Documente Academic

Documente Profesional

Documente Cultură

Chigo Inverters Manual

Încărcat de

hossimo33Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Chigo Inverters Manual

Încărcat de

hossimo33Drepturi de autor:

Formate disponibile

DC Inverter Split Air-Condition Unit

SERVICE MANUAL

- 1 -

Tabl e of Contents

1. The model and the air conditioning unit parameters...........................................................1

2. Units operating working conditions and temperature range ............................................8

3. Units characteristic..................................................................................................................11

4. Indoor and outdoor units size ...............................................................................................26

5. Indoor and outdoor unit explosion diagram and spare parts list .....................................30

6. The analysis of indoor malfunction code ............................................................................35

7. The analysis of the complete units malfunction code.........................................................50

- 2 -

1The model and the air conditioning unit parameters

1.1 the model.

- 3 -

1.2. The air conditioners parameter.

- 4 -

- 5 -

- 6 -

- 7 -

- 8 -

- 9 -

- 10 -

2 RATI NG CONDI TI ONS and Operati ng Li mi ts

2. 1 RATING CONDITIONS

Standard conditions in accordance with ISO 5151, and EN 14511.

Cooling:

Indoor: 27 DB 19 WB

Outdoor:35 DB 24 WB

Heating:

Indoor: 20 DB 15 WB

Outdoor: 7 DB 6 WB

2. 2 Oper at i ng Li mi ts

Outdoor

Upper limit (DB) 46 Cooling

Lower limit (DB) 5

Upper limit (DB) 24 Heating

Lower limit (DB) -15

Voltage 1PH 220-240V

- 11 -

3Uni ts characteri sti c

R410a

Low noise level

Wide operating range with outdoor air temperatures, cooling:5-46,heating:-15-24

High efficiency and energy saving

Air filters easy to remove and clean

Twin rotary compressor

Auto-restart after a power supply blackout

Single-phase power supply thanks to DC inverter technology low consumption

Dynamic refrigerant control by DC inverter compressor and circuit, electronic valve and fuzzy logic

managed by a powerful micro program

EEV for each indoor unit

- 12 -

- 13 -

The compressors energy consumption graph .

COP (W/W)/2ND

The compressors condensing pressure graph .

- 14 -

Indoor Units Data

Indoor Units Capacity For 2.0KW

Capacity Model

2.0KW CMV-V20G3A-M75/81/84/85/87/88/95/96

Cooling Capacity (KW)---Run Model (Unit A,B,C or D),220-240V,Indoor fan at high speed

INDOOR ENTERING AIR DB/WB TEMPERATURE [

0

C]

OUTDOOR

ENTERING AIR DB

TEMPERATURE

[

0

C] DATA 22/15 24/17 27/19 29/21 32/23

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

-10 - 20

(protection range)

PI 25 - 50 % of nominal

TC 1.94 2.06 2.18 2.32 2.44

SC 1.72 1.75 1.79 1.82 1.85

25

PI 0.49 0.50 0.51 0.51 0.53

TC 1.84 1.96 2.10 2.22 2.34

SC 1.67 1.70 1.75 1.79 1.82

30

PI 0.55 0.55 0.56 0.57 0.58

TC 1.74 1.88 2.00 2.12 2.26

SC 1.63 1.67 1.70 1.73 1.77

35

PI 0.60 0.61 0.62 0.63 0.64

TC 1.66 1.78 1.90 2.04 2.16

SC 1.58 1.62 1.65 1.70 1.73

40

PI 0.66 0.67 0.68 0.69 0.69

TC 1.54 1.66 1.80 1.92 2.04

SC 1.53 1.56 1.60 1.63 1.68 46

PI 0.73 0.74 0.74 0.76 0.76

Heating Capacity (KW)---Run Model (Unit A,B,C or D),220-240V,Indoor fan at high speed

ID COIL ENTERING AIR DB TEMPERATURE [

0

C]

OD COIL

ENTERING

AIR DB/WB

TEM PERATU RE

[

0

C]

DATA 15 20 25

-15/-16

TC

1.54 1.42 1.32

PI 0.40 0.44 0.48

-10/-12 TC 1.70 1.58 1.49

PI 0.48 0.52 0.57

-7/-8 TC 1.82 1.73 1.61

PI 0.55 0.59 0.63

-1/-2 TC 1.90 1.80 1.68

PI 0.58 0.62 0.66

2/1

TC

1.94 1.82 1.73

- 15 -

PI 0.60 0.64 0.68

7/6

TC

2.50 2.40 2.30

PI 0.63 0.67 0.71

10/9

TC

2.64 2.54 2.42

PI 0.67 0.71 0.75

15/12

TC

2.78 2.69 2.57

PI 0.70 0.74 0.78

1524 TC 85 - 105 % of nominal

(Protection Range) PI 80 - 120 % of nominal

Capacity Correction Factors

Cooling Capacity Ratio Vs. Outdoor Temperature

Cooling Capacity Correction Factor

0

0.2

0.4

0.6

0.8

1

1.2

1.4

25 30 35 40 45

Outdoor Temperature (deg C)

C

a

p

a

c

i

t

y

R

a

t

i

o

32/23

29/27

27/19

24/17

22/15

Heating Capacity Ratio Vs. Outdoor Temperature

Heating Capacity Correction Factor

0

0.2

0.4

0.6

0.8

1

1.2

1.4

-15 -10 -5 0 5 10 15 20

Outdoor Temperature (deg C)

C

a

p

a

c

i

t

y

R

a

t

i

o

15

20

25

- 16 -

Indoor Units Capacity For 2.5KW

Capacity Model

2.5KW CMV-V25G3A-M75/81/84/85/87/88/95/96

Capacity (KW)---Run Model (Unit A,B,C or D),220-240V,Indoor fan at high speed

INDOOR ENTERING AIR DB/WB TEMPERATURE [

0

C]

OUTDOOR

ENTERING AIR DB

TEMPERATURE

[

0

C] DATA 22/15 24/17 27/19 29/21 32/23

TC 80 - 110 % of nominal

-10 - 20 SC 80 - 105 % of nominal

(protection range) PI 25 - 50 % of nominal

TC 2.42 2.57 2.73 2.89 3.05

25 SC 1.72 1.75 1.79 1.82 1.86

PI 0.58 0.59 0.60 0.61 0.62

TC 2.30 2.46 2.62 2.77 2.93

30 SC 1.67 1.71 1.74 1.78 1.81

PI 0.65 0.66 0.67 0.68 0.69

TC 2.18 2.34 2.50 2.66 2.82

35 SC 1.63 1.66 1.70 1.74 1.77

PI 0.71 0.72 0.74 0.75 0.76

TC 2.07 2.23 2.38 2.54 2.70

40 SC 1.59 1.62 1.66 1.69 1.73

PI 0.78 0.79 0.80 0.81 0.82

TC 1.93 2.09 2.24 2.40 2.56

46 SC 1.53 1.57 1.60 1.64 1.67

PI 0.86 0.87 0.88 0.89 0.91

Heating Capacity (KW)---Run Model (Unit A,B,C or D),220-240V,Indoor fan at high speed

