

3

10

2

44 . 4

) 5 ( 10 22 . 2

3

KVA A K B A f Q

w w m i

Note it is same as for 1-phase core type transformer i.e. equ (3)

(3) For 3-phase core type transformer

Rating is given by

Q =

3

1 1

10 3

I V KVA

= ( )

3

1 1

10 44 . 4 3

I N f

m

KVA

( )

1 1

44 . 4 N f V

m

= ( )

3

1 1

10 44 . 4 3

I N B fA

m i

KVA -----------(6)

) (

m i m

B A

Window Space Factor

http://eed.dit.googlepages.com, Prepared by: Nafees Ahmed

2

L

V

L

V

H

V

H

V

L

V

L

V

H

V

H

V

3-phase core type transformer with

concentric windings

L

V

L

V

H

V

H

V

Window

1-phase shell type transformer with

sandwich windings

LV

HV

LV

HV

LV

LV

HV

LV

HV

LV

Window

) (

w

w

A Area Window

Window in Windings of Area Section Cu Actual

K

w

A

N a N a ) ( 2

2 2 1 1

+

[ ]

) / & / (

) / ( ) / ( 2

2 2 1 1

2 2 1 1

I a I a

A

N I N I

w

+

w

A

N I N I

) ( 2

2 2 1 1

+

) (

2 2

2 2 1 1

1 1

N I N I r Transforme Ideal For

A

N I

w

So

) 7 (

4

1 1

w w

A K

I N

Put equation value of N

1

I

1

form equation (7) to equation (6)

KVA

A K

B A f Q

w w

m i

3

10

4

44 . 4 3

) 8 ( 10 33 . 3

3

KVA A K B A f Q

w w m i

(3) For 3- phase shell type transformer

Window Space Factor

K

w

w

A

N a N a

2 2 1 1

+

) / & / (

) / ( ) / (

2 2 1 1

2 2 1 1

I a I a

A

N I N I

w

+

w

A

N I N I

2 2 1 1

+

) (

2

2 2 1 1

1 1

N I N I r Transforme Ideal For

A

N I

w

So

) 9 (

2

1 1

w w

A K

I N

Put equation value of N

1

I

1

form equation (9) to equation (6)

KVA

A K

B A f Q

w w

m i

3

10

2

44 . 4 3

) 10 ( 10 66 . 6

3

KVA A K B A f Q

w w m i

CHOICE OF MAGNETIC LOADING (B

m

)

http://eed.dit.googlepages.com, Prepared by: Nafees Ahmed

3

3-phase shell type transformer with

sandwich windings

Window

(1) Normal Si-Steel 0.9 to 1.1 T

(0.35 mm thickness, 1.5%3.5% Si)

(2) HRGO 1.2 to 1.4 T

(Hot Rolled Grain Oriented Si Steel)

(3) CRGO 1.4 to 1.7 T

(Cold Rolled Grain Oriented Si Steel)

(0.14---0.28 mm thickness)

CHOICE OF ELECTRIC LOADING

( )

This depends upon cooling method employed

(1) Natural Cooling: 1.5---2.3 A/mm

2

AN Air Natural cooling

ON Oil Natural cooling

OFN Oil Forced circulated with Natural air cooling

(2) Forced Cooling : 2.2---4.0 A/mm

2

AB Air Blast cooling

OB Oil Blast cooling

OFB Oil Forced circulated with air Blast cooling

(3) Water Cooling: 5.0 ---6.0 A/mm

2

OW Oil immersed with circulated Water cooling

OFW Oil Forced with circulated Water cooling

CORE CONSTRUCTION:

http://eed.dit.googlepages.com, Prepared by: Nafees Ahmed

4

(a) U-I type (b) E-I type

(c) U-T type

(d) L-L type

EMF PER TURN:

We know

) 1 ( 44 . 4

1 1

N f V

m

) 2 ( 44 . 4 /

1

1

m t

f

N

V

E Turn EMF So

and

Q =

3

1 1

10

I V KVA (Note: Take Q as per phase rating in KVA)

= ( )

3

1 1

10 44 . 4

I N f

m

KVA

) 3 ( 10

3

1 1

KVA I N E

t

In the design, the ration of total magnetic loading and electric loading may be kept constant

Magnetic loading =

m

Electric loading =

1 1

I N

So

) 3 ( ) " " ( tan

1 1

1 1

eqution in put

r

I N r say t cons

I N

m m

KVA

r

E Q

m

t

3

10

Or

KVA

r f

E

E Q

t

t

3

10

44 . 4

using equation (2)

