Documente Academic

Documente Profesional

Documente Cultură

Cutting Tool 1

Încărcat de

chandankrdumka0 evaluări0% au considerat acest document util (0 voturi)

45 vizualizări22 paginiThe document deals with general machine tools used in machining operations.

It mainly focuses on the point to point constituents, properties these incorporate, significance of those properties, and application according to these.

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThe document deals with general machine tools used in machining operations.

It mainly focuses on the point to point constituents, properties these incorporate, significance of those properties, and application according to these.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

45 vizualizări22 paginiCutting Tool 1

Încărcat de

chandankrdumkaThe document deals with general machine tools used in machining operations.

It mainly focuses on the point to point constituents, properties these incorporate, significance of those properties, and application according to these.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 22

CUTTING TOOL

PROPERTIES, CONSTITUENTS AND APPLICATIONS

By Chandan Kumar

NIT Jamshedpur

2013 pass out batch

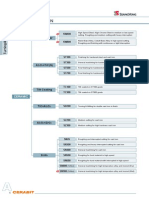

CLASSIFICATION

TOOLS

CARBON

TOOL

HSS

T- TYPE M-TYPE

COBALT

ALLOY

CARBIDEs

CEMENTED

CARBIDE

HIGH Co

CARBIDE

LOW Co

CARBIDE

CERMENTS

COATED

CARBIDE

CERAMIC

Al2O3

SILICON

NITRIDE

SIALON

DIAMOND CBN

CUTTING TOOL PROPERTIES

HARDNESS, HOT HARDNESS, TOUGHNESS, CUTTING VELOCITY

PROPERTIES

Tool Derivatives

properties

Remark Hardness (HK)

Knoop

hardness

Hot hardness

(HK)

Toughness (Mpa)

Transeverse

rupture strength

Velocity (m/min)

For ferous metal

carbon tool steel 600 100 5200 6 very low speed

HSS t-type, M-type 650 200 4100 30

cobalt alloy 650 500 2250 60

cemented

carbides

Low Co content 1800 525 1400 150

High Co content 1700 510 2400 150

ceramic Al2O3, 2100 600 400 600 lesst hardness

Diamond synthetic 8000 8000 1500 1000

speed for non-ferrous

metals

HARDNESS

CARBON STEEL

HSS

COBALT ALLOY

HIGH Co CARBIDE

LOW Co CARBIDE

CERAMIC

DIAMOND

0 1000 2000 3000 4000 5000 6000 7000 8000 9000

1

2

3

4

5

6

7

HARDNESS (hk)

T

O

O

L

M

A

T

R

R

I

A

L

Hardness (HK) Knoop hardness

HIGHEST

LEAST

HIGH

LOW

HOT HARDNESS

CABON TOOL

HSS

COBALT ALLOY

LOW Co CARBIDE

HIGH Co CARBIDE

CERAMIC

DIAMOND

0 1000 2000 3000 4000 5000 6000 7000 8000 9000

1

2

3

4

5

6

7

Hot hardness (HK)

