Documente Academic

Documente Profesional

Documente Cultură

Breakdown in Solid Dielectrics

Încărcat de

RohinigpTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Breakdown in Solid Dielectrics

Încărcat de

RohinigpDrepturi de autor:

Formate disponibile

ELECTRO CHEMICAL BREAKDOWN

In presence of air and other gases some dielectric materials undergo chemical changes when subjected to continuous electrical stresses. Some of the important chemical reactions that occur are

Oxidation Hydrolysis Chemical action

OXIDATION

In presence of air or oxygen, materials such as rubber and polyethylene undergo oxidation giving rise to surface cracks.

HYDROLYSIS

When moisture or water vapour is present on the surface of a solid dielectric, hydrolysis occurs and materials lose their electrical and mechanical properties. Electrical properties of materials such as paper, cotton tape and other cellulose materials deteriorate very rapidly due to hydrolysis. Plastics like polyethylene undergo changes and their service life considerably reduces.

CHEMICAL ACTION

Even in absence of electric fields, progressive chemical degradation of insulating materials can occur due to

Since different insulating materials come into contact with each other in many practical apparatus, chemical reactions can occur between these various materials leading to reduction in electrical and mechanical strength resulting in failure.

Chemical instability at high temperatures Oxidation and cracking in presence of ozone and Hydrolysis due to moisture and heat

The effects of electrochemical and chemical deterioration could be minimized by carefully studying and examining the materials. High soda content glass insulation should be avoided in moist and damp conditions, because sodium, being very mobile, leaches to the surface giving rise to the formation of a strong alkali which will cause deterioration.

It was observed that this type of material will lose its mechanical strength within 24 hrs, when it is exposed to atmospheres having 100 % relative humidity at 70 0 C. In paper insulation, even if partial discharges are prevented completely, breakdown can occur due to chemical degradation. Chemical and electrochemical deterioration increases very rapidly with temperature and hence high temperatures should be avoided.

BREAKDOWN DUE TO TREEING AND TRACKING

These are breakdowns which occur after prolonged operation. When a solid dielectric subjected to electrical stresses for a long time fails ,normally two kinds of visible markings are observed on the dielectric materials. They are

The presence of conducting path across the surface of the insulation; mechanism whereby leakage current passes through the conducting path finally leading to the formation of a spark. Insulation deterioration occurs as a result of these sparks.

Tracking is the formation of a continuous conducting paths across the surface of insulation mainly due to surface erosion under voltage application. The spreading of spark channels during tracking in the form of branches of a tree is called treeing. While in use the insulator progressively gets coated with moisture that causes increased conduction leading to the formation of surface tracks.

Consider a system of solid dielectric having a conducting film and two electrodes on its surface . In practice, conducting film very often is formed due to moisture. On application of voltage, the film starts conducting, resulting in the generation of heat and surface starts becoming dry. The conducting film becomes separate due to drying and so sparks are drawn damaging the dielectric surface.

With organic insulating materials such as paper and bakelite, the dielectric carbonizes at the region of sparking, and the carbonized region act as permanent conducting channels resulting in increased stress over the rest of region. This is a cumulative process and insulation failure occurs when carbonized tracks bridge the distance between the electrodes. This phenomenon called tracking is common between layers of bakelite, paper and similar dielectrics built of laminates.

Treeing occurs due to erosion of material at the tips of the spark. Erosion results in roughening of the surfaces and hence becomes a source of dirt and contamination. This causes increased conductivity resulting either in the formation of a conducting path bridging the electrodes or in a mechanical failure of the dielectric.

r V1

1 d1

d2

d2

V2

When a dielectric material lies between two electrodes, there is a possibility for two different dielectric media, the air and the dielectric to come in series. The voltage across the two media are V1 across the air gap, and V2 across the dielectric. The voltage V1 across the air gap is V1 = Vd1/[d1+(1/ 2)d2]

Since 1>2, most of the voltage appears across d1, the air gap. Sparking will occur in the air gap and charge accumulation takes place on the surface of insulation. Sometimes spark erodes the surface of the insulation. As time passes breakdown channels spread through the insulation in an irregular tree like fashion leading to the formation of conducting channels. This kind of channeling is called treeing.