Q r f E

t

) 10 44 . 4 (

3 2

Or Turn Volts Q K E

t t

/

Where

3

10 44 . 4

r f K

t

is a constant and values are

K

t

= 0.6 to 0.7 for 3-phase core type power transformer

K

t

= 0.45 for 3-phase core type distribution transformer

K

t

= 1.3 for 3-phase shell type transformer

K

t

= 0.75 to 0.85 for 1-phase core type transformer

K

t

= 1.0 to 1.2 for 1-phase shell type transformer

ESTIMATION OF CORE X-SECTIONAL AREA A

i

We know

) 1 ( Q K E

t t

http://eed.dit.googlepages.com, Prepared by: Nafees Ahmed

5

(e) Mitred Core Construction (Latest)

45

o

m t

f E 44 . 4

Or

) 2 ( 44 . 4

m i t

B A f E

So

) 3 (

44 . 4

m

t

B f

E

A

i

Now the core may be following types

d = Diameter of circumscribe circle

For Square core

Gross Area

2

5 . 0

2 2

d

d d

Let stacking factor

9 . 0

i

K

Actual Iron Area

2

5 . 0 9 . 0 d A

i

2

45 . 0 d (0.45 for square core and take K as a general case)

2

d K

So

2

d K A

i

Or

K

A

d

i

Graphical method to calculate dimensions of the core

Consider 2 step core

Steps of No n

n

o

+

,

1

90

o

o

n e i

30

1 2

90

2 .

dSin b

dCos a So

Percentage fill

4

2

2

d

K Kd

le circumcirc of Area

core Stepped of Area Gross

i

core Step for

d

d

4

) (

4

9 . 0 / 625 . 0

2

2

= 0.885 or 88.5%

No of steps 1 2 3 4 5 6 7 9 11

http://eed.dit.googlepages.com, Prepared by: Nafees Ahmed

6

d

d/2

1-Step

Or Square- Core

2-Step

Or Cruciform- Core

3-Step Core

4-Step Core

K= 0.45 0.56 0.60 0.625

2-Step

Or Cruciform- Core

b

a

b

a

% Fill 63.7% 79.2% 84.9% 88.5% 90.8% 92.3% 93.4% 94.8% 95.8%

ESTIMATION OF MAIN DIMENSIONS:

Consider a 3-phase core type transformer

We know output equation

KVA A K B A f Q

w w m i

3

10 33 . 3

So, Window area

2

3

10 33 . 3

m

K B A f

Q

A

w m i

w

where K

w

=Window space factor

KVA upto for

HigherKV

K

w

10

30

8

+

KVA upto for

HigherKV

K

w

200

30

10

+

KVA upto for

HigherKV

K

w

1000

30

12

+

For higher rating K

w

= 0.15 to 0.20

Assume some suitable range for

D = (1.7 to 2) d

Width of the window W

w

= D-d

Height of the window

) (

w

w

W window of width

A

L

) (

w w

A W L

Generally

4 2 to

W

L

w

Yoke area A

y

is generally taken 10% to 15% higher then core section area (A

i

), it is to reduce the iron loss in

the yoke section. But if we increase the core section area (A

i

) more copper will be needed in the windings

and so more cost through we are reducing the iron loss in the core. Further length of the winding will

increase resulting higher resistance so more cu loss.

A

y

= (1.10 to 1.15) A

i

Depth of yoke D

y

= a

http://eed.dit.googlepages.com, Prepared by: Nafees Ahmed

7

d

L

W

D

(D-d)

W

w

=

H

h

y

3-phase core type transformer

2-Step

Or Cruciform- Core

b

a

b

a

Height of the yoke h

y

= A

y

/D

y

Width of the core

W = 2*D + d

Height of the core

H = L + 2*h

y

Flux density in yoke

m

y

i

y

B

A

A

B

ESTIMATION OF CORE LOSS AND CORE LOSS COMPONET OF NO LOAD CURRENT I

C

:

Volume of iron in core = 3*L*A

i

m3

Weight of iron in core = density * volume

=

i

* 3*L*A

i

Kg

i

= density of iron (kg/m3)

=7600 Kg/m

3

for normal Iron/steel

= 6500 Kg/m

3

for M-4 steel

From the graph we can find out specific iron loss, p

i

(Watt/Kg ) corresponding to flux density B

m

in core.

