Documente Academic

Documente Profesional

Documente Cultură

Ignition Module

Încărcat de

Roberto Sanchez ZapataDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ignition Module

Încărcat de

Roberto Sanchez ZapataDrepturi de autor:

Formate disponibile

IM

DESCRIPTION

Waukeshas Custom Engine Control (CEC) Ignition Module (IM) provides accurate and reliable ignition g timing for optimum stationary engine operation. Specically designed to enhance the performance ormance and costeffectiveness of Waukesha engines, the IM offers improved starting, smoother operation, and increased spark plug life. The IM is an electronic, microcircuit-based digital ignition system that is standard andard on ATGL, VHP, and VGF engines. When the IM is integrated with the CEC Detonation Sensing Module (DSM) system, the ignition ition system protects the engine from detonation and costly downtime, and maximizes power availability y under adverse conditions. Together the IM and DSM form a protection system to extend engine life, fe, optimize engine performance, and protect against engine detonation.

Ignition Module

FEATURES AND BENEFITS

Optimum Performance - Accurate ignition timing is critical as horsepower demands increase and

engine applications become more diversied. The IM provides better cycle-to-cycle and d cylinder-to-cylinder accuracy for more consistent emissions, higher power availability and nd greater engine stability. Timing is controlled within 1/4 degree of the desired setting. With more consistent ring of each cylinder, the engine e is optimized for power, performance, and emissions.

No Scheduled Maintenance - The CEC IM offers no scheduled maintenance operation. Since the IM

is electronically controlled, there are no moving parts to wear out. The circuit boards controlling ntrolling engine timing are mounted inside the IM housing.

High Energy - The CEC IM operates on a capacitor discharge principle. This consistently provides ovides high

energy for maximum ignition spark, allowing greater spark plug life and engine performance. nce.

Diagnostics - Three on-board diagnostic LEDs provide visual troubleshooting. These LEDs give ive operators

conrmation on 1) incoming power, 2) Hall-effect pickup signal, and 3) proper application n settings.

Expandable - Waukeshas CEC IM is expandable to incorporate the CEC DSM. A 14-pin expansion port on

the IM allows for connection to the DSM. The DSM makes it possible for the IM to individually time engine cylinders. This allows maximum advance of timing providing better fuel consumption and optimum performance.

Application Flexibility - The IM is capable of providing timing for more than one fuel or load point. With two 16

Custom Engine Control

IM

CSA Certication, Class I, Division 2, Group D Optimizes performance Built-in diagnostics/status LEDs Dual fuel capabilities PLC interface capability

position rotary timing switches, the engine can be set up to operate on two different fuels. This eliminates the need to manually make timing adjustments and provides application exibility. Timing can also be selected to minimize emissions or maximize efciency.

COMPONENTS

Waukeshas CEC IM system consists of an electronic module, Hall-effect pickup (two for AT27GL), timing disc or gear, wiring harnesses, and one ignition coil for each cylinder. Use of a Hall-effect sensor(s) provides simple, reliable installation and operation.

RETROFIT CAPABILITY

Retrot kits are available for VGF, VHP, and ATGL engines.

S P E C I F I CAT I O N S

Module Size 3.70" H 8.85" L 7.12" W Mounting Centers 7.75" L 6.25" W Number of Cylinders 6, 8, 12, and 16 Voltage Output to Coils 130 - 180 VDC Ground Negative Timing Accuracy 1/4

CEC Product Family The CEC family consists of an Ignition Module (IM), Detonation Sensing Module (DSM), Air/Fuel Module (AFM), and, on ATGL engines, the Turbocharger Control Module (TCM). Together they form a comprehensive engine management system that optimizes engine performance. Even when large changes in operating conditions occur, there is no discernible difference in engine performance.

IGNITION MODULE

The CEC Ignition Module (IM) is a microcircuit-based, digital ignition system. With no scheduled maintenance, and built in diagnostics, the IM is designed to enhance the reliability and performance of your Waukesha Engine while maximizing engine up-time.

