Documente Academic

Documente Profesional

Documente Cultură

Cylindrical Member Design

Încărcat de

olomuDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cylindrical Member Design

Încărcat de

olomuDrepturi de autor:

Formate disponibile

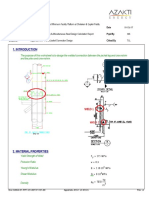

PROJ No PHSE/CTR ACTIVITY PROJECT SUBJECT PATH REVISION

SHEET FILE

OF

ANALYSIS ALLOWABLE STRESS CALCS FOR CYLINDRICAL MEMBERS

\\vboxsrv\conversion_tmp\scratch_1\[211802627.xls.ms_office.xls]TUBULAR MEMBER STRESS CALC.

DATE BY CHECKED APPROVED REVISION DATE BY CHECKED APPROVED

2/17/2014 5:26 Design of Cylindrical Members DATA Yield Strenght Young Modulus of Elasticity Effective Length Factor Unbraced Length Traverse Shear Force axial load bending moment about y-axis bending moment about x-axis poisson's ratio computed compressive bending stress absolute value of hoops compressive stress factor of safety for axial tension factor of safety for hoop compression factor of safety for bending euler stress divided by a factor of safety elastic hoop buckling stress critical hoop buckling stress inelastic local buckling stress reduction factor ( check API RP 2A-WSD for values) critical elastic buckling coefficient (0.3) outside diameter Inside diameter wall thickness torsional moment polar moment of inertia length of cylinder btw stiffening rings, diaphrams or end connections seawater density (64Ibs/ft3) design hydrostatic head wave height depth below still water surface including tide wave length still water depth ring spacing

OKC

Fy E K l V P My Mz v b h SFx SFh SFb Fe ' Fhe Fhc Fxc Cm C D D1 t Mt Ip

50 29000 1 200.98 2 355.1475 -4903.79 -5373.29 0.3 -15.1526 2 1.5 1.5 0.75 2 2 5 36 0.85 0.3 24 22.25 0.875 3324.037 8500

L Hz Hw z L d L

16.75 490 2 7 7 8 5 16.75

pastic section modulus pastic section modulus Cross sectional Area Radius of gyration Axial Tension Allowable tensile strenght Ft =

Z I A r

468.1432 4255.342 63.56816 8.18

0.6Fy

22 1/2 )

30

API RP 2A-WSD EQN 3.2.1-1

Cc = Kl/r = Axial Compression Column Buckling Allowable axial compressive stress For (D/t60) & Kl/r<Cc

107.00 24.56

Fa =

2 1 22 3 5 3 + 3 8 83

27.80 ksi

API RP 2A-WSD EQN 3.2.2-1

Allowable axial compressive stress For D/t60 & Kl/rCc

Fa =

122 23 2

247.48 ksi

API RP 2A-WSD EQN 3.2.2-2

Fa = Local buckling Elastic Local Buckling Stress Inelastic Local Buckling Stress Inelastic Local Buckling Stress For (D/t60) Bending Allowable Bending Stress For D/t1500/Fy Allowable Bending Stress For 1500/Fy< D/t3000/Fy Allowable Bending Stress For 3000/Fy< D/t 300 Shear Beam Shear Maximum Beam Shear stress Fxe = Fxc = Fxc=Fy

27.80 ksi

2 Fy[1.64-0.23(D/t)1/4]

634.38 ksi 55.68 ksi 50 ksi

API RP 2A-WSD EQN 3.2.2-3 API RP 2A-WSD EQN 3.2.2-4 API RP 2A-WSD EQN 3.2.2-4

Fb =

0.75Fy

37.5 ksi

API RP 2A-WSD EQN 3.2.3-1

Fb =

Fy[0.84-1.74(FyD/Et)] Fy[0.72-0.58(FyD/Et)]