HIGHEST

LEAST

LOW

MEDIUM

HIGH

TOUGHNESS

CERAMIC

LOW Co CARBIDE

DIAMOND

COBALT ALLOY

HIGH Co CARBIDE

HSS

CARBON TOOL

0 1000 2000 3000 4000 5000 6000

1

2

3

4

5

6

7

8

9

TOUGHNESS

HIGHEST

LEAST

MEDIUM

HIGH

LOW

CUTTING VELOCITY

CARBON TOOL

HSS

COBALT ALLOY

LOW Co CARBIDE

HIGH Co CARBIDE

CERAMIC

DIAMOND

0 200 400 600 800 1000 1200

1

2

3

4

5

6

7

Velocity

HIGHEST

LEAST

LOW

HIGH

MEDIUM

SIGNIFICANCE OF PROPERTIES

HIGHER HARDNESS, LESSER ABRASION

HIGHER HARDNESS, HIGHER WEAR RESISTANCE

HIGH HARDNESS WORKPIECE CAN BE MACHINED

HARDNACE

HIGHER THE ABILITY TO MAINTAIN HARDNESS AT ELEVATED

TEMPERATURE

HIGHER CUTTING VELOCITY

HOT

HARDNACE

HIGHER THE ABILITY TO WITHSTAND SHOCK LOAD

REDUCES FRACTURE FAILURE

TOUGH MATERIAL TOOLS CAN BE USED FOR INTERMITTENT CUTTING

OPERATIONS e.g MILLING

HIGHER TOUGHNESS , HIGHER FEEDRATE, HIGHER DEPTH OF CUT

TOUGHNESS

CUTTING TOOL COMPOSITION-

CONSTITUENTS AND PROPERTIES THEY INCORPORATE

ALLOY TOOLS

CARBON TOOLS

CARBON 0.6-1.5

PERCENT

INTRODUCES

HARDNESS BY

FORMING

CARBIDES

Mg, W, Mo, ETC VERY

SMALL PERCENTAGE

VERY SMALL HOT

HARDNESS

CARBON TOOL

ALLOY TOOLS

HSS

T-TYPE

TUNGSTEN18

HARDNESS BY

FORMING

CARBIDES

CHROMIUM 4

DEPTH

HARDENING

VENADIUM- 1

COMBINES WITH

CARBON

INCREASING

HARDNESS

INCREASES

TOUGHNESS

M-TYPE

MOLYBDENUM -8

HARDNESS BY

FORMING

CARBIDES

LESSER Mo IS

NEEDED THAN

W FOR SAME

HARDNESS

CHROMIUM- 4

-DO-

VENEDIUM- 1

-DO-

CARBON TOOL

ALLOY TOOLS

(PM)

COBALT ALLOY

COBALT (Co)-30

HOT HARDNESS

TUNSTEN (W) 10

HARDNESS

COBALT ALLOY TOOL

TOOL

CARBIDES CERAMICS DIAMOND CBN

ADVANCE TOOLS

CARBIDES

(SINTERED)

CEMENTED CARBIDE

NON-STEEL

WC-Co

HIGH Co

CONTENT

HIGH TOUGHNESS,

SMALL HARDNESS

LOW Co

CONTENT

LOW TOUGHNESS,

HIGH HARDNESS

STEEL GRADE

WC-Co + TiC + TaC

HIGH Co CONTENT

LOW Co CONTENT

CERMENTS

CERAMIC

TiN, TiC

METALLIC METALS

(BINDERS)

Ni, Mo

COATED CARBIDES

CARBIDES

COATING-Al2O3

ELIMINATES REACTION

WITH CARBON IN STEEL

CARBIDE TOOLS

CERAMIC

ALUMINA

VERY LOW

TOUGHNESS

SILICON

NITRIDE( SiN)

SIALON

ALUMINA

SILICON

NITRIDE

CERAMIC TOOLS

CUTTING TOOL APPLICATION-

APPLICATION ACCORDING TO PROPERTIES

CARBON STEEL

PROPERTIES HARDNESS HOT HARDNESS TOUGHNESS

VALUE LEAST LEAST HIGHEST

OPERATION WOOD LOWEST SPEED ROUGHING

HSS

PROPERTIES HARDNESS HOT HARDNESS TOUGHNESS

VALUE LOW LOW HIGH

OPERATION

VERSATILE FERROUS AND

NON FERROUS METALS

AND ALLOY

VELOCITY- LOW,

30 M/MIN

ROUGHING- MILLING,

TURNING

FINISHING- REAMING

COBALT ALLOY

PROPERTIES HARDNESS HOT HARDNESS TOUGHNESS

VALUE

LOW LOW MEDIUM

OPERATION

STEEL. CAST IRON, Al, Cu MEDIUM ROUGHING-

CEMENTED CARBIDE( HIGH Co)

PROPERTIES HARDNESS HOT HARDNESS TOUGHNESS

VALUE

HIGH MEDIUM MEDIUM

OPERATION

STEEL GRADE-STEEL,CAST

IRON,

NON-STEEL GRADE- Al, Cu

MEDIUM ROUGHING

CEMENTED CARBIDE( LOW Co)