So

Iron loss in core =pi*

i

* 3*L*A

i

Watt

Similarly

Iron loss in yoke = p

y

*

i

* 2*W*A

y

Watt

Where p

y

= specific iron loss corresponding to flux density B

y

in yoke

Total Iron loss P

i

=Iron loss in core + Iron loss in yoke

Core loss component of no load current

I

c

= Core loss per phase/ Primary Voltage

I

c

1

3V

P

i

ESTIMATION OF MAGNETIZING CURRENT OF NO LOAD CURRENT I

m

:

Find out magnetizing force H (at

core

, at/m) corresponding to flux density B

m

in the core and at

yoke

corresponding to flux density in the yoke from B-H curve

( ) m at B m at B

yoke c core m

/ , /

So

MMF required for the core = 3*L*at

core

http://eed.dit.googlepages.com, Prepared by: Nafees Ahmed

8

MMF required for the yoke = 2*W*at

yoke

We account 5% at for joints etc

So total MMF required = 1.05[MMF for core + MMF for yoke]

Peak value of the magnetizing current

1

,

3N

required MMF Total

I

peak m

RMS value of the magnetizing current

2

,

,

peak m

RMS m

I

I

1

,

2 3 N

required MMF Total

I

RMS m

ESTITMATION OF NO LOAD CURRENT AND PHASOR DIAGRAM:

No load current Io

2 2

m c o

I I I +

No load power factor

o

c

o

I

I

Cos

The no load current should not exceed 5% of the full the load current.

ESTIMATION OF NO OF TURNS ON LV AND HV WINDING

Primary no of turns

t

E

V

N

1

1

Secondary no of turns

t

E

V

N

2

2

ESTIMATION OF SECTIONAL AREA OF PRIMARY AND SECONDARY WINDINGS

Primary current

1

3

1

3

10

V

Q

I

Secondary current

1

2

1

2

3

2

3

10

I

N

N

OR

V

Q

I

Sectional area of primary winding

1

1

I

a

http://eed.dit.googlepages.com, Prepared by: Nafees Ahmed

9

I

c

I

m

I

o

V

1

=-E

1

E

2

0

No load phasor diagram

Sectional area of secondary winging

2

2

I

a

Where is current the density.

Now we can use round conductors or strip conductors for this see the IS codes and ICC (Indian Cable

Company) table.

DETERMINATION OF R

1

& R

2

AND CU LOSSES:

Let L

mt

= Length of mean turn

Resistance of primary winding

) (

) (

10 021 . 0

2

1

1

6

75 , , 1

m a

m N L

R

mt

dc

o

o o

dc ac

R to R

75 , , 1 75 , , 1

) 20 . 1 15 . 1 (

Resistance of secondary winding

) (

) (

10 021 . 0

2

2

2

6

75 , , 2

m a

m N L

R

mt

dc

o

o o

dc ac

R to R

75 , , 2 75 , , 2

) 20 . 1 15 . 1 (

Copper loss in primary winding Watt R I

1

2

1

3

Copper loss in secondary winding Watt R I

2

2

2

3

Total copper loss

2

2

2 1

2

1

3 3 R I R I +

) ( 3

'

2 1

2

1

R R I +

p

R I

2

1

3

Where

side primary to referred ce resis Total

R R R R

p

tan

'

2 1 01

+

Note: On No load, there is magnetic field around connecting leads etc which causes additional stray losses

in the transformer tanks and other metallic parts. These losses may be taken as 7% to 10% of total cu losses.

DETERMINATION OF EFFICIENCY:

Efficiency

Power Input

Power Output

Losses Power Output

Power Output

+

100

+ +

loss Cu Loss Iron Power Output

Power Output

%

ESTIMATION OF LEAKAGE REACTANCE:

Assumptions

1. Consider permeability of iron as infinity that is MMF is needed only for leakage flux path in the

window.

2. The leakage flux lines are parallel to the axis of the core.

Consider an elementary cylinder of leakage flux lines of thickness dx at a distance x as shown in following

figure.

MMF at distance x

http://eed.dit.googlepages.com, Prepared by: Nafees Ahmed

10

x

x

a

b

1

b

2

dx

N

1

I

1

=N

2

I

2

L

c

MMF Distribution

x

b

I N

M

x

1

1 1

Permeance of this elementary cylinder

L

A

o

c

mt

o

L

dx L

(L

c

=Length of winding)

,

_

S

Permeance

A

L

S

o

1

&

1

Leakage flux lines associated with elementary cylinder

Permeance M d

x x

Flux linkage due to this leakage flux

x x

d associated is it which with truns of No d

c

mt

o

L

dx L

x

b

I N

b

I N

1

1 1

1

1 1

dx

b

x

I

L

L

N

c

mt

o

2

1

1

2

1

,

_

Flux linkages (or associated) with primary winding

,

_

1

0

2

1

1

2

1

'