ID COIL ENTERING AIR DB TEMPERATURE [

0

C]

OD COIL

ENTERING

AIR DB/WB

TEM PERATU RE

[

0

C]

DATA 15 20 25

-15/-16

TC

1.92 1.77 1.65

PI 0.49 0.54 0.59

-10/-12 TC 2.13 1.98 1.86

PI 0.59 0.64 0.70

-7/-8 TC 2.28 2.16 2.01

PI 0.67 0.72 0.77

-1/-2 TC 2.37 2.25 2.10

PI 0.71 0.75 0.80

2/1

TC

2.43 2.28 2.16

PI 0.73 0.78 0.83

- 17 -

7/6

TC

3.12 3.00 2.88

PI 0.77 0.82 0.87

10/9

TC

3.30 3.18 3.03

PI 0.82 0.87 0.92

15/12

TC

3.48 3.36 3.21

PI 0.86 0.90 0.96

15-24 TC 85 - 105 % of nominal

(Protection Range) PI 80 - 120 % of nominal

LEGEND

TC Total Cooling Capacity, kW

SC Sensible Capacity, Kw

PI Power Input, kW

WB Wet Bulb Temp., (

o

C)

DB Dry Bulb Temp., (

o

C)

ID Indoor

OD Outdoor

Capacity Correction Factors

Cooling Capacity Ratio Vs. Outdoor Temperature

Cooling Capacity Correction Factor

0

0.2

0.4

0.6

0.8

1

1.2

1.4

25 30 35 40 45

Outdoor Temperature (deg C)

C

a

p

a

c

i

t

y

R

a

t

i

o

32/23

29/27

27/19

24/17

22/15

- 18 -

Heating Capacity Ratio Vs. Outdoor Temperature

Heating Capacity Correction Factor

0

0.2

0.4

0.6

0.8

1

1.2

1.4

-15 -10 -5 0 5 10 15 20

Outdoor Temperature (deg C)

C

a

p

a

c

i

t

y

R

a

t

i

o

15

20

25

Indoor Units Capacity For 3.5KW

Indoor Units Capacity For 3.5KW

Capacity Model

CMV-V35G3A-M75/81/84/85/87/88/95/96

3.5KW

CMV-V35G3A-P84/94/98

Cooling Capacity (KW)---Run Model (Unit A,B,C or D),220-240V,Indoor fan at high speed

INDOOR ENTERING AIR DB/WB TEMPERATURE [

0

C]

OUTDOOR

ENTERING AIR DB

TEMPERATURE

[

0

C] DATA 22/15 24/17 27/19 29/21 32/23

TC 80 - 110 % of nominal

-10 - 20 SC 80 - 105 % of nominal

(protection range) PI 25 - 50 % of nominal

TC 3.40 3.61 3.82 4.06 4.27

25 SC 3.03 3.09 3.15 3.21 3.27

PI 0.86 0.87 0.89 0.90 0.93

TC 3.22 3.43 3.68 3.89 4.10

30 SC 2.94 3.00 3.09 3.15 3.21

PI 0.96 0.97 0.99 1.00 1.02

TC 3.05 3.29 3.50 3.71 3.96

35 SC 2.88 2.94 3.00 3.06 3.12

PI 1.06 1.08 1.09 1.11 1.12

TC 2.91 3.12 3.33 3.57 3.78

40 SC 2.79 2.85 2.91 3.00 3.06

PI 1.16 1.18 1.19 1.21 1.22

TC 2.70 2.91 3.15 3.36 3.57

46 SC 2.70 2.76 2.82 2.88 2.97

PI 1.28 1.30 1.31 1.33 1.34

- 19 -

Heating Capacity (KW)---Run Model (Unit A,B,C or D),220-240V,Indoor fan at high speed

ID COIL ENTERING AIR DB TEMPERATURE [

0

C]

OD COIL

ENTERING

AIR DB/WB

TEM PERATU RE

[

0

C]

DATA 15 20 25

-15/-16

TC

2.56 2.36 2.20

PI 0.67 0.73 0.80

-10/-12 TC 2.84 2.64 2.48

PI 0.80 0.87 0.94

-7/-8 TC 3.04 2.88 2.68

PI 0.91 0.98 1.04

-1/-2 TC 3.16 3.00 2.80

PI 0.95 1.02 1.09

2/1

TC

3.24 3.04 2.88

PI 0.99 1.05 1.12

7/6

TC

4.16 4.00 3.84

PI 1.04 1.11 1.18

10/9

TC

4.40 4.24 4.04

PI 1.11 1.18 1.24

15/12

TC

4.64 4.48 4.28

PI 1.17 1.23 1.30

1524 TC 85 - 105 % of nominal

(Protection Range) PI 80 - 120 % of nominal

Capacity Correction Factors

Cooling Capacity Ratio Vs. Outdoor Temperature

Cooling Capacity Correction Factor

0

0.2

0.4

0.6

0.8

1

1.2

1.4

25 30 35 40 45

Outdoor Temperature (deg C)

C

a

p

a

c

i

t

y

R

a

t

i

o

32/23

29/27

27/19

24/17

22/15

- 20 -

Heating Capacity Ratio Vs. Outdoor Temperature

Heating Capacity Correction Factor

0

0.2

0.4

0.6

0.8

1

1.2

1.4

-15 -10 -5 0 5 10 15 20

Outdoor Temperature (deg C)

C

a

p

a

c

i

t

y

R

a

t

i

o

15

20

25

Indoor Units Capacity For 5.0KW

Capacity Model

5.0KW CMV-V50G3A-P75/81/84/85/87/88/95/96

Cooling Capacity (KW)---Run Model (Unit A,B,C or D),220-240V,Indoor fan at high speed

INDOOR ENTERING AIR DB/WB TEMPERATURE [

0

C]

OUTDOOR

ENTERING AIR DB

TEMPERATURE

[

0

C] DATA 22/15 24/17 27/19 29/21 32/23

TC 80 - 110 % of nominal

-10 - 20 SC 80 - 105 % of nominal

(protection range) PI 25 - 50 % of nominal

TC 4.85 5.15 5.45 5.80 6.10

25 SC 4.55 4.64 4.73 4.82 4.91

PI 1.23 1.25 1.28 1.29 1.33

TC 4.60 4.90 5.25 5.55 5.85

30 SC 4.41 4.50 4.64 4.73 4.82

PI 1.37 1.39 1.42 1.44 1.47

TC 4.35 4.70 5.00 5.30 5.65

35 SC 4.32 4.41 4.50 4.59 4.68

PI 1.51 1.54 1.56 1.59 1.61

TC 4.15 4.45 4.75 5.10 5.40

40 SC 4.19 4.28 4.37 4.50 4.59

PI 1.65 1.68 1.70 1.73 1.75

TC 3.85 4.15 4.50 4.80 5.10

46 SC 4.05 4.14 4.23 4.32 4.46

PI 1.83 1.86 1.87 1.90 1.92

- 21 -

Heating Capacity (KW)---Run Model (Unit A,B,C or D),220-240V,Indoor fan at high speed