37.9 ksi

API RP 2A-WSD EQN 3.2.3-1b

Fb =

34.6 ksi

API RP 2A-WSD EQN 3.2.3-1c

Fv =

0.5

0.4Fy

0.06 ksi 20 ksi

API RP 2A-WSD EQN 3.2.4-1 API RP 2A-WSD EQN 3.2.4-2

Allowable Beam Shear Stress Torsional Shear Maximum Torsional Shear stress Allowable Torsional Shear Stress

Fv =

Fvt = Fvt =

(Mt(D/2))/Ip

0.4Fy

4.693 ksi 20 ksi

API RP 2A-WSD EQN 3.2.4-3 API RP 2A-WSD EQN 3.2.4-4

Hydrostatic Pressure (stiffened and Unstiffened Cylinders) Acting Membrane Stress fh =

3.33 ksi

API RP 2A-WSD EQN 3.2.5-1

Acting Membrane Stress Design Hydrostatic Head Hydrostatic Pressure Design Head

fh =

13440 ksi

API RP 2A-WSD EQN 3.2.5-2

P =

Hz

980 ksi

cosh(k(d-z)) = coshkd =

API RP 2A-WSD EQN 3.2.5-3

2.51 25.39

Hz

Fhe k

cosh ) ( 2

7.35

Hoop Buckling Stress

= =

2

2/L D/t

343.32 0.79 27.428571 ksi 0.16

API RP 2A-WSD EQN 3.2.5-4

Elastic Hoop Buckling Stress critical hoop buckling coefficient Ch M when M1.6D/t when 0.825D/tM<1.6D/t when 3.5M<0.825D/t when 1.5M<3.5 Ch Ch Ch Ch = = = = = =

L(2D/t)1/2/D 0.44 x t/D 0.44(t/D)+0.21(D/t) M4 0.736/(M-0.636) 0.755/(M-0.559)

3

5.17 0.02 6.09 0.16 0.16 0.8

API RP 2A-WSD EQN 3.2.5-5

0.825D/t 1.6D/t

22.628571 43.885714

Ch when M<1.5 = 0.8 NOTE: for M1.6D/t, the elastic buckling stress is approximately equal to that of a long unstiffened cylinder. Thus stiffening rings, if required should be spaced such that M<1.6D/t in order to be beneficial.

critical hoop buckling stress when Fhe0.55Fy when 0.55Fy<Fhe1.6Fy when 1.6Fy<Fhe6.2Fy when Fhe>6.2Fy

Fhc Fhc Fhc Fhc Fhc

50.00 ksi Fhe 0.45Fy + 0.18Fhe 1.31Fy/(1.15 + (Fy/Fhe)) Fy 343.32 ksi 84.30 ksi 50.55 ksi 50 ksi

0.55Fy= 1.6Fy= 6.2Fy=

API RP 2A-WSD EQN 3.2.5-6

27.5 80 310

Ring Design required moment of inertia for ring composite tLD2 x Fhe/8E

4 12 in

Ic

API RP 2A-WSD EQN 3.2.5-7

NOTE see note in API RP 2A-WSD under Ring Design COMBINED STRESSES FOR CYLINDRICAL MEMBERS Combined Axial Compression & Bending Cylindrical Members a Fa a 0.6Fa Cm(bx2 + by2) [1-a/Fe']Fb (bx2 + by2) Fb 1.0 0.8565 Ok (bx + by ) a/Fe' 1.0 0.7225 Ok

API RP 2A-WSD EQN 3.3.1-3

2 2

fa fa/Fa 1.0 0.6545 Ok by bx (bx2 + by2)

5.59 0.201 -15.1526 -13.82861 382.4611 19.556612 0.02

when a/Fa 0.15 a Fa (bx2 + by2) Fb

fa/Fa+

Cylindrical Piles a

2 2 + 1 1

1.0

0.6545

Ok

API RP 2A-WSD EQN 3.3.1-4

(bx2 + by2) Fb

1.0

0.708

Ok

0.6Fxc Pile Overload Analysis P/A Fxc COMBINED AXIAL TENSION AND BENDING Same analysis with 1. above