1

b

c

mt

o

dx

b

x

I

L

L

N

,

_

3

1

1

2

1

b

I

L

L

N

c

mt

o

Flux linkages (or associated) with the space a between primary and secondary windings

a I

L

L

N

c

mt

o o 1

2

1

We consider half of this flux linkage with primary and rest half with the secondary winding. So total flux

linkages with primary winding

2

'

1 1

o

,

_

+

2 3

1

1

2

1 1

a b

I

L

L

N

c

mt

o

Similarly total flux linkages with secondary winding

2

'

2 2

o

,

_

+

2 3

2

2

2

2 2

a b

I

L

L

N

c

mt

o

Primary & Secondary leakage inductance

,

_

+

2 3

1 2

1

1

1

1

a b

L

L

N

I

L

c

mt

o

,

_

+

2 3

2 2

2

2

2

2

a b

L

L

N

I

L

c

mt

o

Primary & Secondary leakage reactance

,

_

+

2 3

2 2

1 2

1 1 1

a b

L

L

N f fL X

c

mt

o

,

_

+

2 3

2 2

2 2

2 2 2

a b

L

L

N f fL X

c

mt

o

http://eed.dit.googlepages.com, Prepared by: Nafees Ahmed

11

c

mt

o

L

dx L

x

b

I N

1

1 1

Total Leakage reactance referred to primary side

,

_

+

+

+ a

b b

L

L

N f X X X X

c

mt

o P

3

2

2 1 2

1

'

2 1 01

Total Leakage reactance referred to secondary side

,

_

+

+

+ a

b b

L

L

N f X X X X

c

mt

o S

3

2

2 1 2

2 2

'

1 02

It must be 5% to 8% or maximum 10%

Note:- How to control X

P

?

If increasing the window height (L), L

c

will increase and following will decrease b

1

, b

2

& L

mt

and so we can reduce the value of X

P

.

CALCULATION OF VOLTAGE REGULATION OF TRANSFORMER:

100 . .

2

2 2 2 2 2 2

E

Sin X I Cos R I

R V

o o

100

/

100

/

2 2

2 2

2 2

2 2

t

I E

Sin X

I E

Cos R

o o

2 2 2 2

% % Sin X Cos R

o o

t

TRANSFORMER TANK DESIGN:

Width of the transformer (Tank)

W

t

=2D + D

e

+ 2b

Where D

e

= External diameter of HV winding

b = Clearance width wise between HV and tank

Depth of transformer (Tank)

l

t

= D

e

+ 2a

Where a= Clearance depth wise between HV and tank

Height of transformer (Tank)

H

t

= H + h

Where h=h

1

+ h

2

= Clearance height wise of top and bottom

http://eed.dit.googlepages.com, Prepared by: Nafees Ahmed

12

b

b

a

a

W

t

l

t

D D

D

e

L

W

(D-d)

W

w

H

h

y

Tank of a 3-Phase transformer

CALCULATION OF TEMPERATURE RISE:

Surface area of 4 vertical side of the tank (Heat is considered to be dissipated from 4 vertical sides of the

tank)

S

t

= 2(W

t

+ l

t

) H

t

m

2

(Excluding area of top and bottom of tank)

Let

= Temp rise of oil (35

o

C to 50

o

C)

12.5S

t

=Total full load losses ( Iron loss + Cu loss)

So temp rise in

o

C

t

S 12.5

losses load full Total

If the temp rise so calculated exceeds the limiting value, the suitable no of cooling tubes or radiators must be

provided

CALCULATION OF NO OF COOLING TUBES:

http://eed.dit.googlepages.com, Prepared by: Nafees Ahmed

13

H

W

h

1

h

2

H

t

Specific Heat dissipation

6 Watt/m

2

-

0

C by Radiation

6.5 Watt/m

2

-

0

C by Convection

Let xS

t

= Surface area of all cooling tubes

Then

Losses to be dissipated by the transformer walls and cooling tube

= Total losses

( ) losses Total 5 . 8 5 . 12 +

t t

xS S

So from above equation we can find out total surface are of cooling tubes (xS

t

)

Normally we use 5 cm diameter tubes and keep them 7.5 cm apart

A

t

= Surface area of one cooling tube

mean tube tube

l d

,

Hence

No of cooling tubes

t

t

A

xS

WEIGHT OF TRANFORMER:

Let

W

i

= Weight of Iron in core and yoke (core volume* density + yoke volume* density) Kg

W

c

= Weight of copper in winding (volume* density) Kg

(density of cu = 8900 Kg/m

3

)

Weight of Oil

= Volume of oil * 880 Kg

Add 20% of (W

i

+W

c

) for fittings, tank etc.

