Documente Academic

Documente Profesional

Documente Cultură

Chapter 1 Ships Electrical Systems Safety & Maintenance

Încărcat de

BacamarteDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Chapter 1 Ships Electrical Systems Safety & Maintenance

Încărcat de

BacamarteDrepturi de autor:

Formate disponibile

\-

Chapter

One:

ShiPs'

electrical

systems

-

safetY

and maintenance

ShiF' Ehctricd

System

Electrical Disgrams

Electrical Sefely

Elcctric Shock

lnsulalbD Resistsnce

Testing

Insulalion

'festing

Continuily

TestinS,

Multimcters

Dbdc Tests

Currenl Clampmeters

Live-Line Testers

Gencral Eleclrical Maintenance

t l l

r 12

t / s

r 16

t l 6

r 17

r l 7

r l e

r / r o

I

l t 2

r l 12

r

/ 13

l / r 3

I ntroduclion

l hi s chaptcr

Prcscnl s

an overvi ew ol a shi P' s cl cctr i c l sl stcnr and dcseri bcs vari ous types of

ci rcui t rl i agrams uscd i | l cl ectri c t work. l l asi c cl ectri cal :al el y precauti ons and el ectri cal

testi ng fl l cthods i trc outl i ncd toScther wi l h a dcscri pttott of gcncral cl cctri cal mui nl nance.

Ships' clcctricNl system

Auxi l i ary scrvi ces on btl arrl shi p range frrttn cngi trc rtxrnl putl tps and l ans' dcck wi nches and

wi ndl asscs tr.r gcncral l i ghti ng, catcri rrg and ai r condi ti onrng. El cctri cal power i s used todri ve

the nraj ori ty ,rf thcse auxi l i ary scrvi ccs.

' l

hc cl ectri cl l po$cr svsl cl tl

()tl

bturd shi p i s desi gned

to provi dc a sccurc suppl y t0 tl l Irads wi th i l dcqui ttc htl i l l i n pr()tccti ()n f()t l he equi pment and

opcrari nS, pcrsttntrcl .

' fhc

gcncral schctne of a shi p s ch;ctri eal

Powcr

system i s conl mon t(t

near l y al l shi ps.

)ao I

GIIERATOR

l{o 2

OENERAIOR

1,RGEirY

GNERAIOR

' l

hc gcncrators (l i otncti ntes cal l crl i thctnators) producc the cl cetri eal

prwcr' l t i s col l ccl cd al

the mai n swi tchboard and thcn tl i stri hutcd t(! thc vari ous auxi l i ary *.-rvi ccs conl pri l i nE l he

t l t

v

clectrical load. An emergency generator and mcrgency swirchboard mainrain supplies in the

cvent of a mai n power fai l ure.

compare thisgcneral layout with the system on yourship.

Notc the grear similariries and also

note the differences

-

all ships' systems differ in some res1rcct.

The generators

may bc driven by a diesel engine. by a steam or gas turbine, or by the main

propulsion engine. The rype of prime mover is derermined by the design of rhe ship and by

cconomic factors.

The power rating ofth generators is determined by the power demand of the electrical load.

Large passengcr ships have three or four large generators rated at 2MW or more to supply the

ertcnsivc hotel services on board. A cargo ship may have two main generators

lypically rated

from 350 to l000kW which are sufficient to supply the engine room auxiliaries while at sca and

thc winches or cranes for handling cargo while in port. The limiied load required during an

cmergency requires that the emergency generators

may be rated from about l0kW for a small

coaster to about 300kW or more for a cargo liner. The shipbuilder must estimaie the number

and power rating ofthe required generators by assessing the pnwerdemand of the load for all

situations whether at sea or in port.

Electrical power on board ship is commonly generated ar 440V,60Hz (somerimes

380V, 50

Hz). These values have been adopted because they are standard shore practice in the

Americas and in Europe. Ships with a very large electrical power demand may be designed to

operate at 3.3kV and even 6.6kV, or hi gher.

The Bri ti sh Standard and IEC defi ni ri on of LOW VOLTAGE i s between 50V ac and 10fi )V

ac (the IEC gi ve thi s defi ni ri on ro harmoni ze Bri ti sh and European standards).

Li ghti ng and other domesti c suppl i es usual l y operate ar I | 5V or 220V, si ngl e-phase. Trans-

formers are used to reduce rhe

/0r(,)V

geoeraaed voltage to this safer volrage levI. Where

ponable equipment is to be used in dangerous, hot and damp locations, it is advisable to

oprate at 55V or even 24V suppl i ed agai n by a srep-d()wn rransformer. Occasi onal l y,

transformers are al so used to step up vol rages. e.g. suppl yi ng a l arge 3.3kV bow thrustel

motor from a 4zl0V switchboard supply.

Batteri es for vari ous servi ces operate at I2V or 24V but someri mcs hi gher vol tages are used.

Elcctricrl dlrgrrms

There are vari Ous typs of di agram whi eh attcnrpt t(| sh()w how an cl cctri cal ci rcui t operates.

Symbol s are used to represent i tems of equi pment. Thc shi pbui l tter provi des a compl ete sct of

shi ps' el ectri cal di agrams. l t i s i mgrrtant that you \i udy rhese dragrams to bc abl ,j to read and

understand them compctentl y, and to use them as an ai d i n kxati ng el ectri cat faul ts.

A BLOCK DIAGRAM shows i n si mpl i fi ed form the mai n i nrer-rel ati onshi ps of the el emenrs

i n a sysl m, and how the system works or may bc operai d. Such di agrams are oftn used to

depi ct control systems and oi her compl cx rel ari onshi ps.

3-..I-.*..--

l l

l'::T'

a

Di agrams l i ke thi s state the tuncti ()n ol cach bkrck but usual l y gi vc n. i nl ornruti on of thc

comfxl nents i n each bkl ck nor how thc bkxks arc i ntcrconnccted

A SYSTEM DIAGRAM shows thc murn l cl tures of a systcm and i rs b()unds. wi thout

necessari l y showi ng causc- l o-effcct. l ts matn use i s to i l l ustratC l hc ways

()f

operati ng the

t 1 2

-

sFtcm. Detril is omined in order to make the diagram as clear as possible, and so easily

undcrstood.

A CIRCUIT DIACRAM shows, lN FULL, the functioning of a circuit. All csscntial p.tt!

rnd conncctiom are dcpicted by means of symbols arranged to show the opcration es clcrly

.r

pcriblc bur without rcgard lo the physical layout of lhe various ilcms, thcir p$lt or

conncc'tions.

o (

o

o

..O+

O_--*----.-{.1

---O

Thc clectrical connections of rhe above m(Nor starteJ are clearly shown in the simPlest

poesible way. A most important

F)int

is that no attempl is made to show thc movinS conlacls

of e rclay or conlactor alongside the coil that operatcs therh

(whcrc they aac actually

t l t

physi cal l y l ocated). l ' . tead

numbr oi l ei l r.

