Documente Academic

Documente Profesional

Documente Cultură

t9 Cooling Tower

Încărcat de

Izzat FakhriDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

t9 Cooling Tower

Încărcat de

Izzat FakhriDrepturi de autor:

Formate disponibile

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

TABLE OF CONTENT

Content

Title Theory / Introduction

Page

2 3

Experiment 9.1 Objective Procedure Result and Discussion Conclusion

16 16 16 17 19

Experiment 9.2 Objective Procedure Result and Discussion Conclusion

20 20 20 21 26

Experiment 9.3 Objective Procedure Result and Discussion Conclusion

26 26 26 27 29

Overall Summary

29

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

TITLE:

T9: BENCH TOP COOLING TOWER

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

THEORY: Basic Principle First consider an air stream passing over the surface of a warm water droplet or film. If we assume that the water is hotter than the air, then the water temperature will be cooled down by radiation, conduction and convection, and evaporation. The radiation effect is normally very small and may be neglected. Conduction and convection depend on the temperature difference, the surface area, air velocity, etc. the effect evaporation is the most significant where cooling takes place as water molecules diffuse from the surface into the surrounding air. During the evaporation process, the water molecules are replaced by others in the liquid form which the required energy is taken. Evaporation from a Wet Surface When considering evaporation from a wet surface into the surrounding air, the rate is determined by the difference between the vapor pressure at the liquid surface and the vapor pressure in the surrounding air. The vapor pressure at the liquid surface is basically the saturation pressure corresponding with the surface temperature, whereas the total pressure of the air and its absolute humidity determines the vapor pressure in the surrounding air. Such evaporation process in an enclosed space shall continue until the two vapor pressures are equal. In other words, until the air is saturated and its temperature equals the surface. However, if unsaturated air is constantly supplied, the wet surface will reach an equilibrium temperature at which the cooling effect due to the evaporation equals the heat transfer to the liquid by conduction and convection from the air, which under these conditions; will be at higher temperature. Under adiabatic conditions, this equilibrium temperature is the wet bulb temperature. For cooling tower of infinite size and with an adequate air flow, the water leaving will be at the wet bulb temperature of the incoming air. Therefore, the difference between the temperature of the water leaving a cooling tower and the local wet bulb temperature is an indication of the effectiveness of the cooling towers. Thus, Approach to Wet Bulb, an important parameter of cooling towers, is the difference between the temperature of water leaving the tower and the wet bulb temperature of entering air.

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

Cooling Tower Performance A study on the performance of a cooling tower can be done with the help of a bench top unit. Students shall be able to verify the effect of these factors on the cooling tower performance: (i). Water flow rates (ii). Water temperatures (iii). Airflow rate (iv). Inlet air relative humidity The effect of these factors will be studied in depth by varying it. In this way, students will gain an overall view of the operation of cooling tower. Thermodynamic Property In order to understand the working principle and performance of a cooling tower, a basic knowledge of thermodynamic is essential to all students. A brief review on some the thermodynamic properties are presented below. At the triple point i.e. . atm and . C , the enthalpy of saturated water is assumed to

be zero, which is taken as datum. The specific enthalpy of saturated water (hf) at a range of temperatures above the datum condition can be obtained from thermodynamic tables. The specific enthalpy of compressed liquid is given by h = hf + vf ( p psat ) (1)

The correction for pressure is negligible for the operating condition of the cooling tower; therefore we can see that h hf at a given temperature. Specific heat capacity (Cp) is defined as the rate of change of enthalpy with respect to temperature (often called as the specific heat at constant pressure). For the purpose of experiment using bench top cooling tower, we may use the following relationship: h = CpT And h = Cp T Where Cp = 4.18kJ.kg-1 (3) (2)

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

Daltons and Gibbs Law It is commonly known that air consists of a mixture of dry air O , N , and other gases and water vapor. Dalton and Gibbs law describes the behavior of such a mixture as: a) The total pressure of the air is equal to the sum of the pressures at which the dry air and the water vapour each and alone would exert if they were to occupy the volume of the mixture at the temperature of the mixture. b) The dry air and the water vapour respectively obey their normal property relationships at their partial pressures. c) The enthalpy of the mixture may be found by adding together the enthalpies at which the dry air and water vapour each would have as the sole occupant of the space occupied by the mixture and at the same temperature.

The Absolute or Specific Humidity is defined as follows: (4)

The Relative Humidity is defined as follows: (5)

The Percentage Saturation is defined as follows:

(6)

At high humidity conditions, it can be shown that there is not much difference between the Relative Humidity and the Percentage Saturation and thus we shall regard as the same.

To measure the moisture content of the atmosphere, this bench top cooling tower unit is supplied with electronic dry bulb and wet bulb temperature sensors. The temperature readings shall be used in conjunction with a psychometric chart.

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

Psychometric Chart The psychometric chart is very useful in determining the properties of air/water vapor mixture. Among the properties that can be defined with psychometric chart are Dry Bulb Temperature, Wet Bulb Temperature, Relative Humidity, Humidity Ratio, Specific Volume and Specific Enthalpy. Knowing two of these properties, any other property can be easily identified from the chart provided the air pressure is approximately atmospheric.

In the Bench Top Cooling Tower application, the air inlet and outlet sensor show the dry bulb temperature and wet bulb temperature. Therefore, the specific enthalpy, specific volume, humidity ratio and relative humidity can be readily read from the psychometric chart. The psychometric chart provided with this manual is only applicable for atmospheric pressure operating condition (1.013 bar). However, the error resulting from variation of local atmospheric pressure normally is negligible up to altitudes 500m above sea level.