DETONATION SENSING MODULE

The CEC Detonation Sensing Module (DSM) works in conjunction with the ignition module to protect Waukesha spark ignited gas engines from damage due to detonation as well as maintain fuel economy and power output during adverse operating conditions.

The Custom Engine Control Family includes (left to right) the Air/Fuel Module, Detontaion Sensing Module, Turbocharger Control Module, and Ignition Module. Together, they form a comprehensive engine management system that optimizes engine performance.

AIR/FUEL MODULE

The CEC Air/Fuel Module (AFM) optimizes fuel consumption and emissions even when fuel composition and ambient conditions change dramatically.

TURBOCHARGER CONTROL MODULE

The CEC Turbocharger Control Module (TCM) improves turbocharger efciency and enhances engine performance by precisely matching turbocharger output to engine needs under all operating conditions.

IM DSM

CEC PRODUCT FAMILY

TCM

Programming Tailored To Your Needs The AFM, DSM and TCM programs can be tailored to meet your performance needs. Thus emissions, fuel consumption and engine response can all be optimized for a given application. The AFM has dual programming schedules to accommodate dual fuel applications. Performance can be tailored on each fuel. There is no need to compromise performance on one fuel due to operating limitations that might be imposed by the other. Similarly, the DSM has dual timing schedules which permit operation in two different timing ranges. This might be required in dual fuel or other applications where optimum performance cannot be achieved with a single timing range. The operation of the TCM can be tailored to facilitate maximum engine response, maximum turndown capability, or maximum fuel efciency whichever is most appropriate for the application.

PERSONAL COMPUTER

AFM

CEC PRODUCT PERFORMANCE

An example of system operation during signicant changes in fuel composition is shown in the gure. In this severe test, the CEC family of products maintained peak engine performance under extreme conditions. Fuel composition was changed from a mixture with 900 Btu/ft3 and a Waukesha Knock Index (WKI) value of approximately 94, to nearly 1200 Btu/ft3 with a WKI value of about 52 within 9 seconds. The CEC engine management system simultaneously adjusted all control parameters as required to keep the engine running smoothly, at rated power and the best fuel economy emissions possible. The AFM system kept the engine from becoming too rich. Only a slight change in air/fuel ratio occurred during the transition in fuel composition. Thus, emissions were maintained and the tendency for detonating was reduced (refer to the average air/fuel ratio curve in the gure at the right). At the same time the AFM was adjusting air/fuel ratio, the DSM system was monitoring the combustion process to see if a change in ignition timing was required. In this test, even with proper air/fuel ratio control, the huge change in WKI necessitated a change in ignition timing. The DSM system retarded and advanced engine timing, via the CEC Ignition Module, to the optimum level. Power was maximized while maintaining detonation free combustion (see the average timing curve in the gure above). This is just one example of how the CEC family of products can enhance engine performance under even the most difcult operating conditions.

ABOVE: An example of system operation during signicant changes in fuel consumption. In this test, the CEC family of products maintained peek engine performance under extreme conditions.

The CEC family forms a comprehensive engine management system that optimizes engine performance.

Data Acquisition Monitoring Capability

It is possible to acquire continuous streams of data about your engines performance from the CEC product family using data acquisition software (provided by customer). The CEC data streams provide information such as knock sensor status, diagnostic codes, air/fuel ratio operating point, and individual cylinder timing. Through the use of a PC this information can be logged and used for system trending and analysis. The gure to the left is an example of a screen developed with data acquisition software which is used to display information and trend data on engine performance. The information format of the serial streams is available from Dresser Waukesha Application Engineering.

ABOVE: An example of a screen developed with data acquisition software which is used to display information and trend data on engine performance.