For cxarnPle: contactor coil

the coil and its related contacls are identified by a common

' cc'

dri ves two auxi l i ary contacts i denti fi ed as

' cc

l ' and

' cr2' .

/A

v

Each wire connection is identified by a number which may be found on a numbcred sleeve on

cach wirc at its termination on a component in ihe actual starter'

Allhough there are international agreements as to ihe symbol to be uscd 1o rpresent

elecrricil components

you must be prepared to meel various different symbols representing

thc samc oomponent. For example: a coil can be represenled as

JTtru

The use of a circuil diagram is to enable the reader to understand the operation of the circuit,

to follow each scquence in the operation from lhe moment of initiatinB the operation (e.g. by

presci ng a' stan' buti on) to the fi nal act

(e.g. starti ng of the motor)' l f the equi pment fai l s to

operatJ correctly, lhe reader can follow the sequence of operalions until he comes to the

opcntion that has failed. He can then examine all the components involved in that faulty

opcration

(and only thos components need be examined) and so locate the fauhy compo-

nint. He has no need to examine other components that are known to function corteclly and

have no influence on the fauli; his work is simplified. A circuit diagram is an essential tool in

trouble shooting.

A WIRING DIAGRAM shows lhe detailed wiring and conneciions between componcnts or

itcms of equipment, and in some cass the routeingofthcsc connections- A wiring diagmm of

an ilem ofequipmenl shows the components in the approximate

Posilion

thy occuPy in rhc

actual equipment. The componnt may be shown complete

(e.9. a contaclor coil togethcr

with all Ge conracts it drives) or may bc simply represented by a blcrck with th necessarry

termi nal s cl earl y marked. Di fferent thi cknesses of l i ne can be used to di ffcl cnti al e bel ween

power and control circuii conneclions.

'I'he

wiring diagram below is of the same starter shown

, _l _.

I llrr-.r I

-l l -rr I

i l t i l t

r l

l L i t I

I

l-.--.-.--J

--E-

for the

previous circuit diagram.

z - - - - - - a - - - - - \

r o r f . o o . t . r r . r , & . 1

+;i

(

t 14

A wiring diagram may be of a fairly simple circuit, but it is quite difficult to use it to work out

thc sequential opcration of the circuit. The purpose of a wiring diagram is to imtruct the wiring

mrn how to construct and connect the equipment. lt is of little use in trouble shooting apart from

idcntifying the cxact position of suspect components and tcrminals.

QUESTION

What are you to do if difficulties arise in locating a fault on an item of equipment and only a

wiring diagram is available?

ANSWER

It may well save time and trouble to convrt the wiring diagram into a much simpler and morc

useful circuit diagram. When converting a wiring diagram into a circuit diagram certain basic

rules and conventions should be followed.

l. Every sequence should be drawn from left to right and from top to bottom (where

prssible).

2. Each stage should be in order of occurrence from left to right.

3. All contacts and components which are in series should be drawn in a straight line

(where possible) with the component they conlrol.

4. All contacts and components which are in parallel should be drawn side by side and at

the same level to emphasise their parallel function.

5. All major components oprating at bus-bar voltage should be drawn at lhe same level

(or aligned horizontally) to help identify the rer;uired components quickly.

6. All contacts should be shown

'open'or 'closed'

as in their NORMAL or unenergiscd

condi ti on.

There are other conventions but lhese cover the main points of g<xrd systematic diagrams.

Bl ock, system, ci rcui t and wi ri ng di agrams are the basrc types i n gcneral use for el ectri cal

work. Other l ypes of di agram arc some ti mcs uscd to gi ve i nti rrmal ron for whi ch thc basi c

types ar unsui tatrl e (e.9. a pi ctori al vi cw of a c()nl poncnt).

You should study the ghip's electrical diagrams so as to gain an underslanding of them whcn

carrying out mainle nance or fault finrling. Ships' diagrams should be regarded as an csscntial

tgol when carryi ng out work on el ectri cal equi pment.

Eloctricd sefety

Before attempting any elecrrical work, there are mme basic safety precautions you must bar

in mind. The possible dangers arising from the misuse of electrical equipment are well known.

Electric shcck and fire can caus loss of life and damage to equipment.

Regul ati ons exi st to control the consl ructi on, i nstal l ati on, oJrrati on and mai nl enance of

el ectri cal equi pment so that dangcr i s el i mi nated as far as possi bl e. Mi ni mum acceptabl e

standards of safety are i ssued by vari ous hodi csj ncl udi ng nati onal govcrnrnents, i nte rnati on-

al governmental conventi ons (e.g. SOLAS), nati onal and i ntcrnati onal standards associ a-

ti ons (e.g. BSS and IEC), l earned soci eti es (e.g. IEE), cl assi fi cati on soci cti cs (e.g. Ll oyds),

etc. Where danger arises it is usually duc to accidcnt, neglect or somc other contravention of

the regulations.

Ships'staff must operate equipment in a safe nrannr and nraintain it in a safe condition at all

times. Failure to do so will causc dangcr with p,ossible disastrous consequenccs. Ships' staff

should keep in mind an essential list of DO's and DONT's when working with electrical

equi pment.

DO get to know the shi p' s el ectri cal systcm and equi pmcnt. Study shi ps' di agramsto pi npoi nt

the location of switches and protection devices supplying distribution boards and essential

i tems of eqdi pment. Wri te down thi s i nformati on i n a note book. Note the normal i ndi cati ons

on swi tchboard i nstruments so that abnormal operati on can be qui ckl y detected.

DO operate equipment according to manufacturcrs' recommendations.

DO maintain equipment according to manufacturers' recommendations or shipowners'

ts3Hffff:tll""iililil;. covers and doors are securety firted anrt ihar all botrs an<t firings

are fitted and tight.

DO i nform the Offi ccr of thc Watch beforc shutti ng"down equi pmcnt for mai ntenance.

r/ s

DO swi tch ttff and l ock off suppl i es. rcmove fuses. and di spl ay warni ng noti ccs bcfore

removi ng covers of equi pment for mai ntenance.

DO confi rm that ci rcui ts arc DEAD (by

usi ng a vol tage tcstcr) bcforc touchi ng conrJuctors

and t ermi nal s.

DON' T touch l i ve conductors under any pretext.

DON' T touch rotati ng parts.

DON' T l eave l i ve conductors or rotati ng parts exposed.

DON' T overl oad equi pment.

DON' T negl ect or abuse equi pment.

You should think

'safety'

at all times and so develop a safety conscious attitude. This may well

save your life and the lives of others. Most accidents occur due to a momentary loss of

concentration or attempts to short-circuit standard safety procedures. DO NOT let this

happen to YOU.