Orifice Calibration As mentioned above, the psychometric chart can be used to determine the value of the specific volume. However, the values given in the chart are for 1kg of dry air the stated total pressure. However, for every 1kg of dry air, there is mass of 1 + kg of water vapour, yielding the total

kg. Therefore, the actual specific volume of the air/vapour mixture is given by: (7)

The mass flow rate of air and steam mixture through the orifice is given by (8)

Where,

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

Thus,

( )

(9)

The mass flow rate of dry air, (0)

(0)

(0)

A simplification can be made since in this application, the value of 0.025. As such, neglecting would not yield significant error.

is unlikely to exceed

Application of Steady Flow Energy Equation Consider System A for the cooling tower defined as in Figure 1. It can be seen that the for this system, indicated by the dotted line, a) Heat transfer at the load tank and possibly a small quantity to surroundings b) Work transfer at the pump c) Low humidity air enters at point A d) High humidity air enters at point B e) Make-up enters at point E, the same amount as the moisture increase in the air stream

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

Figure 2: System A

From the steady flow equation, P = exit - entry ( )B ( ) A (11)

If the enthalpy of the air includes the enthalpy of the steam associated with it, and this quantity is in terms of per unit mass of dry air, the equation may then be written as: P= ( ) (12)

Under steady state conditions, by conservation of mass, the mass flow rate of the dry air and of water (as liquid or vapor) must be the same at inlet and outlet to any system. Therefore, ( )A = ( )B

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

And ( )A + ( )B or (14)

( )B ( )A

The ratio of steam to air () is known of the initial and final state points on the psychometric charts. Therefore, ( )A = ( )B= Therefore, = ( ) (17) and (15) (16)

Say, we re-define the cooling tower system to be as in figure 3 where the process heat and pump work does not cross the boundary of the system. In this case warm water enters the system at point C and cool water leaves at point D.

Figure 3: system B Again from the steady flow energy equation, P=0 may have small value due to heat transfer between the unit and its surroundings.

9

and

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

(18)

Rearranging ( ( ) ) ( ( ) ) (19)

The term

can be neglected.

Characteristics column study In order to study the packing characteristics, we define a finite element of the tower (dz) as shown in Figure 3, the energy balances of water and air stream in the tower are related to the mass transfer by the following equation: Where =specific heat capacity of water =mass flow rate of water per unit plan area of packing =water temperature =mass transfer coefficient =area of contact between air and water per unit volume of packing =volume occupied by packing per unit plan area =difference in specific enthalpy between the saturated boundary layer and the bulk air. ( ) (20)

10

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

Figure 4: schematic representation of the air and water stream entering and leaving a block of packing In this equation, we assume that the boundary layer temperature is equal to the water temperature T and the small change in the mass of water is neglected. Thus from equation 20,

(21)

Integrating equation 21

(22)

The numerical solution to the integral expression equation 22 using Chebyshev numerical method gives,

(23)

Where;

=tower characteristic =value of =value of =value of =value of at at at at ( ( ( ( ) ) ) )

11

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

Thermodynamics state that the heat removed from the water must be equal to the heat absorbed by the surrounding air. Therefore, the following equation is derived: ( Or

( ( ) )

(24)

(25)

Where, =liquid to gas mass flow ratio =cold water temperature =hot water temperature =enthalpy of air-water vapor mixture at exhaust wet-bulb temperature =enthalpy of air-water vapor mixture at inlet wet-bulb temperature

Figure 5: graphical representation of tower characteristics

12

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

The following represent a key to figure 5: BA=initial enthalpy driving force AD=air operating line with slope L/G Referring to equation 22, the tower characteristics could be found by finding the area between ABCD in figure 4. Increasing heat load would have the following effects on the diagram in figure 4: 1. Increase in the length of line CD and a CD line shift to the right 2. Increase in hot and cold water temperature 3. Increase in range and approach areas The increase heat load causes the hot water temperature to increase considerably faster than does the cold water temperature. Although the area ABCD should remain constant, it actually decreases about % for every F increase in hot water temperature above F. to account for this decrease, an adjust hot water temperature is used in cooling tower design. Useful information 1. Orifice Calibration Formula Mass flow rate of air and vapour mixture, ( )

The mass flow rate of dry air, Where, X=orifice differential in =specific volume of air at the outlet =humidity ratio of the mixture ( )

2. Pump work input=80W (0.08kW) 3. Column inner dimension= 150 mm150mm600mm

13

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

APPARATUS:

1 2

3 4

9 8

10

1 2 3 4 5

Orifice Water distributor Packed column Flow meter Receiver tank

6 7

Air blower Differential pressure transmitter 8 Make-up tank 9 Control panel 10 Load tank

