Documente Academic

Documente Profesional

Documente Cultură

CLASAR Check Valve: General Description Design and Features Water Hammer Test Part List Applications Product Pictures

Încărcat de

tilakthakar1Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

CLASAR Check Valve: General Description Design and Features Water Hammer Test Part List Applications Product Pictures

Încărcat de

tilakthakar1Drepturi de autor:

Formate disponibile

CLASAR Check Valve

General description

Design and Features

Water Hammer test

Part list

Applications

Product pictures

nl

nl

CLASAR Check Valve

GENERAL DESCRIPTION

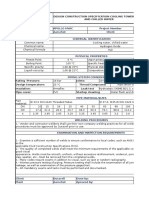

Type : Nozzle type, High dynamic

answer with polyurethane obturator

Non Slam and silent type (no water

hammer)

End connection:

Wafer: DN 80 (3) to DN 500 (20)

Double-Flanged: DN 600 (24) to DN

1800 (72)

Size: DN 80 mm (3) to 1800 mm

(72)

Working pressure: PN10 to PN50

Temperature: -15C to +90 C

nl

CLASAR Check Valve

Design feature: obturator

Obturator made in Polyurethane

(Density = 1) for quick closure

Reduced Water column reverse velocity.

No creation of water hammers (High

dynamic performances)

No noise

No corrosion

Very good erosion coefficient (superior to

SS 316)

Very good resistance to chocks

Spring without guide

No risk of jamming

Spring material: Stainless steel (fresh

water) or Inconel for sea water

nl

CLASAR Check Valve

Design feature: Body

Flow diffuser

Very quick flow recovery

(Less than 2 D)

Double Flanged Body

DN600 (24) to DN1800 (72)

Wafer Body

DN80 (3) to DN500 (20)

Very short face to face

For easy installation in the plant room

Materials

Ductile Iron (Epoxy coated)

Ni-Resist Ductile Iron (Sea Water)

Stainless steel also available

CLASAR Check Valve

nl

Water hammer test comparison:

Swing check type

34 bars of pressure increase

Duo-check type

15 bars of pressure increase

Clasar

Only 5 bars of pressure increase

Applications :

Water Treatment / Pumping / distribution

Large size pumping stations with high water heads

Fresh or sea water cooling systems

HVAC

nl

CLASAR Check Valve

Clasar double-flanged DN600 PN25

CLASAR Check Valve

nl

S-ar putea să vă placă și

- Eaton Vickers Cylinders Hydro TransDocument592 paginiEaton Vickers Cylinders Hydro TransCentral HydraulicsÎncă nu există evaluări

- Tugas Kualitas AirDocument34 paginiTugas Kualitas AirSyarifah Hizriah AlmahdalyÎncă nu există evaluări

- Cooling TanksDocument1 paginăCooling TanksAnonymous 6EW2MsFbkÎncă nu există evaluări

- 1 - 2015 Enimex Ball ValvesDocument55 pagini1 - 2015 Enimex Ball ValvesNoytsias KostantinosÎncă nu există evaluări

- The Boss of Control Loop, Final Control Element: Reliance Industries Ltd. JamnagarDocument61 paginiThe Boss of Control Loop, Final Control Element: Reliance Industries Ltd. JamnagarRaju NaiduÎncă nu există evaluări

- Efco Valve Test BenchesDocument8 paginiEfco Valve Test BenchesFacundo ArgüelloÎncă nu există evaluări

- Butterfly Valve CatalogueDocument6 paginiButterfly Valve CatalogueromeshmoreyÎncă nu există evaluări

- VALVESDocument51 paginiVALVESPalkesh Trivedi100% (2)

- Hydro TestDocument36 paginiHydro TestFasil Paruvanath100% (1)

- Krombach Strainers & GGCDocument35 paginiKrombach Strainers & GGCMeanRatÎncă nu există evaluări

- Hydro TestDocument36 paginiHydro TestAayush PandeyÎncă nu există evaluări

- Automatic Faucet QuotationDocument20 paginiAutomatic Faucet QuotationshadapaaakÎncă nu există evaluări

- Piping Components GuideDocument110 paginiPiping Components Guidearianaseri100% (3)

- Adequa UralitaDocument11 paginiAdequa UralitaDurban Chamber of Commerce and IndustryÎncă nu există evaluări

- Products PortfolioDocument11 paginiProducts PortfolioDurban Chamber of Commerce and IndustryÎncă nu există evaluări

- E 90 21 - FireDocument2 paginiE 90 21 - Firepequenita34Încă nu există evaluări

- Products Services CatalogueDocument79 paginiProducts Services CatalogueMayur PatelÎncă nu există evaluări

- Clack ValveDocument10 paginiClack ValveengineershoaibqaziÎncă nu există evaluări