Under a.c. voltage conditions, treeing can occur in a few minutes or several hours. Hence care must be taken to see that no series air gaps or other weaker insulation gaps are formed. Usually tracking occurs even at very low voltages of the order of about 100 V, whereas treeing requires high voltage.

Treeing can be prevented by having clean, dry and undamaged surfaces and a clean environment. The materials chosen should be resistant to tracking. Sometimes moisture repellant gases are used. But this needs frequent cleaning and regreasing.

S-ar putea să vă placă și

- Busbar Protection TheoryDocument13 paginiBusbar Protection TheoryDEADMANÎncă nu există evaluări

- Knowledge is "Real Power": Introduction to Power QualityDe la EverandKnowledge is "Real Power": Introduction to Power QualityÎncă nu există evaluări

- BYK AdditivesDocument15 paginiBYK Additivestahera aqeelÎncă nu există evaluări

- Upptcl Training (Ee)Document27 paginiUpptcl Training (Ee)AakashÎncă nu există evaluări

- Triplex HarmonicsDocument4 paginiTriplex HarmonicsMounikaÎncă nu există evaluări

- Electrical InstallationsDocument48 paginiElectrical InstallationsSyed Muzammil AliÎncă nu există evaluări

- A Presentation ON Overhead Line Insulators Faculty: Gunjan VarshneyDocument67 paginiA Presentation ON Overhead Line Insulators Faculty: Gunjan VarshneyGunjan VarshneyÎncă nu există evaluări

- Earthing Transformers For Power SystemsDocument12 paginiEarthing Transformers For Power SystemsArunabh BhattacharyaÎncă nu există evaluări

- CORONA ch5Document14 paginiCORONA ch5yaredÎncă nu există evaluări

- Ferroresonance Suppression in Voltage TransformersDocument6 paginiFerroresonance Suppression in Voltage TransformersmmshtÎncă nu există evaluări

- Metrosil Relays Datasheet PDFDocument4 paginiMetrosil Relays Datasheet PDFBaskaran Gangatharan100% (1)

- Calculation of Heat and Mass BalanceDocument18 paginiCalculation of Heat and Mass BalanceJitendra Bhatia100% (3)

- Stoichiometry Notes KEYDocument17 paginiStoichiometry Notes KEYOnofre Algara Jr.Încă nu există evaluări

- La PresentationDocument15 paginiLa Presentationsandeepg_patil14Încă nu există evaluări

- Power System TransientsDocument11 paginiPower System TransientsKhairul AshrafÎncă nu există evaluări

- TOR-WG+B1 38+After+laying+tests+on+AC+and+DC+cable+systems+with+new+technologiesDocument2 paginiTOR-WG+B1 38+After+laying+tests+on+AC+and+DC+cable+systems+with+new+technologiesWalter CataldoÎncă nu există evaluări

- Using Core-Balance Current Transformer For Earth Fault Protection - EEPDocument2 paginiUsing Core-Balance Current Transformer For Earth Fault Protection - EEPcatalinccÎncă nu există evaluări

- Floating Neutral Impact in Power DistributionDocument9 paginiFloating Neutral Impact in Power DistributionSugeng SumarnoÎncă nu există evaluări

- Oal Ed Ethahne: Prof. P. K. SinghDocument67 paginiOal Ed Ethahne: Prof. P. K. SinghViplove RajurkarÎncă nu există evaluări

- Module 5 What Is MatterDocument29 paginiModule 5 What Is MatterDemee ResulgaÎncă nu există evaluări

- Lightning AnalysisDocument21 paginiLightning AnalysisDanialMdNoorÎncă nu există evaluări