2 sin-1 M/Z Fxc

1.0

-7.59

Ok

Axial Tension & Hydrostatic Pressure A = a + b - (0.5h) Fy B = h/Fhc X (SFh) 0.6 (SFx) -0.32 a + b - (0.5h) -10.56572

A2 + B2 + 2v A B Axial Compression & Hydrostatic Pressure

1.0

0.57

Ok

a + (0.5h) (SFx)+ Fb(SFb) 1.0 Fxc Fy h / Fhc (SFh) when x > 0.5Fha x - 0.5Fha Faa - 0.5Fha Faa = Fha = x = a + b + (0.5h) NOTE if b > a + 0.5h both eqn 3.3.3-1 and eqn 3.3.4-1 must be satisfied h Fha Fxe / SFx Fhe / SFh = = =

2

0.74

Ok

a + (0.5 h)

6.5868768

1.0

0.6

Ok

1.0

-0.40

Ok

422.92 228.88 -8.57

S-ar putea să vă placă și

- Bearing CapacityDocument20 paginiBearing CapacityJhoan ParedesÎncă nu există evaluări

- Offshore Riser CalculationDocument10 paginiOffshore Riser CalculationSergio MuñozÎncă nu există evaluări

- Subsee Suction Pile Installation AnalysisDocument11 paginiSubsee Suction Pile Installation AnalysisKen KennyÎncă nu există evaluări

- Case Studies For Evaluating Hydrodynamic Motion Responses Using MOSESDocument26 paginiCase Studies For Evaluating Hydrodynamic Motion Responses Using MOSESATLURI SATYA SRINIVAS oe13m002Încă nu există evaluări

- BOX Sec-Beam-Column-AiscDocument6 paginiBOX Sec-Beam-Column-AiscWintun73Încă nu există evaluări

- Seainp - ZULF EDP-1 OBSDocument37 paginiSeainp - ZULF EDP-1 OBSRamesh SelvarajÎncă nu există evaluări

- Input Parameters: 1.1. Input Surface Areas 1.1.1. Above Mudline Without Corrosion Protection CoatingDocument6 paginiInput Parameters: 1.1. Input Surface Areas 1.1.1. Above Mudline Without Corrosion Protection CoatingThomas StephenÎncă nu există evaluări

- API WSD Punch CodeCheckDocument7 paginiAPI WSD Punch CodeCheckKhải TrươngÎncă nu există evaluări

- GoM Offshore Structures Design CriteriaDocument32 paginiGoM Offshore Structures Design CriteriaDonald.KÎncă nu există evaluări

- Calculation Sheet: Tubular Brace ParametersDocument52 paginiCalculation Sheet: Tubular Brace ParametersRamesh SelvarajÎncă nu există evaluări

- SDC Verifier Main PresentationDocument29 paginiSDC Verifier Main PresentationStefano MilaniÎncă nu există evaluări

- E2336 - DESIGN INPUT REQUIRED - COMBINED NAVAL and STRUCTURALDocument6 paginiE2336 - DESIGN INPUT REQUIRED - COMBINED NAVAL and STRUCTURALRamesh SelvarajÎncă nu există evaluări

- Collapse AnalysisDocument27 paginiCollapse AnalysisLaxmi StrulÎncă nu există evaluări

- Inplace Analysis: Check Print For Submission To Client As RequiredDocument4 paginiInplace Analysis: Check Print For Submission To Client As RequiredRamesh SelvarajÎncă nu există evaluări

- Module 1 - Lecture 2 (Introduction)Document12 paginiModule 1 - Lecture 2 (Introduction)SuryaÎncă nu există evaluări

- Appendix A1Document22 paginiAppendix A1Thomas StephenÎncă nu există evaluări

- Fatigue of Steel StructuresDocument12 paginiFatigue of Steel Structuresshimic32000Încă nu există evaluări

- Chapter J Design of ConnectionsDocument16 paginiChapter J Design of Connectionsghosh73Încă nu există evaluări

