Documente Academic

Documente Profesional

Documente Cultură

QW484B

Încărcat de

Mohamed Ahmed MaherDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

QW484B

Încărcat de

Mohamed Ahmed MaherDrepturi de autor:

Formate disponibile

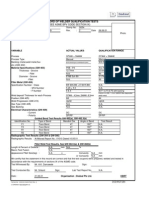

QW-484B SUGGESTED FORMAT B FOR WELDING OPERATOR PERFORMANCE QUALIFICATIONS (WOPQ) (See QW-301, Section IX, ASME Boiler

and Pressure Vessel Code)

Welders name Identification of WPS followed Specification of base metal(s) Base metal P or S-Number Plate Filler metal (SFA) specification to P or S-Number Filler metal or electrode classification Pipe (enter diameter if pipe or tube): Position (2G, 6G, 3F, etc.) Identification no. Test Description (Information Only) Test coupon Thickness Production weld

Testing Conditions and Qualification Limits When Using Automatic Welding Equipment Welding Variables (QW-361.1) Type of welding (Automatic) Welding process Filler metal (EBW or LBW) Type of laser for LBW (CO2 to YAG, etc.) Continuous drive or inertia welding (FW) Vacuum or out of vacuum (EBW) Testing Conditions and Qualification Limits When Using Machine Welding Equipment Welding Variables (QW-361.2) Type of welding (machine) Welding process Direct or remote visual control Automatic arc voltage control (GTAW) Automatic joint tracking Position qualified (2G, 6G, 3F, etc.) Consumable inserts (GTAW or PAW) Backing (metal, weld metal, etc.) Single or multiple passes per side Actual Values Range Qualified Actual Values Range Qualified

RESULTS Visual Examination of Completed Weld (QW-302.4) Bend test; Transverse root and face [QW-462.3(a)]; Longitudinal root and face [QW-462.3(b)]; Side (QW-462.2);

Pipe bend specimen, corrosion-resistant overlay [QW-462.5(c)]; Macro test for fusion [QW-462.5(b)];

Type Result Type

Plate bend specimen, corrosion-resistant overlay [QW-462.5(d)]; Macro test for fusion [QW-462.5(e)]

Result Type Result

Alternative radiographic examination results (QW-191) Fillet weld fracture test (QW-180) Macro examination (QW-184) Other tests Film or specimens evaluated by Mechanical tests conducted by Welding supervised by We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in accordance with the requirements of Section IX of the ASME Code. Organization Date

(7/01)

Length and percent of defects Fillet size (in.) Concavity/convexity (in.) Company Laboratory test no.

By

This form (E0008B) may be obtained from the Order Dept., ASME, 22 Law Drive, Box 2300, Fairfield, NJ 07007-2300.

E 0008B

S-ar putea să vă placă și

- QCF328 Welding Operator Performance Qualification (WOPQ)Document1 paginăQCF328 Welding Operator Performance Qualification (WOPQ)minhnnÎncă nu există evaluări

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- Form Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 paginăForm Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)viswamanojÎncă nu există evaluări

- How to prepare Welding Procedures for Oil & Gas PipelinesDe la EverandHow to prepare Welding Procedures for Oil & Gas PipelinesEvaluare: 5 din 5 stele5/5 (1)

- WPQ TemplateDocument1 paginăWPQ Templatejoshrathburn1980Încă nu există evaluări

- QW484ADocument1 paginăQW484AMohamed Ahmed MaherÎncă nu există evaluări

- Qw-484B Format For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document7 paginiQw-484B Format For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Gerardo Arispe AramayoÎncă nu există evaluări

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 paginăQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Jose Elian Cuellar PinzónÎncă nu există evaluări

- WPQ PDFDocument1 paginăWPQ PDFJose Elian Cuellar PinzónÎncă nu există evaluări

- Form Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 paginăForm Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)KautiilaÎncă nu există evaluări

- WQT 1236Document1 paginăWQT 1236mir31721Încă nu există evaluări

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 paginăQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Alesol EquipmentÎncă nu există evaluări

- Test Description (Information Only)Document2 paginiTest Description (Information Only)dayalramÎncă nu există evaluări

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 paginăQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Aries MarteÎncă nu există evaluări

