Documente Academic

Documente Profesional

Documente Cultură

Blast Furnace Operation

Încărcat de

sourajpatelTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Blast Furnace Operation

Încărcat de

sourajpatelDrepturi de autor:

Formate disponibile

P age |1

BLAST FURNACE

JNIL, SPD, SILTARA, RAIPUR

P age |2

OPERATION

JNIL, SPD, SILTARA, RAIPUR

P age |3

A blast furnace is a type of metallurgical furnace used for smelting of iron ores to producing generally iron . The earth crust contains about 5% iron. However,it is present as a compound mostly as iron oxide. Iron is extracted as metallic iron from the oxide ores of iron by reduction with a reducing agent. the principal agent that is used is a naturally occurring carbon in the form of coke or coal (pulverised coal). The most abundant oxide ores of iron is hematite (Fe2o3) and magnetite is used .but hematite is used mainly in our country iron oxide also contain oxide minerals of some other elements such as aluminium, silicon Mn and P. Sinter is also used in blast furnace. It is the prepared burden which is occurred by the sintering process .this is agglomeration process which utilises the fines of iron , fluxes and coke. 80 to 90 % of sinter is charged in our JNIL blast furnace.

BLAST FURNACE OPERATING DATA :Number of furnace 01 Useful volume 680 cub.met. Working volume 560 Throat diameter 5.10 No. Of tuyers 16 Tuyer diameter 110 mm Tap hole single Slag notch refractory lining micropour carbon block Top charging system bell less top No. Of stoves 03 Cooling system stave Hot blast volume 1,05,000Nm3/hr. Hot blast pressure 1.9Kg/cm2 Furnace top pressure 0.88Kg/cm2

JNIL, SPD, SILTARA, RAIPUR

P age |4

INPUT BLAST FURNACE

Raw material : Iron ore &sinter-(size 10 to 30) Flux, limestone, dolo, & quartz-( size10 to 30mm) Mn ore ( size10 to 30mm) Coke (size 25 to 80mm) Hot blast air (Temp. 980Deg.C) PCI ( as injection)

OUTPUT - BLAST FURNACE

Hot metal Steel melting Shop Pig Casting Machine Blast furnace Gas Power Plant Rolling Mill Sinter Plant Slag granulated Cement Plant

JNIL, SPD, SILTARA, RAIPUR

P age |5

HOT METAL ANALYSIS

Si% = 0.5 TO 0.8 Mn% = 0 to 0.6 S% = 0.06 max.

FOUNDRY GRADE :FROM FURNACE / BY ADD. OF Fe-Si; Si% = 2.0 to 2.5 Mn% = 0.5 to 1.0 S% = 0.06max.

BASIC GRADE :Si% =0.5 to 0.8 Mn% = 0.5max. S% = 0.06max.

GAS ANALYSIS

CO% = 25 Co2% = 17 H2% = 2.5 O2% = 0.5 CV = 750 to 800 Kcal

COKE DETAILS

FC% = 85.52 S % = 0.58 Ash% = 13 M10% = 4.6

JNIL, SPD, SILTARA, RAIPUR

P age |6

IRON ORE DETAILS

Fe% = 60 to 65 Al2o3% = 2 to 3.5 Sio2% = 1.5 to 3

SLAG ANALYSIS

Cao% = 32 to 34 Sio2% = 33 to 35 Al2o3% = 21 to 23 Mgo% = 10.5 to 11.05

Cao Limestone Dolomite Quartzite Mn ore Fe ore Sinter

48.50 28.0 -----------------------8.50

Mgo

1.70 18.50 -----------------------2.20

Sio2

4.0 4.0 96.0 ------1.56 4.5

Al2o3

0.90 0.90 1.42 --------------2.8

Fe

0.46 0.46 -------28.20 66.0 58.0

Mn

-------------------26.70 ---------------

JNIL, SPD, SILTARA, RAIPUR

P age |7

INPUT< ----------------------------------------------------------------------->OUTPUT

I I I I I I I

PROCESS

The blast furnace process is based on counter current principle. The input and output are of modern blast furnace practice .the furnace is refractory lined and is filled with material from the stock rod level down to bottom. Solid raw material at room temperature or preheated furnace temp. At beginning the process are charged from the top of the furnace . Preheated air above 950 to 980 deg.C is blown through tuyer pipe inserted in to the furnace wall along with injection of pulverised coal. The highest temp. Of the furnace is at the level of tuyere. This heat is transferd from bottom to top. That result direct and indirect reaction occurred.

PROCESS REACTION :OXIDATION REACTION ;-C + 1/2O C + O2 C + CO2 ---------------- --------------- --------------- CO CO2 2CO

JNIL, SPD, SILTARA, RAIPUR

P age |8

REDUCTION REACTION ;-3Fe2o3 + Co ------------ 2Fe3o4 + Co2 Fe3o4 + Co ------------ 3Feo + Co2 Feo + Co ----------- Fe + Co2

DIRECT REACTION;-Feo + C ----------- Fe + Co Sio2 + 2C ---------- Si + 2Co Mno + C ----------- Mn + Co H2o + C ---------- H2 + Co

INDIRECT REACTION;-Feo + Co ---------- Fe + Co2

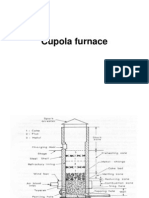

THE FURNACE INTERIOR IS BROADLY DIVIDED IN TO;- STACK, where wall slops outward going downwards. BELLY, the cylindrical portion below the stack. BOSH, below the belly and sloping inwards going downward. HEARTH, below the bosh and tuyere region and the cylindrical portion.

Stack : This zone extends from the stock line down to the metal level . it is the zone in which the burden is completely solid. The charge gets heated from 200 deg. C at the stock line level to nearly 1100 to 1200 deg. C by the line it descents to the bottom of the stack.

JNIL, SPD, SILTARA, RAIPUR

P age |9

Bosh : -The charge materials being to soften and fuse as they come down in to bottom of the stack. The next lower zone is called the bosh in which meeting of the burden, except that of core takes place. The gangue & flux combine to form two slag. TUYERE OR COMBUSTION ZONE:-By the time the charge descends in to the area near the tuyere , except the central column of coke , the entire change in molten . the oxygen of the blast burns coke to CO and several combustion zone. One in front of each tuyere, exist in the tuyere zone .thus, there is a runway or raceway. In front of each tuyere which is first horizontal and then smoothly changes it,s direction to vertical while expanding over the entire cross section of the furnace. In our furnace there are 16 tuyeres, No. Of tuyeres = Hearth dia. * 2 +2 COOLERS:-In our blast furnace having material of tuyeres are, 1 to 4 row 5 to 9 row 10 to 15 row HEARTH:-Although most of the coke burns at the tuyere level , small fraction descends even in to the hearth where it dissolve in the metal to its near saturation .the intir charge is molten and sends to stratify in to slag and metal layer in the hearth from where these are tapped separately. cast iron coolers Cu. Coolers cast iron coolers