- Generac - Gen Insulation ClassDocument4 paginiGenerac - Gen Insulation Class6609503100% (1)

- Real-Time Simulation Technology for Modern Power ElectronicsDe la EverandReal-Time Simulation Technology for Modern Power ElectronicsÎncă nu există evaluări

- Atmospheric Crude Distillation UnitDocument2 paginiAtmospheric Crude Distillation UnitFahmi Ramadhan PutraÎncă nu există evaluări

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsDe la EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsÎncă nu există evaluări

- Transmission & DistributionDocument109 paginiTransmission & Distributionsurya892Încă nu există evaluări

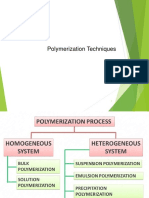

- Polymerisation Practice TEPEDocument39 paginiPolymerisation Practice TEPEDr. Dure Najaf Iqbal100% (3)

- Introduction to EMT Simulations - Mathematical Background and Common ApplicationsDocument32 paginiIntroduction to EMT Simulations - Mathematical Background and Common ApplicationsDaniel PrataÎncă nu există evaluări

- Practical Considerations in Surge Protection ArrestersDocument15 paginiPractical Considerations in Surge Protection ArrestersEl Comedor BenedictÎncă nu există evaluări

- Early Radio Receivers, Called Crystal Radios, Used A "Cat's Whisker" of Fine Wire Pressing On A Crystal ofDocument4 paginiEarly Radio Receivers, Called Crystal Radios, Used A "Cat's Whisker" of Fine Wire Pressing On A Crystal ofPoonam bhavsarÎncă nu există evaluări

- Voltage and Frequency ControlDocument12 paginiVoltage and Frequency ControlKhawarAminÎncă nu există evaluări

- Chapter Four: Relay CoodinationDocument25 paginiChapter Four: Relay Coodinationmuaz_aminu1422Încă nu există evaluări

- HVDC TransmissionDocument16 paginiHVDC TransmissionAritra ChatterjeeÎncă nu există evaluări

- Second Law Analysis of Waste Heat Recovery Power GenerationDocument9 paginiSecond Law Analysis of Waste Heat Recovery Power Generationyahska1305Încă nu există evaluări

- Lightning Model For HVDC Transmission Lines: M. You, B. H. Zhang, L. Y. Cheng, Z. Q. Bo, A. KlimekDocument5 paginiLightning Model For HVDC Transmission Lines: M. You, B. H. Zhang, L. Y. Cheng, Z. Q. Bo, A. Klimekqais652002Încă nu există evaluări

- Losses in TransformerDocument15 paginiLosses in TransformerAnkit SrivastavaÎncă nu există evaluări

- VT Guard Pro Protects VTs from Harmful Ferroresonance EffectsDocument4 paginiVT Guard Pro Protects VTs from Harmful Ferroresonance EffectsAdemir DzanicÎncă nu există evaluări

- 2-Charge Formation in Clouds-1Document26 pagini2-Charge Formation in Clouds-1Gokulraja GokulÎncă nu există evaluări

- Cable Layout and System Design (High Voltage XLPE Cable Systems Techincal User Guide) 13-09-17Document6 paginiCable Layout and System Design (High Voltage XLPE Cable Systems Techincal User Guide) 13-09-17anamulk-1Încă nu există evaluări

- 12 - Chapter 3Document102 pagini12 - Chapter 3Chaitanya Deshpande100% (1)

- Impulse GeneratorDocument3 paginiImpulse GeneratorTanmay RajeÎncă nu există evaluări

- Voltage Control and Power Factor Improvement TechniquesDocument24 paginiVoltage Control and Power Factor Improvement Techniquesrv_andeÎncă nu există evaluări

- TransformerDocument9 paginiTransformerSamPolancosÎncă nu există evaluări

- High Voltage Engineering Module 1Document34 paginiHigh Voltage Engineering Module 1Aafaq AltafÎncă nu există evaluări