- Valves SpecsDocument38 paginiValves Specsprabhu_jay23Încă nu există evaluări

- TescomDocument16 paginiTescomrafaareÎncă nu există evaluări

- Pool Cleaning Products PDF Document Aqua Middle East FZCDocument12 paginiPool Cleaning Products PDF Document Aqua Middle East FZCAdolfsmith69Încă nu există evaluări

- Catálogo WLDocument1 paginăCatálogo WLWillian CastroÎncă nu există evaluări

- Flow measurement of liquids and gasesDocument8 paginiFlow measurement of liquids and gasesابزار دقیقÎncă nu există evaluări

- Tables of Piping Standards - PittsburghDocument166 paginiTables of Piping Standards - PittsburghzhangamecÎncă nu există evaluări

- Spezialzylinder EngDocument18 paginiSpezialzylinder EngccooxxyyÎncă nu există evaluări

- Fluid Lines FittingsDocument61 paginiFluid Lines FittingsVy ThoaiÎncă nu există evaluări

- SPAN Catalog WebDocument20 paginiSPAN Catalog WebJOKO WIKARNAÎncă nu există evaluări

- Copper, Brass, BronzeDocument4 paginiCopper, Brass, BronzeJaideep MukherjeeÎncă nu există evaluări

- TYCO Fire ProtectionDocument8 paginiTYCO Fire ProtectionExtinflashPauloRÎncă nu există evaluări

- Fluid Control System CleanlinessDocument59 paginiFluid Control System CleanlinessJunior Francisco QuijanoÎncă nu există evaluări

- Hoke Needle ValvesDocument38 paginiHoke Needle ValvesmartinvandoornÎncă nu există evaluări

- RV Series: High Pressure Anti-Cavitation Relief ValvesDocument6 paginiRV Series: High Pressure Anti-Cavitation Relief Valveselectrico65Încă nu există evaluări

- Hydro TestDocument36 paginiHydro TestAhmed AshourÎncă nu există evaluări

- Pressure Gauge LimitationsDocument2 paginiPressure Gauge LimitationsJohn MaguireÎncă nu există evaluări

- Valves Product RangeDocument6 paginiValves Product RangesvvsreddyÎncă nu există evaluări

- HDPE Pipe Delivers 100+ Years of Corrosion-Resistant Service for Oil & Gas ApplicationsDocument40 paginiHDPE Pipe Delivers 100+ Years of Corrosion-Resistant Service for Oil & Gas ApplicationsvijayanmksÎncă nu există evaluări

- Float Board Level GaugeDocument6 paginiFloat Board Level GaugeanaismariaÎncă nu există evaluări

- 1-Piping Manual-Pdms12Document413 pagini1-Piping Manual-Pdms12MOHSEN2005IBÎncă nu există evaluări

- Licuadora para LaboratorioDocument1 paginăLicuadora para LaboratorioCarlos PereaÎncă nu există evaluări

- Module III Piping Fundamentals: Pipe Sizing, Materials, Design & LayoutDocument129 paginiModule III Piping Fundamentals: Pipe Sizing, Materials, Design & LayoutMuhammed AfnazÎncă nu există evaluări

- KCA Bladder Tanks en 2010Document11 paginiKCA Bladder Tanks en 2010M Kumar Marimuthu100% (1)

- Needle ValvesDocument38 paginiNeedle ValvesRavichandran MohanÎncă nu există evaluări

- Strainers& Fillter DetailsDocument3 paginiStrainers& Fillter DetailsDineshÎncă nu există evaluări

- Identifying and Selecting Plumbing Materials and FittingsDocument35 paginiIdentifying and Selecting Plumbing Materials and Fittingsdaneca0% (1)

- Diaphragm-Seal Type Pressure Gauges: OutlineDocument40 paginiDiaphragm-Seal Type Pressure Gauges: OutlineFadlul Akbar HerfiantoÎncă nu există evaluări

- Clock Spring ApplicationDocument7 paginiClock Spring Applicationsibi_s_rajÎncă nu există evaluări

- Viking Bladder TanksDocument11 paginiViking Bladder Tanksrasnowmah2012Încă nu există evaluări

- Valves: Types and Working PrinciplesDocument73 paginiValves: Types and Working PrinciplesEhab AbowardaÎncă nu există evaluări

- Pipe and Installation Tools: Wall ChaserDocument12 paginiPipe and Installation Tools: Wall ChaserSamy El-BeheryÎncă nu există evaluări

- Catalog Pak KuntoDocument10 paginiCatalog Pak Kuntopt tabÎncă nu există evaluări

- 0036 - CadDocument9 pagini0036 - Cadanon_343092330Încă nu există evaluări

- POVE-Us Non-Slam Nozzle Check ValveDocument3 paginiPOVE-Us Non-Slam Nozzle Check ValveFrancoPoveÎncă nu există evaluări

- 2hr DistributionSystemsBrandedDocument107 pagini2hr DistributionSystemsBrandedLê Văn Thế QuangÎncă nu există evaluări