JNIL, SPD, SILTARA, RAIPUR

P a g e | 10

PULVERISED COAL INJECTION PCI (pulverised coal injection) is the fine powder of non coaking coal . this coal is injected in a blast furnace . Because the reason is that , by using PCI we can decrease the rate of coke consumption in a blast furnace. PCI RATE:-7 T per hour RAW COAL BUNKER:-Raw coal are stored in to it , the capacity of bunker has 80 T. DRAG CHAIN CONVEYER (DCC):-Drag chain conveyer this is the type of conveyor. But the DCC is differ from belt conveyor because at the bottom of the raw material hopper becomes heavy material load by far DCC is used otherwise slipping is occurred and can not transferred. MILL:-Mill is used for milling the raw coal at the temp. Is 80 to 84deg, C. Temperature is provided for the wet material ( coal) has become dried because this condition coal is well pulverised . Three rollers are held in to a mill for the milling purpose.rollers are rotate through the centre axis of roller table. SCREW CONVEYOR:-In a PCI two numbers of screw conveyors are used for the feeding in single connection from the two bag filter. PC SILO:-PC SILO is a storage tank. Hot gas generator (H.G.G).:-Hot gas generator is used for supply of hot gas in to the mill, because has maintained the mill parameter or temperature apprix,80 deg C.

JNIL, SPD, SILTARA, RAIPUR

P a g e | 11

RAW MATERIAL HANDLING SYSTEM(RMHS)

Raw Material Handling System(RMHS) is the main part of integrated steel plant. This system is raw material supplied and import from the supplier or mines. Main Equipment of RMHS Wagon Tippler Side Arm Charger Stacker cum Reclaimer LOCO Conveyors

Wagon Tippler:Wagon Tippler is the mechanism through this the wagon material ( raw material form the mines and suppliers ) are tippling or tilting in to the hoppers. In our Jayaswal New Industries limited have one Wagon Tippler. In a Wagon Tippler four hydraulic clamps are provided for clamping the Wagon . 58 Wagon of Iron ore 3600 T & 2600 T are required 4 hours for empting.

Side Arm Charger:Side Arm Charger is used for removing the interconnections of the each wagons. By the help of Side Arm Charger wagons has positioned in wagon on table. Side Arm Charger is worked in forward and reversed movement.

Stacker cum Reclaimer:This is a very big machine in Jayaswal Neco Industries Limited. Stacker cum Reclaimer is material handling machine or mechanism. Material to be handled:Iron ore Coke Quartzite _ _ _ 10-40mm 20-80mm 20-50mm

JNIL, SPD, SILTARA, RAIPUR

P a g e | 12

Lime stone Dolomite Stock pile height Travel length

_ _ _ _

20-50mm 20-50mm 12meter 412meter

Bucket Wheel By the help of bucket wheel material has Stacking and reclaiming through the boom conveyor. Stacker Cum Reclaimer is travel on the Conveyor no. -3.

Stock House:It is alsop knows as raw material store section. When the RMHS has some problem are include that condition the raw material are required for continue operating the Blast -furnace as per condition we are provide the stock house for Blast-furnace operating. Stock house are connected through the Junction House-3. Two numbers of Travelling Tipper are held in the stock house. Travelling Tipper-1 on C5 Travelling Tipper-2 on C6 Stock house have 16th bunkers for various type of Raw Material Feeding. Bunker capacity is 30tonne to 250tonne. Weighing hopper are 12 in no. in this hopper the burden has weighted as per required. Screening System:Vibro Screens are used for the Screening purpose and required size material are provide for Blast furnace. Vibro Feeder:This is a feeding equipment. Which is worked on vibration, for this purpose two Vibro Cylenders are used. Pig Casting Machine:-

JNIL, SPD, SILTARA, RAIPUR

P a g e | 13

In a Pig Casting Machine the hot liquid iron(metal) are poured in to the Pig moulds, this complete process is known as casting process. The producyt of casting process is called as Pig or Pig iron. Jayaswal NECO Industries limited have two Pig casting machine. The weight of one piss or pig iron casting has 10kg per pig. 1200 pigs are producing(casting) machine with the help of a one belt or the pig casting machine. Total 4800 pigs are produced in pig casting machine. Pig Storage Yard: The casting pig are transferred through the wagon Pig Storage Yard. Where pigs are accumulate and stay by the gardes. Such as_ Foundary grade Basic grade Then the pigs are loaded on trunk by the Electro magnetic crane and sopplied the customers. Inmotion Bridge: It is used for the reading or taking weight of the metal by the LOCO & ladle car in running condition. tn this bridge 4load cells held. This bridge has worked when the speed of loco is more the 5km/hr..

JNIL, SPD, SILTARA, RAIPUR

P a g e | 14

Gas Cleaning Plant(G.C.P)

Blast furnace produce an effluent gas containing a significant proportion of carbon monoxide. Which could not be used for iron oxide reduction. The actual CO many vary around 20-30% nearly 900kcal/m3 . the quantity of gas produced depends upon the amount of fuel burnt. For one tone of coke burnt nearly 4000m3 of effluent gas may be produced. The effluent gas from the furnace cannot directly be used as a fuel since a substantial quantity of dust & wear in the equipment using the gas. The gas is therefore, clean before its use & in so doing the sensible heat of the gas is invariably lost. So here the chemical heat of the cleaned gas is utilized. In general cleaned is carried out in three stage_ 1. Coarse 2. Semi-fine 3. Fine cleaning There are following arrangement through which cleaning of the gas is carried out in the Gas Cleaninig Plant(G.C.P). The effluent gases from furnace are carried out of the furnace by large vertical pipes called up takes. Up takes are four in number. Two adjacent uptake are joined together to form a single duict & the two such ducts, thus formed, are connected to from only one duct which carriea the gas downwards into trhe duct catcher . the downcoming pipe or doct is called downcomer. A bleeder valve is a safety device which opens automatically or is opened ,to released extre pressure developed inside the furnace and thereby eliminate the danger of explosion. DUST CATCHER;The dust is contained in the gas by virtue of its velocity hence if the velocity is zero the dust particles will be eliminated from the gas.the state of zero velocity is achieved in the gas catcher by simply reversing the direction of the gas flow from vertically to vertically upward diection. The downcomer leads the gases into the dust catcher through a Vertical pipe that flares out and extends nearly to the bottom of the dust catcher. The gases comes

JNIL, SPD, SILTARA, RAIPUR

P a g e | 15

down vertically & suddenly changes its direction to vertically upwards since the outlet is located nearly at the top of dust catcher, The efficient of the dust catcher is usually upto 65%. VENTURY WASHER(1&2):It is a vertical unit with a construction where water is injected in the form of sprays to wet the gas moving downwards. The coarse cleaned gas from the dust catcher enters into the ventury washer-1, where water sprays at angle appoxemately 120 degree. Due to venture effect & the water sprays dust particle is settle down in the B.S.P 1. From venture-1 the cleaned & low pressure gas is fed to the venture washer-2. Where the same way water spray is done & the clear gas upto % is done. B.S.P(Bottom Seal Port):BSP is located near the bottom of venture washer-1 & cyclone separator, where the surry is accumulated & collected bottom of BSP. Cyclone Separator:From venture washer-2 the Blast furnace gas enter into cyclone separator and spun rapidly. The centrifugal force created by the circular flow throws the dust particles toward the wall of the cyclone. After striking the wall, these particles fall into a hopper located underneath. When the gas travel upward in the cyclone separator, strikes with mist eliminator and hence moister is gas is eliminated from the Blast furnace gas. SEPTUM VALVE:Septum valve is use to control the clean gases. Also septum valve is used to maintain the top pressure. Septum valve contain five valve 2 regulating valve(1 pneumatic+ 1 motorized) 2 shutt off valve(both are motorized) 1 valve is always open having a small diameter. FLARE STACK:Flare stack is a stack through which the blast furnace gas is fed into atmosphere.