PROPERTIES HARDNESS HOT HARDNESS TOUGHNESS

VALUE

HIGHER MEDIUM LOW

OPERATION

STEEL GRADE-STEEL,CAST

IRON,

NON-STEEL GRADE- Al, Cu

MEDIUM FINIDHING

CERAMIC (Al2O3)

PROPERTIES HARDNESS HOT HARDNESS TOUGHNESS

VALUE

HIGHER HIGH LEAST

OPERATION

STEEL,CAST IRON,

Al, Cu

HIGH

LOWFEED RATE, LOW DEPTH

OF CUT, RIGID TOOL

MOUNTINGTO MINIMIZE

TOOL CHATTER

FINISHING

DIAMOND

PROPERTIES HARDNESS HOT HARDNESS TOUGHNESS

VALUE

HIGHEST HIGHEST MEDIUM

OPERATION NON FERROUS METALS

AND ALLOYS- AS CARBON

DIFFUSES TO THE

WORKPIECE LEADING

CRATER WEAR

HIGH

LOWFEED RATE, LOW DEPTH

OF CUT, RIGID TOOL

MOUNTINGTO MINIMIZE

TOOL CHATTER

FINISHING

CBN

PROPERTIES HARDNESS HOT HARDNESS TOUGHNESS

VALUE

SECOND HIGHEST HIGH LESS (700)

OPERATION

HARDENED STEEL AND

CAST IRON

HIGH SPEED

LOWFEED RATE, LOW DEPTH

OF CUT, RIGID TOOL

MOUNTINGTO MINIMIZE

TOOL CHATTER

FINISHING

WHAT BRING THOSE PROPERTIES

ALLOY TOOLS

CARBON

TOOLS

CARBON 0.6-

1.5 PERCENT

INTRODUCES

HARDNESS BY

FORMING

CARBIDES

Mg, W, Mo, ETC

VERY SMALL

PERCENTAGE

VERY SMALL

HOT

HARDNESS

HSS

T-TYPE

TUNGSTEN(W)

18

HARDNESS BY

FORMING

CARBIDES

CHROMIUM

4

DEPTH

HARDENING

VENADIUM- 1

COMBINES

WITH CARBON

INCREASING

HARDNESS

INCREASES

TOUGHNESS

M-TYPE

MOLYBDENUM

(Mo)-8

INCRESES

HARDNESS BY

FORMING

CARBIDES

LESSER Mo IS

NEEDED THAN

W FOR SAME

HARDNESS

CHROMIUM- 4

-DO-

VENEDIUM- 1

-DO-

COBALT ALLOY

COBALT (Co)-30

HOT

HARDNESS

TUNSTEN (W)

10

HARDNESS

S-ar putea să vă placă și

- Metal Cutting and Machine ToolsDocument131 paginiMetal Cutting and Machine Toolsthirumalaikumaran100% (1)

- Cutting ToolsDocument61 paginiCutting ToolsKalai SelvanÎncă nu există evaluări

- Cast IronDocument43 paginiCast IronThulasi Ram100% (1)

- Different Types of Cutting Tools Materials and Their PropertiesDocument4 paginiDifferent Types of Cutting Tools Materials and Their PropertiesJackson SichingaÎncă nu există evaluări

- AdditionalNotesonMaterialScience Tech 3Document27 paginiAdditionalNotesonMaterialScience Tech 3Sumit JainÎncă nu există evaluări

- MachiningDocument16 paginiMachiningThakur Kali DassÎncă nu există evaluări

- Tool Steels: Prepared byDocument35 paginiTool Steels: Prepared bySWAPNIL NIGAMÎncă nu există evaluări

- Metal CuttingDocument24 paginiMetal CuttingFRANCIS THOMASÎncă nu există evaluări

- Tool Steels: Prepared byDocument35 paginiTool Steels: Prepared byabdsu75Încă nu există evaluări

- University Institute of Architecture Subject - Building Material and Contruction - V Subject Code - 311 Topic - Ferrous and Non - Ferrous MetalsDocument34 paginiUniversity Institute of Architecture Subject - Building Material and Contruction - V Subject Code - 311 Topic - Ferrous and Non - Ferrous MetalsSaksham SharmaÎncă nu există evaluări