Total weight is equal to weight of above all parts.

http://eed.dit.googlepages.com, Prepared by: Nafees Ahmed

14

d= 5 Cm

7.5 Cm

Tank and Arrangement of Cooling tubes

6 W-Raditon+6.5 W=12.5 Convection 6.5*1.35 W 5 . 8 ( 35% more) Convection only

S-ar putea să vă placă și

- Transformer Design NotesDocument15 paginiTransformer Design Notesrishabh100% (2)

- Transformer Design SheetDocument5 paginiTransformer Design Sheetحسن هادي100% (1)

- 100MVA Design DetailsDocument10 pagini100MVA Design DetailsAnonymous sAmJfcV100% (1)

- TransformerdesignDocument14 paginiTransformerdesigntuqe100% (3)

- Transformer Design CodeDocument10 paginiTransformer Design CodemaheshggargÎncă nu există evaluări

- 63 KVA Transformer Design PDFDocument2 pagini63 KVA Transformer Design PDFgthakur4u0% (1)

- Design of TransformerDocument32 paginiDesign of TransformerCelsiusÎncă nu există evaluări

- Transformer DesignDocument9 paginiTransformer DesignHansraj AkilÎncă nu există evaluări

- 5.short Circuit CalculationsDocument56 pagini5.short Circuit CalculationsPramod B.Wankhade50% (2)

- Transposition in Transformer WindingsDocument29 paginiTransposition in Transformer WindingsM V Ravindra Mutyala100% (1)

- Technical Specifications of Transformers 28.6.2020Document66 paginiTechnical Specifications of Transformers 28.6.2020Sunil GurubaxaniÎncă nu există evaluări

- unit-II TransformersDocument19 paginiunit-II Transformersc.naresh9727100% (1)

- A Calculation Method For Impulse Voltage Distribution in TransformerDocument10 paginiA Calculation Method For Impulse Voltage Distribution in Transformerrajfab86% (7)

- Transformer Design and Design Parameters PDFDocument56 paginiTransformer Design and Design Parameters PDFHemendra Jani60% (5)

- Relay Coordination GuidelinesDocument16 paginiRelay Coordination GuidelinesShah Aizat RazaliÎncă nu există evaluări

- Calculations For Design Parameters of Transformer - Engineer ExperiencesDocument40 paginiCalculations For Design Parameters of Transformer - Engineer ExperiencesSamit DasÎncă nu există evaluări

- Phase Comparison Relay REL352 Current Pickup Calculation: Application NoteDocument10 paginiPhase Comparison Relay REL352 Current Pickup Calculation: Application NoteVimalMakadiaÎncă nu există evaluări

- Transformer Design PDFDocument72 paginiTransformer Design PDFSujon MiaÎncă nu există evaluări

- Earthing CalculationDocument16 paginiEarthing Calculationmanirup_tceÎncă nu există evaluări

- Earthing Calculation As Per Ieee 80Document10 paginiEarthing Calculation As Per Ieee 80Ben HurÎncă nu există evaluări

- PrinciplesofTransformerDesign PDFDocument236 paginiPrinciplesofTransformerDesign PDFelhaffarÎncă nu există evaluări

- Current TransformerDocument19 paginiCurrent Transformerkrajeev2802Încă nu există evaluări

- Design and Selection of Substation EquipmentDocument40 paginiDesign and Selection of Substation EquipmentHasan AlmatroodÎncă nu există evaluări

- Substation Grounding Design - 50kgDocument7 paginiSubstation Grounding Design - 50kgsitifarhaniÎncă nu există evaluări

- Designing and Optimizing Distribution Transformers Using MATLABDocument42 paginiDesigning and Optimizing Distribution Transformers Using MATLABMahidhar Talapaneni100% (4)

- TransformerDocument134 paginiTransformerDilip Gangopadhyay83% (6)

- CT VT Calculation Al AIN Rev.1Document41 paginiCT VT Calculation Al AIN Rev.1jm.mankavil6230Încă nu există evaluări

- On TransformerDocument20 paginiOn TransformerMurshedur Rahman100% (7)

- Transformer Design ManualDocument90 paginiTransformer Design ManualAnonymous sAmJfcV95% (22)

- Fault Level CalculationsDocument28 paginiFault Level CalculationsShyamkantVasekar80% (5)

- Current Transformer Sizing: (August 19, 2010) By: Siva Singupuram James TrinhDocument62 paginiCurrent Transformer Sizing: (August 19, 2010) By: Siva Singupuram James Trinhpccluster50% (4)