JNIL, SPD, SILTARA, RAIPUR

P a g e | 16

GAS HOLDER:Gas holder capicitty 40,000m3 hold or storage the blast furnace gas. Which are not comsume by the plant. BOOSTER STATION:Booster station is used to boost Blast furnace gas to conveyt desired place since it is used long distance like rolling mill etc.

JNIL, SPD, SILTARA, RAIPUR

P a g e | 17

MECHANICAL & ELECTRICAL

JNIL, SPD, SILTARA, RAIPUR

P a g e | 18

BLAST FURNACE MECHANICAL

# Tap Hole Drill Machine(Hydro-pneumatic Equipment)

Supplier- Rotamech, Kolkata Return Speed- 0.603m/s Rotation of drill bit- 395rpm Drill rod length- 4150mm Drill bit dia.- 38mm-65mm Hydraulic rated press- 100kgf/cm2 Hydraulic tank capacity- 800ltr Hydraulic oil- HLP68

2 Hydraulic operation With two cylinder(Big & Small) Big cylinder- Rod dia- 90mm Bore dia-200mm Stroke- 800mm Small cylinder- Rod dia- 45mm Bore dia- 80mm Srtoke- 335mm 3 pneumatic operation *forward, reverse & rotation Globe air motor & drifter *Globe air motor Make- Atlas Capco Model- RM310F *Drifter Make- Haryson Model- BBC120F

JNIL, SPD, SILTARA, RAIPUR

P a g e | 19

#Mudgun

Supplier- Shougang China Rated press- 20 MPa Max press- 25 MPa Hydraulic tank capacity- 800ltr Rated flow capacity- 210ml/rev. Min oil level- 600ltr Hydraulic oil-HLP68 *Operational sequence Swing, Tilt & Push Hydraulic cylindersClay pushing cylinder- Rod dia- 320mm Stroke- 1260mm Total pushing force- 1655kN Tilt cylinder- Rod dia- 45mm Bore dia- 70mm Stroke- 500mm Swing cylinder- Rod dia- 110mm Bore dia- 160mm Stroke- 1000mm

#Skip Charging system

Volume 4.5m3 Capacity- 9 tonne Inclination of bridge- 53 deg. *Skip Winch

JNIL, SPD, SILTARA, RAIPUR

P a g e | 20

Rated elevating capacity- 7 tonne each car Elevating max speed- 2.5m/s Travel time- 54sec. Lenth of rope- 145m each No. of rope- 2 per car Dia of rope- 32mm Motor 160kW DC drive, 1200rpm Skip winch drum dia- 1850mm Double herringbone type gear for skip winch drum Reduction of gear box- 26.92:1

# BLT(bell less top) system

Burden tank consist of 4 valves 3 Hydraulic 1 motorized

*burden receiving valve Bore dia- 80mm Rod dia- 45mm Srtoke- 370mm *Upper seal valve US1-Bore dia- 100mm Rod dia- 56mm Srtoke- 200mm US2- Bore dia- 80mm Rod dia - 45mm Srtoke - 370mm *Lower seal valve

JNIL, SPD, SILTARA, RAIPUR

P a g e | 21

Bore dia- 80mm Rod dia- 45mm Srtoke- 560mm Other than burden tank it consist of 04 hydraulically operated valves *02 equalizing valve *02 pressure relief valve Equalizing valve detail: Bore dia- 80mm Rod dia- 40mm Stroke- 165mm Pressure relief valve detail: Bore dia- 100mm Rod dia- 55mm Stroke- 190mm

#BLT hydraulic system:

Hydraulic tank- 1200ltr Hydraulic pump- 02 nos Working pressure- 9.5 to 11MPa Accumulators- 05 nos #Burden flow regulating valve: Motor 5.5kW, 1500rpm, AC servo motor #Disributor: Motor 7.5kW, 1440rpm, Induction motor #Chute: Motor - 7.5kW, 1440rpm, AC servo motor

JNIL, SPD, SILTARA, RAIPUR

P a g e | 22

#COOLING SYSTEM

1. Bottom hearth pipeline- 23 nos 2. Row no. 1,2,3 No. of cooling plates- 28(each row) Two plates interconnection. 3. Row no. 4 No. of cooling plates- 32 No. of pipelines- 16 4. Row no. 5, 7, 8 & 9 No. of cooling plates- 28 No. of pipelines- 28 5. Row no. 6 No. of cooling plates- 28 No. of pipelines- 14 Two plates interconnection. 6. Row no. 10, 11, 12 No. of cooling plates- 28 No. of pipelines- 14 Two plates interconnection. 7. Row no. 13 & 14 No. of cooling plates- 28 No. of pipelines- 28 8. Row no. 15 No. of cooling plates- 28.

#STOVE AREA

No. of stoves- 03 nos Each stove has following valves: 1. Hot blast valve 2. Cold blast valve 3. Cold blast by pass valve

JNIL, SPD, SILTARA, RAIPUR

P a g e | 23

4. Burner shut off valve 5. Gas regulating valve 6. Gas safety shut off valve 7. CA shutoff valve 8. CA regulating valve 9. Chimney valve 1 & 2 10. Chimney by pass valve 11. Branch bleeder Other than these valves in each stove there are three valves installed in the stove line. 1. Mixed air shutoff valve 2. Mixed air regulating valve 3. Back draft valve

# STOVE PROPER

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 Total height of stove Inner dia. of stove Dome shell inner dia. Dome brick work inner dia. Shell height Stove height to dia. ratio Checker chamber section area Combustion chamber section area Overall heat accumulating area of stove Checker type Overall height of checker Overall weight of checker Ceramic burner type Capacity of burner No of column Weight of each column No of grids No of beams 35.261m 7000mm 8000mm 6632mm 35800mm 5 118.79m2 3.14m2 19040m2 7 hole honey comb 27m 728 tone Sleeve type 32000m3/hr 18 635kg. 14 24

JNIL, SPD, SILTARA, RAIPUR

P a g e | 24

#GAS CLEANING PLANT

Dust catcher- Dry type

Venture 1: Type- adjustable throat venture Make- kirloskar AAF Ltd. Pressure drop- 600 to 800mmwc Water circulating rate- 110 m3/hr Temp. at outlet- 60 to 70 deg.