- Welders Performance Qualification Record (WPQ) : Welder Name Identification No. Test DescriptionDocument8 paginiWelders Performance Qualification Record (WPQ) : Welder Name Identification No. Test DescriptionGerardo Arispe AramayoÎncă nu există evaluări

- Book 1Document3 paginiBook 1ansarmulla711Încă nu există evaluări

- WPQ PDFDocument0 paginiWPQ PDFstanleyÎncă nu există evaluări

- Saravanan Wpq-5g 50nbDocument1 paginăSaravanan Wpq-5g 50nbDeepakÎncă nu există evaluări

- mohanWPQ-1G 40NBDocument1 paginămohanWPQ-1G 40NBDeepakÎncă nu există evaluări

- WPQ Format Sec IxDocument2 paginiWPQ Format Sec IxParminder SinghÎncă nu există evaluări

- Ab-076a Welder Qualification Record WQRDocument1 paginăAb-076a Welder Qualification Record WQRAhmed Shaban KotbÎncă nu există evaluări

- WPQ 2Document1 paginăWPQ 2FirozÎncă nu există evaluări

- Machote WPQ SoldadoresDocument17 paginiMachote WPQ SoldadoresAries MarteÎncă nu există evaluări

- Welder Performance Qualification-Interactive Form QW-484ADocument1 paginăWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- Suggested Wps Forms ASME - IX 2010Document5 paginiSuggested Wps Forms ASME - IX 2010Ajay ChodankarÎncă nu există evaluări

- Interactive Form QW-485 PDFDocument1 paginăInteractive Form QW-485 PDFRama Krishna Reddy DonthireddyÎncă nu există evaluări

- WPQ CS SmawDocument1 paginăWPQ CS Smawniket0Încă nu există evaluări

- WPQRDocument1 paginăWPQRShani MalikÎncă nu există evaluări

- Ab-076a Welder Qualification Record WQRDocument1 paginăAb-076a Welder Qualification Record WQRvinodÎncă nu există evaluări

- QW484Document1 paginăQW484Anonymous 4e7GNjzGWÎncă nu există evaluări

- Welder Performance Qualification (WPQ)Document2 paginiWelder Performance Qualification (WPQ)alokbdasÎncă nu există evaluări

- Form Qw-485 Suggested Format For Demonstration of Standard Welding Procedure Specifications (SWPS) (See Article V)Document1 paginăForm Qw-485 Suggested Format For Demonstration of Standard Welding Procedure Specifications (SWPS) (See Article V)Emma DÎncă nu există evaluări

- Welder Certificate Sample1Document1 paginăWelder Certificate Sample1Buddy EkoÎncă nu există evaluări

- ASME BPVC Sec IX 2023 - Demonstration FormDocument1 paginăASME BPVC Sec IX 2023 - Demonstration Formmr.bakhtiari.mahmoudÎncă nu există evaluări

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 pagină193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Record of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Document1 paginăRecord of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Weld Bro SandeepÎncă nu există evaluări

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Încă nu există evaluări

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarÎncă nu există evaluări

- PQRDocument2 paginiPQRSreenivas Kamachi Chettiar100% (1)

- WPQ Format - SMAWDocument3 paginiWPQ Format - SMAWBalkishan DyavanapellyÎncă nu există evaluări

- 161 Gmaw Zug Asme (Beni Kantona 3g) WPQDocument2 pagini161 Gmaw Zug Asme (Beni Kantona 3g) WPQMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Încă nu există evaluări

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Încă nu există evaluări

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Încă nu există evaluări

- 188-Gmaw-Zug-Asme (Rivaldy Hendrawan-3g) - WPQDocument1 pagină188-Gmaw-Zug-Asme (Rivaldy Hendrawan-3g) - WPQMuhammad Fitransyah Syamsuar Putra100% (1)

- WOPQ Form English1Document2 paginiWOPQ Form English1oaperuchenaÎncă nu există evaluări

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Încă nu există evaluări

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)ravi00098Încă nu există evaluări

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Încă nu există evaluări

- WPQ Certificates Klis14Document8 paginiWPQ Certificates Klis14AdhicharanÎncă nu există evaluări

- QW-483 BlankDocument2 paginiQW-483 BlankCraftyBob100% (1)