Ehctric shock

Nearly everyone has experienced an electric shock at some time. At best ir is an unpleasant

experi ence, at worst i t i s fatal . Anyone who has access to l i ve el ectri cal equi pment must be

fully aware of first aid and safety procedures related to electric shock as described in relevant

safety acts. copies of these safery procedures should bc displayed on board ship.

Electric shock is due to the flow of current through your body. This is ofien from hand to hand

or from hand to foot. A shock current as low as l5mA ac or dc may be fatal. Obviously the size

of shock current i s rel ated to the appl i cd vol tage and your body resi stance. Unfi rrtunarel y,

your body resi stance goes down as the appl i ed vol tage goes up. Thi s means that rhe shock

currenl is further increased at high voltages. The size of your body resistance also depends on

other factors such as your state of heal th. the degree of contact wi th l i ve wi res and thc

perspi rati on or dampness on y()ur ski n. l ' ypi cal dry ful l contact hody rcsi stancc i s about

5UnQ at 25V fal l i ng to abour 2(XXIQ ar 2-5(,V.

QUESTTON

What woul d the equi vhl ent shock currcnr l evel s be ar 25V and 250V?

ANSWNR

5mA and l 25mA.

Voltages of about filV and bekrw are regarded as reasonably safe for portablc hantl tools.

Thi s i s why speci al step-down i sol ati ng transfornrcrs are used wi th portabl c rrxl l s an{

handl amps.

' Ihese

transft)rmers suppl y the tool or l amp at I l 0V ac but because rhc seconcl ary

wi ndi ng i s cent re-t apped t o eart h, t he maxi mum shock vol t age t o cart h i s 55V.

El ectri c shock i s often accompani ed by fal l i ng. whi ch may causc adtl i ri onal physi cal i nj ury

and requi re fi rst ai d acti on, l f the shock vi cti m i s unconsci ous. resusci tati on must take pri ri ri ty

over fi rst ai d methods. Check the resusci tati on techni qucs di spl aycd on rhe cl ccrri c sho,ck

posters

di spl ayed on board.

Insulatiron resistance

Al l el ectri cal equi pment has i nsul ati on.

' l "hc

purpose of the i nsul ari on i s to kcep el ectri c

currents i n thc conductors and to prevent contact wi th l i ve wi res.

' Ihc

el cctri cal resi stance of

i nsul ati on must be very hi gh (MC2) to prevent currcnt

' l caki ng'

awry from conducttl rs.

Insul al i on resi stance i s the resi stancc of thc i nsul al i rl n measured (u) bctwecn conductor ancl

earth or (b) between conductor and other c(,nductor(s). The i nsuhti orr resi stancc i ncl udes

the resi stance of the i nsu.l ati on matcri al and al so the rcsi stancc of any surfucc dcposi ts of di rt.

oi l , moi sture, etc.

r n l u r a l r o n r a t r a t a n a a

Dat r aai t ar i l l nat a

l r l

I

I

:

U6

. . . l i a a l r r r . O c l a i t

Surfrcc depxits cnn rcducc the inculation resi$tsncc. Thc flow of leakugc curre ntlr through

ruch surfilce dc;xrsits is called

' TRACKING' ,

Equipment mu$t be nruintaincd in o clcrn

condition to prsvcnt trucking und to muintein a high value of insulation resistancc (usually

at

l cast I MO),

Inrulatkrn millcrills are non-mctallic and have vcry few of the generally good physicrl

propcrtics essocialed with mctnls. Insulation is adversely affected by many factors such ss

humidity. lemperelure. clcctrical and mechsnical stresl, vibrrtion, chemicals, oil, dirt end, of

coursct old uge.

Traditional insulstion malerisls include cotton. silk, papcr. ctc, Thcy msy bc cithcr dry or

trcelcd with euitable varnishcs or rcsins to cxclude moisturc and othcr harmful substrnccr.

Othcr materials include mica. glass fibre. etc., and morc modarn materirls such m PVC rnd

othcr photict and compounds. An cxtensivcly uscd insulant not nolmElly considercd rr en

inrulation matcrial is air.

The majority of insulation materials in common usc cannot withstand tcmpcraturcs much in

exccss of ltf0oC, All elcctrical equipmcnt heats up when,carrling lbarl current with thc

con$equcnt rise in tempcralure, This temperature rise is above that of the ambient ooling air

lemperuture, All electrical equipment is constructed and reted to work satisfactorily in a

maximum amhient uir temperature of 45' C (Lloyds),

Under these conditions the expcctcd

tcmperature rise will nol exceed the permitted temperature limit set for the insulation

mrterial, lt is therefore the insulation matcrial that dictates the maximum permitted opclst.

ing temperature of thc electrical equipment.

For thir purposc insulation is elassificd according to t[c maximum tcmpcrstu]c ot which it ir

refe io opcrate, Various clasEcs of ineulation are listed'in British Stbndards but normrlly only

clattcr A, E and B are uscd for marinc elcctrical cquipment, Thc mexlmum tcmpclsturc

rlbwcd for cach of thesc clarrer is:

CLASS A

E

B

55'C CLASS F 105.C

7rc H l$.c

&fC C l3{fC +

Thesc are stearly surfaee temperatures measured with equipment stopped and no flow of

cooling rir.

' llot

spot' temperatures of 105"C

(Clasr

A) and l30o(i

(Class

B) arCgencrrlly

scceptcd ar normal at the centre of coils and windings of machrnes with thesc rurfrcc

tempcreturcs, A machin operating continuously with these hot sErt tempratures would

hrve an expected life of l5 to 2() years before the insulation failed completely. Howevcr, thc

life would be halved firr every llPC above these allowed hrlt spol temperaturcs.

Tcsting

Thi s *cti rl n kxrks al thc vari ous el ccl ri cal tesl i nB operal i rl nr you may nced ttl carry out. and

at l he i nstrumenl s vou wi l l necd.

' l ' hc

mai n l ests are ti rr:

-

l nsul ati on Rcsi stancc

-

Ci rcui t Conti nui l v

-

Com;xrncnt Resi stancc

-

Vrrl tagc

-

Currenl

Inrulrtlon te$lnt

A mcl surenr*n, Jrt l hc i nsul ati on resi stunce gi vcs rl nc of thc besl gui dcs to rhe stal c of hcal rh

rl l cl cctri cal cqui pmcnt.

' [' hc

rcsi stance shoul d be mcasurcd hctwccn i nsul ated conductors

und curth. and hetwcc' n conducl ors.

An i nsul ati ol t l cstcr i s a hi gh rcl di ng rcsi sti l ncc nrel cr usi ng a hi gh tcsr vttl tagr,.

-

usuul l y 500V

dc.