Venture 2: Pressure drop-1600 to 2000mmwc Water circulating rate- 110 m3/hr Temp. at outlet- 50 deg. Cyclone separator: Type- centrifugal Make- kirloskar AAF Ltd. Diameter- 3650mm Height- 13300mm Pressure drop- 75mmwc Mist eliminator Type- chevron Make- kirloskar AAF Ltd. Size- 1000*600 & 1000*400 mm2 No of passes- 2 pass Pressure drop- 25mmwc Flare stack: Capacity- 90000Nm3/hr Inlet pressure- 900mmwc Overall height- 55m Type- tip burning No of pitot burner- 04 nos Fuel for burner- LPG Gas holder

JNIL, SPD, SILTARA, RAIPUR

P a g e | 25

Effective volume- 40000 m3 Operating pressure- 875mmwc-600mmwc Design pressure- 1000mmwc Design temperature- 70 deg.

STOCK HOUSE EQUIPMENT SPECIFICATION

JNIL, SPD, SILTARA, RAIPUR

P a g e | 26

Weighing Hopper (WH): WH No. 01 to 03 04 to 08 05 to 09 06 to 07 Material Iron ore Flux Flux Coke m3 4.5 0.2 1.2 4.5 Capacity(tone) 5 3 3 5 Load cell Compression type 04 nos Single ended 03 nos Single ended 03 nos Compression type 03 nos

Quadrant Gates (QG): 1. QG type A: Electrical actuator operated 1000mm stroke, 1000kg thrust QG 01, 02, 03, 10, 11, 12 Iron ore QG 04, 05, 08, 09 Flux QG 13, 14 Intermediate hopper 2. QG type B: Electrical actuator operated 600mm stroke, 500kg thrust QG 06, 07 Coke Vibroscreen 01 to 03 & 06 to 08 Make: International Combustion Qty: 06 nos Wire deck size: 1390*1035 Wire mesh size: 10mm2 Feed material: I/O Feed rate: 200 TPH Separation: 10mm Motor: 11kW, 1000rpm Coupling: U coupling

JNIL, SPD, SILTARA, RAIPUR

P a g e | 27

Shaft: Carden Shaft Bulk density: 2.5 T/m3

Vibroscreen 04 & 05 Make: International Combustion Qty: 02 nos Wire deck size: 1380*1130 Wire mesh size: 25mm2 Feed material: Coke Feed rate: 110 TPH Separation: 25mm Motor: 7.5kW Coupling: U coupling Shaft: Carden Shaft Bulk density: 0.5 T/m3

Vibrofeeders 05 to 12 Make: International Combustion Inclination angle: 10 deg Liner: 04mm thick Feed material: LS/DOLOMITE/Mn ore/Qtz. Bulk density: 1.6/1.65/2.0/2.5 T/m3 Feed size: 20 - 50 mm Feed rate: 260 TPH Feed rate variation 10% - 100%

JNIL, SPD, SILTARA, RAIPUR

P a g e | 28

WAGON TIPPLER

Type of wagon tippler Hydraside Gross weight of wagon to be handled 110 tonne Max angle of rotation of tippler 155 No. of load cell provided: 06 nos No. of top clamp 4 nos Drive Unit: Hydraulic motor powered through power pack mounted outside of the tippler rotating body. Gear box: Planetary Tippler drive motor: 90kW, 1440rpm Type of wagon clamping: Hydraulic

SIDE ARM CHARGER

Motor for power pack- 45kW, 1450rpm Charger drive type: Planetary gear box (1:77) Arm drive: Hydraulic cylinder 02 nos

STACKER CUM RECLAIMER

Materials to be handled Iron ore = 10 30 mm Coke = 20 80 mm Qtz = 20 50 mm Limestone = 20 50 mm Dolomite = 20 50 mm Stockpile height 12 m Travel length 412 m Capacity While stacking

JNIL, SPD, SILTARA, RAIPUR

P a g e | 29

I/O 1500TPH Coke- 450 TPH Mn ore, Qtz, LS, Dolomite 1500 TPH While reclaiming I/O 650 TPH Coke 130 TPH Mn ore 500 TPH Qtz, LS, Dolomite - 400 TPH

Drive details: Motor: 06 nos, 7.5kW, 1500rpm AC variable frequency control Coupling: Flexible brake coupling Gear box: Vertical gear unit Brake: Thrust operated jaw brake

Bucket Wheel: Type: cell less No. of bucket: 08 nos Bucket capacity: 250 ltrs. No. of discharge/min.: 28 RPM: 3.5 Motor: 45kW, 1500rpm, AC SCIM reversible Gear box: Planetary gear box (410:1) Boom Conveyor: Belt width: 1400rpm Belt speed: 1.75 m/s Conveyor length: 33.407m Motor: 75kW, 1500rpm, AC SCIM reversible Gear box: Bevel helical triple reduction gear, 28:1 Brake: DC electromagnetic brake 400 Slewing mechanism: Slewing speed at centre of bucket wheel: 08 32 mtr/min Slewing angle: 105 Motor: 02 nos, 10kW, 150 1500rpm, continuously variable DC drive Lifting mechanism for boom

JNIL, SPD, SILTARA, RAIPUR

P a g e | 30

Type: hydraulic No. of cylinder: 02 Speed: 03 m/min. Type of cylinder: differential double acting cylinder BELT CONVEYOR DETAILS: Conveyors Belt Length (m) 36 C1 299 C2 1249 C3 400 C4/C4A 400 C5/C6 95 C7/C8 54 C9A 63 C9B 142 C11/C11A 145 C12 165 BF1

Belt Speed (m/s) 1.75 1.75 1.75 1.75 1.75 1.25 0.5 0.5 0.5 0.5 0.75

Motor (kW) 30 200 280 90 75 22 11 5.5 11 30 7.5

Belt Size (mm) 1400 1400 1400 900/800 900 1000 650 650 650 500 500

PCI (PULVERIZED COAL INJECTION) EQUIPMENTS:

ID FAN: Flow rate: 43900 53000 m3/ln Pressure: 2256 2432 Pa Working temp: 150 300C RPM: 0 1480 CA BLOWER: Flow rate: 3963 4792 m3/ln Pressure: 4256 4662 Pa Working temp: 20C RPM: 2900 COAL MILL:

JNIL, SPD, SILTARA, RAIPUR

P a g e | 31

Capacity: 15.1 TPH Diff. pressure: 5 6 kPa Inlet flow rate: 40000 m3/ln Max inlet size: 50 mm Inlet temp.: 300C Outlet temp.: 80 - 100C Inlet moisture: <12% BAG FILTER: Flow rate: 40000 m3/ln Inlet temp.: <120C Filtering speed: 0.41m/min Filtering area: 1610 m2 Density inlet: <1000 g/m3 Density outlet: <50 g/m3 PC BUNKER: Volume of tank: 140 m3 Weight level limit: 90T max 20T min COAL BUNKER: Volume of tank: 130 m3 Weight level limit: 90T max 20T min BELT CONVEYOR: NO. 01 & 02 Breadth: 650mm Speed: 1.25 m/s Quality: 120TPH Length: 86.4m & 84.82m.

ELECTRICAL OF BLAST FURNACE ;

JNIL, SPD, SILTARA, RAIPUR

P a g e | 32

1. 2. 3.