IGNITION MODULE (IM) SYSTEM LAYOUT

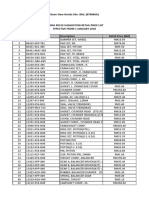

IGNITION MODULE MODEL ENGINE APPLICATIONS Model 811

VHP 6 Cyl. Engines VGF 6 and 8 Cyl. Engines ATGL 8 Cyl. Engines

Model 1211

VHP 12 Cyl. Engines VGF 12 Cyl. Engines ATGL 12 Cyl. Engines

Model 1611

VHP 16 Cyl. Engines VGF 16 Cyl. Engines ATGL 16 Cyl. Engines

IGNITION MODULE SELECTOR SWITCH SETTINGS Selector Model 811 Model 1211 Model 1611 Switch for all 12 for all 16 Setting for 6 and 8

Cyl. Engines VHP/VGF 6 Cyl. Engines No Application VHP/ATGL 8 Cyl. Engines Cyl. Engines Cyl. Engines

A B C

VHP/VGF 12 Cyl. Engines No Application ATGL 12 Cyl. Engines

VHP/VGF 16 Cyl. Engines No Application ATGL 16 Cyl. Engines

IGNITION MODULE SYSTEM POWER REQUIREMENTS Voltage.........................................................24 VDC nominal Operating Range ............................................... 10 - 32 VDC Ripple Peak-to-Peak.....................................less than 2 VAC Steady State Operation Current .................. 2 amps average (up to 30 amp pulses)

ENVIRONMENTAL Ambient Air Temp. Range .................... -40 F (-40C ) to 150 F (66 C) Enclosure...........................................NEMA Type 4X Design Meets CSA Class I, Division 2, Group D, hazardous location requirements The use of a power supply with a battery will eliminate the possibility of engine shutdown if main utility power is lost

OPERATOR INTERFACE Front Panel LED display...................................(Power, Pickup, Application)

Consult your local Waukesha Distributor for system application assistance. The manufacturer reserves the right to change or modify without notice, the design or equipment specications as herein set forth without incurring any obligation either with respect to equipment previously sold or in the process of construction except where otherwise specically guaranteed by the manufacturer.

Bulletin 7100 1008

Dresser Waukesha 1101 West St. Paul Avenue Waukesha, WI 53188-4999 Phone: (262) 547-3311 Fax: (262) 549-2795

2008 Dresser Inc. Dresser, Waukesha, VHP, ATGL, CEC, and VGF are registered trademark of Dresser Waukesha, Dresser, Inc.

Waukesha

www.dresser.com

S-ar putea să vă placă și

- Ramp Power 232 - Operator's Manual - E Option Control Panels - Part #OA7605 - Jun 2003 - GENERAC PDFDocument80 paginiRamp Power 232 - Operator's Manual - E Option Control Panels - Part #OA7605 - Jun 2003 - GENERAC PDFpevare100% (3)

- Cec Ignition Madule O&m PDFDocument142 paginiCec Ignition Madule O&m PDFFaisal Naeem100% (3)

- 10073-1 - VHP 5794,7042,7044 GSI Series Four 12-Cylinder With ESM2 Parts CatalogDocument216 pagini10073-1 - VHP 5794,7042,7044 GSI Series Four 12-Cylinder With ESM2 Parts CatalogMuhammadShadab100% (8)

- Kawasaki Gas EnginesDocument117 paginiKawasaki Gas Enginesfieldysnutz76240489396% (25)

- GE Waukesha Special Tools CatalogDocument94 paginiGE Waukesha Special Tools CatalogMuhammadShadab90% (10)

- Waukesha 12 Cyl Extender Parts (Complete)Document185 paginiWaukesha 12 Cyl Extender Parts (Complete)Stephen Cox94% (17)

- Installation of Waukesha Engines and Enginator SystemsDocument264 paginiInstallation of Waukesha Engines and Enginator SystemsTERRY_HENRRY100% (16)