' I' hc

l ssl r' (tl l l gc i s produccd ci thcr by un i ntcrnul hand-dri vcn gl .ncrut()r or by o bnttery

and cl ccl roni c rol l ugc changcr. A tcst vti l tagc trf 5(X)V dc i s sui tabl e ti rr tcsti ng shi ps'

equi pment rated rl l {(l V . Tcst vol tagcs of l (Ix)V und S{XIf V arc usctl for hi gh vol tagc systcms

on board ship.

t 17

7

---.t -----f_

Therc are rcvernl mnnufacturers of insulation testers available. thc MEGGE,R INSULA-

TION TESTER hcing one of the most common.

J"' tY

a

\.i'.

it

atlraft

ataa

a

Qr ' 1

6

Short thc probcr together, switch to

'M(l'

and turn the handle or prcs3 thc button or

rockerswitch. Thc pointcr should indicate

'0Q'

resistance. Some inrtrumcnts hrve r bettcry

chcck rwitch pooition also. The cquipment to be tcrtcd muit be disconncctcd and lockcd ofi

rmrding to rtandard rafety procedures.

A Mcggcr type lR terter can be uscd to chcck whcthcr the circuit to bc tcsted ir alive. Switch

thc inrtrument io

'MO'

and conncct the probcs to pairs of equipment tcrminalr. DO NOT

Prc$

thc button or lurn thc handle. lf the grinter deflects the circuit is'livc'. lf thc circuit it

'dead',

it ic then safe to press the button (turn

handle), Confirm that a rclirblc crrth

connoction ir obteincd by connecting lhe probcs lo two rcparatc carth

F)ints

on thc

cquipmcnt frame while testing for continuity.

Meacure and log the phase-to'pha*,e insulation rcsistance valucr. Thrce readingt should tr

mcarured:

U - V . V - W . W - U ,

Measure and log the phase-to-earth insulatitln resistance value's. Three readings should bc

measured:

u - E . v - E . w - E .

Insulation resistance decrcases wilh increase of temJrcrature .

1

t 18

rerrrtrn t l Oo

r aar at aaaa

IA

QUESTION

Why slrould thc measurcmcnt of the insulation resistrncc of r machinc ideally bc madc whilc thc

mrchinc is hot?

ANSWER

lnsulation bccomes more'leaky'

(its IR valuc falls) at high temperatures. So testing while hot

shows the realistic lR value at, or near, working temperature. lnsulation resistance can vary

considerably with changing atmosphericconditions. A single readinggives littlc information.

Flowever, the regular recording of insulation resistance readings may show a downward lrend

which indicates impending trouble which can be remedied by preventive maintenancc.

Exampl e of an IR l og:

Confhuity tcclin3

An insulation tester normally also incorporales a continuity test facilily. This is a low

resistance insirumcnt for mcasurinS, the continuity

(or otherwisc) of conductors. lt can bc

used to measure thc low resistancc of cables. motor windings. transformer windings, canhi[t

straps. etc. The pro,cedure for usc is much as for that of thc insulation lester.

PROVE the correct tl perati on of the i nstrumcnt.

ISOLATE and lock off the equipment io be tested

PROVE the equi pment to be dead.

Swi tch the i nstrumenr ro' Q' or' conti nui i y' . Connect thc probes to the ci rcui t. OPcrarc l hc

switch/handle and check the indication on the

'Q'

scale. Lng all readings.

aat a

Jat rll llTr Jai

C l a c U l l : x c . t C O r t a a l a O l

l i t l aa r aa- cal a l r a at t aact t

r p

In the case of three-phase motors and transformers. etc. the comparison betwecn readings is

usual l y more i nrportant than the ahsol ute val dc of the rcadi ngs. Al l rcadi rrgs shoul d trc

i denti cal

-

i f onc readi ng i s si gni fi cantl y smal l er than the others thi s coul d i ndi cate the

possi bi l i ty of short-ci rcui ted turns i n the wi ndi ng bei ng measured. Conversel y, a hi gh con-

ti nui ty resi stance val ue i ndi cates a hi gh resi stance faul t or an open-ci rcui t (e.g. a l oose

connecti on).

Some models of insulation/cohtinuity testers provide means to measure

'ac

voltage' and

resistance in the

'kQ'

range.

Multimcterc

Routine etectrical test work involves measuring amps, volts and ohms. This is most conve-

niently done using a multimeter with all the necessary functions and ranges.

'fhe

instrument

may be the traditional analogue type (pointer and scale) or the more modern digital type with

a numerical display.

Range selection can be by rotary selector switches or a range of push buttons depending upon

the model .

In al l i nstrument model s an i nternal battery i s fi tted for use when measuri ng resi stance.

Before measuring the resistance of a comp,onent it is essential rhat the componenr circuit is

switched off, locked off. and any capacitors discharged. The instrument is likely to be

damaged oiherwise.

The instrument should be proved for correcl operation before use. The manufacturets'

instructions should be carefully followed for this but a general procedure is as follows:

Use the CORRECT probe leads and insert into the correct sockets on the meter. lf the

multimeter is an ANALOCUE type: Ensure the pointer indicates zero

-

adjust if necessary.

Set selector switches to

'51'

and connect probe tips together. Pointer should deflecl to indicate

0Q

-

Adj ust tri mmi ngcontrol s. Check each resi stance range i n thi s way. Set sel ectorswi tch to

' acV' (hi ghest

range). Connect pi obes to a sui tabl e known l i ve suppl y (wi rh

CARE) such as

the el ectri cal workshop test panel . Poi ntcr shoul d i ndi cate correct vol tage.

xr al a, ana t l ' a

r af l acl aa r cal .

aa- I ncl aai i al

l a r o c r r a a r a

r aac aat r l l t cr ar

Instrument battery fai l ure i s checkecl wi th the i nstrument sel to read' Q' wi th the probe ti ps

connected together. lf the pointer fails to reach

'0Q'

after adjustment of the resistance range

adjust knob, the battery must be replaced. The instrument should be switched OFF when not

in use to conserve battery life.

I f t he mbl t i met er i s a DI GI TAL rypc:

Switch on and connect probe tips together. Sct selector switches to

'dcV'

(highest range).

Di spl ay shoul d i ndi cate zero

(Obcf

).