ID COIL ENTERING AIR DB TEMPERATURE [

0

C]

OD COIL

ENTERING

AIR DB/WB

TEM PERATU RE

[

0

C]

DATA 15 20 25

-15/-16

TC

3.71 3.42 3.19

PI 0.97 1.06 1.16

-10/-12 TC 4.12 3.83 3.60

PI 1.16 1.26 1.37

-7/-8 TC 4.41 4.18 3.89

PI 1.32 1.42 1.51

-1/-2 TC 4.58 4.35 4.06

PI 1.38 1.48 1.58

2/1

TC

4.70 4.41 4.18

PI 1.43 1.53 1.63

7/6

TC

6.03 5.80 5.57

PI 1.51 1.61 1.71

10/9

TC

6.38 6.15 5.86

PI 1.61 1.71 1.80

15/12

TC

6.73 6.50 6.21

PI 1.69 1.79 1.88

15-24 TC 85 - 105 % of nominal

(Protection Range) PI 80 - 120 % of nominal

- 22 -

Capacity Correction Factors

Cooling Capacity Ratio Vs. Outdoor Temperature

Cooling Capacity Correction Factor

0

0.2

0.4

0.6

0.8

1

1.2

1.4

25 30 35 40 45

Outdoor Temperature (deg C)

C

a

p

a

c

i

t

y

R

a

t

i

o

32/23

29/27

27/19

24/17

22/15

Heating Capacity Ratio Vs. Outdoor Temperature

Heating Capacity Correction Factor

0

0.2

0.4

0.6

0.8

1

1.2

1.4

-15 -10 -5 0 5 10 15 20

Outdoor Temperature (deg C)

C

a

p

a

c

i

t

y

R

a

t

i

o

15

20

25

- 23 -

Capacity Correction Factor Due to Tubing Length (One Way)

Cooling

Heating

- 24 -

Pressure Curve

Model

CMV-V40H13AD CMV-50V3A-E2 CMV-V71T3AT CMV-V80T3AQ

Cooling--------------Test Model

Heating-----------Test Model

- 25 -

ELECTRI CAL DATA

Model CMV-V40H13AD

Power Supply 220-240V 1PH 50Hz

Connected to Outdoor

Maximum Current 8 A

Inrush Current 15A

Starting Current 1A

Circuit breaker 20A

Power supply wiring - No. x cross section 31.5 mm

2

6680mm

Interconnecting cable - No. x cross section 41.0 mm

2

6300mm

Model CMV-50V3A-E2

Power Supply 220-240V 1PH 50Hz

Connected to Outdoor

Maximum Current 11 A

Inrush Current 35A

Starting Current 1A

Circuit breaker 20A

Power supply wiring - No. x cross section 32.5 mm

2

6480mm

Interconnecting cable - No. x cross section 41.0 mm

2

6300mm

Model CMV-V52E23AT

Power Supply 220-240V 1PH 50Hz

Connected to Outdoor

Maximum Current 11A

Inrush Current 35A

Starting Current 1A

Circuit breaker 20A

Power supply wiring - No. x cross section 32.5 mm

2

6480mm

Interconnecting cable - No. x cross section 41.0 mm

2

6300mm

Model CMV- V71T3AT

Power Supply 220-240V 1PH 50Hz

Connected to Outdoor

Maximum Current 16A

Inrush Current 35A

Starting Current 2A

Circuit breaker 20A

Power supply wiring - No. x cross section 32.5 mm

2

6480mm

Interconnecting cable - No. x cross section 41.0 mm

2

6200mm

- 26 -

Model CMV-V80T3AQ

Power Supply 220-240V 1PH 50Hz

Connected to Outdoor

Maximum Current 16A

Inrush Current 35A

Starting Current 2A

Circuit breaker 20A

Power supply wiring - No. x cross section 32.5 mm

2

6480mm

Interconnecting cable - No. x cross section 41.0 mm

2

16100mm

Note:

Inrush current is the current when power is up. (charging the DC capacitors at outdoor unit

controller).

Starting current is the current when starting the compressor

- 27 -

4. OUTLI NE DI MENSI ON OF OUTDOOR AND I NDOOR

4.1 Outline dimension of outdoor Units

CMV-V40H13AD

CMV-50V3A-E2/ CMV-V52E23AT

- 28 -

CMV- V71T3AT/ CMV-V80T3AQ

4.2 the outdoor unit mounting dimensions

- 29 -

the bodys dimension mounting dimensions Dimensions

Code

outdoor

units type

A B C D E

CMV-V40H13AD 845 304 542 510 278

CMV-50V3A-E2 900 352 590 505 310

CMV-V52E23AT 900 352 590 505 310

CMV-V71T3AT/

CMV-V80T3AQ

900 388 837 600 358

4.3. The indoor unit mounting dimensions

unitmm

- 30 -

the bodys dimension mounting dimensions Dimensions

Code

indoor

units type

A B C D E F

CMV-V20G3A/MXX 800 280 195 490 / /

CMV-V25G3A/MXX 800 280 195 490 / /

CMV-V35G3A/MXX 800 280 195 490 / /

CMV-V35G3A/PXX 900 296 220 583 257.5 257.5

CMV-V50G3A/PXX 900 296 220 583 257.5 257.5

31

5The outdoor uni t str uct ur e expl oded vi ew .