- Structure Calculation of Loading DockDocument19 paginiStructure Calculation of Loading Dockmhajaraswadi2023Încă nu există evaluări

- Appendix e (Sacs Output)Document6 paginiAppendix e (Sacs Output)Tran Van DaiÎncă nu există evaluări

- App 10 Longitudial Shear 2 UC 283Document3 paginiApp 10 Longitudial Shear 2 UC 283yuÎncă nu există evaluări

- Check List For Topside Inplace Analysis: Project Client Model File NameDocument1 paginăCheck List For Topside Inplace Analysis: Project Client Model File NameRamesh SelvarajÎncă nu există evaluări

- Star Plate Check Connection Number: Node Number: G H O P NDocument7 paginiStar Plate Check Connection Number: Node Number: G H O P Nyogs_184Încă nu există evaluări

- Seismic Co-Efficient Calculation As Per NBCC - Equivalent Static Force Procedure For Structures Satisfying The Conditions of ArticleDocument8 paginiSeismic Co-Efficient Calculation As Per NBCC - Equivalent Static Force Procedure For Structures Satisfying The Conditions of ArticleVEERAM AJITHÎncă nu există evaluări

- Hand Out Rigging Design For Offshore Heavy Lifting Leefmans PDF FreeDocument24 paginiHand Out Rigging Design For Offshore Heavy Lifting Leefmans PDF Freeel000011Încă nu există evaluări

- Load Out FixDocument47 paginiLoad Out FixAnonymous SC5fatrFM3Încă nu există evaluări

- PADEYE Design AnalysisDocument9 paginiPADEYE Design AnalysisRamesh SelvarajÎncă nu există evaluări

- Vessel With Stern On Quay - A Simplified Method For Mooring Design - TheNavalArchDocument11 paginiVessel With Stern On Quay - A Simplified Method For Mooring Design - TheNavalArchFederico Babich0% (1)

- Padeye Shackle Sling Calculation r2Document7 paginiPadeye Shackle Sling Calculation r2Peja JusohÎncă nu există evaluări

- Stability CritariaDocument9 paginiStability CritariaAbu Bakar Siddke RumiÎncă nu există evaluări

- Marine Vehicle Pitching Motion and Radius of GyrationDocument6 paginiMarine Vehicle Pitching Motion and Radius of GyrationsibanandarmsÎncă nu există evaluări

- Fatigue AnalysisDocument2 paginiFatigue AnalysisZulham MochtarÎncă nu există evaluări

- (DNV) Det Norske Veritas - 2005 - Material Risk - Ageing Offshore InstallationsDocument66 pagini(DNV) Det Norske Veritas - 2005 - Material Risk - Ageing Offshore InstallationsKaroline Neumann100% (1)

- Calculation Note Stabbing Guide Design Design Code Check:Api RP 2A Check For Tubular Ø 323.9 X 12.70 Due To Boatlanding InstallationDocument8 paginiCalculation Note Stabbing Guide Design Design Code Check:Api RP 2A Check For Tubular Ø 323.9 X 12.70 Due To Boatlanding InstallationSai SushankÎncă nu există evaluări

- Jeddah South Thermal Power Plant Stage-I: OwnerDocument23 paginiJeddah South Thermal Power Plant Stage-I: OwnerAmr AbdeinÎncă nu există evaluări

- Tonnage CalculationDocument5 paginiTonnage CalculationeÎncă nu există evaluări

- Plan Elevation: D D B P M T T ADocument18 paginiPlan Elevation: D D B P M T T ASai SushankÎncă nu există evaluări

- Low Tide Collision: Lowest Astronomical Tide-EL (+) 0.00 MDocument2 paginiLow Tide Collision: Lowest Astronomical Tide-EL (+) 0.00 MSamantha HartÎncă nu există evaluări

- Towing Design Rev2Document19 paginiTowing Design Rev2Ludovic LandemaineÎncă nu există evaluări