SLD OF BLAST FURNACE SLD OF STACKER CUM RECLAIMER SLD OF WAGON TRIPPLER

JNIL, SPD, SILTARA, RAIPUR

P a g e | 33

JNIL, SPD, SILTARA, RAIPUR

P a g e | 34

EOT CRANES

ELECTRIC OVERHEAD TRAVELLING CRANE are used for transporting raw material,laddle etc from one place to another. Components1. Current collector It is mainly used for power supply from down shop line to crane. As crane is movable,

JNIL, SPD, SILTARA, RAIPUR

P a g e | 35

current collector is used which is fixed with respect to crane but movable with respect to dsl. 2. Switch fuse unit- It is used in power panel to prevent from short circuit.

3. Overloading relay- it is used in power panel to prevent the motor from overloading. 4. Miniature circuit breaker and contactor

5. Transformer- A step down transformer is used in power panel. It reduces 44o V to 110 V. 6. Motor 7. Break 8. Limit switch 9. Timer 10. Resistance box

Safety equipments for EOT cranes 1.

Counter weight limit switch- it is

present in the main hoist. When main hoist raise

JNIL, SPD, SILTARA, RAIPUR

P a g e | 36

to maximum limit of height, it touch the counter weight limit switch and entire power supply of crane is cut-off.

2.

Rotary gear limit switch- it has coupling

with the rope drum. There is the limit to revolve the drum in both direction, when the rotation exceed for the limitd value, then power supply is cit off.

3.

End limit switch it is used for both long

travel and cross travel maximum limit, when crane touch the limit switch, power supply cutoff.

4.

corner limit switch- it is situated as the

master panel. If there any fault is found in the crane then supply is cutoff by this switch.

JNIL, SPD, SILTARA, RAIPUR

P a g e | 37

INSTRUMENTATION

JNIL, SPD, SILTARA, RAIPUR

P a g e | 38

INSTRUMENTS IN AGLANCE AT JNIL BLAST FURNACE Instrumentation is used to measure many parameters (physical values). These parameters include: 1. Temperature 2. Pressure, either differential or static 3. 3. Flow 4. Level 5. Weight Thermocouple Theory : A thermocouple, shown in Figure 1, consists of two wires of dissimilar metals joined together at one end, called the measurement (hot) junction. The other end, where the wires are not joined, is connected to the signal conditioning circuitry traces, typically made of copper. This junction between the thermocouple metals and the copper traces is called the reference (cold) junction.

JNIL, SPD, SILTARA, RAIPUR

P a g e | 39

Figure 1. Thermocouple. The voltage produced at the reference junction depends on the temperatures at both the measurement junction and the reference junction. Since the thermocouple is a differential device rather than an absolute temperature measurement device, the reference junction temperature must be known to get an accurate absolute temperature reading. This process is known as reference junction compensation (cold junction compensation.) Thermocouples have become the industry-standard method for cost-effective measurement of a wide range of temperatures with reasonable accuracy. They are used in a variety of applications up to approximately +2500C in boilers, water heaters, ovens, and aircraft enginesto name just a few. The most popular thermocouple is the type K, consisting of Chromel and Alumel (trademarked nickel alloys containing chromium, and aluminum, manganese, and silicon, respectively), with a measurement range

Type K (Chromel / Alumel)

Type K is the 'general purpose' thermocouple. It is low cost and, owing to its popularity, it is available in a wide variety of probes. Thermocouples are available in the -200C to +1200C range. Sensitivity is approx 41uV/C. Use type K unless you have a good reason not to

Type S (Platinum / Rhodium)

Suited for high temperature measurements up to 1600C. Low sensitivity (10uV/vC) and high cost makes them unsuitable for general purpose use. Due to its high stability type S is used as the standard of calibration for the melting point of gold (1064.43C).

Type J (Iron / Constantan)

Limited range (-40 to +750C) makes type J less popular than type K. The main application is with old equipment that cannot accept 'modern' thermocouples. J types should not be used above 760C as an abrupt magnetic transformation will cause permanent decalibration.

What are Rtds?

JNIL, SPD, SILTARA, RAIPUR

P a g e | 40

Resistance Temperature Detectors or RTDs for short, are wire wound and thin film devices that measure temperature because of the physical principle of the positive temperature coefficient of electrical resistance of metals. The hotter they become, the larger or higher the value of their electrical resistance. They, in the case of Platinum known variously as PRTs and PRT100s, are the most popular RTD type, nearly linear over a wide range of temperatures and some small enough to have response times of a fraction of a second. They are among the most precise temperature sensors available with resolution and measurement uncertenties or 0.1 C or better possible in special desions. Usually they are provided encapsulated in probes for temperature sensing and measurement with an external indicator, controller or transmitter, or enclosed inside other devices where they measure temperature as a part of the device's function, such as a temperature controller or precision thermostat. The Advantages of RTDs The advantages of RTDs include stable output for long period of time, ease of recalibration and accurate readings over relatively narrow temperature spans. Their disadvantages, compared to the thermocouples, are: smaller overall temperature range, higher initial cost and less rugged in high vibration environments. They are active devices requiring an electrical current to produce a voltage drop across the sensor that can be then measured by a calibrated read-out device

Platinum RTD Output Equation

ASTM Standards E 1137 for Industrial Platinum Resistance Thermometers specifies that the resistance-temperature relationship for

JNIL, SPD, SILTARA, RAIPUR

P a g e | 41

such devices for the range 0 C to 650C, to within the tolerances given below, will be described by the equation: R(t) = R(0)[1 + At +Bt^2] Where: t = temperature (to ITS-90), C, R(t) = resistance at temperature t, R(0) = resistance at 0C A = 3.9083 * 10^-3(C), and, B = -5.775 * 10^-7(C^2).

LOOP DIAGRAM

JNIL, SPD, SILTARA, RAIPUR

P a g e | 42

Thermocouple/RTD

mV/ohm

Temperature Transmitter

4-20 mA

DCS

JNIL, SPD, SILTARA, RAIPUR

P a g e | 43

PRESSURE MEASUREMENTS

DEFINITION OF PRESSURE Absolute pressure

The pressure is referenced to zero absolute pressure and has units of psia. Absolute pressure can only have a positive value.

Gauge pressure

The pressure is referenced to atmospheric pressure and by convention is measured in the positive direction, i.e. 7 psig.

Vacuum pressure

The pressure is referenced to atmospheric pressure and by convention is measured in the negative direction, i.e. -50 mm Hg.

DP TRANSMITTERS

JNIL, SPD, SILTARA, RAIPUR

P a g e | 44

DP i.e Differential pressure transmitters are used for the measurement of flow and level. Supply: 24v dc Output: 4-20 mA

Types of Flow meters

1. Magnetic Flow meters 2. Vortex Flow meters 3. Ultrasonic Flow meters 4. Coriolis Mass Flow meters 5. DP type flow meter

Types of level measurement

1. Radar 2. Ultrasonic 3. Capacitance

JNIL, SPD, SILTARA, RAIPUR

P a g e | 45

4. Differential pressure 5. Conductive 6. RF Admittance Level Switches

Principles of Radar Level Sensor

The antenna on a radar level gauge generates millions of very short 1 Nano second microwave pulses every second. Each pulse is directed and transmitted to and reflected from a product surface. The elapsed time period between transmission and reception of the signal at the speed of light is measured and calculated as a distance. This continuous stream of

JNIL, SPD, SILTARA, RAIPUR

P a g e | 46

pulses gives real time level information updated and is evaluated many times a second. Radar level sensors work with safe, low emitted power in the c (4 to 8 GHz) and k-band (18 to 26.5 GHz)frequency range. The proven ECHOFOX signal processing selects the correct level echo reliably. Adjustment by filling and emptying the vessel is not necessary, it can normally be done with simple input of vessel dimensions.