5. 1outdoor unit :CMV-V40H13AD

NO. description name number

1 Front Grill 1

2 Front Plate 1

3 Axial flow fan 1

4 Motor 1

5 Motor support 1

6 Condenser 1

7 Top panel 1

8 Electric box 1

9 Rear Grill 1

10 Right panel 1

11 handle 1

12 Valve installation plate 1

13 A DN4 DN4 valve 1

14 A DN8 DN8 valve 1

15 B DN4 DN4 valve 1

16 B DN8 DN8 valve 1

17 Capillary Assy 1

18 Electronic expansion valve 2

19 Four-way valve assembly 1

20 Steam liquid segregator 1

21 Compressor 1

22 Partition board 1

23 Base 1

32

5. 2outdoor uni t : CMV-50V3A-E2/ CMV-V52E23AT

33

NO. description name number

1 front grill 1

2 front panel 1

3 fan 1

4 motor 1

5 motor bracket assemble 1

6 left grill 1

7 left pole 1

8 top cover 1

9 rear grill 1

10 condenser 1

11 4-way valve 1

12 muffle 1

13 filter 1

14 controllor 1

15 control box cover 1

16 electrical control box 1

17 A DN8 DN8 valve for A unit 1

18 A DN4 DN4 valve for A unit 1

19 B DN8 DN8 valve for B unit 1

20 B DN4 DN4 valve for B unit 1

21 valve installation plate 1

22 handle 1

23 right panel 1

24 expand valve 2

25 compressor 1

26 compressor pad 1

27 partition board 1

28 base assemble 1

34

5.3outdoor unit : CMV-V71T3AT/ CMV-V80T3AQ

35

NO. description name number

1 top panel 1

2 electric box 1

3 rear Grill 1

4 partition board 1

5 four-way valve 1

6 electronic expansion valve 1

7 desiccation filter 1

8 right panel 1

9 large handle 1

10 valve installation plate 1

11 oil separator 1

12 high-pressure tank 1

13 compressor 1

14 base 1

15 condenser 1

16 motor support 1

17 DC motor 1

18 axial flow fan 1

19 front Grill 1

20 front Plate 1

21 left protect net 1

22 left panel 1

23 vapor-liquid separator 1

24 back panel 2

25 DN10 DN10 cut-off valve 1

26 DN8 DN8 cut-off valve 1

27 electronic control box support plate 1

28 small hand-pumped 1

29 front maintenance board 1

36

6The analysis of indoor malfunction codeinternal wiring get loose, which

will cause malfunction.

indoor detailed malfunction

1.when indoor unit live wire is disconnectedits lamp panel cant display.

Live wire is off

2.when the transformers secondary and primary disconnect or indoor fuse is offthe indoor unit lamp

panel cant display.

Transformer secondary is off

Transformer primary is off

The relevant transfomer primary

socket

37

Indoor unit fuse is off.

The indoor unit fuse

The condition that the lamp panel

cant display

3.1when the indoor null line is offthe system displays F1 code

2when indoor communication wire is offthe system also displays F1 code

The inserted slice to null line

The indoor unit null line is off

38

2the indoor communication wire is

off.

Communication wire socket.

the indoor lamp panel displays F1 code.

4. when indoor fan mainline or feedback wire is offthe indoor lamp panel displays F4 code. After directly

insert it wellTo restart the unit to recover normal .

Indoor fan mainline is off

The relevant socket with indoor fan mainline

39

indoor fan feedback wire is off

the relevant socket with indoor feedback

wire

The lamp panel displays F4 code.

5.when indoor sensor has the problem, the lamp will display F

2

F

3

code. When indoor coil outlet , inlet

and middle temperature sensor appear malfunction, the lamp panel displays F3 code; when indoor

temperature sensor appears fault, the lamp panel shows F2 fault code.

Indoor temperature sensor plug

the relevant socket of indoor temperature

sensor plug

40

The lamp panel alternately displays F2,F3

fault code.

6.when outdoor temperature sensor is off or loose contactthe indoor lamp panel displays F6 fault

code.

the relevant socket of outdoor temp.

sensor.

The outdoor temperature sensor is

off or loose contact.

41

The indoor lamp panel displays F6

fault code.

7.when the system appears mode conflictthe indoor lamp panel shows d1 code.

the indoor lamp panel shows d1 code.

8.when the system is in the defrosting conditionThe lamp panel displays dF code.

The lamp panel displays dF code.

42

The outdoor electrical control fault code of the America 12K model .

1.the outdoor module temperature sensor is off or loose contactthe lamp panel shows F6 code.

the outdoor module temperature sensor

is off or loose contact .

the relevant socket with the outdoor

module temperature sensor plug .

The lamp panel shows F6 code .

2.The outdoor unit DC busbar voltage is abnormalthe lamp panel shows F7code.

The PN power wire are off .

43

The lamp panel shows F7code.

3.the outdoor module drive wire is off the lamp panel shows FC code .

The outdoor module drive wire is off .

The matching socket with the outdoor

module drive wire

The matching socket with the outdoor

module drive wire .

The outdoor module drive wire is

off .

44

The lamp panel shows FC code .

4the wave filtering board and mainboard power wire is off or loose contactthe lamp panel shoes F1 code .

the wave filtering board and mainboard power

wire is off or loose contact

The matching socket with the wave

filtering board and mainboard power wire

the lamp panel shoes F1 code .

45

5. the evaporator middle temperature and condenser middle temperature sensor is off the lamp panel

displays P8 code .

the evaporator middle temperature and

condenser middle temperature sensor is off

the lamp panel displays P8 code

46

The 67

th

style indoor lamp panel

The timing lamp The turbo lamp The running lamp

The indoor unit faulty display:

Faulty contents Trouble display

Communication fault

The running lamp lightens all the timethe turbo lamp

lightens 2 times and then extinguish 2 seconds

Indoor fan fault

The running lamp lightens all the timethe turbo lamp

lightens 5 timesand then extinguish 2 seconds

Indoor temp. sensor fault

The running lamp lightens all the timethe turbo lamp

lightens 3 times and then extinguish 2 seconds

Indoor coil outlet temp. sensor fault

The running lamp lightens all the timethe turbo lamp

lightens 4 timesand then extinguish 2 seconds

Indoor coil inlet temp. sensor fault

The running lamp lightens all the timethe turbo lamp

lightens 4 times and then extinguish 2 seconds

Indoor coil middle temp. sensor fault

The running lamp lightens all the timethe turbo lamp

lightens 4 times and then extinguish 2 seconds

Mode conflict

The running lamp lightens 1 time and then extinguish

1 second

Defrosting or anti cold air

The timing lamp lightens 1 time and then extinguish

1 second

The outdoor unit faulty display:

Faulty contents Trouble display

the outdoor unit transducer module

protection faulty

The timing lamp lightens all the timethe turbo lamp

lightens 2 times and then extinguish 2 seconds

over current of outdoor unit

The timing lamp lightens all the timethe turbo lamp

lightens 3 times and then extinguish 2 seconds

discharge temp. of compressor too high,

outside ambient temp. too high, switch

temp. of compressor crust cut off, temp.