- Environment/ Metdata/Geotech InputsDocument36 paginiEnvironment/ Metdata/Geotech InputsRajith KrÎncă nu există evaluări

- CD CM Overrides For Report Conductor Shielding FactorDocument2 paginiCD CM Overrides For Report Conductor Shielding FactorRamesh SelvarajÎncă nu există evaluări

- Fatigue-Mat 4-DeterministicDocument35 paginiFatigue-Mat 4-Deterministicfahmi rajziÎncă nu există evaluări

- Mathcad - Laydown Area Deck PlateDocument3 paginiMathcad - Laydown Area Deck PlatePradeep ChitluriÎncă nu există evaluări

- The Purpose of This Worksheet Is To Design The Welded Connection Between The Jacket Leg and Crownshim and The Piles and CrownshimDocument5 paginiThe Purpose of This Worksheet Is To Design The Welded Connection Between The Jacket Leg and Crownshim and The Piles and CrownshimThomas StephenÎncă nu există evaluări

- Pile axial load analysis and FOS resultsDocument2 paginiPile axial load analysis and FOS resultsRamesh SelvarajÎncă nu există evaluări

- A01 Catenary and Wave SystemsDocument14 paginiA01 Catenary and Wave SystemsNithin KannanÎncă nu există evaluări

- Acceleration Value (Motion)Document5 paginiAcceleration Value (Motion)bong2rmÎncă nu există evaluări

- Design Sheet: 1. Material PropertiesDocument10 paginiDesign Sheet: 1. Material PropertiesJun MichaelÎncă nu există evaluări

- Conexion 1Document262 paginiConexion 1luisfdogaviriaÎncă nu există evaluări

- Appendix D 2Document7 paginiAppendix D 2Wistie AnnelyaÎncă nu există evaluări

- Spectral Fatigue Analysis of Jacket Stuctures in Mumbai High Field PDFDocument13 paginiSpectral Fatigue Analysis of Jacket Stuctures in Mumbai High Field PDFA_saravanavelÎncă nu există evaluări

- Catenary Mooring Line Shape Tool (Version 1)Document1 paginăCatenary Mooring Line Shape Tool (Version 1)SaidÎncă nu există evaluări

- Multi Lift Point CalcsDocument3 paginiMulti Lift Point CalcsPhan Trọng NghĩaÎncă nu există evaluări

- DRIVEABILITY ANALYSISDocument4 paginiDRIVEABILITY ANALYSISRamesh SelvarajÎncă nu există evaluări

- Fatigue Methods PDFDocument91 paginiFatigue Methods PDFGodwin100% (1)

- Wing Plate BucklingDocument2 paginiWing Plate BucklingSai SushankÎncă nu există evaluări

- Environmental Forces - Aban VIIIDocument2 paginiEnvironmental Forces - Aban VIIIPrashanth Talkad RajagopalÎncă nu există evaluări

- Cpc-Clpp-L-E-0001 CLPP Iws DatasheetDocument52 paginiCpc-Clpp-L-E-0001 CLPP Iws DatasheetNguyen Ninh BinhÎncă nu există evaluări

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsDe la EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsÎncă nu există evaluări

- Lifting Sets Calculation - API RP 2ADocument11 paginiLifting Sets Calculation - API RP 2AQuang-derer100% (28)

- Eurocode 3 steel joint design guideDocument2 paginiEurocode 3 steel joint design guideneverreturnÎncă nu există evaluări

- 15A 12 ConnectionsDocument20 pagini15A 12 Connectionsumar_contactÎncă nu există evaluări

- Eurocode Basic - Concepts PDFDocument27 paginiEurocode Basic - Concepts PDFgranadosvargasÎncă nu există evaluări

- Eurocode 3 ActionsDocument158 paginiEurocode 3 ActionsKeeran Montag100% (7)

- WorleyParsons Experience Supported PlatformsDocument21 paginiWorleyParsons Experience Supported PlatformsolomuÎncă nu există evaluări

- 3 PietrangeloDocument46 pagini3 PietrangeloWilliam ChongÎncă nu există evaluări