- 1vga671048 - Internal Arc Containment, Resistance and Arc Flash MitigationDocument6 pagini1vga671048 - Internal Arc Containment, Resistance and Arc Flash MitigationdienlangchuÎncă nu există evaluări

- Lecture-3: EE 407 Renewable Electrical Energy ResourcesDocument34 paginiLecture-3: EE 407 Renewable Electrical Energy ResourcesjameelahmadÎncă nu există evaluări

- EENG611-10-Chapter 13Document17 paginiEENG611-10-Chapter 13bazzazÎncă nu există evaluări

- Module 4: Substation Equipment's Details and Operations: July 2021Document14 paginiModule 4: Substation Equipment's Details and Operations: July 2021Gundeboyina GopiÎncă nu există evaluări

- Test Circuit ParametersDocument5 paginiTest Circuit ParametersSamsudin Ahmad100% (1)

- Maintenance On Rotating MachinesDocument8 paginiMaintenance On Rotating MachinesMario ArmelaoÎncă nu există evaluări

- Introduction To Power Systems: (ECEG-3154)Document14 paginiIntroduction To Power Systems: (ECEG-3154)Tsega Solomon KidaneÎncă nu există evaluări

- Chapter05 - Temporary Overvoltages Analysis PDFDocument19 paginiChapter05 - Temporary Overvoltages Analysis PDFEleazar Sierra Espinoza100% (1)

- Kelvin LawDocument6 paginiKelvin LawAbdul AlimÎncă nu există evaluări

- Current Chopping Resistance Switching EtcDocument12 paginiCurrent Chopping Resistance Switching EtcSuneel Kumar MauryaÎncă nu există evaluări

- Insulators: Properties, Types and EfficiencyDocument18 paginiInsulators: Properties, Types and EfficiencyGurpreet UppalÎncă nu există evaluări

- CRGODocument15 paginiCRGOipraoÎncă nu există evaluări

- Fast Methods For Transient Stability Prediction in Power SystemsDocument20 paginiFast Methods For Transient Stability Prediction in Power SystemslisusedÎncă nu există evaluări

- Earthing & Equi Potential BondingDocument27 paginiEarthing & Equi Potential BondingSDE BSS KollamÎncă nu există evaluări

- Shubham SeminarDocument19 paginiShubham SeminarShubham BodadeÎncă nu există evaluări

- Earthing Is AbstractDocument3 paginiEarthing Is AbstractShrikant KajaleÎncă nu există evaluări

- Arc Phenomena and Method of Arc Extinction in Air Circuit Breaker PDFDocument4 paginiArc Phenomena and Method of Arc Extinction in Air Circuit Breaker PDFHANRI ,Încă nu există evaluări

- High Voltage Engineering: Causes of Over Voltage in Power SystemDocument8 paginiHigh Voltage Engineering: Causes of Over Voltage in Power SystemMohammed Sabeel KinggÎncă nu există evaluări

- Liquid DielectricsDocument11 paginiLiquid DielectricsPrakash ParajuliÎncă nu există evaluări

- Investigation On Dielectric Failure of High Voltage Equipment in Substation Caused by Capacitor Bank SwitchingDocument12 paginiInvestigation On Dielectric Failure of High Voltage Equipment in Substation Caused by Capacitor Bank Switchingeeng8124Încă nu există evaluări

- EE458Document36 paginiEE458ArishaÎncă nu există evaluări

- DC Cables AnalysisDocument21 paginiDC Cables AnalysisOm SaxenaÎncă nu există evaluări

- Symmetrical FaultDocument54 paginiSymmetrical FaultshinkazamaÎncă nu există evaluări

- Bonga University: Engineering Material (Meng2091)Document40 paginiBonga University: Engineering Material (Meng2091)Mul'isaa JireenyaaÎncă nu există evaluări