of module too high

The timing lamp lightens all the timethe turbo lamp

lightens 4 times and then extinguish 2 seconds

The outdoor unit DC busbar voltage is

abnormal

The timing lamp lightens all the timethe turbo lamp

lightens 7 times and then extinguish 2 seconds

lack refrigerant or reverse valve fault

The timing lamp lightens all the timethe turbo lamp

lightens 8 times and then extinguish 2 seconds

outdoor sensor fault

The running lamp lightens all the timethe turbo lamp

lightens 7 times and then extinguish 2 seconds

outdoor unit drive fault, start compressor

failure

The running lamp lightens all the timethe turbo lamp

lightens 6 times and then extinguish 2 seconds

47

The 85

th

style indoor lamp panel

The timing lamp The sleeping lamp The running lamp

Faulty contents Trouble display

Communication fault

The timing lamp lightens all the timethe sleeping lamp

lightens 2 times and then extinguish 2 seconds

Indoor fan fault

The timing lamp lightens all the timethe sleeping lamp

lightens 5 times and then extinguish 2 seconds

Indoor temp. sensor fault

The timing lamp lightens all the timethe sleeping lamp

lightens 3 times and then extinguish 2 seconds

Indoor coil outlet temp. sensor fault

The timing lamp lightens all the timethe sleeping lamp

lightens 4 times and then extinguish 2 seconds

Indoor coil inlet temp. sensor fault

The timing lamp lightens all the timethe sleeping lamp

lightens 4 times and then extinguish 2 seconds

Indoor coil middle temp. sensor fault

The timing lamp lightens all the timethe sleeping lamp

lightens 4 times and then extinguish 2 seconds

Mode conflict

The timing lamp lightens 1 time and then extinguish

1 second

Defrosting or anti cold air

The running lamp lightens 1 time and then extinguish

1 second

Faulty contents Trouble display

the outdoor unit transducer module

protection faulty

The running lamp lightens all the timethe sleeping lamp

lightens 2 times and then extinguish 2 seconds

over current of outdoor unit

The running lamp lightens all the timethe sleeping lamp

lightens 3 times and then extinguish 2 seconds

discharge temp. of compressor too high,

outside ambient temp. too high, switch

temp. of compressor crust cut off, temp.

of module too high

The running lamp lightens all the timethe sleeping lamp

lightens 4 times and then extinguish 2 seconds

The outdoor unit DC busbar voltage is

abnormal

The running lamp lightens all the timethe sleeping lamp

lightens 7 times and then extinguish 2 seconds

lack refrigerant or reverse valve fault

The running lamp lightens all the timethe sleeping lamp

lightens 8 times and then extinguish 2 seconds

outdoor sensor fault

The timing lamp lightens all the timethe sleeping lamp

lightens 7 times and then extinguish 2 seconds

outdoor unit drive fault, start compressor

failure

The timing lamp lightens all the timethe sleeping lamp

lightens 6 times and then extinguish 2 seconds

48

6.3 The malfunction of indoor and outdoor unit

1The common malfunction code analysis and solutions!

The fault

code

The fault content The reason of fault and its solutions

F1 The communication fault

1The communication wire is broken off. Please check

whether the wire is disentwined ;

2Please check whether the electrical control board is

damaged. It should be replaced when it is damaged;

3Please check whether the power ground wire is reliable;

4Please check whether the unit is abnormal caused by the

external interference. If it is, then find the interfering

sources, and remove them.

F2

The indoor temperature

sensor fault

1Check whether the resistance of sensor is normal,

otherwise replace it;

2Check whether the sensor wire is short circuit or open

circuit, and whether the plug is well contacted, whether

there is welding off or rosin joint on the electric control

board, repair it if there is any above;

3When the 1 and 2 are both normal, then the component

or integrated circuit is damaged, the electric control board

should be replaced.

F3

The indoor coil

temperature sensor fault

1Check whether the resistance of sensor is normal,

otherwise replace it;

2Check whether the sensor wire is short circuit or open

circuit, and whether the plug is well contacted, whether

there is welding off or rosin joint on the electric control

board ,repair it if there is any above;

3When the 1 and 2 are both normal, then the component

or integrated circuit is damaged, the electric control board

should be replaced.

F4

Indoor PG motor fault

(tap motor hasnt so

breakdown )

1Check whether the contact of the plug of the motor wire

and socket is well. Please make sure it is well contacted;

2Check whether the indoor motor has damaged, the

motor should be replaced when it is damaged;

3 Check whether the controllable silicon and other

components on the electric control board have damaged

replace the controllable silicon or electric control board

when they are damaged;

4Check whether the indoor fan is unobstructed when

running, please fix the indoor fan again when it is

obstructed.

F5

IPM protection

1Check whether the supply voltage is out of ranging from

150 to 270V(overvoltage and undervoltage protection);

Measuring the actual current, if the current is greater than

the rated current of 2A,it is over-temperature protection;

If the above are normal, that is IPM module internal circuit

fault protection, so please replace the IPM module.

F6 The outdoor sensor fault

1Check whether the resistance of sensor is normal,

otherwise replace it;

2Check whether the sensor wire is short circuit or open

circuit, and whether the plug is well contacted, whether

there is welding off or rosin joint on the electric control

board, repair it if there is any above;

3When the 1 and 2 are both normal ,then the component

or integrated circuit is damaged, the electric control board

should be replaced.

49

F7

The outdoor coil

temperature sensor fault

Including the

mid-point of tube

inspiratory gas

1Check whether the resistance of sensor is normal,

otherwise replace it;

2Check whether the sensor wire is short circuit or open

circuit, and whether the plug is well contacted, whether

there is welding off or rosin joint on the electric control

board, repair it if there is any above;

3When the 1 and 2 are both normal, then the component

or integrated circuit is damaged, the electric control board

should be replaced.

F9 Exhaust gas sensor failure

1Check whether the resistance of sensor is normal,

otherwise replace it;

2Check whether the sensor wire is short circuit or open

circuit, and whether the plug is well contacted, whether

there is welding off or rosin joint on the electric control

board, repair it if there is any above;

3When the 1 and 2 are both normal, then the component

or integrated circuit is damaged, the electric control board

should be replaced.

FA

The communication fault

between the wire

controller and the indoor

PCB

1 check whether the wire controllers connecting wire is

short circuit or loose, please make it connect well;

2 Check the connecting linewire controllerPCB

whether they are loose or have a bad contact. Please

make them have a good contact.

FC

outdoor unit driving fault,

starting compressor

failure

1Turn on the power again, and then check whether the

operation of the compressor is normal;

2Check whether the connection of the compressor is

correct or reliable, otherwise repair it;

3Check whether the components on the electric control

board have been damaged, if they are damaged, the

components or the electric control board should be

replaced.;

4Check whether the connecting wires are disentwined

between the Intelligent Power Module board and the main

board, otherwise make the wires connect firmly .

FF

The outdoor DC motor

fault

1Check the resistance value of the DC motor port. If it is

short circuit, please change the DC motor;

2 Check the voltage value of the DC motor port

VCC(15Vdc)Vdm(340Vdc),please change the PCB board

if the voltage values are abnormal;

3if all the voltage values of the DC motor port are

normalthe Vsp voltage0~5vis also ok ,it shows that the

inner PCB board of the DC motor is damaged, then change

the DC motor.

FH

The indoor unit

EEPROM error

1Check whether there are false weld and bad contact etc

between the EEPROM chip block and the electronic

control board ;

2Check whether the EEPROM chip pin is broken foot

and the direction of installation is in line with the

EEPROM block;

3When the procedure of EEPROM chip and itself have

fault it will appear the code FH. That is the need to replace

the EEPROM chip.

dF Defrosting state The unit is in defrosting statethat is normal.

dI Mode conflict

When the running mode for No.1 indoor unit is different

from No.2 indoor unit, the dF is displayed.