14

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

SAFETY PRECAUTION/START-UP/ SHUT-DOWN PROCEDURES: General start-up procedure: 1. The valves are checked properly to ensure that the valves V1 to V6 are closed and V7 is partially opened. 2. The load tank is filled with distilled or deionised water. It is done by first removing the make-up tank and then pouring the water through the opening at the top of the load tank. The make-up tank is replaced onto the load tank and lightly the nuts. The tank is filled with distilled or deionised water. 3. The distilled water or deionised water is added to the wet bulb sensor reservoir to the fullest. 4. All appropriate tubing is connected to the differential pressure sensor. 5. The appropriate cooling tower packing is installed for the experiment. 6. Then, the temperature is set to the set point of temperature controller to 50C. The 1.0kW water heater is switched on and the water is heated up until approximately 40C. 7. The pump is switched on and the control valve V1 is slowly opened and the water flow rate is set to 2.0 LPM. A steady operation is obtained where the water is distributed and flowing uniformly through the packing. 8. The fan damper is fully opened, and then the fan is switched on. The differential pressure sensor is checked whether it is giving reading when the valve manifold is switched to measure the orifice differential pressure. 9. For about 20 minute, the unit is left to run for the float valve to correctly adjust the level in the load tank. The makeup tank is refilled as required. 10. The unit is ready or be use. General shut-down procedure: 1. The heater is switched off and let the water to circulate through the cooling tower system for 3-5 minutes until the water cooled down. 2. The fan is switched off and fully closes the fan damper. 3. The pump and power supply is switch off. 4. Retain the water in reservoir tank for the following experiment. 5. Completely drain off the water from the unit if it is not in used.

15

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

T9.1: END STATE PROPERTIES OF AIR AND STEADY FLOW EQUATIONS

OBJECTIVES: 1. 2. To determined the end state properties of air and water from tables or charts. To determined Energy and mass balances using the steady flow equation on the selected systems. PROCEDURES: 1. The systems under the following conditions are set and stabilizing is allowed for about 15 minutes. Water flow rate Air flow rate Cooling load : 2.0 LPM : Maximum : 1.0 kW

2.

The make-up tank is filled up with distilled water up, the initial water level is recorded and then the stop watch are started.

3. 4.

The make-up water supplies are determined in an interval of 10 minutes. In this 10 minutes interval, a few sets of the measurements (i.e. temperatures (TI-T7), orifice differential pressure (DP1), water flow rate (FT1) and Heater Power (Q1)) are recorded, and then the mean value for calculation and analysis are obtained.

5.

The quantity of makeup water that has been supplied during the time interval are determined by noting the height reduction in the make-up tank.

6.

The observation at different conditions may be repeated, i.e. at different water flow rates, or different air flow rates and with different load.

16

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

RESULT AND DISCUSSIONS: Initial water level Final water level Time interval : __20___cm :___11.9__cm :___10___cm

Packing Density Air Inlet Dry Bulb, T1 Air Inlet Wet Bulb, T2 Air Outlet Dry Bulb, T3 Air Outlet Wet Bulb, T4 Water Inlet Temperatures, T5 Water Outlet Temperatures, T6 Water Make-Up Temperature, T7 Orifice Differential, DP1 Water Flow Rate, FT1 Heater Power, Q1

m-1 C C C C C C C Pa LPM Watt

110 22.1 22.0 23.3 22.6 30.9 22.4 22.9 118.75 1.6 939

Calculation: 1. The make-up rate Water flow rate = 1.6 LPM 1.6 LPM = 0.0016 m3 per minute = 2.67 x 10-5 m3/sec Make-up rate, = FT1 x density of water = 2.67 x 10-5 m3/sec x 1000 kg/m3 = 0.0267 kg/sec

17

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

2. The energy and mass balance

Orifice differential in mm

From the psychometrics chart : Vab= 0.864

Mass flow rate of air and vapour mixture, ( )

The mass flow rate of dry air

The energy balance equation:

may have a small value due to heat transfer between the unit and its surroundings.

18

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

( )

( (

(The term (

can be neglected) ) ( )

= 0.05082kg/s (70.9-66.1) kJ/kg dry air + (0.05174kg/s)( 0.4615kJ/kg.C)(22.4-30.9C) = 0.041 kJ/s DISCUSSION:

(Esther Frederick Uyo - 26237) From the result obtained above, the water flow rate is remained constant at 1.6 LPM throughout the experiment. The result obtained has slightly error due to the human error when handling the cooling tower machine. From the data above, we use the psychometric chart to find enthalpy at given temperature. Hence, we use the energy and mass balance equation to find the energy done of the system per seconds. (Mohd Nur Hilmi bin Sahlan 27011) Based on the result, we know that the water flow rate is constant at 1.6 LPM or 2.67 x 10-5 m3/s. We also obtain the energy flow rate by using the energy and mass balance equation and the enrgy flow rate is = 0.041 kJ/s. In this result also we get the water level drop from 20 cm to 11.9 cm in 10 minutes. But the result has some error due to human error in reading and recording the temperature value.

CONCLUSION: In this experiment, we are asked to find the end state properties of air and water from the tables and psychometric chart. From the data above, we can determine the energy and mass balance using the steady flow equation.