- Dependency of Acidic and Surficial Characteristics of Steamed Y Zeolite.2018Document13 paginiDependency of Acidic and Surficial Characteristics of Steamed Y Zeolite.2018Cecilia ManriqueÎncă nu există evaluări

- Chemdur - 52Document3 paginiChemdur - 52ICPL-RWPÎncă nu există evaluări

- Refineria de Cartagena (Reficar) Refinery Expansion - Hydrocarbons TechnologyDocument3 paginiRefineria de Cartagena (Reficar) Refinery Expansion - Hydrocarbons TechnologyGjorgeluisÎncă nu există evaluări

- Coomassie Blue Staining for Protein DetectionDocument3 paginiCoomassie Blue Staining for Protein DetectionYvy Villafani BÎncă nu există evaluări

- Microporous and Mesoporous Materials: Sean M.W. Wilson, Vida A. Gabriel, F.Handan TezelDocument11 paginiMicroporous and Mesoporous Materials: Sean M.W. Wilson, Vida A. Gabriel, F.Handan TezelEcÎncă nu există evaluări

- Safety Management in Oil & Gas Industry ReportDocument10 paginiSafety Management in Oil & Gas Industry ReportZayn AhmedÎncă nu există evaluări

- Lecturer Chemistry Model QuestionDocument11 paginiLecturer Chemistry Model QuestionPrathana Vidya100% (1)

- Le 3000 Sostanze Controverse Che Neways Non UtilizzaDocument122 paginiLe 3000 Sostanze Controverse Che Neways Non UtilizzaGiorgio FerracinÎncă nu există evaluări

- Safety Data Sheet: Product Name: MOBIL SHC RARUS 68Document10 paginiSafety Data Sheet: Product Name: MOBIL SHC RARUS 68Daniel Rodriguez GutierrezÎncă nu există evaluări

- Gay Lussac (DLP)Document8 paginiGay Lussac (DLP)Marvin EusebioÎncă nu există evaluări

- General Information CoalDocument144 paginiGeneral Information CoalSaravanan RagupathyÎncă nu există evaluări

- Small STNTechnical ManualDocument8 paginiSmall STNTechnical ManualMajid KhanÎncă nu există evaluări

- As Chemistry Practical Booklet 2020-2021: NAME: - CLASS - TEACHERDocument9 paginiAs Chemistry Practical Booklet 2020-2021: NAME: - CLASS - TEACHERPaul MurrayÎncă nu există evaluări

- 03 Trib OlogyDocument24 pagini03 Trib Ologyluis martinezÎncă nu există evaluări

- IJREI_Thermal modelling of three stage vapour compression cascade refrigeration system using entropy generation principle for reducing global warming and ozone depletion using ecofriendly refrigerants for semen preservationDocument7 paginiIJREI_Thermal modelling of three stage vapour compression cascade refrigeration system using entropy generation principle for reducing global warming and ozone depletion using ecofriendly refrigerants for semen preservationIjrei JournalÎncă nu există evaluări

- Development of A Small Solar Thermal PowDocument10 paginiDevelopment of A Small Solar Thermal Powעקיבא אסÎncă nu există evaluări

- VIESSMANN DHW Calculation VitocellTechnicalGuideDocument52 paginiVIESSMANN DHW Calculation VitocellTechnicalGuideaakoglanisÎncă nu există evaluări

- Analysis QBDocument167 paginiAnalysis QBChethan PrabhuÎncă nu există evaluări

- SIS 2.0 Refill Capacities (M0124697-02)Document6 paginiSIS 2.0 Refill Capacities (M0124697-02)Carlos U. CallirgosÎncă nu există evaluări

- Soil Pollution: Causes, Effects and Simple SolutionsDocument7 paginiSoil Pollution: Causes, Effects and Simple SolutionsVon MorenÎncă nu există evaluări

- Hough - The Crystallography, Metallography and Composition of Gold PDFDocument6 paginiHough - The Crystallography, Metallography and Composition of Gold PDFSantiaGoAlejandRoÎncă nu există evaluări