- Cutting Tool MaterialsDocument58 paginiCutting Tool MaterialsBikram Panthee100% (1)

- Aviation Maintenance Technician B1 - Certification Series: Summary MaterialsDocument71 paginiAviation Maintenance Technician B1 - Certification Series: Summary MaterialsSMK Penerbangan SPN Dirgantara BatamÎncă nu există evaluări

- Materials For Cutting ToolDocument19 paginiMaterials For Cutting ToolJyoti KaleÎncă nu există evaluări

- Tool Material Selection Basic Requirement of Tool MaterialsDocument3 paginiTool Material Selection Basic Requirement of Tool MaterialsTesfay AbebeÎncă nu există evaluări

- Maintenance and Repair Welding Training ModuleDocument59 paginiMaintenance and Repair Welding Training ModuleAtefÎncă nu există evaluări

- Cutting Tool MaterialsDocument4 paginiCutting Tool MaterialsJyoti KaleÎncă nu există evaluări

- Somta Tools User GuideDocument150 paginiSomta Tools User GuideBarrie Van Wyk100% (1)

- 14 Material and Heat Treatment of Jigs &Document18 pagini14 Material and Heat Treatment of Jigs &GV RagunathanÎncă nu există evaluări

- Class27 Cutting Tool MaterialsDocument25 paginiClass27 Cutting Tool MaterialsMohamed Farag MostafaÎncă nu există evaluări

- Cutting Tool MatlDocument57 paginiCutting Tool MatlVindy CADÎncă nu există evaluări

- MaterialsDocument23 paginiMaterialsMuhammad Hussain BilalÎncă nu există evaluări

- Steel: Stones Bricks Cement ConcreteDocument46 paginiSteel: Stones Bricks Cement ConcreteKaushik RÎncă nu există evaluări

- Tool Geometry (Effect of Tool Feed Motion) - Tool Materials - Dicka K (I0318025) - Elsa J. (I0318027)Document20 paginiTool Geometry (Effect of Tool Feed Motion) - Tool Materials - Dicka K (I0318025) - Elsa J. (I0318027)Lobesh7062Încă nu există evaluări

- EBSDPrepDocument147 paginiEBSDPrepcam nhung NguyenÎncă nu există evaluări

- FC-06-Engineering Material & Metallurgy PDFDocument431 paginiFC-06-Engineering Material & Metallurgy PDFsomnath ghosh100% (1)

- Module 3-CUTTING TOOL MATERIALSDocument88 paginiModule 3-CUTTING TOOL MATERIALSsushilÎncă nu există evaluări

- Alloy & Special SteelsDocument33 paginiAlloy & Special Steelstanishka narayanÎncă nu există evaluări

- ME-III 3351903 Lab ManualDocument54 paginiME-III 3351903 Lab ManualBgmi TacticianÎncă nu există evaluări

- Ferrous MaterialsDocument73 paginiFerrous Materialsamrptl9010100% (1)

- Pertemuan Steel and Steel AlloyDocument43 paginiPertemuan Steel and Steel AlloyAmran WiratmaÎncă nu există evaluări

- MaterialsDocument23 paginiMaterialsNowsherwan MazariÎncă nu există evaluări

- Metals and Alloys & Heat Treatment of Steels 2,4Document82 paginiMetals and Alloys & Heat Treatment of Steels 2,4Vimukthi KumaraÎncă nu există evaluări

- Hss Tools and AppilcationDocument17 paginiHss Tools and AppilcationMeena SivasubramanianÎncă nu există evaluări

- Tool SteelsDocument35 paginiTool SteelsHandrizaHanifAsyrafiÎncă nu există evaluări

- 006cutting Tool ProjectDocument5 pagini006cutting Tool Projectরিপন মন্ডলÎncă nu există evaluări

- Unit - 2 Cutting-Tool MaterialsDocument23 paginiUnit - 2 Cutting-Tool MaterialsRavichandran G100% (3)

- Materials and Alloying Tooling MineDocument8 paginiMaterials and Alloying Tooling MineMarium ArifÎncă nu există evaluări

- Classificaition of Plain Carbon SteelDocument10 paginiClassificaition of Plain Carbon SteelSakib RafeeÎncă nu există evaluări