- FQ 069Document1 paginăFQ 069Chava TejaÎncă nu există evaluări

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Încă nu există evaluări

- RSW WOPQ REV. 2010a Interactive FormDocument1 paginăRSW WOPQ REV. 2010a Interactive FormcosmicbunnyÎncă nu există evaluări

- Sa 516 GR 70 WPSDocument5 paginiSa 516 GR 70 WPSRajesh Owaiyar71% (7)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarÎncă nu există evaluări

- Fcaw 16 THKDocument5 paginiFcaw 16 THKAnonymous Ij6VfaÎncă nu există evaluări

- Asme 9 DatosDocument47 paginiAsme 9 Datosvichu_villamarÎncă nu există evaluări

- Format For Manufacturer Record of Welding Operator QualificationDocument1 paginăFormat For Manufacturer Record of Welding Operator QualificationRajeev KumarÎncă nu există evaluări

- Surface Texture (Surface Roughness, Waviness, and Lay) : ASME B46.1-2002Document5 paginiSurface Texture (Surface Roughness, Waviness, and Lay) : ASME B46.1-2002Mohamed Ahmed MaherÎncă nu există evaluări

- A803-2003-Standard Specification For Welded Ferritic Stainless Steel Feedwater Heater TubesDocument7 paginiA803-2003-Standard Specification For Welded Ferritic Stainless Steel Feedwater Heater TubesMohamed Ahmed MaherÎncă nu există evaluări

- APPENDIX B Filler Metal Comparison Chart ABS-AWS-OCRDocument3 paginiAPPENDIX B Filler Metal Comparison Chart ABS-AWS-OCRMohamed Ahmed MaherÎncă nu există evaluări

- Magnetic Particle Testing PDFDocument48 paginiMagnetic Particle Testing PDFMohamed Ahmed MaherÎncă nu există evaluări

- A833-1996-OCR-Standard Practice For Indentation Hardness of Metallic Materials by Comparison Hardness Testers PDFDocument2 paginiA833-1996-OCR-Standard Practice For Indentation Hardness of Metallic Materials by Comparison Hardness Testers PDFMohamed Ahmed MaherÎncă nu există evaluări

- A803-2001-OCR-Standard Specification For Welded Ferritic Stainless Steel Feedwater Heater Tubes PDFDocument6 paginiA803-2001-OCR-Standard Specification For Welded Ferritic Stainless Steel Feedwater Heater Tubes PDFMohamed Ahmed MaherÎncă nu există evaluări

- A833-1996-OCR-Standard Practice For Indentation Hardness of Metallic Materials by Comparison Hardness Testers PDFDocument2 paginiA833-1996-OCR-Standard Practice For Indentation Hardness of Metallic Materials by Comparison Hardness Testers PDFMohamed Ahmed MaherÎncă nu există evaluări

- A800-2001-OCR-Standard Practice For Steel Casting, Austenitic Alloy, Estimating Ferrite Content Thereof PDFDocument6 paginiA800-2001-OCR-Standard Practice For Steel Casting, Austenitic Alloy, Estimating Ferrite Content Thereof PDFMohamed Ahmed MaherÎncă nu există evaluări

- A770-1986-Ocr-Specification For Through-Thickness Tension Testing of Steel Plates For Special ApplicationsDocument8 paginiA770-1986-Ocr-Specification For Through-Thickness Tension Testing of Steel Plates For Special ApplicationsMohamed Ahmed Maher100% (1)

- A763-1993 - (Reapproved 1999) - OCR-Standard Practices For Detecting Susceptibility To Intergranular Attack in Ferritic Stainless Steels PDFDocument11 paginiA763-1993 - (Reapproved 1999) - OCR-Standard Practices For Detecting Susceptibility To Intergranular Attack in Ferritic Stainless Steels PDFMohamed Ahmed MaherÎncă nu există evaluări

- A790-Rev 4Document7 paginiA790-Rev 4Mohamed Ahmed MaherÎncă nu există evaluări

- A800-2001-OCR-Standard Practice For Steel Casting, Austenitic Alloy, Estimating Ferrite Content Thereof PDFDocument6 paginiA800-2001-OCR-Standard Practice For Steel Casting, Austenitic Alloy, Estimating Ferrite Content Thereof PDFMohamed Ahmed MaherÎncă nu există evaluări