- Waukesha Knock IndexDocument5 paginiWaukesha Knock IndexAchmad Nizar Zulmi100% (1)

- Motores Waukesha L5790gsiDocument2 paginiMotores Waukesha L5790gsiEdgar Castro67% (3)

- CAT 938G LoaderDocument25 paginiCAT 938G LoaderMohammed Ali Mahadik60% (5)

- MD-200 PartsDocument181 paginiMD-200 PartsBakht Baidar88% (8)

- 6277-4 VPH 6-12-16 Cylinder O&MDocument310 pagini6277-4 VPH 6-12-16 Cylinder O&Mchejoman1979100% (1)

- 6302-2 VHP Series Four L5774 L5794 L7044 12 Cylinder With ESM Parts CatalogDocument188 pagini6302-2 VHP Series Four L5774 L5794 L7044 12 Cylinder With ESM Parts CatalogMuhammadShadab95% (21)

- tp6456 - 6068 EcuDocument1.566 paginitp6456 - 6068 EcuRoberto Sanchez Zapata95% (19)

- Manual Panel DDocument28 paginiManual Panel DRoberto Sanchez Zapata100% (1)

- Industrial Generator Wiring DiagramsDocument88 paginiIndustrial Generator Wiring DiagramsRoberto Sanchez ZapataÎncă nu există evaluări

- PL6KDocument36 paginiPL6KRoberto Sanchez ZapataÎncă nu există evaluări

- Waukesha - ESM 5144 0107Document2 paginiWaukesha - ESM 5144 0107kooolma100% (4)

- 01.412833 - A9. Engine - VGF F18se-H24se 6&8 Cyl Parts CatalDocument224 pagini01.412833 - A9. Engine - VGF F18se-H24se 6&8 Cyl Parts CatalJorge RiquelmeÎncă nu există evaluări

- ESM O&M 3rd EditionDocument202 paginiESM O&M 3rd EditionLibardo RuzÎncă nu există evaluări

- VHP 7042GSI MaintenanceDocument4 paginiVHP 7042GSI MaintenanceFernando Bravo100% (2)

- (REHS0371) Installation and Initial Start Up Procedures For G3300 and G3400 EnginesDocument16 pagini(REHS0371) Installation and Initial Start Up Procedures For G3300 and G3400 Enginesvictor.cipriani100% (1)

- Ariel JGK4 F11982 PartsDocument19 paginiAriel JGK4 F11982 PartsAnonymous TXOkcdy100% (3)

- Waukesha L7044GSI PLANOS ESM2Document443 paginiWaukesha L7044GSI PLANOS ESM2Juan Hernández Gil100% (3)

- Docslide - Us - Waukesha VHP Esm Manual PDFDocument221 paginiDocslide - Us - Waukesha VHP Esm Manual PDFRandy Marzeind50% (2)

- Waukesha VHP Serie 5Document45 paginiWaukesha VHP Serie 5dfmolina100% (1)

- Waukesha - Installation Operation Maintenance R PDFDocument117 paginiWaukesha - Installation Operation Maintenance R PDFLEE100% (4)

- Ariel JGK4 Gfi PDFDocument4 paginiAriel JGK4 Gfi PDFFitrian HermawanÎncă nu există evaluări

- 7044 GSI S4 Spare Parts ManualDocument216 pagini7044 GSI S4 Spare Parts ManualEng Mohamed Hanafy100% (3)

- DST4602 enDocument255 paginiDST4602 enMarcos BrandãoÎncă nu există evaluări

- Waukesha Service Repair Kits 2005Document205 paginiWaukesha Service Repair Kits 2005Javier Leonidas92% (13)

- Caterpillar Common RailDocument6 paginiCaterpillar Common Rail08088338100% (2)

- TP 6437Document34 paginiTP 6437Roberto Sanchez ZapataÎncă nu există evaluări

- Industrial Generator Wiring DiagramsDocument47 paginiIndustrial Generator Wiring DiagramsRoberto Sanchez ZapataÎncă nu există evaluări