- Cutting Tool Materials ME MechanicalDocument4 paginiCutting Tool Materials ME MechanicalManish Kumar100% (1)

- Steel Making Axle Forging Heat Treatment MachiningDocument41 paginiSteel Making Axle Forging Heat Treatment MachiningAsif Ali PCÎncă nu există evaluări

- Recommended Rotational Speed Range RPM - TC Burrs For High-Performance ApplicationsDocument1 paginăRecommended Rotational Speed Range RPM - TC Burrs For High-Performance ApplicationsLeandro BatistaÎncă nu există evaluări

- Introduction To Material Science and Engineering: Engr. Ana Lorraine M. Dalilis, RcheDocument64 paginiIntroduction To Material Science and Engineering: Engr. Ana Lorraine M. Dalilis, RcheTracy Gale MiddleborgÎncă nu există evaluări

- 5-b - Carbon and Alloy SteelsDocument43 pagini5-b - Carbon and Alloy SteelszzirapovÎncă nu există evaluări

- Tool Life, Tool Material, Cutting Force, Cutting Fluids and Machinable MaterialDocument17 paginiTool Life, Tool Material, Cutting Force, Cutting Fluids and Machinable MaterialShakeel MohmandÎncă nu există evaluări

- 1 Cutting ToolDocument27 pagini1 Cutting ToolKemalMalovcicÎncă nu există evaluări

- 10020dep-Notice 11042020Document32 pagini10020dep-Notice 11042020Shivam VermaÎncă nu există evaluări

- 1Document4 pagini1Anonymous 6MI1wMÎncă nu există evaluări

- Cutting Tool Materials NotesDocument7 paginiCutting Tool Materials NotesMurali100% (3)

- Carbon and Alloy Steels: - All of These Steels Are Alloys of Fe and CDocument42 paginiCarbon and Alloy Steels: - All of These Steels Are Alloys of Fe and CShashank SaxenaÎncă nu există evaluări

- Alloy Steels: Dr. Indika de SilvaDocument25 paginiAlloy Steels: Dr. Indika de SilvaChandima K PriyamalÎncă nu există evaluări

- Steel: Building Const. & MatDocument16 paginiSteel: Building Const. & MatManjeet CinghÎncă nu există evaluări

- 2 Grade InformationDocument17 pagini2 Grade InformationAndres Alejandro RoblesÎncă nu există evaluări

- Weldability of High Strength Low Alloy SteelDocument34 paginiWeldability of High Strength Low Alloy SteelGanesan Veerasamy100% (1)

- Manufacturing Technology MaterialDocument72 paginiManufacturing Technology Materialabhishekray6370Încă nu există evaluări

- Ferrous Alloys - 13th August2021 (1) (3 Files Merged)Document56 paginiFerrous Alloys - 13th August2021 (1) (3 Files Merged)jayakrishnan psÎncă nu există evaluări

- Piping Materials Selection TrainingDocument60 paginiPiping Materials Selection TrainingKagira Drawing Soltuion100% (2)

- Forging Operations - Machine Forging, Forging Dies and Special Forging OperationsDe la EverandForging Operations - Machine Forging, Forging Dies and Special Forging OperationsÎncă nu există evaluări

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDe la EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonEvaluare: 4 din 5 stele4/5 (1)

- The Essentials of Material Science and Technology for EngineersDe la EverandThe Essentials of Material Science and Technology for EngineersEvaluare: 5 din 5 stele5/5 (1)

- Diman Road AccidentDocument1 paginăDiman Road AccidentchandankrdumkaÎncă nu există evaluări

- TSCR MillDocument10 paginiTSCR MillchandankrdumkaÎncă nu există evaluări

- SP and Rmbbfy22 ReportDocument2 paginiSP and Rmbbfy22 ReportchandankrdumkaÎncă nu există evaluări

- Interal Safety Audit . Shutdown Date: - / - / - Department: FM MechanicalDocument3 paginiInteral Safety Audit . Shutdown Date: - / - / - Department: FM MechanicalchandankrdumkaÎncă nu există evaluări