- University of Turkish Aeronautical Association Faculty of Engineering EEE DepartmentDocument57 paginiUniversity of Turkish Aeronautical Association Faculty of Engineering EEE DepartmentratheeshkumardÎncă nu există evaluări

- Important NumericalsDocument1 paginăImportant NumericalscheshankarÎncă nu există evaluări

- Transformer DesignDocument27 paginiTransformer DesignNitesh BharadwajÎncă nu există evaluări

- Overhead Transmission Lines ExplainedDocument95 paginiOverhead Transmission Lines ExplainedMarcosArielRamirezV100% (1)

- Basic Understanding On Voltage TransformerDocument34 paginiBasic Understanding On Voltage Transformersitifarhani100% (14)

- Chapter 7 Overload Capacity of Power TransformersDocument10 paginiChapter 7 Overload Capacity of Power Transformerstenk_man100% (1)

- Knee Point Voltage Calculation of CTDocument2 paginiKnee Point Voltage Calculation of CTYogesh Patil100% (4)

- Tneb Power Engineers HandbookDocument2 paginiTneb Power Engineers Handbooksalman50% (4)

- 2.0 Fault LevelDocument23 pagini2.0 Fault Levelrathaurs100% (2)

- Statement of The Problem: Figure No. 1 Current TransformerDocument12 paginiStatement of The Problem: Figure No. 1 Current TransformerAngelo Caimol Sergantes100% (1)

- Lecture No. 3 - Per-Unit System and Impedance DiagramDocument4 paginiLecture No. 3 - Per-Unit System and Impedance DiagramSteven John De VeraÎncă nu există evaluări

- Electrical Loads and Cable Sizing for RoomsDocument8 paginiElectrical Loads and Cable Sizing for Roomsakif amirÎncă nu există evaluări

- CT VT Calculation Al AIN Rev 1Document41 paginiCT VT Calculation Al AIN Rev 1senthilÎncă nu există evaluări

- IsolatorsDocument109 paginiIsolatorsnmshamim100% (4)

- TANTRANSCO TENDER Supply of 11kV & 33kV Outdoor Vacuum Circuit BreakersDocument71 paginiTANTRANSCO TENDER Supply of 11kV & 33kV Outdoor Vacuum Circuit BreakersKrishnaFBÎncă nu există evaluări

- Training Report on Winding of TransformersDocument15 paginiTraining Report on Winding of TransformersJanmejaya Mishra100% (2)

- Instrument Transformer Basics PDFDocument37 paginiInstrument Transformer Basics PDFPedro Pereira100% (2)

- Transformer Design FormulasDocument8 paginiTransformer Design FormulasJavierÎncă nu există evaluări

- Parameters: Calculation For Al Bus Bar Suitable For 50ka Fault LevelDocument1 paginăParameters: Calculation For Al Bus Bar Suitable For 50ka Fault Levelanand_girgaonkarÎncă nu există evaluări

- Busbar Clearance BarrierDocument2 paginiBusbar Clearance BarrierSundaresan Sabanayagam100% (1)

- TransformerDocument67 paginiTransformerlallyprabh100% (2)

- 3 Phase Transformer Vector GroupsDocument35 pagini3 Phase Transformer Vector GroupsAbhishek Modak100% (2)

- CSP Transformer in IndiaDocument56 paginiCSP Transformer in Indiavinay kumarÎncă nu există evaluări

- Calculation of The Current Transformer Accuracy Limit FactorDocument14 paginiCalculation of The Current Transformer Accuracy Limit FactorWeiKiat Goh67% (3)

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenDe la EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenEvaluare: 4 din 5 stele4/5 (2)

- Switching in Electrical Transmission and Distribution SystemsDe la EverandSwitching in Electrical Transmission and Distribution SystemsÎncă nu există evaluări

- Electrical Transformer Thermal Analysys Using Ansys Fluent (CFD)Document1 paginăElectrical Transformer Thermal Analysys Using Ansys Fluent (CFD)Anonymous sAmJfcVÎncă nu există evaluări

- 02 2 Maxwell Eddy CurrentDocument12 pagini02 2 Maxwell Eddy CurrentAnonymous sAmJfcVÎncă nu există evaluări

- Icepak-Intro 14.5 L01 Agenda and ANSYS Intro PDFDocument11 paginiIcepak-Intro 14.5 L01 Agenda and ANSYS Intro PDFAnonymous sAmJfcVÎncă nu există evaluări

- Distribution TransformerDocument17 paginiDistribution TransformerveerendraprasadÎncă nu există evaluări

- SolidWorks API Series 1 - Programming & Automation PDFDocument268 paginiSolidWorks API Series 1 - Programming & Automation PDFAnonymous sAmJfcV86% (7)

