Documente Academic

Documente Profesional

Documente Cultură

M Effect in Fuse

Încărcat de

Bilawal RattarTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

M Effect in Fuse

Încărcat de

Bilawal RattarDrepturi de autor:

Formate disponibile

M effect M effect stands for 'Metcalf' effect after the person who discovered it.

It involves the use of a small amount of low-melting point alloy (often solder) fixed to the fuse element (wire or strip). Under low overload conditions the fuse element heats up causing the M-effect alloy to diffuse into the metal of the element, increasing its resistance and hence shortening the time to blow comparedto the same element without Meffect. Under high overload conditions the fuse element heats up soquickly that there is no time for diffusion to occur. Surprisingly, fuse designers use this effect as a way of creating a fuse with time-delay characteristic, because it allows them to use a thickerwire (or strip) than they would otherwise be able to for a given current rating. It is this thickermaterial that allows a time-delay fuse to withstand short-duration highcurrent surges.

S-ar putea să vă placă și

- 22 - Altenhuber - Guidance For The Application of Low Voltage FusesDocument10 pagini22 - Altenhuber - Guidance For The Application of Low Voltage FusesRagowo Tri WicaksonoÎncă nu există evaluări

- Different Types of BusDocument2 paginiDifferent Types of Busrodolfoordiguez_70Încă nu există evaluări

- BS en 50368 Cable CleatDocument27 paginiBS en 50368 Cable CleatNima dawa SherpaÎncă nu există evaluări

- International Standard: Norme InternationaleDocument19 paginiInternational Standard: Norme InternationaleCarlos Julio Lozano Piedrahita100% (1)

- Failure Modes of Outdoor InsulatorsDocument4 paginiFailure Modes of Outdoor InsulatorszerferuzÎncă nu există evaluări

- (3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2Document3 pagini(3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2ErwinÎncă nu există evaluări

- G81 - 2 Housing Materials PDFDocument17 paginiG81 - 2 Housing Materials PDFHassan SaeedÎncă nu există evaluări

- Quotation For Power Supply To RobertDocument2 paginiQuotation For Power Supply To RobertEdwin KevynÎncă nu există evaluări

- Hubbell - Connector Theory - Failure Modes & Practical ApplicationsDocument30 paginiHubbell - Connector Theory - Failure Modes & Practical Applicationssulemankhalid100% (1)

- Re: Isolated Phase BusductDocument8 paginiRe: Isolated Phase BusductRamesh AnanthanarayananÎncă nu există evaluări

- As 60265.2-2005 High-Voltage Switches High-Voltage Switches For Rated Voltages of 52kV and Above (IEC60265-2Document9 paginiAs 60265.2-2005 High-Voltage Switches High-Voltage Switches For Rated Voltages of 52kV and Above (IEC60265-2SAI Global - APACÎncă nu există evaluări

- PILC Cable Data Sheet PDFDocument2 paginiPILC Cable Data Sheet PDFbiglee82Încă nu există evaluări

- Tracking in InsulatorsDocument6 paginiTracking in InsulatorsGaurav kumarÎncă nu există evaluări

- 2011.10 Electra Report Non Conventional LPSDocument6 pagini2011.10 Electra Report Non Conventional LPSRigoberto CuellarÎncă nu există evaluări

- Chapter 1 - INTRODUCTIONDocument7 paginiChapter 1 - INTRODUCTIONMark Loyd ColoniaÎncă nu există evaluări

- As 60269.3.0-2005 Low-Voltage Fuses - Supplementary Requirements For Fuses For Use by Unskilled Persons (FuseDocument8 paginiAs 60269.3.0-2005 Low-Voltage Fuses - Supplementary Requirements For Fuses For Use by Unskilled Persons (FuseSAI Global - APAC0% (2)

- Selection of Surge Protective Device (SPD) - (Part 3) - Electrical Notes & ArticlesDocument8 paginiSelection of Surge Protective Device (SPD) - (Part 3) - Electrical Notes & ArticlesRahul ItaliyaÎncă nu există evaluări

- Bus Bar Insulating ShroudsDocument3 paginiBus Bar Insulating ShroudsRohit SharmaÎncă nu există evaluări

- InsulationDocument9 paginiInsulationASDFGHJKÎncă nu există evaluări

- How To Control Electric Stress in Cable JointsDocument7 paginiHow To Control Electric Stress in Cable JointsS S V Jagannadha Sarma GummaÎncă nu există evaluări

- 8DA10 Installation Manual PDFDocument52 pagini8DA10 Installation Manual PDFzarchiwin05Încă nu există evaluări

- HYGK-306 Circuit Breaker TesterDocument31 paginiHYGK-306 Circuit Breaker TesterEdgar CooÎncă nu există evaluări

- I-Line II: Schneider BuswayDocument23 paginiI-Line II: Schneider BuswaymahmoudÎncă nu există evaluări