19

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

T9.2: INVESTIGATION OF THE EFFECT OF AIR VELOCITY ON WET BULB APPROACH AND PRESSURE DROP THROUGH THE PACKING OBJECTIVE: To investigate the effect of air velocity on: a) Wet Bulb Approach b) The pressure drop through the packing PROCEDURES: 1. Systems were set under following conditions and stabilizing is allowed for about 15 minutes. Water flow rate: 2.0 LPM Air flow: Maximum Cooling load: 1.0 kW

2. A few sets of measurement (i.e. temperature (T1-T6), orifice differential pressure (DP1), water flow rate (FT1). Heater Power (Q1) and pressure drop across packing (DP2)) is recorded after the system stabilizes, then the mean value for calculation analysis obtained. 3. The test repeated with 3 different sets of orifice pressure drop values (75%, 50% and 25% of the maximum value) without changing the water flow rate and cooling loads. 4. The cross sectional area of the column is measured. 5. The test may repeated: a. At another constant load b. At another constant water flow rate

20

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

RESULT AND DISCUSSIONS:

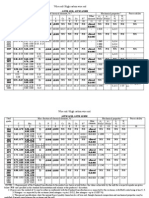

Description Packing Density Air Inlet Dry Bulb, T1 Air Inlet Wet Bulb, T2 Air Oulet Dry Bulb, T3 Air Outlet Wet Bulb, T4 Water Inlet Temperature, T5 Water Outlet Temperature, T6 Orifice Differential, DPI

(when V4 and V5 open)

Unit m-1

o o o o o o

Air Flow 100% 110 22.1 22.1 23.5 23.2 30.8 22.8 118.75 1.6 913 43.75 75% 110 22.4 22.2 23.6 23.2 30.2 23.1 89.00 1.6 911 31.25 50% 110 22.4 22.3 23.6 23.4 30.3 23.3 59.38 1.6 913 25.00 25% 110 22.6 22.4 24.1 23.6 30.5 24.3 29.69 1.6 912 12.50

C C C C C C

Pa LPM Watt Pa

Water Flow Rate, FT1 Heater Power, Q1 Pressure Drop Across Packing, DP2 (when V3 and V6 open)

Calculations: 1. Calculate the normal velocity of air and approach to wet bulb. By taking the data obtained when 100% of air flow was employed: Air inlet wet bulb = 22.1oC Water outlet temperature = 22.8oC Approach to wet bulb = 22.8oC 22.1oC = 0.7 oC Air Outlet Dry Bulb = 23.5oC Specific volume of air at outlet by placing Air Outlet Dry Bulb and Attribute Psychometric Chart = 0.867 m3/kg

21

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

(x = 118.75 Pa X 1 mmH2O / 10.13mmH2O = 11.72 Pa) Mass flow rate,

= 0.05037 kgs-1 Air Volume Flow Rate = = (0.05037 kgs-1)(0.867 m3/kg) = 0.04367 m3/s Cross Sectional Area of empty tower A = 0.15 X 0.15 = 0.0225 m2 Air Velocity,

For 75% of air flow was employed, Va= 0.865 m3/kg (x = 89 Pa X 1 mmH2O / 10.13mmH2O = 8.78 Pa) Mass flow rate,

= 0.04365 kgs-1 Air Volume Flow Rate = = (0.04365 kgs-1)(0.865 m3/kg) = 0.03776 m3/s Cross Sectional Area of empty tower A = 0.15 X 0.15 = 0.0225 m2 Air Velocity,

22

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

For 50% of air flow was employed, Va= 0.864 m3/kg (x = 59.38 Pa X 1 mmH2O / 10.13mmH2O = 5.86 Pa) Mass flow rate,

= 0.03568 kgs-1 Air Volume Flow Rate = = (0.03568 kgs-1)(0.864 m3/kg) = 0.03083 m3/s Cross Sectional Area of empty tower A = 0.15 X 0.15 = 0.0225 m2 Air Velocity,

For 25% of air flow was employed, Va= 0.868 m3/kg (x = 29.69 Pa X 1 mmH2O / 10.13mmH2O = 2.93Pa) Mass flow rate,

= 0.02517 kgs-1 Air Volume Flow Rate = = (0.02517 kgs-1)(0.868 m3/kg) = 0.02185 m3/s

23

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

Cross Sectional Area of empty tower A = 0.15 X 0.15 = 0.0225 m2 Air Velocity,

Air Flow Nominal Velocity, m/s Approach to Wet Bulb, K Packing Pressure Drop , Pa

100% 1.94 273.7 43.75

75% 1.68 273.9 31.25

50% 1.37 274.0 25.00

25% 0.97 274.9 12.50

Graph 2.1

Approach to wet bulb against norminal velocity

275 0.97, 274.9 Approach to wet bulb (K) 274.8 274.6 274.4 274.2 274 273.8 1.94, 273.7 273.6 0 0.5 1 1.5 2 2.5 Norminal velocity (m/s) 1.37, 274 1.68, 273.9

24

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

Graph 2.2

Packing pressure drop against norminal velocity

50 45 40 35 30 25 20 15 10 5 0 0 0.5 1 Packing Pressure Drop (Pa) 1.94, 43.75

1.68, 31.25 1.37, 25 Y-Values 0.97, 12.5

1.5

2.5

Norminal velocity (m/s)

DISCUSSION: (Esther Frederick Uyo 26237) From this experiment, we can find out the influence of air flow with the temperature of the air and water and the pressure drop across packaging. The air flow is represented by the nominal velocity. The pressure drop across the packing increases with the increasing in the nominal velocity of the air. However, there is some error of value in the temperature obtained due to the human error. This causing there are some errors result obtained in the wet bulb approach. (Mohd Nur Hilmi bin Sahlan 27011) Based on the graph, we know that the nominal velocity or air flow velocity will affect the temperature on wet bulb approach and the pressure drop through the packing. The higher the air flow velocity, the temperature will drop and the pressure will increase. In this result also we did have slightly error in recording the temperature that will affect the temperature in wet bulb approach due to human error.