- 0E7738Document78 pagini0E7738Roberto Sanchez ZapataÎncă nu există evaluări

- TP 6813Document68 paginiTP 6813Roberto Sanchez Zapata100% (1)

- Tp6083 Dec550 OperationDocument168 paginiTp6083 Dec550 OperationedukrlÎncă nu există evaluări

- Solar Centaur Turbine Engine Startup ProcessDocument32 paginiSolar Centaur Turbine Engine Startup ProcessFarhanÎncă nu există evaluări

- P&W PT6 Engine SeriesDocument8 paginiP&W PT6 Engine SeriesJuanOñate50% (2)

- Volvo D7D Engine EC290-240 Service ManualDocument93 paginiVolvo D7D Engine EC290-240 Service ManualJrodríguez Rodríguez100% (1)

- Waukesha 7101 SpecDocument4 paginiWaukesha 7101 SpecDennis Daniel100% (1)

- Custom Engine ControlDocument5 paginiCustom Engine ControlMmekaJoshua100% (3)

- 6286-2 Web - AFM PDFDocument434 pagini6286-2 Web - AFM PDFshahzad100% (1)

- Waukesha Gas Engines: GE Power & WaterDocument10 paginiWaukesha Gas Engines: GE Power & WaterdfmolinaÎncă nu există evaluări

- Waukesha VGF h24gld Product Sheet 1Document2 paginiWaukesha VGF h24gld Product Sheet 1nps100% (2)

- Altronics DISN800C IOM 11-1997 PDFDocument18 paginiAltronics DISN800C IOM 11-1997 PDFSMc67% (3)

- 6277-5 WebDocument356 pagini6277-5 WebTravisÎncă nu există evaluări

- L5794LT Form8023 0413 PDFDocument2 paginiL5794LT Form8023 0413 PDFDuvan NietoÎncă nu există evaluări

- ESM VHP Manual All PDFDocument215 paginiESM VHP Manual All PDFHimawanÎncă nu există evaluări

- SECTION 5.10: Ignition SystemDocument36 paginiSECTION 5.10: Ignition SystemLUISA FERNANDA TORRES MANOSALVAÎncă nu există evaluări

- Af2 Adjustment PDFDocument4 paginiAf2 Adjustment PDFFaisal NaeemÎncă nu există evaluări

- Waukesha 7044 SparesDocument7 paginiWaukesha 7044 SparesHisham Elsayed100% (1)

- 6388-1 Web PDFDocument466 pagini6388-1 Web PDFjonathan50% (2)

- VHP Parts BookDocument19 paginiVHP Parts Bookhuskerchamps100% (6)

- KG6 04 PDFDocument4 paginiKG6 04 PDFAhmed Sherif CupoÎncă nu există evaluări

- Wuaukesha EnginesDocument4 paginiWuaukesha EnginesVirbiirÎncă nu există evaluări

- ESM PresentationDocument30 paginiESM Presentationnicol_sgÎncă nu există evaluări

- DC30D Configuration and Instructions Ver1.0Document8 paginiDC30D Configuration and Instructions Ver1.0JaimeCoello100% (2)

- Waukesha Gas Engine SparesDocument122 paginiWaukesha Gas Engine Sparesakamalapuri388100% (6)

- Waukesha V HP Series 4Document4 paginiWaukesha V HP Series 4rohizatÎncă nu există evaluări

- F3521GLDocument2 paginiF3521GLRose Marie100% (1)

- Tad 1641 GeDocument2 paginiTad 1641 GeGiangDoÎncă nu există evaluări

- 6284 4 10 PDFDocument14 pagini6284 4 10 PDFnps100% (1)

- Air Fuel Ratio Control 3516BDocument4 paginiAir Fuel Ratio Control 3516Bwagner_guimarães_1Încă nu există evaluări

