Documente Academic

Documente Profesional

Documente Cultură

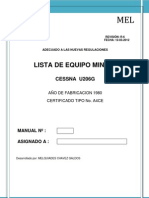

Pma Cessna U206g

Încărcat de

melzevahcTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pma Cessna U206g

Încărcat de

melzevahcDrepturi de autor:

Formate disponibile

EDITADO POR: MELQUIADES CHAVEZ GALDOS

PROGRAMA DE MANTENIMIENTO CESSNA MODEL U206G

EDITADO POR: MELQUIADES CHAVEZ GALDOS

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

INDICE

INDICE

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : i-0

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

INDICE

INDICE

CONTENIDO INDICE PROCEDIMIENTO PARA LA REVISION DEL PMA REGISTRO DE REVISIONES LISTA DE PAGINAS EFECTIVAS CAPITULO I (Procedimientos de Inspeccin) CAPITULO II ( Formatos de Inspeccin) CAPITULO III (Registro de Overhaul \ Reemplazos) ANEXO A CONTINUED AIRWORTHINESS PROGRAM (CAP), PRESENTADO POR SEPARADO. ANEXOB SUPPLEMENTAL INSPECTION DOCUMENT (SID) PRESENTADO POR SEPARADO.

PAGINA i-0 ii-0 iii-0 iv-0 I-0 II-0 III-0 IV-0 V-0

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: i-1

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

REGISTRO DE REVISIONES

Regresar al ndice

PROCEDIMIENTO PARA LA REVISION DEL PMA

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : ii-0

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

REGISTRO DE REVISIONES

PROCEDIMIENTOS PARA LAS REVISONES DEL PMA CARATULA DEL PROGRAMA Es la primera pgina sin numeracin de este Programa con el propsito facilitar su identificacin. CARATULA DE ASIGNACION DEL PROGRAMA Es la Segunda Pagina sin numeracin de este Programa donde se registra el Numero del Manual asignado, el Nmero de Revisin actual y el nombre del departamento, entidad o a quien es asignado el presente el manual. NUMERO DE CONTROL Y LISTA DE DISTRIBUCION DEL PROGRAMA Los Programa asignados sern numerados correlativamente con un nmero de control. El departamento de Control de Mantenimiento mantendr una Lista de Asignacin de los Manuales en la que incluir el nmero de control y las revisiones que se han incorporado. de

01 02 03 04 05 06 07

Direccin General de Aeronutica Civil (D.G.A.C.) (CD) Director de Mantenimiento Departamento de Control de Mantenimiento Estacin de Lnea Nazca Lnea Ica Departamento de Instruccin y Publicaciones TMA/OMA Contratado (CD)

PROCEDIMIENTOS PARA LAS REVISIONES En este prrafo se establecen los procedimientos para que el PMA (Programa de mantenimiento Aprobado) se mantenga actualizado. La revisin del PMA, es responsabilidad directa del Director de Mantenimiento. El responsable de efectuar la revisin recibir todas las sugerencias de revisiones al manual de los usuarios asignados, insertando las correcciones o modificaciones que considere necesarias; una vez realizada la revisin se insertar al pie de pgina la fecha de la revisin seguido del N de revisin correspondiente, para posteriormente solicitar a travs del Inspector Principal de Mantenimiento (IPM DGAC) su aprobacin. FECHA : 30 JUNIO 2012 REVISION: R-8 PAGINA : ii-1

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

REGISTRO DE REVISIONES

El responsable de la revisin remitir al IPM de Travel Air, a travs de mesa de partes del MTC, una carta de presentacin con el logo tipo de la compaa y la firma del Director de Mantenimiento junto con un ejemplar de las pginas revisadas y dos copias de la lista de pginas efectivas. Una vez aprobada la revisin, con la refrenda del IPM en la lista de las pginas efectivas, el Departamento de Control de Mantenimiento sacar copias suficientes de las revisiones para su distribucin a las diferentes reas.

REGISTRO DE ACTUALIZACIONES El Departamento de Control de Mantenimiento, mantendr un registro de las enmiendas y revisiones que contenga cada nmero de manual y a que persona o departamento hubiera sido asignado que incluir tambin la fecha de insercin y fecha de vigente de las revisiones. . REVISIONES TEMPORALES Debido a que este manual ser peridicamente adecuado, modificado, revisado y corregido, se insertaran revisiones temporales en hoja A4 color amarillo con el ttulo REVISION TEMPORAL 01, 02, 03 etc. El cual tendr una duracin de 3 meses desde su publicacin, hasta que se remita a la DGAC la revisin correspondiente para su aprobacin. Las Revisiones temporales deben ser firmadas y aprobadas por el Director de Mantenimiento.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : ii-2

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

REGISTRO DE REVISIONES

Regresar al ndice

REGISTRO DE REVISIONES

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: iii-1

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

REGISTRO DE REVISIONES REGISTRO DE REVISIONES

REVISION ORIGINAL R-1 R-2 R.3 R-4 R-5 Reedicin R-6 R-7 R-8 FECHA REVISION 07. JUL.2008 10. Nov. 2008 26. Mar. 2009 20. Jul. 2009 15. Feb.2010 10. Ago. 2010 18. Nov. 2010 20. Ene. 2011 02. Jun. 2012 ELABORADA POR Carlos Palacin C. Alberto Coca Tello Alberto Coca Tello Alberto Coca Tello Alberto Coca Tello Carlos Palacin C. Carlos Palacin C. Carlos Palacin C. Carlos Palacin C. FECHA APROBACION 13 Ago. 2008 04 Dic 2008 14 Abr. 2009 28 Set 2009 07 M ay 2010 30 Set 2010 07 Feb. 2011 08 Feb. 2012 INSERTADA POR E. Mendoza Z. E. Mendoza Z. E. Mendoza Z. E. Mendoza Z. E. Mendoza Z. E. Mendoza Z. E. Mendoza Z. V. Llerena G.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: iii-1

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

LISTA DE PAGINAS EFECTIVAS

Regresar al ndice

LISTA DE PGINAS EFECTIVAS

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : iv-0

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

LISTA DE PAGINAS EFECTIVAS

LISTA DE PGINAS EFECTIVAS N DE PAGINA i-0 i-1 ii-0 ii-1 ii-2 iii-0 iii-1 iv-0 iv-1 iv-2 I-0 I-1 I-2 I-3 I-4 I-5 I-6 I-7 I-8 I-9 I-10 I-11 I-12 II-0 II-1 II-2 II-3 II-4 II-5 II-6 II-7 II-8 II-9 II-10 II-11 II-12 II-13 II-14 II-15 N DE REVISION R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 FECHA EFECTIVA 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: iv-1

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

LISTA DE PAGINAS EFECTIVAS

LISTA DE PAGINAS EFECTIVAS (Cont.) N DE PAGINA II-16 II-17 II-18 II-19 II-20 II-21 II-22 II-23 II-24 II-25 II-26 II-27 II-28 II-29 II-30 II-31 II-32 II-33 II-34 II-35 II-36 II-37 II-38 II-39 II-40 II-41 II-42 II-43 II-44 II-45 II-46 II-47 II-48 II-49 II-50 II-51 II-52 II-53 II-54 II-55 N DE REVISION R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 FECHA EFECTIVA 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: iv-2

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

LISTA DE PAGINAS EFECTIVAS

LISTA DE PAGINAS EFECTIVAS (Cont.) N DE PAGINA III-0 III-1 III-2 III-3 III-4 III-5 III-6 IV-0 V-0 N DE REVISION R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 R-8 FECHA EFECTIVA 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012 30-JUNIO-2012

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: iv-3

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO I. PROCEDIMIENTOS DE INSPECCION

Regresar al ndice

CAPITULO I PROCEDIMIENTOS DE INSPECCIONES

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : I-0

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO I. PROCEDIMIENTOS DE INSPECCION

1 INFORMACION GENERAL: Travel Air EIRL, posee un Permiso de Operaciones de Transporte Areo Nacional No Regular, Transporte Areo Especial Turstico y de Observacin, con base de Operaciones en el Aerdromo Las Dunas de Ia ciudad de Ica y una Estacin de Lnea en el Aerdromo Mara Reiche de la ciudad de Nazca. Las tareas de mantenimiento sern efectuadas por un Taller de Mantenimiento Aeronutico (TMA) u Organizacin de Mantenimiento Aeronutico (OMA) aprobados por la autoridad Aeronutica, para tal efecto ambas partes celebraran un contrato de mantenimiento. El presente manual contiene la informacin y los procedimientos necesarios para el desarrollo de las labores de mantenimiento de la aeronave Cessna Modelo U206G que opera la Compaa. Es importante resaltar que la Aeronave Cessna U206G se encuentra certificada bajo el Type Certifcate N A4CE 2 MARCO DE REFERENCIA: Travel Air E.I.R.L con Permiso de Operaciones No. 28, en su calidad de explotador de Transporte Areo Nacional No Regular, Transporte Areo Especial Turstico y de Observacin, reconoce como autoridad a la Direccin General de Aeronutica Civil, por lo que la confeccin del presente Manual ha sido realizada de acuerdo con el Manual de Servicio P/N D2070-3-13, Boletines del fabricante, la Ley 27261 y su reglamento, as como las Directivas DGAC, NTCs, RAPs, y las recomendaciones dadas en el Doc. 9389-AN/919 de la OACI. 3 DISTRIBUCION DEL MANUAL Copia de este Manual debe ser distribuida a: N 1 N 2 N 3 N 4 N 5 N 6 Direccin General de Aeronutica Civil (CD) Control Mantto. (PAPEL) Estacin de Lnea Nazca (PAPEL) TMA/OMA-Contratado (CD) Biblioteca (PAPEL) Lnea-Ica (PAPEL)

La Autoridad que aprueba el presente Manual, as como sus modificaciones y actualizaciones es la DGAC.