25

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

CONCLUSION: In this experiment, we are to find the effect of air velocity to the wet bulb approach and the pressure drop through the packing. When the air flow is high, the greater the pressure drops through the packing. While the wet bulb approach decreases with the increasing in the nominal velocity of air.

26

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

T9.3: INVESTIGATING OF THE RELATIONSHIP BETWEEN COOLING LOAD AND COOLING RANGE OBJECTIVE: To investigate the relationship between cooling load and cooling range PROCEDURE: 1. The system is set under the following conditions and allowed stabilizing for about 15 minutes:

Water flow rate Air flow rate Cooling load

: 2.0 LPM : Maximum : 0.0kW

2. After the system stabilized, a few sets of measurements [i.e. temperature (T1-T6), orifice differential pressure (DPI), water flow rate (FT1) and heater power (Q1)] are recorded, the mean value then obtained for calculation and analysis. 3. Without changes in the condition, the cooling load increased to 0.5kW. When the system stabilized, all data are recorded. 4. The experiment is repeated at 1.0kW and 1.5kW. 5. The test may be repeated: i. ii. At other water flow rates At other air flow rate

27

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

RESULT AND DISCUSSIONS: Description Packing Density Air Inlet Dry Bulb, T1 Air Inlet Wet Bulb, T2 Air Outlet Dry Bulb, T3 Air Outlet Web Bulb, T4 Water Inlet Temperature, T5 Water Outlet Temperature, T6 Orifice Differential, DP1 Water Flow Rate, FT1 Heater Power, Q1 Unit m-1 o c o c o c o c o c o c Pa LPM Watt 0.0kW 110 21.9 21.8 20.1 20.1 20.3 19.1 119.5 1.6 0 0.5kW 110 21.9 21.7 19.9 19.9 19.9 18.8 119.5 1.6 463 1.0kW 110 21.7 21.8 20.0 19.9 21.8 19.1 119.5 1.6 925 1.5kW 110 22.0 21.8 20.8 20.4 25.0 20.1 119.5 1.6 1390

Cooling Load (kW) 0.0 0.5 1.0 1.5

Cooling range (oc) 20.3 19.1 19.9 18.8 21.8 19.1 25.0 20.1

Average cooling temperature (oc) 1.2 1.1 2.7 4.9

cooling range against cooling load

6 5 coolong range (oc) 4 3 2 1 0 0 0.2 0.4 0.6 0.8 cooling load (oc) 1 1.2 1.4 1.6 0, 1.2 0.5, 1.1 1.5, 4.9

1, 2.7

28

KNJ 2251 Mechanical and Manufacturing Engineering Laboratory 3 Faculty of Engineering University Malaysia Sarawak

DISCUSSION: (Esther Frederick Uyo 26237) We can clearly obtain the explanation by observing the graph above. The cooling range is influence by the cooling load. The greater the cooling loads, the greater the cooling range of the tower. There are some slightly error in the cooling range obtained, this is due to the human error handling and obtain the data from the cooling tower machine. (Mohd Nur Hilmi bin Sahlan 27011) From the graph obtained, we can see that cooling load will affect the cooling range. If we increase the cooling load, the cooling range will also increase. However, the graph shows a slightly drop in cooling range at the beginning and increase after that. This is once again due to the error in recording the temperature. CONCLUSION: We can found out the relationship of cooling range and cooling load from this experiment. The cooling range increases with the increasing in the cooling load.

OVERALL SUMMARY: Bench top cooling tower is used to study the performance of a cooling tower. From this experiment, we obtained the entire desired objective. We use the psychometric chart, properties table, energy and mass balance equation to solve the entire question given in this experiment. Through this experiment, we can verify the effect of the following factor on the performance of the cooling tower: 1. Water flow rates 2. Water temperature 3. Air flow rate 4. Inlet air relative humidity

29

S-ar putea să vă placă și

- Fe Exam Review BookDocument1.229 paginiFe Exam Review BookDeneme Dedeoğlu98% (50)

- APT300S Tutorial - RefrigerationDocument2 paginiAPT300S Tutorial - Refrigerationcarleston thurgood0% (1)

- Cooling Tower Design Part I PDFDocument9 paginiCooling Tower Design Part I PDFVictor AugelloÎncă nu există evaluări

- HEAT BALANCE OF COOLING WATER SYSTEM CALCULATION 冷却水系统热平衡计算书 REV 0Document4 paginiHEAT BALANCE OF COOLING WATER SYSTEM CALCULATION 冷却水系统热平衡计算书 REV 0rudiawanÎncă nu există evaluări

- CSTRDocument20 paginiCSTRSharing Caring100% (1)

- CH 7 PowerCyclesDocument12 paginiCH 7 PowerCyclescarleston thurgoodÎncă nu există evaluări

- Heat Exchanger Sample Report 2018Document55 paginiHeat Exchanger Sample Report 2018RahulSrivastava100% (1)

- Weekly Industrial Training Report Mohd Izzat - Week 1Document3 paginiWeekly Industrial Training Report Mohd Izzat - Week 1Izzat FakhriÎncă nu există evaluări

- Effect of Temperature and pH on Salivary Amylase ActivityDocument11 paginiEffect of Temperature and pH on Salivary Amylase ActivityAmberValentineÎncă nu există evaluări

- Cooling Tower PDFDocument7 paginiCooling Tower PDFShahid HussainÎncă nu există evaluări