Rep.ot for al l

' dcV'

sel ector swi rch prsi ti ons anrl note

movement of the deci mal poi nt. Scparate probe ti ps. Sct scl cctor swi tches to' Q' (hi ghest

range). Di spl ay shoul d i ndi cat e' OL' (over-range) or' 1i l )' (depcnds upon model ). Connect

probe ti ps together

-

di spl ay shoul d i ndi cate zero (OOO). Repeat for al l

' Q'

sel ector swi tch

posi ti ons and notei movemenl of the deci mal ptl i nt. Set sel ector swi tches to

' acV'

(hi ghest

rangc). Connect protrcs to a sui tabl e known l i ve suppty. Di spl ay shoul d i nrJi catc c()rrecl

vol tage. Test the dc vol tage range al so and note thc pol ari ty i ndi cati on on the nt!.ter.

g t t a c l o i

6 f r t c h c s o l s ? t a Y

r r o o q c v

t oo oc v

t o o c v

I GCV

t OOhv OCv

ooot l

oo. o

o, oo

' o o o

o o o

|

/ 10

In:rrunrcnr hatrcrv fl i l ure i s i ndi catcd hy thc numcri c di spl ay. The tl i spl ay may i ncl ude' BT'

()r

the 6eci rntl poi nt may bl i nk. or some other di spl ay mcans may be used.

' I' he

i nstrumenl

shguld be switchc{

'OFF'

when not in usc ttl conserve baltery life.

These simple

'proving

tcsts' should be performed every time before using the instrument for

.real ' .

l t i s obvi gusl y rl ungerous to touch conductorb bel i evi ng them to be

' dead'

havi ng

checkcd thcm wi th a faul ty i nstrument.

To MEASURE RESTSTANCE the procedure to be a<l opted shoul d be:

PROVE the correct operati on of the i nstrument.

ISOLATE and lock off the equipment to be tested.

PROVE the equi pment to be dead'

SWTTCH the insrrument to the appropriate resistance range, connect the probes to'the

equipment and note the resistance value.

Disconnect the probes and switch the instrument to OFF.

To MEASURE VOLTAGE:

PROVE the crrrrect i nstrument operati on.

SWI' ICH the i nstrumenr ro the HIGHEST vol tage range (ei ther acV or dcV as appropri ate).

CONNECT the probes to the terminals being tested. Takc great care not to touch the probe tipl

and remember that the equipment being tested b LIVE.

NOTE rhe voltage reading" If a LOWER voltage range would give a more accurate reading'

adjust the selector switches accordingly.

No harm will be causerl to the instrumenl by operating the selector range swilches while still

connected ro a l i ve suppl y. BUT CREAT CARE must be taken nol to swi tch i nto ei ther thc

current or resistance mo{e. This woukJ almost certainly operate the instrumeni overlord

device and may cause severe damage to the instrument and danger to yourself. Take your

ti me t6 oprate the sel ector swi tches rturi ng the operati on and THINK about whal ydu are

doi ng.

Di sconnect the probes and swi tch the i nstrument to' OFF' '

To MEASURE CURRENT:

Most test i nsl ruments can onl y measure up to a fcw amps (usual l y l 0A or l ess)'

' I' he

cufrcnt

measuring facility is inrenderl only for light-current componenls, and in particular, fol

electroniC circuits. The insrrument will almost certainly be damaged if it is used to fieasurc

the current of motors and other power ci rcui ts.

The basi c currenr range can be exl ended by usi ng external shunts (dc) and currenl transfor'

mers (ac).

' [hcse

acccssrtri es are gene ral l y purchased separatel y from the i nsl rument manu'

facturers.

The procedure trt be used lo measure. currenl in a light'current circuit is as follows:

PROVE thc corrcct i nstrument operati on.

SWl l ' Cl l rhc i nsrrumcnr rtr thc l l l Gtl EsTcurrent range

(ei ther acA ordcA as appropri ate).

Turn

()Fl -

thc powcr ttt the ci rcui l to be tested and di scharge al l capaci tors.

OPEN tl re ci rcui t i n whi ch current i s trl be measured

-

removi ng a fusc-l i nk often gi ves a

convcni cnt poi nl ti l r currcnt measurcment.

Securel y conncct the prrl bes i n seri es wi rh the kratl i n whi ch current i s to be measured. Turn

ON. rhe power to the i i rcui r bei ng tested, R.l ,.l l hc currcnt val ue ol i the meter di spl ay. Turn

OFF rhi power to rhe circuit being testerJ and discharge all capacitgrs. Disconnect lhc tesl

probes and swi rch the i nstrument to OFF. Reconn.ect the ci rcui t thut was bei ng testcd.

I t ] " i

3 &

r l l l

Diodc tcsts

Di odes can be tested usi ng a di gi tal type i nstrumenr usi ng the fol l owi ng pr<redure:

PROVE the correct i nstrument operati on.

SWITCH the instrument to diode test.

--ff

In thi s test the i nstrument dri ves a smal l dc current (a few mA) through the di ode whi l e i t al so

acts as a vol tmeter to measure the vol t-drop across i t. If l he dbde i s sti l l i n ci rcui t. turn off the

power to the circuit, discharge all capacitors and remove fuses.

CONNECT the probes across the diode.

READ the forward volt drop across the diode. This should be between 500 and 9(Xf mV for a

healthy silicon diode. REVERSE the probe connections and the display should indicate

'over-range'.

lf the display indicates over-range in both directions the diode is

'open-circuit'

faulted.

If the display indicates less than I V in both directions, the diode may be short-circuit faulted.

The associated diode circuitry may be giving false readings and the diode must be discon-

nected from the circuit then retested.

Currcnt clrmpmcters

Power currents can be measured simply by means of a clampmeter. The instrument

'tongs'

are clipped round a single insulated conductor

-

the circuit is not interrupted. The current is

read off either from a digital display or an analogue display.

Many modern cl ampmeters are vi rtual l y mul ti meters wi th the addi ti on of faci l i ti es to measure

voltage and resistance as well as measuring currents up to lffnA.

CARE must be taken when measuri ng the current i n UNINSULATED conductors.

QUF^STION

What woul d acl ampmeter i nrJi cate i f cti ppeO around,a.3-core cabl c whi ch i s known i o bc

carrying l00A ac to a motor?

l lrz

ANSWER

Zero. This is because the clampmeter monitors the magnetic flux around the cable which is

produced by the current. ln a balanced 3-core (or 2-core for that matter) cablc, the net flux is

zero

-

hence no indication. This is why the clampm0ter is only connected arcund one

conductor.

Live-llm teslcrs

When equipment is to be inspected for maintenance it is important that supplies be switchcd

OFF and locked OFF. The equipment must then b PROVED to be dead ro eliminate thc

danger of electric shock. A live-line (or voltage) tester is a simplc device to check whcther or

not a voltage exists at lerminals.

Live-line testers are of various types. Some light up (e.g. screwdriver type with a neon

indicator). some make a noise, others operate mechanical indicators (flags) to indicate thc

approximate value of voltage. It is important that voltage ibsters themselves be PROVED to

operale correctly before use. This can be conveniently carried out at lhe e lectrical workshop

test panel.

Home-made test lamps should not be used as they can be dangerous.

Gcncrd dccfricrl mrfoilenemc

All equipment is subject to wear and tear. ventually reaching rhe end of its useful life when it

must be replaced. As equipme nt nears the end of its lifc its condition can delerioratc to such

an extent as to be a danger to prsonnel and other plant. The purpose of maintename,

therefore, is to extend the useful life by repair and/or replacement of defective parts and lo

maintain it in a safe and serviceable condition.