4. RESERVADO

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : I-1

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO I. PROCEDIMIENTOS DE INSPECCION

5. OBJETIVO El presente Programa de Mantenimiento de la Compaa Travel Air EIRL, tiene por objeto detallar las tareas de mantenimiento y las Inspecciones que se realizan a esta aeronave Cessna Modelo U206G, el cual ha sido desarrollado en base al Manual de Servicio D2060-1-13 de la aeronave Cessna Aircraft Company, fabricante del avin. 6. FINALIDAD El Programa de Mantenimiento se ha desarrollado con la finalidad de dar cumplimiento a lo dispuesto por: a) b) c) d) 7. Ley de Aeronutica Civil N 27261, su reglamento y disposiciones vigentes. RAP (Regulaciones Aeronuticas del Per). Recomendaciones OACI Oficios Circulares DGAC

PROGRAMA DE MANTENIMIENTO Travel Air EIRL basados en las recomendaciones de Cessna y la experiencia propia de la compaa, ha desarrollado el Programa de Mantenimiento que se basa en una serie de inspecciones del Avin, nominadas de 50, 100, 200, Inspecciones Especiales de 1,000 horas, Inspecciones Especiales (SPC) e tem de Inspeccin Requerida (RII), As como tambin el cumplimiento de Boletines de Servicio y Directivas de Aeronavegabilidad aplicables, Normas Tcnicas Complementarias aplicables y Normas Tcnicas Extraordinarias aplicables. Adicionalmente a la Gua de Inspeccin se dar estricto cumplimiento a las Cartas de Servicio y Lubricacin proporcionadas por el fabricante. Asimismo, en el anexo A se encuentra el Programa de Aeronavegabilidad Continuada (CAP) desarrollado por TRAVEL AIR E.I.R.L. en base al Manual D5121-1-13 publicado por Cessna Aircraft Company, como un complemento al Programa de Mantenimiento Aprobado por la DGAC, y en el Anexo B se encuentra el Supplemental Inspection Document (SID) desarrollado por TRAVEL AIR E.I.R.L. en base al Manual D2060-1-13 publicado por Cessna Aircraft Company, como un complemento al Programa de Mantenimiento Aprobado por la DGAC.

8.

FASES DE INSPECCIONES En el Captulo II de este programa se incluye unas guas de inspeccin de 50, 100 y 200 horas e Inspecciones Especiales de 1000 horas elaboradas por Travel Air EIRL en base al Ground handling/Servicing Inspection del Manual de Servicio del Fabricante. Los tems de Inspeccin Especial que requieran Inspeccin cada 1000 horas, sern cumplidas en la quinta Inspeccin de 200 horas o cuando corresponda su cumplimiento de acuerdo con las recomendaciones descritas en el Manual de Servicio del fabricante P/N D2070-3-13.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : I-2

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO I. PROCEDIMIENTOS DE INSPECCION

La programacin para el cumplimiento de todas las tareas descritas anteriormente est a cargo del Departamento de Control de mantenimiento bajo la supervisin del Director de mantenimiento. En cada gua de inspeccin (50, 100 y 200 horas) existe una columna marcados con la siglas RII (tems de Inspeccin requerida), los cuales debern ser cumplidos solo si el componente en mencin ha sido instalado, ajustado, calibrado o realizado un reglaje, en su defecto se colocara el signo N/A (No Aplicable). Adicionalmente existen columnas tituladas con el indicativo MECH e INSP. Correspondiente al espacio habilitado para las firmas y/o sello y nmero de licencia de Mecnico e Inspector. La columna de Inspecciones Especiales (SPC), estn identificadas por nmeros y letras, los cuales deben ser verificados en los intervalos de 50, 100 y 200 horas, segn corresponda la accin de mantenimiento. a) FASE DE 50 HORAS. Esta fase de inspeccin esta detallada en la Gua de Inspeccin de 50 horas y deber cumplirse a intervalos de 50 horas de operacin, mas las Inspecciones Especiales (SPC), e tems de Inspeccin Requerida (RII) de ser requeridas. Las Inspecciones Especiales estn identificadas por Letras o Nmeros, existiendo al final de la Gua de Inspeccin un listado con los nmeros indicados. b) FASE DE 100 HORAS: Esta fase de inspeccin esta detallada en la Gua de Inspeccin de 100 horas e incluye todos los detalles de la Gua de Inspeccin de 50 horas, y deber cumplirse a intervalos de 100 horas de operacin, mas las Inspecciones Especiales (SPC) e tems de Inspeccin Requerida (RII) de ser requeridas. Las Inspecciones Especiales estn identificadas por Letras o Nmeros, existiendo al final de la Gua de Inspeccin un listado con los nmeros indicados. c) FASE DE 200 HORAS: Esta fase de inspeccin esta detallada en la Gua de Inspeccin de 200 horas e incluye todos los detalles de la Gua de Inspeccin de 50 y 100 horas y deber cumplirse a intervalos de 200 horas de operacin, mas las Inspecciones Especiales (SPC) e tems de Inspeccin Requerida (RII) de ser requeridas, Las Inspecciones Especiales estn identificados por Letras o Nmeros, existiendo al final de la Gua de Inspeccin un listado con los nmeros indicados. d) INSPECCIONES ESPECIALES DE 1,000 HORAS: Estas Inspecciones estarn anexadas en la quinta Inspeccin de 200 horas y se cumplir a intervalos de 1000 horas, asimismo se cumplir con la Inspeccin de Corrosin de acuerdo con las recomendaciones del fabricante.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : I-3

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO I. PROCEDIMIENTOS DE INSPECCION

Adicionalmente a cada Fase de Inspeccin se dar cumplimiento estricto a los requerimientos de las Cartas de Servicio y Lubricacin detallada por el fabricante, Directivas de Aeronavegabilidad y Boletines de Servicios aplicables a la aeronave y componentes. e) f) INSPECIONES CAPs, Los tems de inspeccin correspondiente a Aeronavegabilidad Continuada, se presentan por separado en el anexo A. la

INSPECIONES SIDs, Los tems de inspeccin correspondiente al SIDs, se presentan por separado en el anexo B.

9. SISTEMA DE INSPECCION El mantenimiento ser ejecutado por una organizacin de mantenimiento aprobado (OMA) de acuerdo a la RAP 145. (135.1410 (a) (3). Los datos registrados por la tripulacin en el registro tcnico de vuelo (RTV) son la base fundamental para la programacin de los eventos de mantenimiento as como los reportes de discrepancias surgidas durante un vuelo. Basados en esta informacin el Departamento de Control de Mantenimiento ingresara estas horas de vuelo al sistema computarizado a fin de tener controlado la programacin de cada una de las tareas de mantenimiento. El encargado del Departamento del Control de Mantenimiento solicitara mediante una carta y/o orden de trabajo con 10 horas de anticipacin el cumplimiento de las tareas de mantenimiento (50, 100, 200 horas) al Taller de Mantenimiento Aeronutico (TMA) u Organizacin de Mantenimiento Aeronutico (OMA) aprobadas por la DGAC. Debiendo elaborar el TMA/OMA la apertura de su orden de trabajo, record de discrepancias y la apertura de todos los formatos de inspeccin contenidos su correspondiente Manual de Procedimientos de Inspeccin (MPI) o Manual de la Organizacin de Mantenimiento (MOM) en forma integral para su cumplimiento. El encargado o Control de Calidad del TMA u OMA autorizado por la DGAC verificar que todas las tareas de mantenimiento, hayan sido satisfactoriamente culminadas, los rcords de mantenimiento hayan sido debidamente registrados y firmados (Libreta de Avin, Motor y Hlice, como as tambin el ITV correspondiente). Constituyendo este procedimiento la certificacin de la aeronave para retornar al servicio. El Programa de mantenimiento como es establecido por el fabricante, Cessna Aircraft Company, consiste bsicamente en inspecciones que se llevan a cabo peridicamente, de acuerdo a lo establecido en correspondiente ficha de inspeccin, si la aeronave opera menos de 100 horas anuales o no tiene operacin por un periodo mximo de 06 meses continuos, ser necesario efectuar una inspeccin completa (200 horas, especiales, Directivas de Aeronavegabilidad, Boletines de Servicio, control de corrosin y otros ) a la aeronave, motores hlices y accesorios antes de retornarlas al servicio.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : I-4

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO I. PROCEDIMIENTOS DE INSPECCION