- Effective Thermal Design of Cooling TowersDocument13 paginiEffective Thermal Design of Cooling TowersKarthick VelayuthamÎncă nu există evaluări

- Colling Tower: Mechanical Lab / Exp. NO.Document10 paginiColling Tower: Mechanical Lab / Exp. NO.Dalal Salih100% (1)

- Experiment 7 Cooling TowerDocument9 paginiExperiment 7 Cooling TowerRicky Jay0% (1)

- Lab Report 1 Tray DrierDocument7 paginiLab Report 1 Tray Drier_never_mind_100% (1)

- Cooling TowersDocument16 paginiCooling TowersAhmed GadÎncă nu există evaluări

- Cooling Tower Report PDFDocument49 paginiCooling Tower Report PDFSyed Waqas HussainÎncă nu există evaluări

- Cooling TowerDocument12 paginiCooling TowerLillianLinÎncă nu există evaluări

- Thermal Performance Assessment of Steam Surface CondenserDocument8 paginiThermal Performance Assessment of Steam Surface CondenserJeeEianYannÎncă nu există evaluări

- L6 Cooling Tower PDFDocument58 paginiL6 Cooling Tower PDFharris100% (1)

- Exp. 5 Heat Transfer Study On Plate Heat ExchangerDocument6 paginiExp. 5 Heat Transfer Study On Plate Heat ExchangerElaine PuiÎncă nu există evaluări

- Cooling TowerDocument28 paginiCooling TowerKangae Ilham100% (4)

- Cooling Tower ReportDocument11 paginiCooling Tower Reportbae zazÎncă nu există evaluări

- Thermal Vapor RecompressionDocument2 paginiThermal Vapor Recompressionmohammad shoaib0% (2)

- Brentwood Technical Papers Thermal PerformanceDocument28 paginiBrentwood Technical Papers Thermal PerformanceWalter J Naspirán Castañeda100% (1)

- Single Effect Evaporation (SEE) ProcessesDocument28 paginiSingle Effect Evaporation (SEE) ProcessesAl- Dhaheri0% (1)

- Cooling TowerDocument18 paginiCooling TowerSalehAfadlehÎncă nu există evaluări

- CT Performance Study & Enhancement at Jindal Steel Power PlantDocument25 paginiCT Performance Study & Enhancement at Jindal Steel Power PlantSuhail A MansooriÎncă nu există evaluări

- Cooling Tower PDFDocument3 paginiCooling Tower PDFmaimslapÎncă nu există evaluări

- Evaporator Types and ApplicationsDocument54 paginiEvaporator Types and ApplicationsakusuperÎncă nu există evaluări

- Cooling TowerDocument8 paginiCooling TowerMohammed IhsanÎncă nu există evaluări

- Vapor-Compression Refrigeration SystemsDocument28 paginiVapor-Compression Refrigeration Systemsm_alodat6144Încă nu există evaluări

- Cooling Tower1Document66 paginiCooling Tower1Er Bali Pandhare100% (1)

- Design of Cooling TowerDocument17 paginiDesign of Cooling TowerMohan VarkeyÎncă nu există evaluări

- 42-Single Effect Evaporator-21-May-2021Material I 21-May-2021 Single Effect EvaporatorDocument8 pagini42-Single Effect Evaporator-21-May-2021Material I 21-May-2021 Single Effect EvaporatorAbhishek KarpeÎncă nu există evaluări

- First Law of ThermodynamicsDocument50 paginiFirst Law of ThermodynamicsRohit Singh LatherÎncă nu există evaluări

- Condenser, Reboiler and Evaporator: Dr. Rakesh KumarDocument70 paginiCondenser, Reboiler and Evaporator: Dr. Rakesh KumarAbhimanyu SinghÎncă nu există evaluări

- Packed Bed FermentersDocument20 paginiPacked Bed FermentersGerald Owen FranzaÎncă nu există evaluări

- Multiple Effect EvaporatorDocument5 paginiMultiple Effect EvaporatorRhea MambaÎncă nu există evaluări

- Cooling Towers PDFDocument60 paginiCooling Towers PDFRamakrishnaÎncă nu există evaluări

- 181CTDCHA2 - Learning Unit 1BDocument64 pagini181CTDCHA2 - Learning Unit 1BESTHER TSAKANE MONKWEÎncă nu există evaluări

- Distillation Tower DesignDocument65 paginiDistillation Tower DesignAntonio SilvaÎncă nu există evaluări

- Heat Exchanger Lab Report FinalDocument22 paginiHeat Exchanger Lab Report FinalAliyu AbdulqadirÎncă nu există evaluări

- Optimization of Cooling TowersDocument49 paginiOptimization of Cooling TowersKhalil LasferÎncă nu există evaluări

- Cooling TowerDocument23 paginiCooling TowerHasan Farooq100% (1)

- Evaporation Technolgy Mechanical Vapour Recompression - GEA - Wiegand - enDocument24 paginiEvaporation Technolgy Mechanical Vapour Recompression - GEA - Wiegand - enhardik033Încă nu există evaluări

- Cooling Tower Heat and MassDocument18 paginiCooling Tower Heat and MassChris Mark100% (2)

- Air Properties-Psycometric ChartsDocument6 paginiAir Properties-Psycometric Chartsa_j_sanyal259Încă nu există evaluări

- Psychrometric Chart HumidificationDocument26 paginiPsychrometric Chart HumidificationOky TresiaÎncă nu există evaluări