Principles of Conductive level Sensor

JNIL, SPD, SILTARA, RAIPUR

P a g e | 47

Principles of Loadcell

JNIL, SPD, SILTARA, RAIPUR

P a g e | 48

Application of loadcell

Application of loadcell

JNIL, SPD, SILTARA, RAIPUR

P a g e | 49

Application of loadcell

Opacity Meter

Opacity meter is used for the measurement of opacity and dust concentration within the flue gas.

JNIL, SPD, SILTARA, RAIPUR

P a g e | 50

2. Measurement Principle Consider the two identical transceiver units positioned at either side of the flue(or duct), unit 1 and unit 2. The transmissivity of light from unit 1 to unit 2 (unit 1transmitting) can be represented by the equation : t12 = K1 (D21/D11) where : K1 = gain constant to produce t = 1 (100% transmissivity, clean air condition) D11 = the detector output at unit 1 (internal reference level) D21 = the detector output at unit 2

The transmissivity of light from unit 2 to unit 1 (unit 2 transmitting) can also be represented by the equation : t21 = K2 (D12/D22) D12 = the detector output

where : K2 = gain constant to produce t = 1,

at unit D22 = the detector output at unit 2 (internal reference level)

Control valve

Control valves are used to control the process

JNIL, SPD, SILTARA, RAIPUR

P a g e | 51

Parameters such as flow, pressure, temperature, level.

It works under force balance principle. Control valve accessories include: AFR-air filter regulator I/p- current to pressure Positioner.

Control valves are of two types:

Air to close Air to open

JNIL, SPD, SILTARA, RAIPUR

P a g e | 52

Flow diagram of control valve

Instrument air

(5-6 kg/cm2)

AFR

(1.5kg/cm2)

I/P (0.2 -1 kg/cm2)

Positioner

AFR

(2-3 kg/cm2)

I to P converter

I to P converts an analog signal (4 to 20 mA) to a proportional linear pneumatic output (.2 to 1 kg/cm2). Its force balance principle is a coil suspended in a magnetic field on a flexible mount. At the lower end of the coil is a flapper valve that operates against a precision ground nozzle to create a backpressure on the servo diaphragm of a booster relay. The input current flows in the coil and produces a force between the coil and the flapper valve, which controls the servo pressure and the output pressure.

Positioner

JNIL, SPD, SILTARA, RAIPUR

P a g e | 53

Positioner consist of air supply port , signal input port, out put port.When positioner get input signal ,it compare with stem position and output is generated and signal boosted sufficiently to operate the valve . It uses force balance system.

JNIL, SPD, SILTARA, RAIPUR

P a g e | 54

I/Os defined in DCS

DI signals Signals Coming from swicthes,sensors,etc DI FIM card -32 channels are used. DO signals - Signals given to drives,shut off valves etc. DO FIM card-32 channels are used. AI Signals Signals coming from transmitters,etc AI FIM card 16 channels are used. AO signals Signals given to control valves,regulating power cylinders,etc AO FIM card 8 channels are used.

JNIL, SPD, SILTARA, RAIPUR

S-ar putea să vă placă și

- Astm B221Document15 paginiAstm B221prakhar tandon67% (3)

- Plain Bearing FailuresDocument7 paginiPlain Bearing FailuressourajpatelÎncă nu există evaluări

- Sinter Making0260307Document47 paginiSinter Making0260307honeygupta12150% (2)

- Blast FurnaceDocument91 paginiBlast FurnaceSarbajitManna100% (1)

- Electric Arc Furnace Compendium PDFDocument82 paginiElectric Arc Furnace Compendium PDFAbhishekÎncă nu există evaluări

- NAAMM NOMMA Finishes Manual PDFDocument116 paginiNAAMM NOMMA Finishes Manual PDFMichaelTorresÎncă nu există evaluări

- Blast Furnace Cooling System MonitoringDocument27 paginiBlast Furnace Cooling System MonitoringAnil MistryÎncă nu există evaluări

- Steel Making & Blast FurnaceDocument18 paginiSteel Making & Blast FurnaceHarish LakshminarayananÎncă nu există evaluări

- Standard Operating Procedures for BF Blowing-InDocument18 paginiStandard Operating Procedures for BF Blowing-InTheleapInoblivionÎncă nu există evaluări

- Coke OvenDocument19 paginiCoke Ovensourajpatel100% (1)

- HVAC Handbook Part 6 Air Handling EquipmentDocument75 paginiHVAC Handbook Part 6 Air Handling EquipmentTanveerÎncă nu există evaluări

- BSSL Blow-In Plan r1 PDFDocument37 paginiBSSL Blow-In Plan r1 PDFROWHEIT100% (1)

- The Melt Shop ProcessDocument38 paginiThe Melt Shop ProcessAmr Tarek100% (3)

- Ironmaking and SteelmakingDocument436 paginiIronmaking and SteelmakingSandip KumarÎncă nu există evaluări

- Report on steel melting shop processesDocument18 paginiReport on steel melting shop processesRahul PandeyÎncă nu există evaluări

- CAESAR II Pipe Stress Analysis GuideDocument37 paginiCAESAR II Pipe Stress Analysis GuideEko Idris Hutagaol100% (1)

- Coke Preparation in BatteriesDocument22 paginiCoke Preparation in BatteriesRaju Kalintha100% (2)

- Control and Analysis in Iron and SteelmakingDe la EverandControl and Analysis in Iron and SteelmakingEvaluare: 3 din 5 stele3/5 (2)

- BLAST FURNACE OPERATIONS-TATA STEEL - Dipika Sinha - 5.6.20 PDFDocument22 paginiBLAST FURNACE OPERATIONS-TATA STEEL - Dipika Sinha - 5.6.20 PDFGAGAN SOLANKIÎncă nu există evaluări

- Steel Melt Shop 2 Process .Document50 paginiSteel Melt Shop 2 Process .Rahul Pandey0% (2)

- Energy Optimizing FurnaceDocument4 paginiEnergy Optimizing Furnacesourajpatel100% (1)

- Modern Blast Furnace Ironmaking An Introduction (Hoogovens)Document177 paginiModern Blast Furnace Ironmaking An Introduction (Hoogovens)Edwin van Es100% (3)

- Fundamentals of The EAF ProcessDocument54 paginiFundamentals of The EAF ProcessradynasrÎncă nu există evaluări

- Induction HeatingDocument5 paginiInduction HeatingPavan KumarÎncă nu există evaluări

- Steeelmaking 130109095431 Phpapp02Document251 paginiSteeelmaking 130109095431 Phpapp02Debasish Chatterjee ChatterjeeÎncă nu există evaluări