- WaukeshaDocument18 paginiWaukeshaOmar Alexander Cañon Ortegon100% (9)

- Mining TruckDocument24 paginiMining TruckJaime SantamariaÎncă nu există evaluări

- MINING TRUCK 793 C (Camion Minero)Document24 paginiMINING TRUCK 793 C (Camion Minero)Christian KariÎncă nu există evaluări

- Ignition ModuleDocument4 paginiIgnition ModuleMari Carmen RodriguezÎncă nu există evaluări

- Catalogo 962GII PDFDocument28 paginiCatalogo 962GII PDFlkrlozZ100% (1)

- 2002 01 0378v001 PDFDocument12 pagini2002 01 0378v001 PDFwinter1998100% (1)

- D6NDocument24 paginiD6Ntestecalculo0% (1)

- Cat 775eDocument28 paginiCat 775emattsicsÎncă nu există evaluări

- Hehh3856 01 (329D)Document20 paginiHehh3856 01 (329D)agegnehutamiratÎncă nu există evaluări

- Diesel Generator Set S Series: Specification SheetDocument4 paginiDiesel Generator Set S Series: Specification SheetRamesh AnanthanarayananÎncă nu există evaluări

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusDe la EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusÎncă nu există evaluări

- Manual Panel E PlusDocument36 paginiManual Panel E PlusRoberto Sanchez Zapata100% (1)

- TP 6434Document38 paginiTP 6434Roberto Sanchez Zapata100% (1)

- Generator Set Accessories with Advanced Digital ControlDocument2 paginiGenerator Set Accessories with Advanced Digital ControlRoberto Sanchez ZapataÎncă nu există evaluări

- TP 6832Document96 paginiTP 6832Roberto Sanchez Zapata100% (1)

- Manual Panel CDocument52 paginiManual Panel CRoberto Sanchez Zapata100% (3)

- Residenciales 8 A 22 KWDocument2 paginiResidenciales 8 A 22 KWRoberto Sanchez ZapataÎncă nu există evaluări

- TP 6814Document56 paginiTP 6814Roberto Sanchez ZapataÎncă nu există evaluări

- TP 6777Document60 paginiTP 6777Roberto Sanchez Zapata100% (1)

- TP 6389Document24 paginiTP 6389Roberto Sanchez ZapataÎncă nu există evaluări

- TP 6799Document84 paginiTP 6799Roberto Sanchez Zapata100% (1)

- TP 6798Document108 paginiTP 6798Roberto Sanchez Zapata100% (2)

- TP 6744Document14 paginiTP 6744Roberto Sanchez ZapataÎncă nu există evaluări

- TP 6713Document88 paginiTP 6713Roberto Sanchez ZapataÎncă nu există evaluări

- TP 6744Document14 paginiTP 6744Roberto Sanchez ZapataÎncă nu există evaluări

- Kohler generator set testing programDocument1 paginăKohler generator set testing programRoberto Sanchez ZapataÎncă nu există evaluări

- TP 6814Document56 paginiTP 6814Roberto Sanchez ZapataÎncă nu există evaluări

- Service Parts: EngineDocument44 paginiService Parts: EngineRoberto Sanchez ZapataÎncă nu există evaluări

- Tp6667 Generator SetsDocument108 paginiTp6667 Generator SetsRoberto Sanchez ZapataÎncă nu există evaluări

- Service Parts: Residential/Commercial Generator SetsDocument68 paginiService Parts: Residential/Commercial Generator SetsRoberto Sanchez ZapataÎncă nu există evaluări

- Renewing Valve Stem Oil Seals With Cylinder Head Installed: Special Tools and Workshop Equipment RequiredDocument5 paginiRenewing Valve Stem Oil Seals With Cylinder Head Installed: Special Tools and Workshop Equipment RequiredArkidÎncă nu există evaluări