No es la poltica de la Travel Air EIRL exceder los limite estipulados para el cumplimiento de inspecciones programadas, Directivas de Aeronavegabilidad, Normas Tcnicas Complementarias, Boletines de Servicio, tiempos limites de operacin de accesorios y componentes, sin embargo si fuera necesario por alguna razn sea esta por ubicacin geogrfica de la aeronave y la lejana de la misma de algn lugar o facilidad de mantenimiento para el cumplimiento de lo indicado se solicitara una autorizacin especial (Permiso de Vuelo Ferry), ante la Direccin General de Aeronutica Civil previo al vuelo intentado. 10. INSPECCIONES DE PRE Y POST VUELO Para las inspecciones enunciadas como Pre y Post Vuelo, el fabricante Cessna Aircraft Company, no ha contemplado en el manual de mantenimiento de la aeronave las mencionadas inspecciones, sin embargo Travel Air EIRL utilizando el mejor de los criterios propios y las recomendaciones de la D.G.A.C., ha elaborado un formato para el Pre/Post vuelo utilizando como referencia el Manual de Operaciones del fabricante, copia del cual anexamos en las paginas II2 al II-5 de este manual. Para los efectos de Post Vuelo de esta aeronave, se utilizar la misma cartilla de Pre-Vuelo con las variantes aplicables para efectos de Post-Vuelo, ejemplo: 1. Cockpit Central Lock ............................................. Install and Secure 11. ITEMS QUE REQUIEREN INSPECCION (R.I.I.) Los tems que requieren inspeccin (RII) son aquellos trabajos en unidades Sistemas en las cuales su mantenimiento, alteracin o reparacin debe ser inspeccionado despus de concluido o completado por un inspector o su designado. Los tems que requieren inspeccin (RII) deben ser inspeccionados y firmados solamente por un inspector autorizado. 12. CUMPLIMIENTO DE DIRECTIVAS DE AERONAVEGABILIDAD, BOLETINES DE SERVICIO, NORMAS TECNICAS COMPLEMENTARIAS y NORMAS TECNICAS EXTRAORDINARIAS. Dada la gran importancia para Travel Air EIRL como empresa aeronutica la conservacin, mantenimiento y seguridad de vuelo que las Directivas de Aeronavegabilidad, Normas Tcnicas Complementarias (NTC), Boletines de Servicio representan; esta no dudar a la recepcin de estos documentos en efectuar su cumplimiento dentro del trmino especificado, haciendo para esto uso de la informacin tcnica recibida y actualizada, Las mismas que sern registradas en los formatos contenidos en el Apndice A (FORM CP-366), (FORM CP-367) y (FORM CP-368) del MGM/MCM.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : I-5

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO I. PROCEDIMIENTOS DE INSPECCION

13. CONTROL DE CORROSION Para los efectos del control de corrosin de la aeronave, esta se realizara de acuerdo al Programa de Control y Prevencin de Corrosin descrita en la SECCION 2A-30-00 del Manual de Servicio, D2060-1-13. 14. ANEXOS COMPLEMENTARIOS Este Programa de Mantenimiento cuenta con varios Anexos Complementarios, los cuales ayudan a que ste se cumpla eficazmente y en forma precisa. Estos son: - Anexo A Continued Airworthiness Program (CAP)*. - Anexo "B" Supplemental Inspection Document (SID)*. - Cessna Service Manual P/N. D2070-3-13* - Cessna Parts Manual P/N. P703-12* - Teledyne Continental Overhaul Manual P/N X3003* - Teledyne Continental Operators Manual P/N X30041* * Tomos presentados por separado

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : I-6

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO I. PROCEDIMIENTOS DE INSPECCION

EXTINTOR MANUAL DE FUEGO - DESCRIPCIN Y OPERACIN GENERALIDADES: El Extintor de Fuego porttil, es operado manualmente, est montado y localizado en un lugar de fcil acceso, para ser usado en un evento de fuego.

DESCRIPCIN Y OPERACIN: El Extintor de fuego porttil, operado manualmente est montado debajo de la parte delantera del asiento del Piloto, el agente extintor es HALOTRON y puede ser usado sobre combustibles slidos, lquidos y elctricos, el extintor de fuego. El servicio del extintor puede ser manejado por los distribuidores del equipo del fuego. esta montado en un conjunto de soporte y abrazadera de liberacin rpida.

1. Conjunto de soporte (Bracket). 2. Boquilla de extintor de fuego. 3. Palanca de descarga. 4. Pines de seguridad. 5. Maneta 6. Instrumento de Presin. 7. Conjunto de Extintor de Fuego. 8. Abrazadera de liberacin rpida. 9. Tornillo de anclaje. 10. Asiento del Piloto.

10

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : I-7

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO I. PROCEDIMIENTOS DE INSPECCION

PAGINA EN BLANCO DEJADO INTENCIONALMENTE

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : I-8

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO I. PRESERVACION DE LA AERONAVE

PRESERVACION DE LA AERONAVE Debido a la influencia principalmente de los elementos climatolgicos, es de suma importancia tomar en cuenta aspectos concernientes a la forma como se debe preservar la aeronave, para este efecto Cessna Aircraft Company describe en forma detallada en la seccin 2 de su manual de Servicio No D2060-1-13, los procedimientos a seguir. En forma abreviada podemos describir los siguientes periodos o lapsos de almacenamiento de la Aeronave: a) Preservacin en Condicin Operativa: Se define de este modo la condicin en la que la Aeronave va a permanecer en tierra por un periodo mximo de 30 das, sin que el motor sea corrido (REF. Manual de Servicio tem 2-7). b) Preservacin Temporal: Se define como la condicin en la que la Aeronave va a permanecer en condicin inoperativa por un mximo de 90 das (REF. Manual de Servicio tem 2-9). c) Preservacin Indefinida: Se define como la condicin en que la Aeronave va a permanecer en condicin inoperativa por un periodo indefinido de tiempo (REF. Manual de Servicio tem 2-12).

NOTA: Adicionalmente es altamente recomendable el frecuente lavado con agua dulce de las superficies de la Aeronave, encerado y limpieza, como as tambin el uso de cubiertas y/o plugs en los orificios de ventilacin, de preferencia la aeronave debe permanecer dentro de un hangar sobre todo en las proximidades del mar. SERVICING REQUERIMENTS:

FUEL: Grade 100LL ENGINE OIL: W100 HYDRAULIC FLUID: MIL-H-5606 GENERAL PURPOSE GREASE: MIL-G-81322 HIGH TEMPERATURE GREASE: MIL-PRF-23827C

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : I-9

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO I. PRESERVACION DE LA AERONAVE

PAGINA EN BLANCO DEJADO INTENCIONALMENTE

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : I-10

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO I. PRESERVACION DE LA AERONAVE

PAGINA EN BLANCO DEJADO INTENCIONALMENTE

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : I-11

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO I. PRESERVACION DE LA AERONAVE

PAGINA EN BLANCO DEJADO INTENCIONALMENTE

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : I-12

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

II. FORMATO DE INSPECCIONES

Regresar al ndice

CAPITULO II

FORMATO DE INSPECCIONES

TABLA DE CONTENIDO INSPECCION DE PRE-VUELO FORMATO DE INSPECCION DE 50 FORMATO DE INSPECCION DE 100 HORAS FORMATO DE INSPECCION DE 200 HORAS CORROSION FORMATO DE INSPECCIONES ESPECIALES DE 1,000 HORAS FORMATO DE RETIRO E INSTALACION DEL COMANDO Y PEDALES II-1 al II-7 II-8 al II-16 II-17 al II-29 II-30 al II-45 II-46 al II-48 II-49 al II-52 II-53 al II-55

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : II-0

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. INSPECCION DE PREVUELO

INSPECCIN DE PRE-VUELO

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA : II-1

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. INSPECCION DE PREVUELO

TA-001

INSPECCION DE PRE-VUELO Y POST VUELO CESSNA U206G

1.- CABINA Documentacin completa (ITV, Certificados de Aeronavegabilidad y Matrcula, POH, MEL, cartillas de pasajeros, etc.). Seguro de control de mandos. Interruptor de ignicin. Interruptor de avinicos. Interruptor maestro. Indicadores de cantidad de combustible por correcta indicacin. Interruptor maestro. Vlvula Selectora de Combustible, en posicin tanque ms lleno. Control de compensadores. Vlvula alterna de presin esttica (si est instalada). Asientos, cinturones y arneses de seguridad en buen estado Placards legibles y/o completos (ver MEL si es necesario) Controles de motor por condicin general, recorrido y libre operacin. Botiqun de primeros auxilios completo y lista actualizada Extintor por seguridad y fecha de vencimiento GPS AERA 500 (para los cuidados refirase a la pagina 148 del PILOT GUIDE P/N 19001117-02 Rev. A). 1.-Mster ON - el equipo debe encender automticamente - Mster OFF. 2.- EMPENAJE Superficies de control por libertad de movimiento y seguridad. Puertas, seguros e interruptor de flaps por correcto funcionamiento. 3.- BORDE DE SALIDA ALA DERECHA Alern, por libertad de movimiento y seguridad. 4.- ALA DERECHA Ventilacin del tanque de combustible, por obstruccin. Llanta del tren principal (presin 42 psi). Antes del primer vuelo del da y despus de cada recarga de combustible usar un vasito drenador completamente limpio, por presencia de agua, sedimentos y grado apropiado de combustible. NOTA: Si el combustible no est libre de contaminantes, incluido agua (aeronave NO-GO). Notifique a su supervisor inmediatamente. La cantidad de combustible (usando la regla). Tapa de tanque de combustible segura y orificio de ventilacin sin obstrucciones. 5.- NARIZ Orificios de entrada de presin esttica (ambos lados del fuselaje), sin obstruccin Hlice y cono, por aseguramiento, abolladuras y fuga de aceite o grasa. Ref. MPC-11 Sec 3, Prrafo 3-23. NOTA: Ejercite extrema precaucin al girar manualmente la hlice, en caso de ser necesario. Palas de la hlice por picaduras, abolladuras, Corrosin, Ralladura y juego radial de movimiento. Ref. MPC-11 Seccin 3, Prrafo 3-15. ADVERTENCIA: Una fuga anormal de grasa puede ser una indicacin de una falla del cubo o un componente de retencin de la pala. Esto puede resultar una separacin de una pala en vuelo y como resultado un accidente catastrfico de la aeronave. Entradas de aire, induccin de aire al motor sin restricciones. Luces de taxeo y aterrizaje, por condicin, limpieza y operatividad. Amortiguador del Tren de nariz (aprox. 4 pulgadas de luz) deber tener despus de actuar el amortiguador (subir y bajar). NOTA: Limpie y lubrique el tramo cromado del amortiguador. Llanta del tren de nariz, presin 29 psi. Nivel de aceite del motor. No operar con menos de 9 Qts. (Correcto nivel 12 Qts). Tapa de aceite del motor cerrado correctamente.