- Commandbutton1 Commandbutton2: Shaft 2 Dia 0.5 Bevel 2 Dia 2Document1 paginăCommandbutton1 Commandbutton2: Shaft 2 Dia 0.5 Bevel 2 Dia 2Anonymous sAmJfcVÎncă nu există evaluări

- SolidWorks API Demystified: What is Covered HereDocument8 paginiSolidWorks API Demystified: What is Covered HereAnonymous sAmJfcVÎncă nu există evaluări

- Distribution TransformerDocument17 paginiDistribution TransformerveerendraprasadÎncă nu există evaluări

- Guaranteed Technical Particulars: 1. SpecificationsDocument2 paginiGuaranteed Technical Particulars: 1. SpecificationsAnonymous sAmJfcVÎncă nu există evaluări

- SolidWorks API Demystified: What is Covered HereDocument8 paginiSolidWorks API Demystified: What is Covered HereAnonymous sAmJfcVÎncă nu există evaluări

- SolidWorks API Demystified: What is Covered HereDocument8 paginiSolidWorks API Demystified: What is Covered HereAnonymous sAmJfcVÎncă nu există evaluări

- 100kva Core Temp Rise Using With ComsolDocument14 pagini100kva Core Temp Rise Using With ComsolAnonymous sAmJfcV100% (1)

- 100kva Dry Main and CoreDocument1 pagină100kva Dry Main and CoreAnonymous sAmJfcVÎncă nu există evaluări

- Calculating Core TemperatureDocument6 paginiCalculating Core TemperatureAnonymous sAmJfcVÎncă nu există evaluări

- Models - Mph.heat Transient AxiDocument6 paginiModels - Mph.heat Transient AxiAnonymous sAmJfcVÎncă nu există evaluări

- SolidWorks Simulation Black BookDocument40 paginiSolidWorks Simulation Black BookAnonymous sAmJfcV50% (6)

- Transformers for the Metal Industry: Furnace and Rectifier TypesDocument3 paginiTransformers for the Metal Industry: Furnace and Rectifier Typesjoydeep_d3232Încă nu există evaluări

- Models - Heat.electronic Enclosure CoolingDocument20 paginiModels - Heat.electronic Enclosure CoolingAnonymous sAmJfcVÎncă nu există evaluări

- Vpi Resin Impregnated Dry Type TransformerDocument9 paginiVpi Resin Impregnated Dry Type Transformershona_shanuÎncă nu există evaluări

- Cast Resin Dry Type Transformer DesignDocument1 paginăCast Resin Dry Type Transformer DesignAnonymous sAmJfcV100% (1)

- Haritha ThesisDocument105 paginiHaritha ThesisAnonymous sAmJfcVÎncă nu există evaluări

- Cast Resin Dry Type Transformer DesignDocument1 paginăCast Resin Dry Type Transformer DesignAnonymous sAmJfcV100% (1)

- Siemens MS2014Document4 paginiSiemens MS2014Carlos TuestaÎncă nu există evaluări

- Models - Llse.busbar LlseDocument12 paginiModels - Llse.busbar LlseAnonymous sAmJfcVÎncă nu există evaluări

- Epoxylite TSA 220 - TDS - 2008Document3 paginiEpoxylite TSA 220 - TDS - 2008Anonymous sAmJfcVÎncă nu există evaluări

- Models - Acdc.ecore TransformerDocument34 paginiModels - Acdc.ecore TransformerAnonymous sAmJfcVÎncă nu există evaluări

- 5cast Resin Dry-Type TransformerDocument2 pagini5cast Resin Dry-Type TransformerAnonymous sAmJfcVÎncă nu există evaluări

- Induction Motor I 01 Mail GoogDocument249 paginiInduction Motor I 01 Mail GoogAnonymous sAmJfcVÎncă nu există evaluări

- (26 22 10) Dry Type TransformersDocument5 pagini(26 22 10) Dry Type TransformersAnonymous sAmJfcVÎncă nu există evaluări

- Nitrogen fire prevention systemDocument2 paginiNitrogen fire prevention systemsbpathi100% (1)

- Electrical VivaDocument5 paginiElectrical VivaHari KrishnanÎncă nu există evaluări

- Unregulated Power Supply DesignDocument6 paginiUnregulated Power Supply DesignGunawan RudyÎncă nu există evaluări

- Logical Node Classes & DataDocument47 paginiLogical Node Classes & Datank1224Încă nu există evaluări