- Christian Kim Christiansen PHD ThesisDocument197 paginiChristian Kim Christiansen PHD ThesisYuryÎncă nu există evaluări

- 4TL6 PCDocument52 pagini4TL6 PClingeshsaikumar030Încă nu există evaluări

- Lightweight Honda Powered Portable PumpDocument1 paginăLightweight Honda Powered Portable PumpFiretex Protective Technologies Pvt Ltd FiretexÎncă nu există evaluări

- Borescope Inspection Report: Gas Turbine Engine Saturn Hot End Drive Engine Serial NumberDocument16 paginiBorescope Inspection Report: Gas Turbine Engine Saturn Hot End Drive Engine Serial NumberAhmed shaban100% (1)

- TSP Ford CataloguesDocument279 paginiTSP Ford Cataloguessu30mkii83gmail.comÎncă nu există evaluări

- Hydraulic Shoe PartsDocument33 paginiHydraulic Shoe PartsLei ZengrongÎncă nu există evaluări

- Bearings & Deflections - 1Document41 paginiBearings & Deflections - 1Glen MacÎncă nu există evaluări

- Engine ConceptDocument64 paginiEngine ConceptAntónio FernandesÎncă nu există evaluări

- Valve Seat Recession April 2015Document2 paginiValve Seat Recession April 2015Moslem KhanlarpourÎncă nu există evaluări

- After Passing Through A Convergent-Divergent Nozzle, The Temperature of Air Will: A. Increase B. Decrease C. Remains The Same D. None of TheseDocument100 paginiAfter Passing Through A Convergent-Divergent Nozzle, The Temperature of Air Will: A. Increase B. Decrease C. Remains The Same D. None of TheseVJ JhanruxÎncă nu există evaluări

- Waukesha F18GL-GLD - S-7775-45Document10 paginiWaukesha F18GL-GLD - S-7775-45kman548Încă nu există evaluări

- YanmarDocument2 paginiYanmarRicardo Barbosa100% (2)

- 2.0L ENGINE Chevy Tracker 1999Document52 pagini2.0L ENGINE Chevy Tracker 1999andres german romeroÎncă nu există evaluări

- M. Tech. Automotive Curriculum & SyllabusDocument37 paginiM. Tech. Automotive Curriculum & SyllabuskbhattacÎncă nu există evaluări

- Partial Engine Disassembly GuideDocument59 paginiPartial Engine Disassembly Guidevictorjoseteixeira100% (1)

- RS150SuggestionRetailPriceList JAN2018Document17 paginiRS150SuggestionRetailPriceList JAN2018ikkamil78100% (1)

- Informasi Harga Oli Mobil: Merek & Tipe Harga (RP) AgipDocument3 paginiInformasi Harga Oli Mobil: Merek & Tipe Harga (RP) AgipSpeed DriverÎncă nu există evaluări

- Differential Gear MechanismDocument32 paginiDifferential Gear MechanismMohammad Amir100% (2)

- Manufacturer: Ford Model: Transit ('00) 2,0D Di Engine Code: ABFA Output: 74 (100) 4000 Tuned For: Year: 2000-06 © Autodata Limited 2007 14.06.2009Document3 paginiManufacturer: Ford Model: Transit ('00) 2,0D Di Engine Code: ABFA Output: 74 (100) 4000 Tuned For: Year: 2000-06 © Autodata Limited 2007 14.06.2009elvishernandezÎncă nu există evaluări

- Toyota Trouble Code InfoDocument6 paginiToyota Trouble Code InfoFrancis Azul Simalong50% (2)

- CAT - C13 (All Other Prefixes) .Prefix S3CDocument12 paginiCAT - C13 (All Other Prefixes) .Prefix S3CPhil B.Încă nu există evaluări

- Scout Proficiency Badge Training SchemeDocument58 paginiScout Proficiency Badge Training SchemeCuon Scout GroupÎncă nu există evaluări