PRE VERIFICAR REMOVER OFF OFF ON VERIFICAR OFF POSICIONAR NEUTRAL OFF VERIFICAR VERIFICAR CHEQUEAR VERIFICAR VERIFICAR VERIFICAR VERIFICAR REVISAR VERIFICAR VERIFICAR VERIFICAR VERIFICAR

POST

VERIFICAR VERIFICAR VERIFICAR CHEQUEAR

CHEQUEAR VERIFICAR VERIFICAR VERIFICAR VERIFICAR VERIFICAR VERIFICAR

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-2

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. INSPECCION DE PREVUELO

INSPECCION DE PRE-VUELO Y POST VUELO CESSNA U206G (Continuacin)

PRE POST

Antes del primer vuelo del da y despus de cada recarga de combustible, jalar la perilla del drenador del filtro principal de combustible cerca de 04 segundos para VERIFICAR limpiar el filtro de posible contenido de agua o sedimentos, verificar que quede bien cerrado el drenaje. Si se observa agua continuar drenando. NOTA: Si el combustible no est libre de contaminantes y agua, (aeronave NO-GO). 6.- ALA IZQUIERDA VERIFICAR Llanta del tren principal (presin 42 psi). Antes del primer vuelo y despus de cada recarga de combustible, usar el vasito drenador y vaciar una pequea cantidad de combustible por la vlvula de drenaje y si VERIFICAR existe presencia de agua, sedimentos y grado apropiado de combustible. NOTA: Si el combustible no est libre de contaminantes, incluido agua, (aeronave NO-GO). Notifique a su supervisor inmediatamente VERIFICAR Cantidad de combustible (usando la regla). VERIFICAR Tapa de tanque de combustible segura y orificio sin obstrucciones. 7.- BORDE DE ATAQUE ALA IZQUIERDA VERIFICAR Retirar cubierta del tubo pitot y orificio sin obstrucciones. Aleta de advertencia de prdida, libre de movimiento, mientras el interruptor maestro est puesto momentneamente en ON (la sirena debe sonar cuando la aleta es empujada VERIFICAR hacia arriba). VERIFICAR Ventilacin de tanque de combustible por obstrucciones. 8.- BORDE DE SALIDA. VERIFICAR Alern, por libertad de movimiento y seguridad. 9.- MOTOR Remover el cowling del motor e inspeccionar por fugas (aceite, gasolina), mangueras y VERIFICAR cables por rozamiento, y la toma de aire por obstruccin, instalar el cowling y verificar que no hayan broches, tornillos sueltos. CHEQUEAR Respiradero del crter por seguridad y libre restriccin de flujo de aire. Filtro de aire del sistema de induccin deber ser inspeccionado y limpiado de ser necesario REF. (M/S Seccin 2), Verifique la operacin de abastecimiento de aire VERIFICAR alterno. Ref. al M/S Seccin 12. CHEQUEAR Controles del motor por libertad de movimiento y rango de recorrido. CHEQUEAR Sistema de Escape por evidencias de fuga y condicin general. VERIFICAR Switch de Magneto estn conectados al Magneto y que estn en la posicin OFF, Posicin P los cables son puestos a tierra. CHEQUEAR Cantidad de Aceite. Ref. M/S Seccin 2 Motor y Nacelas por material extrao, ausencia de lneas y mangueras rotas, abrazaderas y conexiones flojas, Inspeccione por restriccin de flujo de aire de CHEQUEAR refrigeracin. VERIFICAR Que todos los bafles y sellos de bafles estn instalados y en posicin correcta NOTA: Arranque y corra el motor de ser necesario por cualquier tem reparado y chequee por fugas de aceite y combustible antes de retornar al servicio.

Realizado por: Nombre: ........................................ N de Licencia: ............................ Firma: ........................................... Fecha: ...........................................

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-3

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. INSPECCION DE PREVUELO

OPERACIN EN CLIMA FRIO La zona de operacin de esta Aeronave (Costa peruana), no ofrece condiciones de operacin en clima fri, sin embargo creemos conveniente tomar en cuenta las siguientes recomendaciones: En adicin a la inspeccin de pre-vuelo normal, remueva el hielo, nieve y escarcha de las alas, cola, superficie de control y bisagras, hlice , parabrisas, tapas de recarga de combustible, lneas de ventilacin de combustible, si usted no tiene manera de remover esta formaciones de hielo, nieve y escarcha evite la operacin de la aeronave, estos depsitos pueden cambiar los perfiles aerodinmicos y perturbarlos considerablemente o destruirlos, constituyendo un grave peligro para la seguridad de vuelo. Complete su procedimiento de pre-vuelo normal y verifique el completo y libre movimiento de la superficie de control. Durante el proceso de recarga de combustibles a bajas temperaturas, existen condiciones ms favorables para la formacin de humedad debido a condensacin dentro de los tanques, especial atencin debe tomarse a fin de drenar el sistema adecuadamente. MOTOR Particular cuidado debe tomarse en utilizar el grado y tipo de aceite adecuado, en la seccin 2 del Manual de Servicio Parte No D2060-1-13 ( Servicing) se describe el grado y tipo correcto del aceite a usarse , as mismo previo al arranque, es recomendable girar la hlice a mano varias veces antes del arranque, tomando las precauciones pertinentes (Magnetos OFF , Mixture Cut OFF, acelerador Closed, calzas puestas ). Tambin es recomendable el uso de una fuente externa. Durante condiciones extremas de fri, puede ser necesario precalentar el aceite del motor antes del arranque, un arranque con el aceite congelado en el sistema puede producir una indicacin de presin de aceite normal pero la misma puede disminuir cuando el aceite residual dentro del motor es bombeado dentro del sumidero conteniendo aceite congelado, esta aeronave no cuenta con sistema de precalentador de aceite, por lo que la operacin en climas extremadamente fro no es permitido (-05 C). Es tambin recomendable luego del arranque en clima fro observar cuidadosamente durante el calentamiento del motor, las temperaturas de aceite, debido a que es posible exceder la temperatura de cabeza de cilindro, tratando de hacer subir la temperatura de aceite, por lo que se recomienda el mnimo de RPM durante este proceso y mantener los COWL FLAPS abiertos, as mismo ejercitar la hlice durante varias veces a fin de remover el aceite fro del Hub de la hlice, tambin la hlice deber ser ejercitada varias veces durante el vuelo. As mismo durante el descenso es recomendable prestar especial atencin a los parmetros del motor a fin de evitar el sobre enfriamiento (Shock Cooling ), particular cuidado se deber tomar con el uso de los Cowl Flaps.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-4

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. INSPECCION DE PREVUELO

USO DE FUENTE EXTERNA Durante el uso de planta auxiliar o fuente externa de energa debemos tomar en cuenta las siguientes precauciones: 1. Esta aeronave est equipada con un sistema elctrico de polo negativo a tierra, es de vital importancia asegurarnos de conectar el terminal positivo de la planta auxiliar con el terminal positivo del receptculo de la aeronave y el terminal negativo con el terminal negativo del receptculo. Voltaje positivo tambin se debe aplicar al pequeo pin gua del receptculo. Muy particular cuidado deber tomarse para verificar el uso del voltaje correcto ( 24 Voltios ). 2. Para prevenir la formacin de arco elctrico entre el receptculo y el conector de la fuente externa, la conexin debe efectuarse sin energa en la lnea ( Power OFF ).

3. Asegrese de que el switch de batera de la aeronave se encuentre en ON, los avionicos y los switchs elctricos en OFF, a fin de que la batera este en lnea con el sistema antes de conectar la fuente externa esto protege los sistemas electrnicos asociados de posibles picos de corriente elctrica.