- PC 5kpi (S)Document2 paginiPC 5kpi (S)bullxyzÎncă nu există evaluări

- Section 8 33KVDocument13 paginiSection 8 33KVMuna HamidÎncă nu există evaluări

- Manweir Electrical Repair SolutionsDocument12 paginiManweir Electrical Repair SolutionsClarkFedele27Încă nu există evaluări

- Basic Electronics, Volumes 1-5, (1955) - Text PDFDocument570 paginiBasic Electronics, Volumes 1-5, (1955) - Text PDFfrankÎncă nu există evaluări

- 03 Definition - Classification of Power System Stability IEEE-CIGRE Joint Task Force On Stability Terms and DefinitionsDocument63 pagini03 Definition - Classification of Power System Stability IEEE-CIGRE Joint Task Force On Stability Terms and DefinitionsRosa Elvira Montalvo MartínezÎncă nu există evaluări

- Sizing of Instrument Transformer For 66 KV Ukai Left Branch Canal (LBC) Lift Irrigation SchemeDocument36 paginiSizing of Instrument Transformer For 66 KV Ukai Left Branch Canal (LBC) Lift Irrigation SchemeSumitÎncă nu există evaluări

- ETK - R16.1 - Intro TransformadorDocument15 paginiETK - R16.1 - Intro TransformadorEdjavier CastilloÎncă nu există evaluări

- Harmonic Mitigation Using 36-Pulse AC-DC Converter For Direct Torque Controlled Induction Motor DrivesDocument10 paginiHarmonic Mitigation Using 36-Pulse AC-DC Converter For Direct Torque Controlled Induction Motor DrivesNationalinstituteDsnrÎncă nu există evaluări

- PCS 978Document2 paginiPCS 978Sattawat PuntaÎncă nu există evaluări

- Design and Development Kroto FinderDocument9 paginiDesign and Development Kroto Finderimamul haqueÎncă nu există evaluări

- MQX-Enabled MK30X256 Single-Phase Electricity Meter Reference DesignDocument83 paginiMQX-Enabled MK30X256 Single-Phase Electricity Meter Reference DesignMehmood AhmadÎncă nu există evaluări

- Operation Manual RX MachineDocument17 paginiOperation Manual RX MachineArsenio Fuentes100% (1)

- Force and Torque Measurement TechniquesDocument6 paginiForce and Torque Measurement TechniquesTanvi IsraniÎncă nu există evaluări

- Electrical PDFDocument5 paginiElectrical PDFAkula VeerrajuÎncă nu există evaluări

- 2014 Line Distance Protection Fundamentals - PriceDocument83 pagini2014 Line Distance Protection Fundamentals - PriceRolando Henry Flores CamavilcaÎncă nu există evaluări

- Southern Electric Power Distribution Long Term Development Statement Parts 1 and 2Document40 paginiSouthern Electric Power Distribution Long Term Development Statement Parts 1 and 2Christos ApostolopoulosÎncă nu există evaluări

- A 25 KW Industrial Prototype Wireless Electric Vehicle ChargerDocument6 paginiA 25 KW Industrial Prototype Wireless Electric Vehicle Chargerabhinandan.kumarÎncă nu există evaluări

- Load Flow Basic Principles DigsilentDocument17 paginiLoad Flow Basic Principles Digsilentjcrodriguez83100% (2)

- How To Build A Simple But Powerful Flyback DriverDocument8 paginiHow To Build A Simple But Powerful Flyback DriverGabriel Droguett OleaÎncă nu există evaluări

- How To Solve Short Circuit Calculation Using Point To Point Method PDFDocument6 paginiHow To Solve Short Circuit Calculation Using Point To Point Method PDFMenaÎncă nu există evaluări

- PC5200 V2.0 - Manual Instalare PDFDocument2 paginiPC5200 V2.0 - Manual Instalare PDFDarie SilviuÎncă nu există evaluări

- ISKRA DPM MC740 Parameter List DrawingDocument22 paginiISKRA DPM MC740 Parameter List Drawinghairul hafizÎncă nu există evaluări

- 600W PFC Power Supply For Audio AmplifierDocument37 pagini600W PFC Power Supply For Audio Amplifierpgamez833Încă nu există evaluări

- Info Iec60079-7 (Ed5.0) enDocument19 paginiInfo Iec60079-7 (Ed5.0) enbalajiÎncă nu există evaluări

- Siemens Medium Voltage 24kV Gas Insulated Switchgear 8DJH OandMDocument129 paginiSiemens Medium Voltage 24kV Gas Insulated Switchgear 8DJH OandMmichyimÎncă nu există evaluări

- 3.concepts of Electrical & Electronics EnggDocument15 pagini3.concepts of Electrical & Electronics Enggakangadi09Încă nu există evaluări