- Surge Hopper JobDocument6 paginiSurge Hopper JobchandankrdumkaÎncă nu există evaluări

- Oversize Chute AlignmentDocument2 paginiOversize Chute AlignmentchandankrdumkaÎncă nu există evaluări

- Surge Hopper Job - Rev5Document3 paginiSurge Hopper Job - Rev5chandankrdumkaÎncă nu există evaluări

- DMADICDocument1 paginăDMADICchandankrdumkaÎncă nu există evaluări

- Check List For Expansion Bellow ChangingDocument2 paginiCheck List For Expansion Bellow ChangingchandankrdumkaÎncă nu există evaluări

- Heat TransferDocument5 paginiHeat Transferkb210538Încă nu există evaluări

- Chhattisgarh Knowledge Sharing GISDocument74 paginiChhattisgarh Knowledge Sharing GISchandankrdumkaÎncă nu există evaluări

- OI EoI For Overseas Internship 1 Modified FinalDocument6 paginiOI EoI For Overseas Internship 1 Modified FinalchandankrdumkaÎncă nu există evaluări

- Detailed Advertisement Recruitment of Scientist in BISDocument3 paginiDetailed Advertisement Recruitment of Scientist in BISchandankrdumkaÎncă nu există evaluări

- Plan 2Document1 paginăPlan 2chandankrdumkaÎncă nu există evaluări

- Sp#2 MSD Taskforce Report: Project Crane FMM 55T Crane F A N E A NDocument1 paginăSp#2 MSD Taskforce Report: Project Crane FMM 55T Crane F A N E A NchandankrdumkaÎncă nu există evaluări

- E&jq:l) - : LM / LQDocument1 paginăE&jq:l) - : LM / LQchandankrdumkaÎncă nu există evaluări

- Short Adv of Government JobsDocument1 paginăShort Adv of Government JobschandankrdumkaÎncă nu există evaluări

- Final Seniority List of ADT DDT JDT DIrector DDGDocument124 paginiFinal Seniority List of ADT DDT JDT DIrector DDGchandankrdumkaÎncă nu există evaluări

- Panasonic NN-SD466, 456Document65 paginiPanasonic NN-SD466, 456Darshan VeeraÎncă nu există evaluări

- Vibration Control PDFDocument513 paginiVibration Control PDFchandankrdumkaÎncă nu există evaluări

- Sector Gate Screw Jack ChangingDocument2 paginiSector Gate Screw Jack ChangingchandankrdumkaÎncă nu există evaluări

- 30BRC2Document43 pagini30BRC2chandankrdumkaÎncă nu există evaluări

- Less Money SaveDocument3 paginiLess Money SavechandankrdumkaÎncă nu există evaluări

- Material Science NptelDocument225 paginiMaterial Science NptelchandankrdumkaÎncă nu există evaluări

- Error in English GrammarDocument4 paginiError in English GrammarchandankrdumkaÎncă nu există evaluări

- IES Mechanical Engineering Question PaperDocument17 paginiIES Mechanical Engineering Question PaperSimran SinghÎncă nu există evaluări

- Exercising The PenisDocument227 paginiExercising The PenisMario CarrascoÎncă nu există evaluări

- Assistant Engineers Recruitment Exam-26-2012 (Result) 20-08-2013) - 2 PDFDocument1 paginăAssistant Engineers Recruitment Exam-26-2012 (Result) 20-08-2013) - 2 PDFchandankrdumkaÎncă nu există evaluări

- Chapter 1Document8 paginiChapter 1Carlos VegaÎncă nu există evaluări

- When The Following Word Definitely Begins With A A Consonant Sound, You Need, "A"Document3 paginiWhen The Following Word Definitely Begins With A A Consonant Sound, You Need, "A"chandankrdumkaÎncă nu există evaluări

- Weld RepireDocument91 paginiWeld RepireKapil ManloiÎncă nu există evaluări

- The Aluminium Automotive ManualDocument13 paginiThe Aluminium Automotive ManualFranky DevaereÎncă nu există evaluări