ARRANQUE DE MOTOR USANDO FUENTE EXTERNA 1. 2. 3. 4. 5. 6. 7. 8. 9. Battery switch Alternator, Electrical, and Avionics Equipment Auxiliary Power Unit Auxiliary Power Unit Auxiliary Power Unit Engine Auxiliary Power Unit Auxiliary Power Unit Alternator Switch ON OFF CONNECT SET OUTPUT (Max. 28 Vdc on 24 Vdc systems On START (use normal start procedures) OFF (after engine has been started) DISCONNECT ON

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-5

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. INSPECCION DE PREVUELO

TAXEO Y CORRIDA DE MOTOR

El Taxeo como en cualquier otro avin deber hacerse tomando las debidas precauciones a fin de evitar daos a la aeronave, al equipo en tierra o a personas. Particular cuidado se tomara a fin de comprobar el correcto funcionamiento del sistema de frenos antes de iniciar el rodaje. Para las corridas del motor, se utilizar un rea debidamente habilitada, el mecnico a cargo del mantenimiento de la aeronave, tomara la precaucin de verificar la disponibilidad de un extintor de fuego, una persona apropiadamente calificada (asistente) permanecer en todo momento fuera de la aeronave, en coordinacin, vigilando el rea y alertara al mecnico abordo sobre cualquier eventualidad como as tambin estar listo para la utilizacin del extintor de incendio en caso de ser necesario. Las siguientes acciones sern tomadas antes de iniciar la corrida de motor. 1 .- UBICAR LA AERONAVE EN ZONA AUTORIZADA 2 .- ASEGURAR EL AREA DE CORRIDO DE MOTOR LIBRE DE OBSTACULOS PERSONAS AJENAS O EXTRAAS, EXTINTOR A LA MANO Y ASISTENTE LISTO 3 .- CALZAS PUESTAS REA DE LA HELICE LIBRE 4 .- LA PERSONA A BORDO A CARGO DEL ARRANQUE ALERTARA HACIA EL EXTERIOR CON LA VOZ: 5 .6 .- PROCEDIMIENTO DE ARRANQUE NORMAL. 7 .- NOTA : CORRIDAS DE MOTOR A MAXIMA POTENCIA SERN EFECTUADAS SOLAMENTE SOBRE TERRENO PAVIMENTADO O CEMENTADO Y ZONA AUTORIZADA.

LIBRE !!!

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-6

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE CORRIDO DE MOTOR

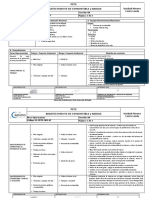

FORMA CP-375

CORRIDA DE MOTOR TELEDYNE CONTINENTAL IO-520-F

Inspeccin Programada, Pre-vuelo o post vuelo. Arranque y corra el Motor de acuerdo a las instrucciones del Manual de Vuelo. Tomando nota de cualquier discrepancia o anormalidad, durante el corrido observe lo siguiente:

TIPO DE AVION: ___________________ ENGINE MODEL: ___________________ S/N: AVION ________________ S/N. MOTOR _________________ MATRICULA: ____________________ FECHA: ____________________

CORRIDO DE MOTOR

PARAMETROS Opere el motor colocando en posicin LH, RH y OFF para verificar que la vlvula Selectora opera correctamente.

OBSERVACIONES

ANTES DE LA INSP. DESPUES DE LA INSP.

LH . RH ... OFF ..

LH . RH . OFF ..

1. Vlvula Selectora. 2. Calentar el motor , mezcla rica , paso de hlice adelante 3. Chequeo de Magnetos (Ajuste el acelerador a 1700 RPM) 4. Chequeo de Hlice (A 1700 RPM) 5. Temperatura de Aceite 6. Presin de Aceite 7. CHT (Temp. Cabeza Cilindros) 8. Check Alternador (A 1700 RPM) 9. Indicador de succin (A 1700 RPM) 10. Chequeo de Mezcla 11. Corrido Esttico (Potencia de decolaje) Enfrentar el avin a la direccin del viento 12. Indicador de Flujo de combustible 13. Presin de manifold 14. Respuesta de Motor a cambios de potencia 15. Funcionamiento del Motor 16. RPM Mnimo 17. Chapa(llave) de start del motor

1000 RPM La cada de RPM no debe exceder los 150 rpm en ambos magnetos, 50 RPM de diferencia entre ambos Magnetos Jalar la maneta de hlice (cycle) de alta a baja RPM: retorne a ALTA RPM (Maneta al fondo). o 100 - 240 F Operacin Normal o 240 F Mximo 10 PSI Mnimo 30-60 PSI Operacin Normal 100 PSI Mximo en arranque 200-460 F

o

RH LH .

RH ... LH

Operacin Normal

Switch ALT OFF-ON 4.6 5.4 In. Hg Ajustar a 1000 RPM, Lentamente Cortar la mezcla (50 RPM Mximo). 2700 RPM en tierra (rango de precaucin) 2850 RPM (mximo) 7.0 17.0 Gal/Hrs (Arco verde) 3.5 y 19.5 PSI (25.2 Gal/Hrs) (Lnea Roja) 15 - 25 In. Hg (Arco verde) Observar 1--Ruidos Extraos 2--Vibraciones 600 (+)(-) 25 RPM Magnetos a tierra en mnimo (600 RPM)

1 .. 2 . 1. 2 . Incre ... Incre ..

Despus que una inspeccin Programada haya sido completada, un nuevo corrido de motor debe ser realizado para determinar que cualquier discrepancia o anormalidad haya sido corregida.

______________________ FIRMA Y N DE LICENCIA

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-7

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 50 HORAS

FORMATO DE INSPECCION 50 HORAS

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-8

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 50 HORAS

CESSNA U206G 50, HOUR AND SPECIAL INSPECTION FORM

DATE MODEL TYPE SERIAL NUMBER TOTAL TIME TIME SINCE O/H REGISTRATION No TIPO INSPECCION FECHA DE INICIO FECHA TERMINO 5 0 RII SPECIAL Hrs 400 Yrs 1 Year AIRCRAFT ENGINE PROPELLER

DESCRIPTION

B. FUSELAGE ( Section 3 ) 11. Upholstery, Headliner, Trim and Carpeting - Check condition and clean as required.

MECH.

INSP.

15. Seat Tracks and Stops Inspect seat tracks for condition and security of installation. Check seat track stops for damage and correct location. Ensure inspection of seat rails for cracks EACH 50 HOURS. Refer to Section 3. 16. Control Column Inspect pulleys, cables, sprockets, bearings, chains, bungees, and turnbuckles for condition and security.

RII

19. Cockpit or Cabin mounted Hallotron type fire ExtinguisherEmpty, inspect for damage and recharge.

1 Year 05 Year

20. Cockpit and Cabin mounted Halotron type fire ExtinguisherPerform hydrostatic test. The hydrostatic test shall be at fiveyear intervals based on initial servicing or date last hydrostatic test. C.WINGS AND EMPENNAGE ( Section 4 ) 4. Metal Lines, Hoses, Clamps, and Fittings - Check for leaks, condition, and security. Check for proper routing and support.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-9

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 50 HORAS

DESCRIPTION

D. LANDING GEAR AND BRAKES (Section 5 )

5 0

R I I

SPECIAL MECH. Hrs Yrs INSP.

3. Brake Lines, Wheel Cylinders, Hoses, Clamps, and Fittings Check for leaks, condition, and security and hoses for bulges and deterioration. Check brake lines and hoses for proper routing and support. 10 Wheel Bearings - Clean, inspect and lube.

400

A

1 Year

12

Brake System Overhaul brake discs, parking brake system, wheel cylinders, and master cylinders. Replace brake pads and all rubber goods.

E. AILERON CONTROL SYSTEM ( Section 6) 2 Aileron Structure, Control Rods, Hinges, Balance Weights, Bellcranks, Linkage, Bolts, Pulley, and Pulleys Brackets Check condition, operation, and security of attachment. 3 Ailerons and Cables Check operation and security of stops. Check cables for tension, routing, fraying, corrosion, and turnbuckle safety. Check travel if cable tension, requires adjustment or if stops are damaged. Check fairleads and rub strips for condition.

X RII

F. WING FLAP CONTROL SYSTEM ( Section 7 ) 1 Flaps Check tracks, rollers, and control rods for security of attachment. Check operation.

Flap Structure, Linkage, Bellcranks, Pulleys, and Pulley Brackets Check for condition, operation and security.

Year

5 Flaps and Cables - Check cables for proper tension, routing, fraying, corrosion, and turnbuckle safety. Check travel if cable tension requires adjustment. X RII

G. ELEVATOR CONTROL SYSTEM ( Section 8 ) 2 Elevator, Hinges, and Cable Attachment Check condition, security and operation.

RII

Elevator Control System - Inspect pulleys, cables, sprockets, bearings, chains, and turnbuckles for condition, security, and operation. Elevator/Rudder Downspring Check structure, bolts, linkage, bellcrank, and push-pull tube for condition, operation, and security. Check cables for tension, routing, fraying, corrosion, and turnbuckle safety. Check travels if cables require tension adjustment or if stops are damaged.

RII

X

RII

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-10

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 50 HORAS

DESCRIPTION

H. ELEVATOR TRIM TAB CONTROL SYSTEM (Section 9).

5 0

RII

SPECIAL Hrs Yrs

MECH.

INSP.

Elevator Trim Tab Actuator-Clean, lubricate, and check for free-play.

RII

I. RUDDER CONTROL SYSTEM (Sect. 10). 3. Rudder, Tips, Hinges, Clips and Cable. Attachment Check condition, security, and operation. J. NORMALLY ASPIRATED ENGINES ( Sect. 12 ) 1. Cowling and Cowl Flaps Inspect for crack, dents and other damage, security of cowl fasteners, and cowl mounted landing light for attachment. Check cowl flaps for condition, security and operation. 2. Engine Inspect for evidence of oil and fuel leaks. Wash engine and check for security of accessories. 3. Cowl Flap Controls Check freedom of movement through full travel.

4. Engine, Propeller Controls, and Linkage - Check general condition, freedom of movement through full range. Check for proper travel, security of attachment, and for evidence of wear. Check friction locks for proper operation. Refer to TCM Service Bulletin SB95-2 or latest revision for detailed instructions on control linkage inspection and lubrication. 8. Induction System Check security of clamps, tubes, and ducting. Inspect for evidence of leakage.