The marine environment is particularly arduous for electrical equipment due to the damp.

salt'laden atmosphere. extremes of temperature and constant vibration. Shipboard equip-

ment is in particular need of correct maintenance. The continuous operation of equipment on

board ship demands high operating efficiency and optimum economy in ortler to keep down

costs io maintain financial competitiveness.

Nearl y al l equi pment NEEDS mai ntenance. An effi ci ent mai ntenance engi neer must

tct

to

know his plant. He.must be able to check shipc'drawings and diagrams and relate rhiin to

actual equipment. Equipment must be kept under continuous observation so that normel

heahhy operating conditions become known. and abnormal operation becomes quickly

apparent. Faults can then be pin-pointed and corrected before a breakdown occurs. Maintc-

nance can be classified as: Breakdown maintenance. Planned maintenancc and Condition

moni tori ng.

Breakdown mai ntenance (correcti ve

mai ntenance) i s that i n whi ch equi pment i s l eft un-

touched until a breakdown occurs. At this time the equipme nt is re paired or replaccd and any

other speci fi ed mai ntenance prrxedure carri ed out.

Pl anned mai ntenance (preventi ve

mai ntenance) i s that i n whi ch equi pment i s regul arty

inspected and maintained according to a laid rlown rimetable and se t of procedurer speiifyin!

the actual work to be done at parti cul ar ti mes i n order to prevent fai ture of equi pment.

Condi ti on moni tori ng (anothe r form of preventi ve mai ntenance) i s that i n whi ch equi pment

i s regul arl y moni torcd and tested. Whcn moni tori ng i ndi cates that breakdown i s i mmi ncnt,

the equipment is repaired or replaced and any other specified maintenance proccdures

carri ed out. Regul ar i nsul ati on testi ng and vi brati on testi ng arb two forms oi condi ti on

moni t ori ng.

There are several di sadvantages i n breakdown mai ntenance:

l . A seri ous breakdown of equi pment may cause suffi ci ent down ti me to put rhe shi poul of

commi ssi on unti l i t i s repai red.

2. If seve ral .breakdowns occur si mul taneousl y the avai l abl e manpower on board shi p may

not be abl e to cope adequatel y, resul ti ng i n del ays.

3. Some i l ems of equi pment may need thc speci al i st servi ces of the manufacturer to carry

out repai rs whi ch may cause furrher del ays.

Pl anned mai ni enancc i s carri ed out at fi xed regul ar i nterval s whether rhe equi pment needs i t

or not and the ai m i s to prevent breakdown. Thi s type of mai ntenance has the fol l owi ng

advantages:

l. Fewcr brcakdowns and reduced tlown time prlxlutes highdr levels.of operating cffi-

ci ency.

l / r 3------s-

2. Mai ntenancc i s carri cd out l t ti mcs favourabl c to the rrpcrati on of thc pl ant,

3. More effecti ve l atxrur uti l i sul i on bccause mai ntenance i s carri cd oui at ti me s l avourahl e

to ships' staff.

4. Repl acement equi pment can be ordered i n advance.

5. Equi pment i s mai ntai ncd i n a safe condi ti on wi th reduced possi bl c di tngcrs.

6. Where speci al i st manufacturers' scrvi ccs are requi red these can be obtai ned al pre-

pl anned and conveni ent ti mes.

7. Repl acement of short l i fe components at schedul ed ti mes.

Condi ti on moni tori ng i s al so carri ed out at fi xed rcgul ar i nterval s. The ai m i s to forestal l

breakdown by predicting probable failure from the TREND shown by the monitoring results.

The advantage of this type of maintenance is that equipment is not subjected to unnecessary

maintenance.

Equipment is regularly condition-monitored according to a monitoring schedule. Measure-

ments are taken of i nsul ati on resi stance. temperature and vi brati on (of motoqs). Contacts

and other parts subject to deterioration are inspected. All findings are recortled in an

hi stori cal record fi l e. No mai ntenance i s carri ed out unti l fi n<fi ngs i ndi cate that i t i s ahsol utel y

necessary. The equi pment i s then ei ther repl aced. repai red or subj ected l rl a maj or overhaul

as specified on a

job

card.

A ricords system is required. The recorcled measurements of insulalion resistance may show

a fal l i ng trend i ndi cati ng a progressi ve degradati on of i nsul ati on. The equi pment shoul d be

i nspected and repai red before the i nsul ati on resi stance fal l s to a dangerousl y kl w val ue.

The recorded measurements of the vibration of a motor may follow a rising trend indicating

progressive bearing deterioration. Bearings should be replaced before a final bearing failure

(rccurs..

lmmediate repair or maintenance is probably not necessary but should be put in hand

at the earl i est conveni ent momnl .

I

l t 4

S-ar putea să vă placă și

- Ship Automation ppt.1Document17 paginiShip Automation ppt.1Uchenna Claudio100% (1)

- Class 2 Electrical Sorted QuestionsDocument8 paginiClass 2 Electrical Sorted QuestionsPrakhyati RautÎncă nu există evaluări

- Electricity Objective-Watermark PDFDocument135 paginiElectricity Objective-Watermark PDFsyed muffassirÎncă nu există evaluări

- 1.H2219-20 MSBD (Rev.e - 11.04.11)Document138 pagini1.H2219-20 MSBD (Rev.e - 11.04.11)Aleksandr AndreevÎncă nu există evaluări

- Putri Iona - Survey StatusDocument28 paginiPutri Iona - Survey StatusDiana Triswasti KumariÎncă nu există evaluări

- Electric Propulsion SystemDocument2 paginiElectric Propulsion SystemABIR MUKHERJEEÎncă nu există evaluări

- 11S Emergency Procedures - Engine FailureDocument11 pagini11S Emergency Procedures - Engine FailureashishÎncă nu există evaluări

- #Marine Electricity GenerationDocument29 pagini#Marine Electricity GenerationThe Linden Tree StoreÎncă nu există evaluări

- HV Manual MCADocument262 paginiHV Manual MCAsocrates19582405100% (1)

- Duties of 2nd Engineer On ShipDocument9 paginiDuties of 2nd Engineer On ShipAbebè TeferiÎncă nu există evaluări

- Meo Met OralsDocument18 paginiMeo Met OralsAnjali ChandravanshiÎncă nu există evaluări

- YD Series Three Phase Asynchro Conveyor MotorDocument18 paginiYD Series Three Phase Asynchro Conveyor MotorAditya SafarudinÎncă nu există evaluări

- Standard Safety High Voltage 12Document4 paginiStandard Safety High Voltage 12clinthenÎncă nu există evaluări