50

The fault

code

The fault content The reason of fault and solution

P1

Indoor coil

temperature

over-temperature

protection for heating

(thermal overload),

outdoor coil

temperature

overheating protection

for cooling (cooling

overload)

1 Check whether the ambient temperature is over the range

of air-conditioning running temperature ;

2 Check whether the indoor coil temperature is higher than

or equal to 63 degrees when heating and check whether

the outdoor coil temperature is higher than or equal to 65

degrees when cooling, it will appear protection if the

value is over the above;

3 Check whether the parameters of indoor and outdoor coil

temperature sensors are normal, if abnormal, please

replace the sensors;

4 If the above are normal, check whether the main control

board output parameters are normal, if abnormal, please

replace the main control board.

P2

The outdoor unit

inverter module

protection fault

1Check whether the connection of the compressor is reliable,

otherwise connect firmly again;

2Check whether the fixation between the IPM module and

the radiator is firm.;

3Check whether the compressor is well, otherwise replace it;

4Check whether the IPM module is abnormal, otherwise

replace it.

P3

Over current of

outdoor unit

1 Check whether the ambient temperature exceeds the

operation range for the air conditioner;

2Check whether the current detection circuit is abnormal, the

electric control should be replaced when it is abnormal..

P4

discharge temperature of

compressor is too high, the

outside ambient

temperature

over-temperature, switch

off the compressor shell

temperature, module

temperature

over-temperature

1Check whether the pressure is normal when the unit is

running, if it is abnormal, you should detect the leakage and

then welding and adding refrigerant;

2Check whether the ambient temperature is too high or too

low, when the temperature is more than -20 degrees and less

55 degrees, it can disappear automatically;

3 Check whether temperature switch of compressor is

damage, it should be replaced if it is damaged.

P7

The outdoor unit DC

generatrix voltage is

abnormal

1Check whether the supply voltage is out of ranging from

150 to 270V;

2Check the voltage detection circuit of the IPM base board is

abnormal, if it is abnormal, the IPM base board or the electric

control board should be replaced.

P8

lack refrigerant or reverse

valve fault

1Check whether the high and low pressure valves have been

opened, otherwise open the valves;

2Check whether the indoor coil pipe temperature sensor is

normal, if it is abnormal, the sensor should be replaced;

3Check whether the indoor coil temperature sensor hung in

the airplease plug it in a correct position if the indoor coil

temperature sensor hung in the air;

4Check the system pressure is abnormal, if it is abnormal,

yon should detect leakage and the welding and adding the

refrigerant.;

5Please change the outdoor PCB board , if all above are

normal.

PA

protection when indoor

pipe temperature is too

low (Anti-icing)

1 Check whether the ambient temperature is over the range

of air-conditioning running temperature;

2 Check the indoor coil temperature is less than or equal to

-1 degrees, if more than this value it will be the protection

of;

3 Check whether the indoor coil temperature sensor

51

parameters are normal, if abnormal it is the replacement

of the sensor;

4 If the above are normal, check whether the main control

board output parameters are normal, if abnormal ,please

replace the main control board.

PC

Outdoor ambient

temperature

over-temperature

protection (including high

and low)

1 Check whether the outdoor ambient temperature is too

high or too low, when the ambient temperature is lower

than (T> -20, T <55), this fault automatically discharges;

2 Check whether the outdoor temperature sensors ring

temperature parameters are normal, if abnormal ,please

replace the sensor;

3 If the above are normal, check whether the main control

boards output parameters are normal, f abnormal ,please

replace the main control board.

PE

EEPROM reading error

(outdoor unit)

1Check whether there are false weld and bad contact etc

between the EEPROM chip block and the electronic control

board ;

2Check whether the EEPROM chip pin is broken foot and

the direction of installation is in line with the EEPROM block;

3When the procedure of EEPROM chip and itself have fault

it will appear the code PE. At this time there is the need to

replace the EEPROM chip.

S-ar putea să vă placă și

- LG Multi Inverter - Solución de ProblemasDocument87 paginiLG Multi Inverter - Solución de ProblemasJarvin Saenz PavónÎncă nu există evaluări

- Basic InverterDocument26 paginiBasic InverterFatwa Mulya SariÎncă nu există evaluări

- (SM) M (2 3 4 5) OE 14 42HFN1 Q (Multi Outdoor) - EngDocument57 pagini(SM) M (2 3 4 5) OE 14 42HFN1 Q (Multi Outdoor) - EngDee RajaÎncă nu există evaluări

- Danfoss GPY16RDa R134a 115 60Document4 paginiDanfoss GPY16RDa R134a 115 60Camilo Carreño TorresÎncă nu există evaluări

- WallMountedS24S5 Chassis Inverter ServiceManualDocument72 paginiWallMountedS24S5 Chassis Inverter ServiceManualcaovadio88100% (1)

- LG Multi F 3828a20097w 1Document254 paginiLG Multi F 3828a20097w 1Claudiu RaduÎncă nu există evaluări

- Trouble Shooting Guide - 2010Document154 paginiTrouble Shooting Guide - 2010Roberto SuarezÎncă nu există evaluări

- Secop Compressors CatalogueDocument180 paginiSecop Compressors CatalogueBraian Cabañas Visca BarçaÎncă nu există evaluări

- Trouble Shooting For VRFDocument55 paginiTrouble Shooting For VRFFelixÎncă nu există evaluări

- 5Document208 pagini5Syed Noman AhmedÎncă nu există evaluări

- Service Manual: Washing MachineDocument29 paginiService Manual: Washing MachineremikhaledÎncă nu există evaluări

- (2016) Embraco Hermetic Compressor Catalog - For Asia Pacific - EngDocument126 pagini(2016) Embraco Hermetic Compressor Catalog - For Asia Pacific - EngIskandar FirdausÎncă nu există evaluări

- User Manual - YCZ-A003 PDFDocument37 paginiUser Manual - YCZ-A003 PDFEdward ToroÎncă nu există evaluări

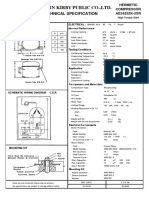

- Kulthorn Kirby Public Co.,Ltd.: Technical SpecificationDocument2 paginiKulthorn Kirby Public Co.,Ltd.: Technical SpecificationPradhish RejiÎncă nu există evaluări

- Room Air Conditioner: Service ManualDocument80 paginiRoom Air Conditioner: Service ManualHugo londoñoÎncă nu există evaluări

- Termostato TRANEDocument14 paginiTermostato TRANECarolina LopezÎncă nu există evaluări

- Highly Compressor Model Code IdentificationDocument6 paginiHighly Compressor Model Code IdentificationChaman SinghÎncă nu există evaluări

- Lista Compresores 2 - de - AgostoDocument11 paginiLista Compresores 2 - de - Agostojuan luis loaiza correaÎncă nu există evaluări

- TECUMSEH Model Number CodesDocument6 paginiTECUMSEH Model Number Codesd3xter0% (1)