- Gas Compressor Turbine Foundation Load PDFDocument2 paginiGas Compressor Turbine Foundation Load PDFolomuÎncă nu există evaluări

- Rotating Equipment Foundation Design ReportDocument25 paginiRotating Equipment Foundation Design ReportolomuÎncă nu există evaluări

- Calculation Soil Bearing Ratio Mannually For Rotating Equipment FoundationDocument16 paginiCalculation Soil Bearing Ratio Mannually For Rotating Equipment FoundationolomuÎncă nu există evaluări

- Civil Engineers FeeDocument5 paginiCivil Engineers FeeolomuÎncă nu există evaluări

- Designing Floor Slabs On GradeDocument281 paginiDesigning Floor Slabs On GradeAddrien DanielÎncă nu există evaluări

- Soil Bearing CapacityDocument55 paginiSoil Bearing CapacityolomuÎncă nu există evaluări

- Gas Compressor Turbine Foundation Load PDFDocument2 paginiGas Compressor Turbine Foundation Load PDFolomuÎncă nu există evaluări

- Handbook of Concrete EngineeringDocument909 paginiHandbook of Concrete Engineeringolomu100% (3)

- Project Administration Handbook For Civil Engineering WorksDocument1.502 paginiProject Administration Handbook For Civil Engineering Worksolomu100% (5)

- Chapter 6 Plate GirderDocument23 paginiChapter 6 Plate GirderolomuÎncă nu există evaluări

- Sea TransportationDocument8 paginiSea TransportationMark Samsel RohanÎncă nu există evaluări

- Design of Metal Flag PoleDocument25 paginiDesign of Metal Flag PoleolomuÎncă nu există evaluări

- 14 Inches Pig Launcher Supports Design PDFDocument10 pagini14 Inches Pig Launcher Supports Design PDFolomuÎncă nu există evaluări

- Sea TransportationDocument8 paginiSea TransportationMark Samsel RohanÎncă nu există evaluări

- 30 Good Rules for Cost-Effective Connection DesignDocument4 pagini30 Good Rules for Cost-Effective Connection Designมานะ จรูญพงษ์ศักดิ์Încă nu există evaluări

- Guidelines For The Design of High Mast Pole FoundationDocument62 paginiGuidelines For The Design of High Mast Pole Foundationolomu100% (8)

- 12 Inches Pig Receiver Supports Design PDFDocument13 pagini12 Inches Pig Receiver Supports Design PDFolomuÎncă nu există evaluări

- On-Bottom Stability AnalysisDocument3 paginiOn-Bottom Stability AnalysisBolarinwaÎncă nu există evaluări

- On-Bottom Stability AnalysisDocument3 paginiOn-Bottom Stability AnalysisBolarinwaÎncă nu există evaluări

- Arch324 w09 Lecture Unit8Document19 paginiArch324 w09 Lecture Unit8olomuÎncă nu există evaluări

- Comb - Foot Slab MCNDocument7 paginiComb - Foot Slab MCNolomuÎncă nu există evaluări

- Caltrans Memo To Designers 4-1 - November 2003 - Spread FootingDocument3 paginiCaltrans Memo To Designers 4-1 - November 2003 - Spread FootingRC Dela RocaÎncă nu există evaluări

- Footing DesignDocument30 paginiFooting DesignShaikh Muhammad Ateeq100% (1)

- Centrifugal Pump System Curves ExplainedDocument5 paginiCentrifugal Pump System Curves ExplainedPTC Phils.Încă nu există evaluări

- CavitationDocument1 paginăCavitationmcsfuvÎncă nu există evaluări

- Restrained and Unrestrained Zones of Buried PipelinesDocument8 paginiRestrained and Unrestrained Zones of Buried PipelinesAnjani PrabhakarÎncă nu există evaluări