- Melting Point Specific Gravity (G/CC) Weight Per Cu. In. (Troy Oz.) Metal Symbol ºF ºCDocument2 paginiMelting Point Specific Gravity (G/CC) Weight Per Cu. In. (Troy Oz.) Metal Symbol ºF ºCshyam sundarÎncă nu există evaluări

- Aluminum The Wiring Material of The FutureDocument7 paginiAluminum The Wiring Material of The FuturevkmsÎncă nu există evaluări

- RacerX SunlitNightsDocument2 paginiRacerX SunlitNightsLeo Hurtado0% (1)

- Reaming Speeds and Feeds PDFDocument1 paginăReaming Speeds and Feeds PDFWarrior TempurÎncă nu există evaluări

- New Form 3Document4 paginiNew Form 3seenÎncă nu există evaluări

- Report WeldingDocument11 paginiReport WeldingSomasundaram SomanoÎncă nu există evaluări

- Electrode: Flux Lime Silica Calcium FluorideDocument2 paginiElectrode: Flux Lime Silica Calcium FluoridemihirthakkarÎncă nu există evaluări

- MSE 2010-2160-2170 Sample Test 4Document11 paginiMSE 2010-2160-2170 Sample Test 4Rachel HowellÎncă nu există evaluări

- Rusting of Iron-1 PDFDocument10 paginiRusting of Iron-1 PDFDeepanshu ThakurÎncă nu există evaluări

- Electrochemistry - Cont Module 4 STPMDocument10 paginiElectrochemistry - Cont Module 4 STPMPavithiranÎncă nu există evaluări

- Welding InspectionDocument15 paginiWelding InspectionSreedhar Patnaik.MÎncă nu există evaluări

- MIG and TIG WeldingDocument2 paginiMIG and TIG WeldingshahzafÎncă nu există evaluări

- Magnesium Alloys in Ingot Form For Sand Castings, Permanent Mold Castings, and Die CastingsDocument4 paginiMagnesium Alloys in Ingot Form For Sand Castings, Permanent Mold Castings, and Die CastingsDhavalÎncă nu există evaluări

- Design of Lathe Chucks and AccessoriesDocument12 paginiDesign of Lathe Chucks and AccessoriesRaasik Jain100% (1)

- O Final Mj14 Chemistry P 1 5070 01Document373 paginiO Final Mj14 Chemistry P 1 5070 01AHMADÎncă nu există evaluări

- High Strength Low Alloy (HSLA) : Prof. Dr.-Ing. Bambang SuharnoDocument28 paginiHigh Strength Low Alloy (HSLA) : Prof. Dr.-Ing. Bambang SuharnoLuan carlosÎncă nu există evaluări

- Specific Heat Capacity WorksheetDocument3 paginiSpecific Heat Capacity WorksheetMuhamad Zahwan AnwarÎncă nu există evaluări

- 2012 PSPM Kedah Kimia 3 W AnsDocument20 pagini2012 PSPM Kedah Kimia 3 W AnsSya VetÎncă nu există evaluări

- GPM RevDocument138 paginiGPM RevJuan Cortes TorizÎncă nu există evaluări

- Chapter 37 CeilingsDocument10 paginiChapter 37 CeilingsSonia GandhiÎncă nu există evaluări

- Science Test BookDocument3 paginiScience Test Bookayush sonar100% (1)

- Is 5986-2011Document14 paginiIs 5986-2011oneakshay100% (1)

- Tecnical Specification For Materials Division 9Document238 paginiTecnical Specification For Materials Division 9Julio Cesar ChiaÎncă nu există evaluări

- Introduction To Engineering Materials: 1 Sanjib Jaypuria, SME, KIIT UniversityDocument21 paginiIntroduction To Engineering Materials: 1 Sanjib Jaypuria, SME, KIIT Universitytanishka narayanÎncă nu există evaluări

- Zinc Chloride: Data SheetDocument4 paginiZinc Chloride: Data SheetPurtiah Rantau SariÎncă nu există evaluări

- Invar - Advanced MaterialsDocument17 paginiInvar - Advanced MaterialsAndreea StamatÎncă nu există evaluări

- Industrial MineralsDocument43 paginiIndustrial MineralsadisatriowicaksonoÎncă nu există evaluări