RII X F

11. Alternate Induction Air System -Check for obstructions, operation, and security.

12. Alternator and Electrical Connections - Check condition and security of alternator and support brackets. Check alternator belts for condition and proper adjustment. 13. Alternator Check brushes, leads, commutator or slip ring for wear.

H I

15. Oil Cooler Check for obstructions, leaks, and security of attachment.

16. Exhaust System - Inspect for cracks and security. Air leak check exhausts system. Refer to Sections 12, for inspection procedures.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-11

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 50 HORAS

DESCRIPTION

17. Exhaust System (Turbocharger engine) Inspect couplings, seal, clamps and expansion joints for cracks Air Leak check exhaust. Refer to Sections 12, for inspection procedures. 20. Magnetos-check external condition, security, and electrical leads for condition. Check timing to engine and internal timing if engine timing requires adjustment. Ref. TCM Service Bulletin MSB94-8C 21. Magnetos Timing Procedures and intervals, lubrication, and overhaul procedures.

5 0

X

RII

SPECIAL Hrs Yrs

MECH.

INSP.

J K

27. Hoses, Metal Lines, and Fittings - Inspect for signs of oil and fuel leaks. Check for abrasions, chafing, security, proper routing and support and for evidence of deterioration. 30. Engine Baffles and Seals - Check condition and security of attachment.

35.Engine Oil Change Normally Aspirated Engine Without Oil Filter : a. Engine Oil Without Oil Filter Drain oil sump and oil cooler, clean and inspect screen, and refill with recommended grade aviation oil. K. FUEL SYSTEM (Section 13) 2 Integral Fuel Tanks Drain fuel and check tank interior and outlet screens. Fuel Tank or bladders - Drain drain water and sediment.

11

Fuel Quantity Indicators - Check for damage, security of installation, and perform accuracy test.

EA CH 1 RII EA CH 1 V

12

Fuel Quantity Indicating check for damage and security of installation and perform accuracy test. Inspect / clean the fuel injection nozzle. Ref. Service Information Directive SID05-7

13

L.

PR0PELLER AND PROPELLER GOVERNOR (Section 14). X Propeller Governor and Control - Inspect for oil and grease leaks. If leakage is evident, refer to McCauley Service Manual. Proper Mounting - Check for security of installation.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-12

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 50 HORAS

5 0 X X RII SPECIAL Hrs Yrs

DESCRIPTION

3 Propeller Blades Inspect for cracks, dents, nicks, scratches, erosion, corrosion, or other damage. Spinner - Check general condition and attachment.

MECH.

NSP.

Propeller Assembly - Overhaul.

M. 1.

UTILITY SYSTEMS ( Section 15 ) Ventilation System - Inspect clamps, hoses, and valves for condition and security. Pitot Tube and Stall Warning Vane - Check for condition and obstructions.

400 X

4.

5. Pitot Tube Heater Element Perform operational check.

N. 2.

INSTRUMENTS AND INSTRUMENT SYSTEM ( Section 16 ) Vacuum System Hoses - Inspect for deterioration, looseness, or collapsed hoses. hardness,

U Q

4.

5.

Vacuum System Air Filter - Inspect for damage, deterioration and contamination. Clean or replace, if required. NOTE: Smoking will cause premature filter clogging. Vacuum System relief Valve - Inspect for condition and security.

10. Airspeed indicator, Vertical speed indicator, and magnetic compass calibrate

11. Altimeter and Static System - Inspect in accordance with FAR RAP 91.411.

17.

Vacuum Manifold Check Valve (If so equipped)

O.

ELECTRICAL SYSTEMS (Sect 17).

4. Battery Check general condition and security. Check level of electrolyte.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-13

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 50 HORAS

50 RII SPECIAL Hrs X Yrs

DESCRIPTION

P. POST INSPECTION 1. Re-install fairings, doors, and access hole covers. Ground check engine, alternator charging rate, oil pressure, tachometer, oil temperature and pressure gages, and general operation of components. Q. PERFORM THE FOLLOWING OPERATIONAL CHECK 1. Brakes - Test toe brakes and parking brake for proper operation. R. SERVICE BULLETINS/AIRWORTHINES DIRECTIVES 1. Check that all applicable Cessna Service Bulletins, CAPs, SIDs and Supplier Service Bulletins are complied with. A compliance record shall be filled every inspection 2. Check that all applicable Airworthiness Directives, Normas Tcnicas Complementarias and RAPs are complied with.

MECH.

INSP.

X X

3. Ensure all Maintenance Record Entries required by RAPs are completed before returning the airplane to service.

After the inspection has been completed, an engine RUN UP should again be performed to determine that any discrepancies or abnormalities have been corrected.

Date of Completion

_____/_____/_____

TASKS PERFORMED BY: MECHANIC

NAME Lic FIRMA NAME

INSPECTOR

Lic. FIRMA

NOTA: Para el caso en el que durante un procedimiento de mantenimiento rutinario (Ejem.: Inspeccin de 50, 100, 200 horas, Inspecciones Especiales de 1000 horas), en que no aplique la ejecucin de un RII, (por no haberse efectuado instalacin, ajuste, calibracin o reglaje), en el espacio correspondiente se anotar el signo N/A (no Aplicable).

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-14

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 50 HORAS

CESSNA U206G SPECIAL INSPECTION ITEM GUIDE

A.- First 100 hours and each 500 hours thereafter. More often if operated under prevailing wet or dusty conditions. B.- Serial U20603522 thru U20604649: Each 5 years. Serial U20604650 and on: Overhaul components and replace rubber goods on-condition basis. C.- Each 600 hours or 1 years, whichever comes first D.- Lubrication of the actuator is required each 1000 hours or 3 years, whichever comes first. See figure 2-5 (service manual) for grease specification. E.- Serial U20604650 thru U20605919: Compliance with Cessna Service Letter SE80-65 is required. F.Lubricate each 100 hours (except in dusty conditions). These controls are not repairable and should be replaced every 1500 hours or sooner if required.

G.- Clean filter per paragraph 2-23 (service manual). Replace paper filters at least each 500 hours. Filter element BA-2205L replace each 200 hours. (STC N SA71GL) H.- Check belt tension after 10 to 25 hours of operation. Refer to Section 17 (service manual). I.J.Inspect each 500 hours. If magneto-to-engine timing is correct within plus zero degrees to minus two degrees, internal timing need not be checked. If timing is out of tolerance, remove magneto and set internal timing, then install and time to the engine. Maintenance and overhaul information covering Slick magnetos is available from Cessna Parts Distribution (CPD 2). Order L-1037C1-13 for 4200/6200 series magnetos, or L-1020-13 for 400/600 series magnetos. Every 500 hours of operation, perform the following items. a. Inspect contact points for condition and adjust or replace as required. b. Inspect carbon brush, high-tension lead, and distributive block for condition. Clean or replace parts as required. c. Inspect impulse coupling and pawls for condition and replace as required. Use light pressure only. Do not force when checking pawls. d. Inspect and lubricate bearings; replace as required. e. Lubricate contact point cam. The magnetos must be overhauled or replaced with new or rebuilt magnetos at every engine overhaul.

K.-

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-15

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 50 HORAS

L.Replace engine compartment rubber hoses (Cessna installed only) every 5 years or at engine overhaul whichever occurs firts. This does not include drain hoses. Hoses which are beyond these limits and are in a serviceable condition must be placed on order immediately and then replaced within 120 days after receiving the new hose(s) from Cessna. Replace drain hoses on condition. For Engine flexible hoses. (Continental Installed), Refer to Continental Maintenance Manual and Continental engine Service Bulletin.

M.- Replace check valves in turbocharger oil lines each 1000 hours. N.- First 25 hours: Refill with straight grade mineral oil and use until a total of 50 hours have accumulated, or oil consumption has stabilized. Change oil, replace filter, and refill sump with recommended grade of ashless dispersant oil. Change oil and replace filter at least every six months, regardless of accumulated hours. O.- Each 1000 hours. P.- See McCauley Service Manual. Refer to list of publication. Q.- Replace every 500 hours. R.- Replace filter each 100 hours. S.- Check electrolyte level and clean battery box each 100 hours or 90 days. T.- Check condition and operation of check valve manifold beginning five years from date of manufacture and every twelve months thereafter: replace check valve manifold ten years from date of manufacture. Refer to the latest revision of Airborne Service Letter 39 for date of manufacture information and check procedures. U.V.Replace S1495 hoses every 10 years. At the first 100-hour inspection on new, rebuilt or overhauled engines, remove And clean the fuel injection nozzles. Thereafter, the fuel injection nozzles must be Cleaned at 300 hour intervals or more frequently if fuel stains are found.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-16

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 100 HORAS

FORMATO DE INSPECCION 100 HORAS

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-17

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 100 HORAS

CESSNA U206G 100, HOUR AND SPECIAL INSPECTION FORM

DATE MODEL TYPE SERIAL NUMBER TOTAL TIME TIME SINCE O/H REGISTRATION No TIPO INSPECCION

AIRCRAFT

ENGINE

PROPELLER

FECHA DE INICIO FECHA TERMINO

DESCRIPTION

B. FUSELAGE ( Section 3 ) 1. Fuselage Surface - Inspect for skin damage, loose rivets, condition of paint, and check pitot-static ports and drain holes for obstruction. Inspect covers and fairings for security.