- SM MultiV IV Air Outdoor Units 4 15 - 20150414080917Document150 paginiSM MultiV IV Air Outdoor Units 4 15 - 20150414080917avelarmatosÎncă nu există evaluări

- Hk35aa009 UserDocument4 paginiHk35aa009 UserUbaldo Brito50% (2)

- Challenger 3000 Parts ManualDocument52 paginiChallenger 3000 Parts ManualCristhian Aguilar100% (1)

- Compressor SpecificationsDocument1 paginăCompressor SpecificationsSilas NjueÎncă nu există evaluări

- Baldor Motor Lubrication RecommendationsDocument122 paginiBaldor Motor Lubrication RecommendationsjoelÎncă nu există evaluări

- 30gtn 4siDocument12 pagini30gtn 4siAngel RojasÎncă nu există evaluări

- Digipro Manual For PDRCF Series DryersDocument13 paginiDigipro Manual For PDRCF Series DryersGabun KirillÎncă nu există evaluări

- Techrite Siemens Siemens Qra Uv Flame Detection 013060323409Document14 paginiTechrite Siemens Siemens Qra Uv Flame Detection 013060323409Ali Hadi100% (1)

- Operating Instructions: Variotrane Tr1 Series 2800Document137 paginiOperating Instructions: Variotrane Tr1 Series 2800adylazar7Încă nu există evaluări

- York VRF Error Codes: Skip To ContentDocument7 paginiYork VRF Error Codes: Skip To Contentshadab nazÎncă nu există evaluări

- 8 65 105 EvapsDocument41 pagini8 65 105 EvapsRestino KionyÎncă nu există evaluări

- Equipos Mini Splits Comfortstar CSC1024CDDocument4 paginiEquipos Mini Splits Comfortstar CSC1024CDAguilar Joel100% (1)

- Inverter Compressor Technology For Refrigerator (Reciprocating) PDFDocument7 paginiInverter Compressor Technology For Refrigerator (Reciprocating) PDFel_george0079491Încă nu există evaluări

- SM Auhf12lal Aohb12lall 10 en PDFDocument25 paginiSM Auhf12lal Aohb12lall 10 en PDFpepondeAviles100% (1)

- Samsung Rotary Type CompressorDocument18 paginiSamsung Rotary Type CompressorJupiter3108Încă nu există evaluări

- McQuay (Plata)Document70 paginiMcQuay (Plata)Ana Gil Pinto Brás100% (2)

- 50Hz Compressors For Light Commercial Applications: CatalogueDocument16 pagini50Hz Compressors For Light Commercial Applications: CatalogueMass Max Mab100% (1)

- Compresseur Danfoss Secop sc21cl PDFDocument2 paginiCompresseur Danfoss Secop sc21cl PDFOscar MendozaÎncă nu există evaluări

- FFU100HAK 115-127 V 60 HZ 1Document3 paginiFFU100HAK 115-127 V 60 HZ 11000tech refrigeracao50% (2)

- FujikokiDocument87 paginiFujikokisam100% (2)

- Kcn430Lal-Bxxxh B330H, B331H: Emerson Climate Technologies (India) LimitedDocument6 paginiKcn430Lal-Bxxxh B330H, B331H: Emerson Climate Technologies (India) LimitedRaja Velu100% (1)

- U25HSP Spec Sheet PDFDocument1 paginăU25HSP Spec Sheet PDFjerbÎncă nu există evaluări

- Midea Modularni Cilleri MGB-service ManualDocument119 paginiMidea Modularni Cilleri MGB-service ManualGermánCastiglioniÎncă nu există evaluări

- Service Manual: SJ-58L-C2W SJ-63L-C2W SJ-68L-C2WDocument32 paginiService Manual: SJ-58L-C2W SJ-63L-C2W SJ-68L-C2WWee Chuan PoonÎncă nu există evaluări

- Shiller York ManualDocument54 paginiShiller York ManualUndibal Alejandro Rivas100% (1)

- Manual Semicompleto de Chiller York de 300 T.R.Document118 paginiManual Semicompleto de Chiller York de 300 T.R.JUAN CARLOS FLORES MORALES100% (1)

- Samsung Rl23-25-28 Dats Datw Service ManualDocument28 paginiSamsung Rl23-25-28 Dats Datw Service ManualKonstantinas OtÎncă nu există evaluări

- Refrigeration Product: CatalogueDocument10 paginiRefrigeration Product: CatalogueDipendraTomarÎncă nu există evaluări

- Catalog General Rhoss 2008 PDFDocument118 paginiCatalog General Rhoss 2008 PDFCalin Stefanescu100% (1)

- Ae4460e FZ1B PDFDocument4 paginiAe4460e FZ1B PDFMateo AcuñaÎncă nu există evaluări

- Evergreen Chiller Performance Outputs: Tag Name: Selection1 - Sel01Document1 paginăEvergreen Chiller Performance Outputs: Tag Name: Selection1 - Sel01picuÎncă nu există evaluări

- 4 Common Refrigerator Compressor ProblemsDocument32 pagini4 Common Refrigerator Compressor ProblemsPat Ike100% (1)

- McQuay Water Cooled Package MWCP-2004 PDFDocument40 paginiMcQuay Water Cooled Package MWCP-2004 PDFbluemojo75% (4)

- Panasonic: MATSUSHITA CompressorDocument2 paginiPanasonic: MATSUSHITA CompressorJosé Gregorio González TorresÎncă nu există evaluări

- Service: ManualDocument53 paginiService: ManualFlorian Leordeanu100% (1)

- Galanz - Galaxy 7-9-12K - SPLIT PDFDocument42 paginiGalanz - Galaxy 7-9-12K - SPLIT PDFUbaldo BritoÎncă nu există evaluări

- Yccd Cu Condensing Units 52 158 KWDocument12 paginiYccd Cu Condensing Units 52 158 KWSarb PaulÎncă nu există evaluări

- 2 4Document14 pagini2 4rafaelki100% (2)

- 2CDC002157D0201Document7 pagini2CDC002157D0201260380sdÎncă nu există evaluări

- SM - Pool Heat Pump 60 - 140Document37 paginiSM - Pool Heat Pump 60 - 140elshan_asgarovÎncă nu există evaluări

- Swimming Pool Type Heat Pump Water Heater Technical ManualDocument35 paginiSwimming Pool Type Heat Pump Water Heater Technical ManualPavel Gonzalez100% (1)

- Day 3: God With UsDocument2 paginiDay 3: God With Ushossimo33Încă nu există evaluări

- Chigo Inverters ManualDocument52 paginiChigo Inverters Manualhossimo33Încă nu există evaluări

- Day 2: Give Him The Name JesusDocument2 paginiDay 2: Give Him The Name Jesushossimo33Încă nu există evaluări

- Day 1Document2 paginiDay 1hossimo33Încă nu există evaluări

- Ds250vg - Citel SpdsDocument2 paginiDs250vg - Citel Spdshossimo33Încă nu există evaluări