- A611-1997-OCR-Last-Standard Specification For Structural Steel (SS), Sheet, Carbon, Cold-Rolled PDFDocument1 paginăA611-1997-OCR-Last-Standard Specification For Structural Steel (SS), Sheet, Carbon, Cold-Rolled PDFMohamed Ahmed MaherÎncă nu există evaluări

- A700-2005-OCR-Standard Practices For Packaging, Marking, and Loading Methods For Steel Products For ShipmentDocument40 paginiA700-2005-OCR-Standard Practices For Packaging, Marking, and Loading Methods For Steel Products For ShipmentMohamed Ahmed MaherÎncă nu există evaluări

- Application Form For CSWIP 10 Year Assessment (Overseas) No LogbookDocument7 paginiApplication Form For CSWIP 10 Year Assessment (Overseas) No LogbookMohamed Ahmed MaherÎncă nu există evaluări

- 34 Samss 711Document26 pagini34 Samss 711Mohamed Ahmed MaherÎncă nu există evaluări

- ABS Guide For Building and Classing Subsea Pipeline SystemsDocument184 paginiABS Guide For Building and Classing Subsea Pipeline SystemsLiu MengLongÎncă nu există evaluări

- Astm A 610 PDFDocument2 paginiAstm A 610 PDFMohamed Ahmed MaherÎncă nu există evaluări

- A20-2000 - Standard Specification For General Requirements For Steel Plates For Pressure VesselsDocument31 paginiA20-2000 - Standard Specification For General Requirements For Steel Plates For Pressure VesselsMohamed Ahmed MaherÎncă nu există evaluări

- APPENDIX B Filler Metal Comparison Chart ABS-AWS-OCRDocument3 paginiAPPENDIX B Filler Metal Comparison Chart ABS-AWS-OCRMohamed Ahmed MaherÎncă nu există evaluări

- Liquid Penetrant TestingDocument20 paginiLiquid Penetrant TestingsanjibkrjanaÎncă nu există evaluări

- 12 Samss 007 PDFDocument30 pagini12 Samss 007 PDFMohammadAseef100% (1)

- 01 Samss 035Document28 pagini01 Samss 035Mohamed Ahmed MaherÎncă nu există evaluări

- Magnetic Particle TestingDocument34 paginiMagnetic Particle Testingmnaseemiqbal4200Încă nu există evaluări

- FormP 2Document2 paginiFormP 2Mohamed Ahmed MaherÎncă nu există evaluări

- Materials System Specification: IndraDocument13 paginiMaterials System Specification: IndrasridharÎncă nu există evaluări

- FormU 1Document2 paginiFormU 1Mohamed Ahmed MaherÎncă nu există evaluări

- QW484BDocument1 paginăQW484BMohamed Ahmed MaherÎncă nu există evaluări

- Effect of Elements On SteelDocument18 paginiEffect of Elements On SteelMohamed Ahmed MaherÎncă nu există evaluări

- FormP 2Document2 paginiFormP 2Mohamed Ahmed MaherÎncă nu există evaluări

- Guide of Methods For Determining The Condition of Stator Winding Insulation - ELT - 270 - 3 PDFDocument4 paginiGuide of Methods For Determining The Condition of Stator Winding Insulation - ELT - 270 - 3 PDFrad1962Încă nu există evaluări

- Surface Tension and Molar Surface Free Energy and Entropy of Water To - 27.2Document4 paginiSurface Tension and Molar Surface Free Energy and Entropy of Water To - 27.2ANGELICA ALEJANDRA MORENO CONTEREASÎncă nu există evaluări

- The Onion Cell LabDocument2 paginiThe Onion Cell LabRahmania Okta0% (1)

- TRASCO ES Couplings PDFDocument16 paginiTRASCO ES Couplings PDFAlvaro Felipe CharlinÎncă nu există evaluări

- Cement and Concrete CompositesDocument7 paginiCement and Concrete CompositessattiricÎncă nu există evaluări