100

RII

SPECIAL Hrs Yrs

MECH.

INSP.

RII X

6. Emergency Locator Transmitter :(Ref: Description, Operation, Installation and Maintenance Manual ME406 and ME406HM ELT). a. - Chequear aseguramiento del equipo y correcta operacin, chequear las antenas y sus terminales por correcto ajuste, corrosin, aislamiento y sellado.

b. - Revisin del correcto ruteado de los cables y correcta fijacin.

c.- Requerimientos de Prueba: 1- Sintonice el radio VHF de la Aeronave a la frecuencia de 121.5 MHz 2- Presione el interruptor del remote Switch ELT en ON durante 1 segundo, luego regrese a la posicin ARM. 3- El receptor VHF emitir unos 3 barridos de audio y el panel LED deber presentar un pulso (flash). Un flash indica que el sistema est en buen funcionamiento. Si se muestran ms pulsos (flashes), se determina que existe falla en el ELT. 4. - El zumbador (BUZZER) sonar durante el pulso (flash) emitido.

RII

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-18

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 100 HORAS

DESCRIPTION

8. Pilots and Copilots Inertia Reels - Inspect for security of installation, proper operation, and evidence of damage.

100

RII

SPECIAL Hrs Yrs

MECH.

INSP.

9. Seats, Seat Belts, and Shoulder Harnesses - Check general condition and security. Check operation of seat stops and adjustment mechanism. Inspect belts for condition and security of fasteners. 10. Windows, Windshield, Doors, and Seals Inspect general condition. Check latches, hinges, and seals for condition, operation, and security of attachment. 11. Upholstery, Headliner, Trim and Carpeting - Check condition and clean as required.

400

12. Flight Controls Check freedom of movement and proper operation through full travel with and without flaps extended. Check electric trim controls for operation (as applicable). 13. Aileron, Elevator, and Rudder Stops - Check for damage and security. Compliance with Cessna Service Letter SE8065 is required. 14. Portable Hand Fire Extinguisher - Inspect for proper operating pressure, condition, security of installation, and servicing date. Ref.Pg I-6 15. Seat Tracks and Stops Inspect seat tracks for condition and security of installation. Check seat track stops for damage and correct location. Ensure inspection of seat rails for cracks EACH 50 HOURS. Refer to Section 3. 16. Control Column Inspect pulleys, cables, sprockets, bearings, chains, bungees, and turnbuckles for condition and security. 17. Fuel Line and Selector Valve Drain(s) - Remove plug and drain.

RI I

RI I

RI I

18.Reel Type Secondary seat stop Make sure the manual lock operates correctly

19. Cockpit or Cabin mounted Halotron type fire ExtinguisherEmpty, inspect for damage and recharge.

1 Year

20. Cockpit and Cabin mounted Halotron type fire ExtinguisherPerform hydrostatic test. The hydrostatic test shall be at twelve-year intervals based on initial servicing or date last hydrostatic test.

05 Year

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-19

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 100 HORAS

ESCRIPTION C.WINGS AND EMPENNAGE ( Section 4 ) 1. Wing Surfaces and Tips Inspect for skin damage, loose rivets, and condition of paint. 4. Metal Lines, Hoses, Clamps, and Fittings - Check for leaks, condition, and security. Check for proper routing and support. 6. Vertical and Horizontal Stabilizers, Tips and Tailcone Inspect externally for skin damage and condition of paint.

7. Vertical and Horizontal Stabilizers and Tailcone Structure Inspect bulkheads, spars, ribs, and skins for cracks, wrinkles, loose rivets, corrosion, or other damage. Inspect vertical and horizontal stabilizer attach bolts for looseness. Retorque as necessary. Check security of inspection covers, fairings, and tips. X RII

1 0 0

X

RI I

SPECIAL Hrs Yrs

MECH.

INSP.

RII

8. Wing Struts and Strut Fairings - Check for dents, cracks, loose screw and rivets, and condition of paint.

D. LANDING GEAR AND BRAKES (Section 5 ) 1. Brakes, Master Cylinders, and Parking Brake - Check master cylinders and parking brake mechanism for condition and security. Check fluid level and test operation of toe and parking brake.

2. Main Gear Tubular Struts Inspect for cracks, dents, corrosion, condition of paint or other damage. Check axles for condition and security.

RII X

3. Brake Lines, Wheel Cylinders, Hoses, Clamps, and Fittings Check for leaks, condition, and security and hoses for bulges and deterioration. Check brake lines and hoses for proper routing and support.

400

4. Tires - Check for tread wear and general condition. Check for proper inflation.

5. Wheel Fairings, Strut Fairings, and Cuffs - Check for cracks, dents, and condition of paint.

6. Main Landing Gear Structure - Check for damage, cracks, loose rivets, bolts and nuts and security of attachment.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-20

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 100 HORAS

1 0 0

X

RII

SPECIAL

Hrs Yrs

MECH.

INSP.

DESCRIPTION

7. Main Landing Gear attachment - Check for damage, cracks, loose rivets, bolts and nuts and security of attachment

8. Nose Gear - Inspect torque links, steering rods, and boots for condition and security of attachment. Check strut for evidence of leakage and proper extension. Check strut barrel for corrosion, pitting. and cleanliness. Check shimmy damper and/or bungees for operation, leakage, and attach points for wear and security.

10

Wheel Bearings - Clean, inspect and lube.

11 Nose Gear Attachment Structure Inspect for cracks, corrosion, or other damage and security of attachment. Brake System Overhaul brake discs, parking brake system, wheel cylinders, and master cylinders. Replace brake pads and all rubber goods.

12

E. 1 2

AILERON CONTROL SYSTEM ( Section 6) Aileron Hinges Check condition, security and operation. Aileron Structure, Control Rods, Hinges, Balance Weights, Bellcranks, Linkage, Bolts, Pulley, and Pulleys Brackets Check condition, operation, and security of attachment.

Ailerons and Cables Check operation and security of stops. Check cables for tension, routing, fraying, corrosion, and turnbuckle safety. Check travel if cable tension, requires adjustment or if stops are damaged. Check fairleads and rub strips for condition. Autopilot Rigging check Avionics Installation manual

RII

Aileron Controls Check freedom of movement and proper operation through full travel with and without flaps extended. WING FLAP CONTROL SYSTEM ( Section 7 ) Flaps Check tracks, rollers, and control rods for security of attachment. Check operation. Flap Actuator Threads Clean and lubricate Refer to paragraph 2.51 for detailed instructions. Flap Structure, Linkage, Bellcranks, Pulleys, and Pulley Brackets Check for condition, operation and security. Flaps and Cables - Check cables for proper tension, routing, fraying, corrosion, and turnbuckle safety. Check travel if cable tension requires adjustment.

F. 1 2

P X X 1

RII

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-21

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 100 HORAS

DESCRIPTION

G. ELEVATOR CONTROL SYSTEM ( Section 8 ) 1 Elevator Control Check freedom of movement and proper operation through full travel. 2 Elevator, Hinges, and Cable Attachment Check condition, security and operation. 3 Elevator Control System - Inspect pulleys, cables, sprockets, bearings, chains, and turnbuckles for condition, security, and operation.

1 0 0

RII

SPECIAL

Hrs Yrs

MECH.

INSP.

X X

RIII

Elevator/Rudder Downspring Check structure, bolts, linkage, bellcrank, and push-pull tube for condition, operation, and security. Check cables for tension, routing, fraying, corrosion, and turnbuckle safety. Check travels if cables require tension adjustment or if stops are damaged. H. ELEVATOR TRIM TAB CONTROL SYSTEM (Section 9). 1 Elevator Trim Tab and Hinges Check condition, security, and operation. 2. Elevator Trim System Check cables, push-pull rods, bellcrancks, pulleys, turnbuckles, fairleads, rub strips, etc. for proper routing, condition, and security. 4 3 Trim Controls and Indicators Check freedom of movement and proper operation through full travel. Check pulleys, cables, sprockets, bearings, chains, bungees, and turnbuckles for condition and security. Check electric trim controls for operation as applicable. Elevator Trim Tab Actuator-Clean, lubricate, and check for free-play.

RII

RII

RII

RII

I. RUDDER CONTROL SYSTEM (Sect. 10). 1.Rudder Inspect the rudder skins for cracks and loose rivets, rudder hinges for condition, cracks and security; hinge bolts, hinge bearings, hinge attach fittings, and bonding jumper for evidence of damage and wear, failed fasteners, and security. Inspect the rudder hinge bolts for proper safetying of nuts with cotter pins. Inspect balance weight for looseness and the supporting structure for damage 3. Rudder, Tips, Hinges, Clips and Cable. Attachment Check condition, security, and operation.

J. NORMALLY ASPIRATED ENGINES ( Sect. 12 ) 1. Cowling and Cowl Flaps Inspect for crack, dents and other damage, security of cowl fasteners, and cowl mounted landing light for attachment. Check cowl flaps for condition, security and operation. 2. Engine Inspect for evidence of oil and fuel leaks. Wash engine and check for security of accessories. 3. Cowl Flap Controls Check freedom of movement through full travel.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-22

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 100 HORAS

DESCRIPTION

4. Engine, Propeller Controls, and Linkage - Check general condition, freedom of movement through full range. Check for proper travel, security of attachment, and for evidence of wear. Check friction locks for proper operation. Refer to TCM Service Bulletin SB95-2 or latest revision for detailed instructions on control linkage inspection and lubrication. 5. Ignition Switch and Electrical Harness - Inspect for damage, condition, and security.