- Arduino Starter Kit Tutorals 100-104Document76 paginiArduino Starter Kit Tutorals 100-104BLuu21Încă nu există evaluări

- Surge Protection For Surveillance SystemsDocument16 paginiSurge Protection For Surveillance Systemshossimo33Încă nu există evaluări

- ArduinoDocument26 paginiArduinoErshad Shafi AhmedÎncă nu există evaluări

- STARDELTADocument2 paginiSTARDELTAhossimo33Încă nu există evaluări

- Surge Protector For One and Two Pair Telephone Lines B180T/MJ6 and B280T/MJ6Document2 paginiSurge Protector For One and Two Pair Telephone Lines B180T/MJ6 and B280T/MJ6hossimo33Încă nu există evaluări

- Outdoor PCB Pinouts of Connection.: Imperial Hotel Cold Room NotesDocument1 paginăOutdoor PCB Pinouts of Connection.: Imperial Hotel Cold Room Notespuckie33Încă nu există evaluări

- IEC61643 1approvedDocument4 paginiIEC61643 1approvedajalbornozÎncă nu există evaluări

- Booklet GuideDocument3 paginiBooklet Guidehossimo33Încă nu există evaluări

- RCDs Operating TimeDocument2 paginiRCDs Operating Timehossimo33Încă nu există evaluări

- ESR Tables For Electrolyric Caps.Document3 paginiESR Tables For Electrolyric Caps.hossimo33Încă nu există evaluări

- Omron TimerDocument12 paginiOmron Timerpuckie33Încă nu există evaluări

- 599329115Document109 pagini599329115soft4gsm100% (1)

- KEC-KMe ManualDocument5 paginiKEC-KMe Manualhossimo33Încă nu există evaluări

- Group 24 Project Proposal (Rain Watermill)Document3 paginiGroup 24 Project Proposal (Rain Watermill)dvianÎncă nu există evaluări

- Section 55 - Electrical Systems Chapter 14G - Fault Codes Semi Powershift Models From Serial No. ACM265009Document456 paginiSection 55 - Electrical Systems Chapter 14G - Fault Codes Semi Powershift Models From Serial No. ACM265009Alef Behling100% (1)

- ManualDocument108 paginiManualCamiloNogueraRiascosÎncă nu există evaluări

- Catalog For Master-KDocument66 paginiCatalog For Master-KAlÎncă nu există evaluări

- Automatic Car Park Barrier System PDFDocument14 paginiAutomatic Car Park Barrier System PDFShyam Krishna M SÎncă nu există evaluări

- Haramaya University: Haramaya Institute of TechnologyDocument15 paginiHaramaya University: Haramaya Institute of TechnologyabdulsemedÎncă nu există evaluări

- Antoine Priore - US Patent # 3,280,816, Method of Producing Radiations For Penetrating Living CellsDocument15 paginiAntoine Priore - US Patent # 3,280,816, Method of Producing Radiations For Penetrating Living CellsoscarnineÎncă nu există evaluări

- 1 Fundamental of DC MachinesDocument28 pagini1 Fundamental of DC MachinesAmitava BiswasÎncă nu există evaluări

- Pi Voltage Control Technique For 3 Phase Induuction Motor Using Simulink and ArduinoDocument37 paginiPi Voltage Control Technique For 3 Phase Induuction Motor Using Simulink and ArduinoPFAÎncă nu există evaluări

- Industrial Ethernet - Issues and Requirements: Marzio PozzuoliDocument61 paginiIndustrial Ethernet - Issues and Requirements: Marzio PozzuoliJeissonBurgosÎncă nu există evaluări

- D 3820Document41 paginiD 3820teja tejaÎncă nu există evaluări

- Important Questions - APS - IDocument3 paginiImportant Questions - APS - IAakash MehtaÎncă nu există evaluări

- Electrician PDFDocument53 paginiElectrician PDFAbujaid KahnÎncă nu există evaluări

- Fimer Trio 5.8 7.5 8.5 TL Outd Product Manual en Reve (M000018eg)Document117 paginiFimer Trio 5.8 7.5 8.5 TL Outd Product Manual en Reve (M000018eg)hmm.hugo7845Încă nu există evaluări

- 110KV BB 01Document37 pagini110KV BB 01karthikÎncă nu există evaluări

- Ericsson 2G Cell HandlingDocument34 paginiEricsson 2G Cell HandlingManish Sharma100% (2)

- What Is A DC Shunt Motor?: Shunt Motor. The Main Difference Between DC Series Motor As Well As DCDocument3 paginiWhat Is A DC Shunt Motor?: Shunt Motor. The Main Difference Between DC Series Motor As Well As DCالموعظة الحسنه chanelÎncă nu există evaluări

- A-31 Battery Chargers and Inverters - 1465724852 - A-31 - PubDocument18 paginiA-31 Battery Chargers and Inverters - 1465724852 - A-31 - Pubnicolas.travailÎncă nu există evaluări

- Prediction On Future DC Power System: Qianzhi Zhou, Senior Member of IEEE, Defang YuanDocument4 paginiPrediction On Future DC Power System: Qianzhi Zhou, Senior Member of IEEE, Defang YuanAbdeldjalil AchourÎncă nu există evaluări

- Electric Motors DrivesDocument2 paginiElectric Motors Drivesprashant srivastavÎncă nu există evaluări

- High Efficiency High Step-Up DC/DC Converters - A Review: A. Tomaszuk and A. KRUPADocument9 paginiHigh Efficiency High Step-Up DC/DC Converters - A Review: A. Tomaszuk and A. KRUPAmaazÎncă nu există evaluări

- A Project Report On Hand Crank Mobile Charger: Sant Gadge Baba Amravati University, Amravati (M.S.) 444 602Document39 paginiA Project Report On Hand Crank Mobile Charger: Sant Gadge Baba Amravati University, Amravati (M.S.) 444 602Rohit JibhakateÎncă nu există evaluări

- Itron ACE8000 PDFDocument92 paginiItron ACE8000 PDFBruno De Brida100% (1)

- Rectifier PS4890 DescriptionDocument57 paginiRectifier PS4890 DescriptionMuhammad Rauf AkramÎncă nu există evaluări

- 10.solar Based Mini Hybrid Vehicle-2016Document69 pagini10.solar Based Mini Hybrid Vehicle-2016msathish_eeeÎncă nu există evaluări

- Wireless Power Transmission Project ThesisDocument4 paginiWireless Power Transmission Project Thesislucynaderfortwayne100% (2)

- Acceptance Test Procedure For Alcatel-Lucent Bts A9100Document20 paginiAcceptance Test Procedure For Alcatel-Lucent Bts A9100Tuan Luong CaoÎncă nu există evaluări

- 30V 100ah Vrla Battery & ChargerDocument11 pagini30V 100ah Vrla Battery & ChargersamarbtechÎncă nu există evaluări

- G83 2 ChangesDocument2 paginiG83 2 ChangesJohnWilliamsÎncă nu există evaluări