- Knife Gate Valves: Highest Performance Zero LeakageDocument30 paginiKnife Gate Valves: Highest Performance Zero Leakagesingh_729Încă nu există evaluări

- Item CodeDocument3 paginiItem CodePkKhakeÎncă nu există evaluări

- Cooling Tower and Chilled Water SpecificationDocument42 paginiCooling Tower and Chilled Water SpecificationEugen LupanÎncă nu există evaluări

- CV For Pressure Up To 50bDocument4 paginiCV For Pressure Up To 50bmattuiffÎncă nu există evaluări

- Simple Plumbing Repairs for the Home and FarmsteadDe la EverandSimple Plumbing Repairs for the Home and FarmsteadÎncă nu există evaluări

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!De la EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Evaluare: 5 din 5 stele5/5 (2)

- Oil and Gas Artificial Fluid Lifting TechniquesDe la EverandOil and Gas Artificial Fluid Lifting TechniquesEvaluare: 5 din 5 stele5/5 (1)

- Crowdfunding Pitch Deck 2017: Back A WinnerDocument14 paginiCrowdfunding Pitch Deck 2017: Back A Winnertilakthakar1Încă nu există evaluări

- Community-Focused Craft Brewery & Taproom Opening in Worcester, MADocument10 paginiCommunity-Focused Craft Brewery & Taproom Opening in Worcester, MAtilakthakar1Încă nu există evaluări

- Trademark Brewing - SlideRabbit34Document2 paginiTrademark Brewing - SlideRabbit34tilakthakar1Încă nu există evaluări

- Dynamic Characteristics Check ValvesDocument12 paginiDynamic Characteristics Check ValvesZoran DanilovÎncă nu există evaluări

- 11 - Forged Gate Valves RPC Procedure PDFDocument52 pagini11 - Forged Gate Valves RPC Procedure PDFtilakthakar1Încă nu există evaluări

- AVV Seal Research Paper PDFDocument20 paginiAVV Seal Research Paper PDFtilakthakar1Încă nu există evaluări

- Manhattan Crown Seal DocumentDocument8 paginiManhattan Crown Seal Documenttilakthakar1Încă nu există evaluări

- Manufacturing of MilkDocument3 paginiManufacturing of Milktilakthakar1Încă nu există evaluări

- PDF Optimizer ProcedureDocument3 paginiPDF Optimizer ProceduregadflovelvalvescomÎncă nu există evaluări

- KF Check IOM Series50PistonDocument4 paginiKF Check IOM Series50Pistontilakthakar1Încă nu există evaluări

- Marine LifecycleDocument19 paginiMarine Lifecycletilakthakar1Încă nu există evaluări

- GaugesDocument11 paginiGaugesSameer KotwalÎncă nu există evaluări

- Grayloc Products An IntroductionDocument10 paginiGrayloc Products An Introductiontilakthakar1Încă nu există evaluări

- Dynamic Characteristics Check ValvesDocument12 paginiDynamic Characteristics Check ValvesZoran DanilovÎncă nu există evaluări

- Stellite 6 - ERCoCrADocument2 paginiStellite 6 - ERCoCrAtilakthakar1Încă nu există evaluări

- Ball Check ValveDocument5 paginiBall Check Valvetilakthakar1Încă nu există evaluări

- DNC Wireless CommuDocument2 paginiDNC Wireless Commutilakthakar1Încă nu există evaluări

- Duplex VendorDocument2 paginiDuplex Vendortilakthakar1Încă nu există evaluări

- Sahsb 0006 enDocument8 paginiSahsb 0006 entilakthakar1Încă nu există evaluări

- Before Installation, These Instructions Must Be Fully Read and UnderstoodDocument1 paginăBefore Installation, These Instructions Must Be Fully Read and Understoodtilakthakar1Încă nu există evaluări

- Typical Specification Clasar PDFDocument2 paginiTypical Specification Clasar PDFtilakthakar1Încă nu există evaluări

- Typical Specification Clasar PDFDocument2 paginiTypical Specification Clasar PDFtilakthakar1Încă nu există evaluări

- MSS SP-25 (1998)Document30 paginiMSS SP-25 (1998)tilakthakar1Încă nu există evaluări

- Typical Specification Clasar PDFDocument2 paginiTypical Specification Clasar PDFtilakthakar1Încă nu există evaluări

- Before Installation, These Instructions Must Be Fully Read and UnderstoodDocument1 paginăBefore Installation, These Instructions Must Be Fully Read and Understoodtilakthakar1Încă nu există evaluări

- Ball Check ValveDocument5 paginiBall Check Valvetilakthakar1Încă nu există evaluări

- Valve Material ApplicationDocument16 paginiValve Material Applicationari_prasÎncă nu există evaluări

- EN-558-1 Standard For ValvesDocument3 paginiEN-558-1 Standard For Valvestilakthakar1Încă nu există evaluări