- Cilindro Servo KONGSBERGDocument47 paginiCilindro Servo KONGSBERGAnonymous UjSbzQ100% (1)

- Electric Arc Furnace Steel MakingDocument11 paginiElectric Arc Furnace Steel MakingM. Didik Suryadi100% (2)

- Cupola and Blast FurnaceDocument26 paginiCupola and Blast FurnaceGurjinder SinghÎncă nu există evaluări

- Steel: Continuous Casting Simulation, Version 1.51. User GuideDocument23 paginiSteel: Continuous Casting Simulation, Version 1.51. User GuideBiswadeb Ghosh100% (1)

- An Introductory Presentation On Coke Oven PlantDocument32 paginiAn Introductory Presentation On Coke Oven PlantRohit Vijayvargiya60% (5)

- Electric Arc Furnace: The Melting Heart of SteelmakingDocument12 paginiElectric Arc Furnace: The Melting Heart of Steelmakingjonathan_dianÎncă nu există evaluări

- Coke OvenDocument22 paginiCoke OvenSuwasit DhimanÎncă nu există evaluări

- Coke Oven HeatingDocument12 paginiCoke Oven HeatingSatyajit ray ChoudhuryÎncă nu există evaluări

- Cast HouseDocument18 paginiCast HousemasantaÎncă nu există evaluări

- Steel Making Fundamentals and ApplicationsDocument212 paginiSteel Making Fundamentals and Applicationsernestaugustus5167100% (2)

- Eliminating Molten Metal Splash and Furnace BreakdownsDocument15 paginiEliminating Molten Metal Splash and Furnace BreakdownsAaradhya Poddar0% (1)

- 20samarat Annd1Document35 pagini20samarat Annd1Prabhakar Tiwari100% (1)

- Vocational training report on steel melting processesDocument45 paginiVocational training report on steel melting processesRahul Pandey100% (1)

- Induction FurnaceDocument7 paginiInduction FurnaceDeepak Velusamy100% (2)

- Studies On Blast Furnace Slag Flow CharacteristicsDocument67 paginiStudies On Blast Furnace Slag Flow CharacteristicsFilipe MansurÎncă nu există evaluări

- Sponge Iron PlantDocument12 paginiSponge Iron PlantASHISH MOHAPATRAÎncă nu există evaluări

- M-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionDocument2 paginiM-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionAJAY1381Încă nu există evaluări

- Blast Furnace Equations, Heat Balance, Mass BalanceDocument9 paginiBlast Furnace Equations, Heat Balance, Mass BalanceSamanway Das100% (1)

- Guidelines For Proper Coreless Furnace Maintenance.Document7 paginiGuidelines For Proper Coreless Furnace Maintenance.iowafurnace83100% (2)

- Coke Oven PDFDocument22 paginiCoke Oven PDFPrabhanjan BeheraÎncă nu există evaluări

- Iron MakingDocument135 paginiIron MakingSandeep Bandyopadhyay50% (2)

- Electric Arc Furnace Injection System For OxygenDocument7 paginiElectric Arc Furnace Injection System For OxygenIcilma LiraÎncă nu există evaluări

- Blast Furnace Iron Making IIT KGP Oct 26 2010Document85 paginiBlast Furnace Iron Making IIT KGP Oct 26 2010Samanway DasÎncă nu există evaluări

- Operation Manual FurnaceDocument21 paginiOperation Manual FurnaceAshutosh SinghÎncă nu există evaluări

- Factors Affecting Coke Rate in A Blast Furnace - Ispatguru PDFDocument3 paginiFactors Affecting Coke Rate in A Blast Furnace - Ispatguru PDFWallisson Mendes OsiasÎncă nu există evaluări

- Mill Introduction 170616Document37 paginiMill Introduction 170616Kadala MadhuriÎncă nu există evaluări

- Shivir Study MaterialDocument48 paginiShivir Study Materialkumarkg1Încă nu există evaluări

- Blast Furnace Full SlideDocument31 paginiBlast Furnace Full SlideJunaedyDjafarÎncă nu există evaluări

- Producing Metals Through Blast Furnace MetallurgyDocument32 paginiProducing Metals Through Blast Furnace MetallurgyShailesh SharmaÎncă nu există evaluări

- Blast Furnace Iron Making, IIT, KGP, Oct 26, 2010Document85 paginiBlast Furnace Iron Making, IIT, KGP, Oct 26, 2010Vikas Solanki100% (1)

- Heat & Mass Balance For Blast Furnace - Report Rev 1Document19 paginiHeat & Mass Balance For Blast Furnace - Report Rev 1Fikan Mubarok RohimsyahÎncă nu există evaluări

- Blast Furnace Gas CleaningDocument25 paginiBlast Furnace Gas Cleaningusmanbzu100% (1)

- Effect of Nut Coke On The Performance of The Ironmaking Blast Furnace Qingshi SongDocument159 paginiEffect of Nut Coke On The Performance of The Ironmaking Blast Furnace Qingshi SongGaurav SrivastavaÎncă nu există evaluări

- Ironmaking SSDocument459 paginiIronmaking SSAnjaniAkulaÎncă nu există evaluări

- Sms ProcessDocument7 paginiSms ProcessAnonymous p4GdtQpÎncă nu există evaluări

- Sponge Iron PlantDocument23 paginiSponge Iron Plantashu_update100% (2)

- Gopal Sponge Executive Summary - 08.05Document15 paginiGopal Sponge Executive Summary - 08.05vuonghnÎncă nu există evaluări

- Causes and Prevention of Tuyere BurningDocument4 paginiCauses and Prevention of Tuyere Burningsatya7960100% (1)

- NIPPON STEEL TECHNICAL REPORT No. 89 JANUARY 2004 Development of Visual Evaluation and Numerical Analysis System of Blast FurnaceDocument8 paginiNIPPON STEEL TECHNICAL REPORT No. 89 JANUARY 2004 Development of Visual Evaluation and Numerical Analysis System of Blast Furnacescribdaccount0Încă nu există evaluări

- Apple Industries LTD - Anantapur Dist Exe Sum EngDocument8 paginiApple Industries LTD - Anantapur Dist Exe Sum EngRashmi PatelÎncă nu există evaluări

- Arcelor Mittal Newcastle WorksDocument12 paginiArcelor Mittal Newcastle WorkssinhabillolÎncă nu există evaluări

- Roll Cooling Report2Document7 paginiRoll Cooling Report2sourajpatelÎncă nu există evaluări

- Roll Cooling Report2Document7 paginiRoll Cooling Report2sourajpatelÎncă nu există evaluări

- GuidingDocument1 paginăGuidingsourajpatelÎncă nu există evaluări

- Tax Saving (ELSS) Statement: Souraj Ranjan PatelDocument2 paginiTax Saving (ELSS) Statement: Souraj Ranjan PatelsourajpatelÎncă nu există evaluări

- Mill Operation Shift Schedule1Document32 paginiMill Operation Shift Schedule1sourajpatelÎncă nu există evaluări

- Ø72 04.05.23 PDFDocument1 paginăØ72 04.05.23 PDFsourajpatelÎncă nu există evaluări