1 0 0

X

RII

SPECIAL

Hrs F Yrs

MECH.

INSP.

8. Induction System Check security of clamps, tubes, and ducting. Inspect for evidence of leakage.

9. Induction Airbox, Valves, Doors and Controls-Remove air filter and inspect hinges, doors, seals and attaching parts for wear and security. Check operation. Clean and inspect air filter and re-oil if flock-coated. Refer to Cessna Service Letter SE80-12. 10. Induction Air Filter Inspect the filter grill, filter frame, filter mountings and entire intake system for security, wear and any deformation. Ref. Brackett air filters document I-194. (STC N SA71GL) 11. Alternate Induction Air System -Check for obstructions, operation, and security. 12. Alternator and Electrical Connections - Check condition and security of alternator and support brackets. Check alternator belts for condition and proper adjustment. 13. Alternator Check brushes, leads, commutator or slip ring for wear. 14. Starter, Starter Solenoid, and Electrical Connections Check for condition of starter brushes, brush leads, and commutator. 15. Oil Cooler Check for obstructions, leaks, and security of attachment. 16. Exhaust System - Inspect for cracks and security. Air leak check exhausts system. Refer to Sections 12, for inspection procedures. 17. Exhaust System (Turbocharger engine) Inspect couplings, seal, clamps and expansion joints for cracks Air Leak check exhaust. Refer to Sections 12, for inspection procedures. 18. Auxiliary (Electric) Fuel Pump Check pump and fittings for condition, operation, security Remove and clean filter (as applicable). 19. Engine-Driven Fuel Pump-Check for evidence of leakage, security of attachment, and general condition.

H I

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-23

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 100 HORAS

DESCRIPTION

20. Magnetos-check external condition, security, and electrical leads for condition. Check timing to engine and internal timing if engine timing requires adjustment. Ref. TCM Service Bulletin MSB94-8(latest revision) 21. Magnetos Timing Procedures and intervals, lubrication, and overhaul procedures.

1 0 0

X

RII

SPECIAL

Hrs Yrs

MECH.

INSP.

22 Ignition Harness and Insulators Check for proper routing, deterioration, and condition of terminals. 23. Spark Plugs Remove, clean analyze, test, gap and rotate top plugs-to-bottom and bottom plugs-to-top.

24. Cylinder Compression-Perform differential compress test. Perform a cylinder compression test as detailed in TCM Service Bulletin SB03-3 or latest revision. Record the cylinder compression readings. 25. Fuel Injection System - Check security of fuel-air control unit. Manifold valve, nozzles, screws and pump. Check fuel lines for leaks, and proper routing. Ref. TCM Service Bulletin SB95-7. 27. Hoses, Metal Lines, and Fittings - Inspect for signs of oil and fuel leaks. Check for abrasions, chafing, security, proper routing and support and for evidence of deterioration. 28.Cold and Hot Air Hoses - Check condition, routing, and security.

X X

X X

29. Engine Cylinders, Rocker Box Covers, and Pushrod Housings-Check for fin damage, cracks, oil leakage, security of attachment, and general condition. 30. Engine Baffles and Seals - Check condition and security of attachment.

31. Crankcase, Oil Sump, and Accessory Section Inspect for cracks and evidence of oil leakage. Check bolts and nuts for looseness and retorque as necessary. Check crankcase breather lines for obstructions, security, and general condition. 34. Heater components inspect all components for condition and security.

35.Engine Oil Change Normally Aspirated Engine Without Oil Filter : a. Engine Oil Without Oil Filter Drain oil sump and oil cooler, clean and inspect screen, and refill with recommended grade aviation oil.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-24

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 100 HORAS

DESCRIPTION

37. Engine Oil Change - Normally Aspirated Engines With Oil Filters : a. Drain oil sump and refill with recommended grade aviation oil (when system is equipped with short oil filter). b. Drain oil sump, remove and replace long oil filter (approximately 5.8 inches long), and refill with recommended grade aviation oil. K. FUEL SYSTEM (Section 13). 1 Integral Fuel Tanks - Check for evidence of leakage and condition of fuel caps, adapters, and placards. 2 Integral Fuel Tanks Drain fuel and check tank interior and outlet screens.

1 0 0

X

RII

SPECIAL

Hrs N Yrs

MECH.

INSP.

X X

Fuel System - Inspect plumbing and components for mounting and security.

Fuel Tank or bladders - Drain drain water and sediment. Fuel Tank Vent Lines and Vent Valves Check vents for obstruction and proper positioning. Check valves for operation. Fuel Selector Valve - Check controls for detent in each position, security of attachment, and for proper placarding.

Throttle Operated Auxiliary Fuel Pump Switch. Check condition of wiring and security of components. Perform rigging check. Refer to Section 13-33. 10 Fuel Strainer, Drain Valve, and Controls - Check freedom of movement, security, and proper operation. Disassemblies, flush, and clean screen and bowl. 11 Fuel Quantity Indicators - Check for damage, security of installation, and perform accuracy test. Fuel Quantity Indicating check for damage and security of installation and perform accuracy test. Inspect / clean the fuel injection nozzle. Ref. Service Information Directive SID05-7

EAC H 1 RII EAC H 1 V

12

13

L. 1

PR0PELLER AND PROPELLER GOVERNOR (Section 14). Propeller, Governor and Control - Inspect for oil and grease leaks. If leakage is evident, refer to McCauley Service Manual.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-25

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 100 HORAS

DESCRIPTION

2 3 Proper Mounting - Check for security of installation. Propeller Blades Inspect for cracks, dents, nicks, scratches, erosion, corrosion, or other damage. Spinner - Check general condition and attachment.

1 0 0

X X

RII

SPECIAL

Hrs Yrs

MECH.

INSP.

Spinner and Spinner Bulkhead Remove spinner, wash, and inspect for cracks and fractures. UTILITY SYSTEMS ( Section 15 ) Ventilation System - Inspect clamps, hoses, and valves for condition and security. Heater Components, Inlets, and Outlets - Inspect all lines, connections, ducts, clamps, seals, and gaskets for condition, restriction, and security. Pitot Tube and Stall Warning Vane - Check for condition and obstructions.

M. 1 2

400 X

5 Pitot Tube Heater Element Perform operational check.

N. 1 2

INSTRUMENTS AND INSTRUMENT SYSTEM ( Section 16 ) Vacuum System Inspect for condition and security. Vacuum System Hoses - Inspect for deterioration, looseness, or collapsed hoses. hardness,

X X X U

Vacuum Pump - Check for condition and security. Check vacuum system breather line for obstructions, condition, and security. Vacuum System Air Filter - Inspect for damage, deterioration and contamination. Clean or replace, if required. NOTE: Smoking will cause premature filter clogging. Vacuum System relief Valve - Inspect for condition and security. Instruments Check general condition and markings for legibility.

10 Airspeed indicator, Vertical speed indicator, and magnetic compass calibrate

11 Altimeter and Static System - Inspect in accordance with FAR RAP 91.411.

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-26

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 100 HORAS

DESCRIPTION O.

2

1 0 0 X X

RII

SPECIAL

Hrs Yrs

MECH.

INSP.

ELECTRICAL SYSTEMS (Sect 17)

Instrument, Cabin, Navigation, Beacon, Strobe, and Landing Lights Check operation, condition of lens, and security of attachment. 3. Circuit Breakers and Fuses Check operation and condition. Check for required number of spare fuses. 4. Battery Check general condition and security. Check level of electrolyte.

5. Battery Box and Cables - Clean and remove any corrosion. Check cables for routing, support, and security of connections. P. POST INSPECTION 1. Re-install fairings, doors, and access hole covers. Ground check engine, alternator charging rate, oil pressure, tachometer, oil temperature and pressure gages, and general operation of components. Q. PERFORM THE FOLLOWING OPERATIONAL CHECK 1. Brakes - Test toe brakes and parking brake for proper operation R. SERVICE BULLETINS/AIRWORTHINES DIRECTIVES, 1. Check that all applicable Cessna Service Bulletins, CAPs, SIDs and Supplier Service Bulletins are complied with. A compliance record shall be filled every inspection 2. Check that all applicable Airworthiness Directives, Normas Tcnicas Complementarias and RAPs are complied with. 3. Ensure all Maintenance Record Entries required by RAPs are completed before returning the airplane to service. After the inspection has been completed, an engine RUN UP should again be performed to determine that any discrepancies or abnormalities have been corrected.

Date of Completion

_____/_____/_____

TASKS PERFORMED BY: MECHANIC

NAME Lic FIRMA NAME

INSPECTOR

Lic. FIRMA

NOTA: Para el caso en el que durante un procedimiento de mantenimiento rutinario (Ejem.: Inspeccin de 50, 100, 200 horas, Inspecciones Especiales de 1000 horas), en que no aplique la ejecucin de un RII, (por no haberse efectuado instalacin, ajuste, calibracin o reglaje), en el espacio correspondiente se anotar el signo N/A (no Aplicable).

FECHA : 30 JUNIO 2012

REVISION: R-8

PAGINA: II-27

PROGRAMA DE MANTENIMIENTO CESSNA U206G: OB-1192 / OB-1204

CAPITULO II. FORMATO DE INSPECCION DE 100 HORAS CESSNA U206G SPECIAL INSPECTION ITEM GUIDE