- Catalogo FridaDocument30 paginiCatalogo FridaJavier RiveraÎncă nu există evaluări

- OPGW - Optical Ground Wire: Equipment Technical SpecificationDocument25 paginiOPGW - Optical Ground Wire: Equipment Technical SpecificationMAN TÎncă nu există evaluări

- FRP Rods For Brittle Fracture ResistantDocument9 paginiFRP Rods For Brittle Fracture Resistantdmsoares1989Încă nu există evaluări

- Pfisterer Overhead Line Insulators Silicone InsulatorsDocument20 paginiPfisterer Overhead Line Insulators Silicone InsulatorsthangbinhbkÎncă nu există evaluări

- EVS HD 629 1 S2 2006 en PreviewDocument7 paginiEVS HD 629 1 S2 2006 en PreviewSandra Milena Arias BetancourthÎncă nu există evaluări

- HV DC PrysmianDocument32 paginiHV DC PrysmianFiras AtwanÎncă nu există evaluări

- Trench Shenyang TCVT 40.5-550 - ManualDocument27 paginiTrench Shenyang TCVT 40.5-550 - ManualLong TranÎncă nu există evaluări

- Iec Standards For Low Voltage FusesDocument3 paginiIec Standards For Low Voltage Fusesjaideep.patel1516Încă nu există evaluări

- AFL Substation Bus DampersDocument12 paginiAFL Substation Bus Dampersabhi120783Încă nu există evaluări

- A Theoretical Model For Corrosion Assessment in Overhead Line ConductorsDocument6 paginiA Theoretical Model For Corrosion Assessment in Overhead Line Conductorsdeathjester1Încă nu există evaluări

- C Compact EUROMOLDDocument40 paginiC Compact EUROMOLDWalter CahuanaÎncă nu există evaluări

- Communications OPGW Fittings ClosuresDocument20 paginiCommunications OPGW Fittings ClosuresalisolmazÎncă nu există evaluări

- Heatshrink Joints PDFDocument24 paginiHeatshrink Joints PDFMonish KrishnaÎncă nu există evaluări

- Overhead SwitchesDocument24 paginiOverhead SwitchesAnthony LagradaÎncă nu există evaluări

- Three-Phase Shunt Reactors ED3K For Compensation of Reactive CapacitiveDocument2 paginiThree-Phase Shunt Reactors ED3K For Compensation of Reactive CapacitiveGeangu SilviuÎncă nu există evaluări

- Etap ZcociDocument7 paginiEtap ZcociJorgeLabraCanalesÎncă nu există evaluări

- 3X185 RM HT (Test Report)Document1 pagină3X185 RM HT (Test Report)jamilÎncă nu există evaluări

- 3M CtalogueDocument54 pagini3M CtalogueMasoud Baig100% (1)

- Nxplus CDocument172 paginiNxplus Cmurad musslumÎncă nu există evaluări

- GRE160 Manual 6F2T0179-3.1Document357 paginiGRE160 Manual 6F2T0179-3.1VanLoveeÎncă nu există evaluări

- Land Telegraph LinesDocument26 paginiLand Telegraph LinesAlex WarHorseÎncă nu există evaluări

- EDOC-Practical Considerations in Surge ProtectionDocument15 paginiEDOC-Practical Considerations in Surge ProtectionEl Comedor BenedictÎncă nu există evaluări

- GPS Application Guide SDC ENDocument3 paginiGPS Application Guide SDC ENRoberto Amaral FurlaniÎncă nu există evaluări

- SBEC4000 Parts NumbersDocument88 paginiSBEC4000 Parts NumbersRyan WilsonÎncă nu există evaluări

- 4327 Corrosive Sulphur Flyer PDFDocument2 pagini4327 Corrosive Sulphur Flyer PDFMichael Angelo VidalÎncă nu există evaluări

- EDC-DTS-LV002 - Electrical Accessories For LV ABCDocument34 paginiEDC-DTS-LV002 - Electrical Accessories For LV ABCJoe bilouteÎncă nu există evaluări

- Operation Manual: Metal-Clad SwitchgearDocument36 paginiOperation Manual: Metal-Clad Switchgearceti7Încă nu există evaluări

- IEE Wiring RegulationDocument23 paginiIEE Wiring Regulationafterc82100% (1)

- Insulator PDFDocument11 paginiInsulator PDFmanoj_2027100% (1)

- Water Tree Cable JointsDocument151 paginiWater Tree Cable JointsSellappan MuthusamyÎncă nu există evaluări

- Surge Arrester TypeDocument4 paginiSurge Arrester Typefahri adrianÎncă nu există evaluări

- UniGear ZS3.2 Brochure Rev. B EN PDFDocument8 paginiUniGear ZS3.2 Brochure Rev. B EN PDFbpchimeraÎncă nu există evaluări