- The Output Brochure Will Be Assessed Based On The Criteria and Rubrics For A Written ArticleDocument3 paginiThe Output Brochure Will Be Assessed Based On The Criteria and Rubrics For A Written ArticleWilhelmina FernandoÎncă nu există evaluări

- Le Chatelier's PrincipleDocument15 paginiLe Chatelier's PrincipleAldrick VeranoÎncă nu există evaluări

- An Introduction To A Neurofeedback-Based Self-Rewarding Framework On Mobile Devices Using Modern HcisDocument8 paginiAn Introduction To A Neurofeedback-Based Self-Rewarding Framework On Mobile Devices Using Modern HcisakisÎncă nu există evaluări

- Exercise 1 - ElasticityDocument4 paginiExercise 1 - ElasticityMINGHAN HEÎncă nu există evaluări

- KDM 1Document42 paginiKDM 1KarthikeyanRamanujamÎncă nu există evaluări

- Figure Painting Concepts 2018Document23 paginiFigure Painting Concepts 2018Alberto AsiciliaÎncă nu există evaluări

- Grad Student HandbookDocument26 paginiGrad Student HandbookAli BaigÎncă nu există evaluări

- Ingles Manual DL22Document134 paginiIngles Manual DL22ThomasÎncă nu există evaluări

- The Resources, You Can Also Search and Watch Video Presentations Regarding The TopicDocument2 paginiThe Resources, You Can Also Search and Watch Video Presentations Regarding The TopicStefie Grail Coilan EganÎncă nu există evaluări

- Computational Flexible Multibody Dynamics: Bernd SimeonDocument254 paginiComputational Flexible Multibody Dynamics: Bernd SimeonSergio Quisbert P.100% (1)

- UK BIM Alliance, BSI & CDBB Launch UK BIM FrameworkDocument2 paginiUK BIM Alliance, BSI & CDBB Launch UK BIM FrameworkInuyashahanÎncă nu există evaluări

- درجة تضمين مهارات الاقتصاد المعرفي في مقررات الدراسات الاجتماعية للمرحلة الابتدائية بالمملكة العربية السعوديةDocument26 paginiدرجة تضمين مهارات الاقتصاد المعرفي في مقررات الدراسات الاجتماعية للمرحلة الابتدائية بالمملكة العربية السعوديةAbdallah HamedÎncă nu există evaluări

- CAD Designer - Job at Vattenfall in Hamburg, KoldingDocument4 paginiCAD Designer - Job at Vattenfall in Hamburg, KoldingKevin DungÎncă nu există evaluări

- Bulb Plate Section ModulusDocument1 paginăBulb Plate Section ModulusRupesh KarmakerÎncă nu există evaluări

- IELTS Listening Practice 01Document16 paginiIELTS Listening Practice 01ENGLISH LANGUAGE TUTORINGÎncă nu există evaluări

- INOKSAN - Hood AirflowDocument6 paginiINOKSAN - Hood AirflowJaffar AliÎncă nu există evaluări

- Non-Relativistic Limit of The Dirac EquationDocument3 paginiNon-Relativistic Limit of The Dirac EquationFelipe HortzÎncă nu există evaluări

- Graphic Design Thesis TopicsDocument8 paginiGraphic Design Thesis Topicsafkololop100% (1)

- Answer The Following Question by Referring To The ReadingDocument3 paginiAnswer The Following Question by Referring To The ReadingNovaldo GuchiÎncă nu există evaluări

- 5e ModelDocument5 pagini5e ModelMia Claril DecanoÎncă nu există evaluări

- Operations On StringDocument12 paginiOperations On StringyaswanthbusireddyÎncă nu există evaluări

- Exterminate, RegenerateDocument2 paginiExterminate, Regeneratekafka47caÎncă nu există evaluări

- Module 4 AssignmentDocument4 paginiModule 4 AssignmentSophia June NgÎncă nu există evaluări

- Patterns and Correlates of New Psychoactive Substance Use in A Sample of Australian High School StudentsDocument7 paginiPatterns and Correlates of New Psychoactive Substance Use in A Sample of Australian High School StudentsFirli FarhatunnisaÎncă nu există evaluări

- NRS EZ0302 StandardSpecificationDocument40 paginiNRS EZ0302 StandardSpecificationArifÎncă nu există evaluări