- MARINE OIL SEPARATOR PPT 1st ReviewDocument12 paginiMARINE OIL SEPARATOR PPT 1st ReviewretechÎncă nu există evaluări

- Shipboard Electrical EquipmentDocument16 paginiShipboard Electrical EquipmentastefanovichÎncă nu există evaluări

- Bow ThrusterDocument19 paginiBow ThrusterAnakin SkywalkerÎncă nu există evaluări

- Steering SOLAS RegulationsDocument2 paginiSteering SOLAS Regulationsmy print100% (1)

- Electrical Survey:: For UMS OperationDocument3 paginiElectrical Survey:: For UMS OperationSid ACHARYAÎncă nu există evaluări

- Service Bulletin No. 10-08 - Aker SolutionsDocument6 paginiService Bulletin No. 10-08 - Aker SolutionsReda HmrÎncă nu există evaluări

- All Electric Ship Integrated Power Systems PDFDocument6 paginiAll Electric Ship Integrated Power Systems PDFMario BogdanovicÎncă nu există evaluări

- Topic 3-Steering - Part1Document27 paginiTopic 3-Steering - Part1TasmiaH.Shoily100% (1)

- MS-MP00018 Dead Ship Start-Up and Blackout Restart Procedures For BW Joko Tole Revised 10.11.2020Document16 paginiMS-MP00018 Dead Ship Start-Up and Blackout Restart Procedures For BW Joko Tole Revised 10.11.2020Imam Saja Dech100% (1)

- MEO Orals On Marine Electro Technology Function 5Document19 paginiMEO Orals On Marine Electro Technology Function 5Rajeev ValunjkarÎncă nu există evaluări

- What Is Azipod Propulsion System On Ship Marine InsightDocument4 paginiWhat Is Azipod Propulsion System On Ship Marine InsightAffan KhalifÎncă nu există evaluări

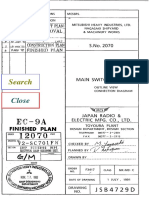

- EC-9A Main SwitchboardDocument130 paginiEC-9A Main SwitchboardABDUL GHAFOORÎncă nu există evaluări

- Where Does NBDP Fit in GMDSS and How To Use ItDocument14 paginiWhere Does NBDP Fit in GMDSS and How To Use ItKunal SinghÎncă nu există evaluări

- Autopilot System: System, The Potentiometer Is Fitted Inside The Feedback UnitDocument3 paginiAutopilot System: System, The Potentiometer Is Fitted Inside The Feedback UnitGAMMA FACULTYÎncă nu există evaluări

- Report of Electrical Desing in A VesselDocument71 paginiReport of Electrical Desing in A VesselNelson Aguirre Bravo100% (1)

- Function 5 ELECTRICAL Quick Reference NotesDocument81 paginiFunction 5 ELECTRICAL Quick Reference NotesAshok Kumar0% (1)

- Ship's Emergency PowerDocument3 paginiShip's Emergency Powerrajjsmit1989Încă nu există evaluări

- Topic: Bulkheads Learning ObjectivesDocument7 paginiTopic: Bulkheads Learning Objectiveskarthika sÎncă nu există evaluări

- Textbook For The Third Engineers (3648)Document29 paginiTextbook For The Third Engineers (3648)Sejo HodzicÎncă nu există evaluări

- MEO Class 4 Safety Questions SpecialDocument23 paginiMEO Class 4 Safety Questions SpecialBhalchandra ChandakkarÎncă nu există evaluări

- Live Graving Dry DockDocument36 paginiLive Graving Dry DockAshiq AbdullahÎncă nu există evaluări

- Motors: Why Starters Are Not Used For Land Based Installations?Document12 paginiMotors: Why Starters Are Not Used For Land Based Installations?avm4343100% (1)

- Banks Have Enhanced Many of Their Customer-Facing, Front-End Operations WithDocument18 paginiBanks Have Enhanced Many of Their Customer-Facing, Front-End Operations WithDivyeshJhaÎncă nu există evaluări

- Accommodation Ladder NewDocument9 paginiAccommodation Ladder NewBrian Voyd RebitoÎncă nu există evaluări

- Automation Monitoring and Alarms of Steering SystemDocument7 paginiAutomation Monitoring and Alarms of Steering SystemAlden Camasosa100% (1)

- Sounding of PipeDocument12 paginiSounding of Pipemyst3rioÎncă nu există evaluări

- Marine Electrical Power System: by Dr. Oladokun Sulaiman Olanrewaju, Ceng, CmarengDocument17 paginiMarine Electrical Power System: by Dr. Oladokun Sulaiman Olanrewaju, Ceng, CmarengMd Rodi BidinÎncă nu există evaluări

- Function of Thermostatic Expansion Valve in Refrigeration SystemDocument5 paginiFunction of Thermostatic Expansion Valve in Refrigeration SystemSumit SinhaÎncă nu există evaluări

- Steering Gear SystemsDocument23 paginiSteering Gear SystemsEzy WaqaÎncă nu există evaluări

- Marine Electro-Technology Test Part1Document6 paginiMarine Electro-Technology Test Part1Grid LockÎncă nu există evaluări

- Ensure Vessel Compliance With EU MRV + IMO DCS Requirements of Data Submission For The Entire YearDocument5 paginiEnsure Vessel Compliance With EU MRV + IMO DCS Requirements of Data Submission For The Entire YearLovien PattathilÎncă nu există evaluări

- Engine MachineriesDocument18 paginiEngine MachineriesNabu NabuangÎncă nu există evaluări

- Solved Numericals in Electrical Topics MEO CLASS 2Document23 paginiSolved Numericals in Electrical Topics MEO CLASS 2sangeet singh Bhanwera100% (1)

- 30 Types of Navigation Equipment and Resources Used Onboard Modern ShipsDocument10 pagini30 Types of Navigation Equipment and Resources Used Onboard Modern ShipsSuiluj Zednanreh100% (1)

- Ways of Starting and Testing Emergency GeneratorDocument4 paginiWays of Starting and Testing Emergency Generatornarendra_katdareÎncă nu există evaluări

- 1.2 - Comparison of Slow Medium and High Speed EnginesDocument6 pagini1.2 - Comparison of Slow Medium and High Speed EnginesNandani Shreya100% (1)

- Main Switch Board (MSB) Safeties, Protection and MaintenanceDocument9 paginiMain Switch Board (MSB) Safeties, Protection and MaintenanceRajeev ValunjkarÎncă nu există evaluări

- 2007 Kamewa CPP System PDFDocument4 pagini2007 Kamewa CPP System PDFsameh farghaly100% (2)

- Ekm Motor Class 2Document84 paginiEkm Motor Class 2Anonymous 4ylE57C6100% (1)