- Descriptive Bulletin 242-32Document25 paginiDescriptive Bulletin 242-32mashan98Încă nu există evaluări

- Fuses LectureDocument14 paginiFuses LectureWilfred AsonmwonririÎncă nu există evaluări

- Librarybussmannhighvoltagefuses PDFDocument65 paginiLibrarybussmannhighvoltagefuses PDFAhmad Yon KhoerulÎncă nu există evaluări

- PrintersDocument1 paginăPrintersBilawal RattarÎncă nu există evaluări

- Em AssignmentDocument5 paginiEm AssignmentBilawal RattarÎncă nu există evaluări

- How To Configure VPN Connection (Win7)Document2 paginiHow To Configure VPN Connection (Win7)Bilawal RattarÎncă nu există evaluări

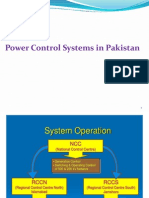

- Lec-3 Power Control Systems in PakistanDocument14 paginiLec-3 Power Control Systems in PakistanBilawal RattarÎncă nu există evaluări

- Lec-3 Distributed ControlDocument6 paginiLec-3 Distributed ControlBilawal RattarÎncă nu există evaluări

- List of Tuition Free Universities in GermanyyDocument1 paginăList of Tuition Free Universities in GermanyyBilawal RattarÎncă nu există evaluări

- Lec-2 SCADA SystemDocument16 paginiLec-2 SCADA SystemBilawal RattarÎncă nu există evaluări

- 23rd March 2012 Freedom Rally in Karachi JSQM Chairmen Bashir Khan QureshiDocument4 pagini23rd March 2012 Freedom Rally in Karachi JSQM Chairmen Bashir Khan QureshiBilawal RattarÎncă nu există evaluări

- Syllabus B.E Electrical (1st To 8th Term)Document43 paginiSyllabus B.E Electrical (1st To 8th Term)Bilawal RattarÎncă nu există evaluări

- Lec-2 Computer Control of Power SystemDocument6 paginiLec-2 Computer Control of Power SystemBilawal RattarÎncă nu există evaluări

- Lec-1 - Structure of Power SystemDocument1 paginăLec-1 - Structure of Power SystemBilawal RattarÎncă nu există evaluări

- Lec-5 Fundamentals of AGCDocument16 paginiLec-5 Fundamentals of AGCBilawal RattarÎncă nu există evaluări

- Lec-1 Automated Power System Control ConceptDocument3 paginiLec-1 Automated Power System Control ConceptBilawal RattarÎncă nu există evaluări

- Lec-1 Need Objective Power System Control - NewDocument3 paginiLec-1 Need Objective Power System Control - NewBilawal RattarÎncă nu există evaluări

- Lec 1 IntroductionDocument6 paginiLec 1 IntroductionBilawal RattarÎncă nu există evaluări

- Matlab ResultsDocument9 paginiMatlab ResultsBilawal RattarÎncă nu există evaluări

- List of Tuition Free Universities in GermanyyDocument1 paginăList of Tuition Free Universities in GermanyyBilawal RattarÎncă nu există evaluări

- TransformerDocument1 paginăTransformerBilawal RattarÎncă nu există evaluări

- Ethics Notes by Hafiz Abdul Aziz MemonDocument15 paginiEthics Notes by Hafiz Abdul Aziz MemonBilawal RattarÎncă nu există evaluări

- Communication SystemDocument26 paginiCommunication SystemBilawal RattarÎncă nu există evaluări

- TransientsDocument7 paginiTransientsBilawal RattarÎncă nu există evaluări

- Test Pattern NTDCDocument2 paginiTest Pattern NTDCBilawal Rattar73% (22)

- Seats in MUETDocument2 paginiSeats in MUETBilawal RattarÎncă nu există evaluări

- Electrical EngineeringDocument2 paginiElectrical EngineeringBilawal RattarÎncă nu există evaluări

- Report of A N G AbbasiDocument42 paginiReport of A N G AbbasiBilawal Rattar100% (1)

- Nagoor Kani Control SystemsDocument209 paginiNagoor Kani Control SystemsAnonymous eWMnRr70q71% (35)

- Nagoor Kani Control SystemsDocument209 paginiNagoor Kani Control SystemsAnonymous eWMnRr70q71% (35)

- AC Transformers - Lecture Notes by Faheemulla ShaikhDocument129 paginiAC Transformers - Lecture Notes by Faheemulla Shaikhlarryschleifer7945Încă nu există evaluări

- 23rd March 2012 Freedom Rally in Karachi JSQM Chairmen Bashir Khan QureshiDocument4 pagini23rd March 2012 Freedom Rally in Karachi JSQM Chairmen Bashir Khan QureshiBilawal RattarÎncă nu există evaluări