- Module 4Document40 paginiModule 4Himanshu ChaudhariÎncă nu există evaluări

- Itp Forabove Grade and Embedded Conduits Rev. 0Document6 paginiItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- Tds 0970 0971 0972Document2 paginiTds 0970 0971 0972José OlivarÎncă nu există evaluări

- Dlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious GroutDocument4 paginiDlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious Grout4919404Încă nu există evaluări

- Concrete Construction - DeTAIL - DeTAILDocument25 paginiConcrete Construction - DeTAIL - DeTAILTriet NguyenÎncă nu există evaluări

- Training at Gurjar Ki Thadi Under Pass, JaipurDocument37 paginiTraining at Gurjar Ki Thadi Under Pass, JaipurDevendra SharmaÎncă nu există evaluări

- 132 kV Transmission Line Foundation Design for Nigeria DeltaDocument57 pagini132 kV Transmission Line Foundation Design for Nigeria DeltavoilÎncă nu există evaluări

- Landfill Design - Bush Tech 17Document2 paginiLandfill Design - Bush Tech 17trishincyberspaceÎncă nu există evaluări

- MOS Mechanical Pipes LayingDocument3 paginiMOS Mechanical Pipes Layingmagdi badranÎncă nu există evaluări

- Analysis and Design of Hollow Reinforced Concrete ColumnsDocument5 paginiAnalysis and Design of Hollow Reinforced Concrete ColumnsEditor IJRITCC100% (1)

- Week-4-Lectures 7 and 8 - Sewerage System Design-Estimation of Flows PDFDocument41 paginiWeek-4-Lectures 7 and 8 - Sewerage System Design-Estimation of Flows PDFAli RazaÎncă nu există evaluări

- Proposed 5 Storey Building with Roof Deck Structural DesignDocument4 paginiProposed 5 Storey Building with Roof Deck Structural DesignAlvin SantosÎncă nu există evaluări

- Basic Theory PumpDocument37 paginiBasic Theory PumpkunkzÎncă nu există evaluări

- Astm D Vol. IIDocument48 paginiAstm D Vol. IIMaonrri BladimirÎncă nu există evaluări

- AISC-Design Properties of Cantilevered BeamsDocument1 paginăAISC-Design Properties of Cantilevered Beamsshak543Încă nu există evaluări

- BREB Tendr ListDocument2 paginiBREB Tendr ListLorem53Încă nu există evaluări

- Choice of Rail WheelsDocument4 paginiChoice of Rail WheelsMahmut KarataşÎncă nu există evaluări

- 30RB-RQ Series 2021 - tcm175-147055Document19 pagini30RB-RQ Series 2021 - tcm175-147055Siva KirupaÎncă nu există evaluări

- SC Weekly Report PBDocument29 paginiSC Weekly Report PBMohd AzwanÎncă nu există evaluări

- Truss Design - 1Document43 paginiTruss Design - 1Syed Intizar MehdiÎncă nu există evaluări

- Client - CPWD Site Location - Janpath New Delhi Building DetailsDocument12 paginiClient - CPWD Site Location - Janpath New Delhi Building DetailsNIBEDITA DEYÎncă nu există evaluări

- The Design of Cooling Towers in Extremely Severe Earthquake ConditionsDocument8 paginiThe Design of Cooling Towers in Extremely Severe Earthquake ConditionsSanjeev KulkarniÎncă nu există evaluări

- Example Report SPT CorrDocument3 paginiExample Report SPT CorredinsonguanchezÎncă nu există evaluări

- Castigliano's TheoremDocument13 paginiCastigliano's TheoremSkektÎncă nu există evaluări

- FLUID MECHANICS QUESTION BANK-unlockedDocument323 paginiFLUID MECHANICS QUESTION BANK-unlockedHemanth Peddavenkatappa GariÎncă nu există evaluări

- BoqDocument5 paginiBoqSubramanian DivakarÎncă nu există evaluări

- MASTERSEAL 550 EL v3 PDFDocument2 paginiMASTERSEAL 550 EL v3 PDFRajesh KumarÎncă nu există evaluări