- PLECS-piece-wise Linear Electrical Circuit Simulation For SimulinkDocument6 paginiPLECS-piece-wise Linear Electrical Circuit Simulation For Simulink曾乙申Încă nu există evaluări

- ECE 306 Manual 1 MergedDocument13 paginiECE 306 Manual 1 MergedErwin PiaÎncă nu există evaluări

- PLECS-piece-wise Linear Electrical Circuit Simulation For Simulink PDFDocument6 paginiPLECS-piece-wise Linear Electrical Circuit Simulation For Simulink PDF曾乙申Încă nu există evaluări

- SY203 DocumentDocument9 paginiSY203 DocumentSyer Khomainie Mohamad YakopÎncă nu există evaluări

- ProtectionDocument79 paginiProtectionNishant Anthwal100% (1)

- Inside Macintosh Hardware 198502Document38 paginiInside Macintosh Hardware 198502Juan Felipe LondoñoÎncă nu există evaluări

- Chapter 8Document9 paginiChapter 8cheraziziÎncă nu există evaluări

- SmibDocument27 paginiSmibSwagat PradhanÎncă nu există evaluări

- BCIAG Info HD308S2 en 18 PDFDocument1 paginăBCIAG Info HD308S2 en 18 PDFBacamarteÎncă nu există evaluări

- Galvanometer 1 PDFDocument22 paginiGalvanometer 1 PDFBacamarteÎncă nu există evaluări

- EMI Filter DesignDocument12 paginiEMI Filter DesignBacamarteÎncă nu există evaluări

- Short Circuit Presentation Lecture 14 SC Calculations According To Standard IEC 60909Document41 paginiShort Circuit Presentation Lecture 14 SC Calculations According To Standard IEC 60909BacamarteÎncă nu există evaluări

- TH - EnglishDocument87 paginiTH - EnglishBacamarteÎncă nu există evaluări

- 04 Power Supply SourcesDocument62 pagini04 Power Supply SourcesBacamarteÎncă nu există evaluări

- Combined Impact and Attrition MethodDocument7 paginiCombined Impact and Attrition MethodBernadette Beltran0% (2)

- Advances in Carbon Nanotube N-Type Doping - Methods, Analysis and ApplicationsDocument37 paginiAdvances in Carbon Nanotube N-Type Doping - Methods, Analysis and Applicationslong rangeÎncă nu există evaluări

- The Threaded Style BackDocument6 paginiThe Threaded Style Backsharif339Încă nu există evaluări

- Aerzen Rental Covers Temporary Air Requirements: Dear ReadersDocument4 paginiAerzen Rental Covers Temporary Air Requirements: Dear ReadersFatih YAŞARÎncă nu există evaluări

- Substrate Integrated Waveguide Microwave Encyclopedia Microwaves101Document5 paginiSubstrate Integrated Waveguide Microwave Encyclopedia Microwaves101Dr-Pritam Singh BakariyaÎncă nu există evaluări

- The Starting SystemDocument20 paginiThe Starting SystemRuth MwendaÎncă nu există evaluări

- Universiti Kuala Lumpur Ccb10702 Material Balances Tutorial 2Document2 paginiUniversiti Kuala Lumpur Ccb10702 Material Balances Tutorial 2Surendra Louis DupuisÎncă nu există evaluări

- DPS Phy - Set - ADocument3 paginiDPS Phy - Set - AscÎncă nu există evaluări

- L Series Lubricated Reciprocating Air Compressors and BoostersDocument4 paginiL Series Lubricated Reciprocating Air Compressors and Boostersatorresh090675Încă nu există evaluări

- User's Manual S10 Series Inverter: Chapter 1 SummaryDocument72 paginiUser's Manual S10 Series Inverter: Chapter 1 SummaryTruongAnÎncă nu există evaluări

- Specification Aeration BlowerDocument52 paginiSpecification Aeration BlowerPendeta MudaÎncă nu există evaluări

- Surface Preparation General Theory: Resists The Seperation of Two Surfaces in Touch)Document5 paginiSurface Preparation General Theory: Resists The Seperation of Two Surfaces in Touch)get5rajesh100% (1)

- SH-01-2018 Wiring & Cable LayingDocument82 paginiSH-01-2018 Wiring & Cable LayingMd. Nobin KhanÎncă nu există evaluări

- 3.3 Busbar Protection SchemesDocument13 pagini3.3 Busbar Protection SchemesAgu prasathÎncă nu există evaluări

- Physics - Reflection & Refraction: Sahil KhandareDocument11 paginiPhysics - Reflection & Refraction: Sahil KhandaressskÎncă nu există evaluări

- Ampacity Calculator RevODocument40 paginiAmpacity Calculator RevOshepyÎncă nu există evaluări

- Silicone ChemistryDocument12 paginiSilicone ChemistryPratiksha PednekarÎncă nu există evaluări

- Silvertop Oxygen SensorDocument1 paginăSilvertop Oxygen SensorJustin LeoÎncă nu există evaluări

- Welding InspectorDocument5 paginiWelding InspectorqaqcnaviÎncă nu există evaluări

- 1 Detail: Gr. Elettrogeno Per Trattore ZG 100/3Document3 pagini1 Detail: Gr. Elettrogeno Per Trattore ZG 100/3npÎncă nu există evaluări

- Application Guide For Selecting Ac Motors Capable of Overcoming Fan Inertia Fe 1800Document8 paginiApplication Guide For Selecting Ac Motors Capable of Overcoming Fan Inertia Fe 1800cavasqueÎncă nu există evaluări

- Electronics Interview QuestionsDocument8 paginiElectronics Interview QuestionsshyamÎncă nu există evaluări

- q1 m6 Heat Temperature Activity Sheet Summative TestDocument5 paginiq1 m6 Heat Temperature Activity Sheet Summative TestALLYSA JANE SIAÎncă nu există evaluări

- Hot Bolt Clamp 8pp BrochureDocument8 paginiHot Bolt Clamp 8pp BrochureAlaxxiÎncă nu există evaluări

- Wa0010.Document6 paginiWa0010.Zaid Hasan KhanÎncă nu există evaluări

- Introduction LetterDocument2 paginiIntroduction Letterbllimbani100% (1)

- Wheelchairchart - 7 31 19Document4 paginiWheelchairchart - 7 31 19lucholadeÎncă nu există evaluări

- Dehumidifier: User'S ManualDocument20 paginiDehumidifier: User'S ManualgaberleÎncă nu există evaluări

- Sitrans T: Unrestricted © Siemens AG 2016 Siemens - Tld/keywordDocument56 paginiSitrans T: Unrestricted © Siemens AG 2016 Siemens - Tld/keywordfredyÎncă nu există evaluări

- A.s.t.m.22 Manual On The Use of ThermocouplesDocument312 paginiA.s.t.m.22 Manual On The Use of ThermocouplesAR RmsÎncă nu există evaluări