- Ø72 04.05.23 PDFDocument1 paginăØ72 04.05.23 PDFsourajpatelÎncă nu există evaluări

- Cont BillDocument17 paginiCont BillsourajpatelÎncă nu există evaluări

- Ø72 04.05.23 PDFDocument1 paginăØ72 04.05.23 PDFsourajpatelÎncă nu există evaluări

- Dismentling ProcedureDocument4 paginiDismentling ProceduresourajpatelÎncă nu există evaluări

- Aarti Steels Limited Roll Shop Process Chart: Stock Size From BD Mill - 127 X 128 MMDocument1 paginăAarti Steels Limited Roll Shop Process Chart: Stock Size From BD Mill - 127 X 128 MMsourajpatelÎncă nu există evaluări

- Ø72 04.05.23 PDFDocument1 paginăØ72 04.05.23 PDFsourajpatelÎncă nu există evaluări

- IDL EL Interview Application FormDocument4 paginiIDL EL Interview Application FormsourajpatelÎncă nu există evaluări

- Final Sheet (Rolled Size)Document12 paginiFinal Sheet (Rolled Size)sourajpatelÎncă nu există evaluări

- RHF Log Books-New (10494)Document2 paginiRHF Log Books-New (10494)sourajpatelÎncă nu există evaluări

- Aarti Steels-23-4-2022Document10 paginiAarti Steels-23-4-2022sourajpatelÎncă nu există evaluări

- Work Instructionfor MISReports 9980Document1 paginăWork Instructionfor MISReports 9980sourajpatelÎncă nu există evaluări

- Electrical Spec. For Cranes (TATA)Document34 paginiElectrical Spec. For Cranes (TATA)sourajpatelÎncă nu există evaluări

- Fiche Technique Steel Bronze - Anglais - Site - 2 1Document1 paginăFiche Technique Steel Bronze - Anglais - Site - 2 1sourajpatelÎncă nu există evaluări

- Final Sheet (Rolled Size) - 24122019Document17 paginiFinal Sheet (Rolled Size) - 24122019sourajpatelÎncă nu există evaluări

- Quality Management System: Work Instruction For Person Working in RHF AreaDocument2 paginiQuality Management System: Work Instruction For Person Working in RHF AreasourajpatelÎncă nu există evaluări

- Quality Management System: Work Instruction For Person Working in RHF AreaDocument2 paginiQuality Management System: Work Instruction For Person Working in RHF AreasourajpatelÎncă nu există evaluări

- Fichetechnique-White-Metal Anglais Site 2Document1 paginăFichetechnique-White-Metal Anglais Site 2sourajpatelÎncă nu există evaluări

- Quality Management System Work Instruction for Roll AssemblyDocument2 paginiQuality Management System Work Instruction for Roll AssemblysourajpatelÎncă nu există evaluări

- Quality Management System: Work Instruction For Operator, Fitters & Helpers in BDM StandDocument2 paginiQuality Management System: Work Instruction For Operator, Fitters & Helpers in BDM StandsourajpatelÎncă nu există evaluări

- Quality Management System: Work Instruction For Roll Inspection and Turning A. New Rolls: InspectionDocument2 paginiQuality Management System: Work Instruction For Roll Inspection and Turning A. New Rolls: InspectionsourajpatelÎncă nu există evaluări

- Quality Management System Work Instruction for Roll AssemblyDocument2 paginiQuality Management System Work Instruction for Roll AssemblysourajpatelÎncă nu există evaluări

- Quality Management System: Work Instruction For Roll Inspection and Turning A. New Rolls: InspectionDocument2 paginiQuality Management System: Work Instruction For Roll Inspection and Turning A. New Rolls: InspectionsourajpatelÎncă nu există evaluări

- Work Instructionfor MISReports 9980Document1 paginăWork Instructionfor MISReports 9980sourajpatelÎncă nu există evaluări

- Sox NOx AnalysersDocument34 paginiSox NOx AnalysersharshalÎncă nu există evaluări

- Chemical Kinetics +Document22 paginiChemical Kinetics +LaraStrbacÎncă nu există evaluări

- Possibility of Production of Bricks Using Waste Materials and Natural Binding Materials in Sri Lanka.Document5 paginiPossibility of Production of Bricks Using Waste Materials and Natural Binding Materials in Sri Lanka.Rohantha RukshanÎncă nu există evaluări

- How To Save 630,000 USD Per Year and Produce The Best PolyesterDocument1 paginăHow To Save 630,000 USD Per Year and Produce The Best Polyesteranil kapadiaÎncă nu există evaluări

- ABB Cable Glands NCG PDFDocument4 paginiABB Cable Glands NCG PDFJimmy F HernandezÎncă nu există evaluări

- Tower Signal BoqDocument2 paginiTower Signal Boqrafael velardeÎncă nu există evaluări

- Bending - Wikipedia, The Free EncyclopediaDocument12 paginiBending - Wikipedia, The Free EncyclopediajazzclubÎncă nu există evaluări

- NEON ELECTRODES CATALOGDocument3 paginiNEON ELECTRODES CATALOGdickdickens100% (2)

- Kema Three Core Power Cables 1Document39 paginiKema Three Core Power Cables 1Anupong JIÎncă nu există evaluări

- Sodium Hydroxide - NaOH - PubChemDocument57 paginiSodium Hydroxide - NaOH - PubChemGemechis AsfawÎncă nu există evaluări

- Bioreactors TypesDocument6 paginiBioreactors TypesHeinerMontalvoÎncă nu există evaluări

- Architectural Woodwork Specification GuideDocument8 paginiArchitectural Woodwork Specification GuideRonnell RepilÎncă nu există evaluări

- As-Welded Wrought Austenitic Stainless Steel Fittings For General Corrosive Service at Low and Moderate TemperaturesDocument4 paginiAs-Welded Wrought Austenitic Stainless Steel Fittings For General Corrosive Service at Low and Moderate Temperaturesrgi178Încă nu există evaluări

- Kurva S (Kelompok 1) FixDocument2 paginiKurva S (Kelompok 1) FixGurusuÎncă nu există evaluări

- Colores BrickformDocument2 paginiColores BrickformzetaequisÎncă nu există evaluări

- 1 s2.0 S2351978919305803 MainDocument8 pagini1 s2.0 S2351978919305803 Mainjbasura69Încă nu există evaluări

- Luis MagneDocument19 paginiLuis Magnerichard gutierrezÎncă nu există evaluări

- Kerala Auto Parts Suppliers DirectoryDocument14 paginiKerala Auto Parts Suppliers Directoryletter2lalÎncă nu există evaluări

- Importing Mining Chemicals From ChinaDocument6 paginiImporting Mining Chemicals From Chinacalisto_rÎncă nu există evaluări

- An Assignment On Granulation of Beneficiation ProcessDocument6 paginiAn Assignment On Granulation of Beneficiation ProcessShowvikÎncă nu există evaluări

- 300i ServiceDocument408 pagini300i ServiceMichael Klein100% (1)

- Esquema Inverter FujiDocument18 paginiEsquema Inverter FujiRicardo Nicolau WerlangÎncă nu există evaluări