- Absorption Lecture Note - DR Akinsiku PDFDocument7 paginiAbsorption Lecture Note - DR Akinsiku PDFGlory UsoroÎncă nu există evaluări

- Evap DesignDocument16 paginiEvap DesignAhmed Ali100% (3)

- Heat and Mass TransferDocument23 paginiHeat and Mass TransferMaria Cecille Sarmiento GarciaÎncă nu există evaluări

- RI Vs Composition Methanol-Water MixtureDocument12 paginiRI Vs Composition Methanol-Water MixtureAnonymous VeJYFSMWLIÎncă nu există evaluări

- Gas Absorption: Determining Drag and Flooding FlowsDocument5 paginiGas Absorption: Determining Drag and Flooding FlowsDean Joyce AlborotoÎncă nu există evaluări

- CPB30004 Process Dynamics and Control Experiment 5: Heat Exchanger Process Control Lab ReportDocument24 paginiCPB30004 Process Dynamics and Control Experiment 5: Heat Exchanger Process Control Lab ReportSiti Hajar Mohamed100% (1)

- Al Duri Tutorial1 AbsorptionDocument2 paginiAl Duri Tutorial1 AbsorptionJia YiÎncă nu există evaluări

- Cooling Tower ReportDocument27 paginiCooling Tower ReportWengLiLeongÎncă nu există evaluări

- Practical Chemical Thermodynamics for GeoscientistsDe la EverandPractical Chemical Thermodynamics for GeoscientistsÎncă nu există evaluări

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4De la EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Evaluare: 5 din 5 stele5/5 (1)

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7De la EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Încă nu există evaluări

- Lab 2-Water Cooling TowerDocument31 paginiLab 2-Water Cooling Towerriniz92100% (4)

- ERT 318/4 Unit Operations SEMESTER 1 (2013/2014) : Water Cooling TowerDocument18 paginiERT 318/4 Unit Operations SEMESTER 1 (2013/2014) : Water Cooling TowerNorzaifee NizamudinÎncă nu există evaluări

- Coolingtower With Tabulation PDFDocument6 paginiCoolingtower With Tabulation PDFsankarsuper83Încă nu există evaluări

- Cooling Tower LabDocument24 paginiCooling Tower LabEmily SwanÎncă nu există evaluări

- Expected ResultDocument5 paginiExpected ResultIzzat FakhriÎncă nu există evaluări

- Result Sem 7Document1 paginăResult Sem 7Izzat FakhriÎncă nu există evaluări

- Variable Raincoat ChecklistDocument1 paginăVariable Raincoat ChecklistIzzat FakhriÎncă nu există evaluări

- Assingment #5 ManuDocument5 paginiAssingment #5 ManuIzzat FakhriÎncă nu există evaluări

- Facilty Layout Planning NewDocument68 paginiFacilty Layout Planning NewRogil Jacob DanielÎncă nu există evaluări

- Name: Muhammad Izzat Fakhri B. Sulaiman Department: Engineering SlicingDocument7 paginiName: Muhammad Izzat Fakhri B. Sulaiman Department: Engineering SlicingIzzat FakhriÎncă nu există evaluări

- Idp Literature ReviewDocument12 paginiIdp Literature ReviewIzzat FakhriÎncă nu există evaluări

- WheelDocument44 paginiWheelIzzat FakhriÎncă nu există evaluări

- Design and Fabrication A Prototype Machine For Speed Up The White Pepper Production Using Enzymes SolutionDocument8 paginiDesign and Fabrication A Prototype Machine For Speed Up The White Pepper Production Using Enzymes SolutionIzzat FakhriÎncă nu există evaluări

- For Orifice Diameter (MM) 13.0Document4 paginiFor Orifice Diameter (MM) 13.0Izzat FakhriÎncă nu există evaluări

- Plant Vs ZombiesDocument1 paginăPlant Vs ZombiesIzzat FakhriÎncă nu există evaluări

- Results Exp 9Document8 paginiResults Exp 9Izzat FakhriÎncă nu există evaluări

- Do Not Left Demount Tank Floor Getting Wet. Always Mop The Floor To Ensure Floor Dry All The TimesDocument1 paginăDo Not Left Demount Tank Floor Getting Wet. Always Mop The Floor To Ensure Floor Dry All The TimesIzzat FakhriÎncă nu există evaluări

- Report FormatDocument1 paginăReport Formattechsupport_50218591Încă nu există evaluări

- Front 64mm 213mm: WIRESAW025: High Sawmark Reject RR146A21-New Web RR146A52 RR146A41 Corner EdgeDocument16 paginiFront 64mm 213mm: WIRESAW025: High Sawmark Reject RR146A21-New Web RR146A52 RR146A41 Corner EdgeIzzat FakhriÎncă nu există evaluări

- Format Internship Weekly Report - Aug 20Document7 paginiFormat Internship Weekly Report - Aug 20Izzat FakhriÎncă nu există evaluări

- Format Internship Weekly Report - Aug 13 2012Document7 paginiFormat Internship Weekly Report - Aug 13 2012Izzat FakhriÎncă nu există evaluări

- Chapter 1Document27 paginiChapter 1Izzat FakhriÎncă nu există evaluări

- Wire Reduction Optimization PresentationDocument18 paginiWire Reduction Optimization PresentationIzzat FakhriÎncă nu există evaluări

- Wire Saw Wire Reduction PRESENTATION Optimization TestDocument18 paginiWire Saw Wire Reduction PRESENTATION Optimization TestIzzat FakhriÎncă nu există evaluări

- Chapter 4 Part 1Document37 paginiChapter 4 Part 1Izzat FakhriÎncă nu există evaluări

- 7 Wonders PhenomenalDocument7 pagini7 Wonders PhenomenalIzzat FakhriÎncă nu există evaluări

- Lecture Week 9-Vision System For Robotics and AutomationDocument16 paginiLecture Week 9-Vision System For Robotics and AutomationIzzat FakhriÎncă nu există evaluări

- Numerical IntegrationDocument36 paginiNumerical IntegrationIzzat FakhriÎncă nu există evaluări

- Week 1 Introduction To Differential Equations: KNF1023 Engineering Mathematics IIDocument34 paginiWeek 1 Introduction To Differential Equations: KNF1023 Engineering Mathematics IIIzzat FakhriÎncă nu există evaluări

- Ans No. 4-Conservation of Mass Equation-: + Known As Continuity EquationDocument4 paginiAns No. 4-Conservation of Mass Equation-: + Known As Continuity EquationHimanshu TrivediÎncă nu există evaluări

- Phytochemical and antioxidant potential of Martynia annua fruit oilDocument7 paginiPhytochemical and antioxidant potential of Martynia annua fruit oilRam SahuÎncă nu există evaluări

- Gas Welding (Oxy-Acetylene)Document20 paginiGas Welding (Oxy-Acetylene)Muhammad Ali BakhtÎncă nu există evaluări

- Polyurea Resistance ChartDocument1 paginăPolyurea Resistance ChartTanmay GorÎncă nu există evaluări

- Measuring errors and their classificationDocument6 paginiMeasuring errors and their classificationNarendra Reddy0% (1)

- College Physics 7th Ed Serway Chapter 11Document30 paginiCollege Physics 7th Ed Serway Chapter 11Jorge GomezÎncă nu există evaluări

- Reinforced Concrete Column Design QuestionsDocument4 paginiReinforced Concrete Column Design QuestionssrikanthÎncă nu există evaluări

- 1400 10MDocument5 pagini1400 10MAngelia WileyÎncă nu există evaluări

- Experiment No. 1 Rockwell Hardness Group 1 Final - PaperDocument3 paginiExperiment No. 1 Rockwell Hardness Group 1 Final - PaperThomas Jefferson AntonioÎncă nu există evaluări

- M20Document54 paginiM20Mijail Pérez Miranda100% (1)

- ReaPan 34G 38G ReagentDocument2 paginiReaPan 34G 38G ReagentReaMetrixÎncă nu există evaluări

- Mnemonics ExampleDocument10 paginiMnemonics ExampleArchana PattnaikÎncă nu există evaluări

- Molar Mass, Moles, and Avogadro's Number ExplainedDocument5 paginiMolar Mass, Moles, and Avogadro's Number ExplainedMegan CabahugÎncă nu există evaluări

- Concrete Repair and Protection System1 - CeresitDocument12 paginiConcrete Repair and Protection System1 - CeresitJill Jim LivestockÎncă nu există evaluări

- Global Warming TextsDocument3 paginiGlobal Warming TextsAnonymous NbKeZIGDVMÎncă nu există evaluări

- Microbiology Exam QuestionsDocument23 paginiMicrobiology Exam Questionswhitewave25Încă nu există evaluări

- Iron Sulfides - Effect On Amine PlantsDocument6 paginiIron Sulfides - Effect On Amine PlantsHsien Yu100% (1)

- Lighting Techniques TVDocument29 paginiLighting Techniques TVMireya FernandezÎncă nu există evaluări

- Crude Oil Tank Mixer Data SheetDocument3 paginiCrude Oil Tank Mixer Data Sheetsiska bedegul100% (1)

- High Carbon Wire RodDocument9 paginiHigh Carbon Wire Rodninganray6316100% (1)

- UTM Arau Prepares 4-BromobenzophenoneDocument7 paginiUTM Arau Prepares 4-BromobenzophenoneMay Lee100% (1)

- Clean Light-Colored Bricks SafelyDocument1 paginăClean Light-Colored Bricks SafelymutazsalihÎncă nu există evaluări

- Establishing Scientifically Justified Acceptance Criteria For The Cleaning Validation of Apis (Active Pharmaceutical Ingredients) (Le Blanc)Document6 paginiEstablishing Scientifically Justified Acceptance Criteria For The Cleaning Validation of Apis (Active Pharmaceutical Ingredients) (Le Blanc)jorgeÎncă nu există evaluări

- API 2H Grade 50 Steel Plate SpecificationDocument3 paginiAPI 2H Grade 50 Steel Plate SpecificationJym GensonÎncă nu există evaluări

- Cyliani's Hermes UnveiledDocument31 paginiCyliani's Hermes UnveiledAndre Bambu100% (2)

- TSR81 Standard Single Screw Extruder Start Up-Shutdown and Emergency Shutdown ProceduresDocument4 paginiTSR81 Standard Single Screw Extruder Start Up-Shutdown and Emergency Shutdown ProceduresahumairÎncă nu există evaluări

- Polyaldo PolyglycerolEsters SLSDocument8 paginiPolyaldo PolyglycerolEsters SLSSantos GarciaÎncă nu există evaluări

- Complementary Commutation by AshakoorDocument16 paginiComplementary Commutation by AshakoorSobi100% (2)