Documente Academic

Documente Profesional

Documente Cultură

SN756 2005-02 e

Încărcat de

Christopher Lloyd100%(1)100% au considerat acest document util (1 vot)

2K vizualizări4 paginiSMS STANDARD

Titlu original

SN756_2005-02_e

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentSMS STANDARD

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

2K vizualizări4 paginiSN756 2005-02 e

Încărcat de

Christopher LloydSMS STANDARD

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

February 2005

High-pressure hoselines SN 756

Dimensions in mm

1 Field of application

The hoselines of this standard are used for high-pressure hydraulic systems operating on mineral-oil basis and with water-

glycol emulsion, and for light fuel oil, lubricating oils, water and air. In air systems application is only up to a max. pressure of

50 bar.

The hoselines are suitable for a temperature range from -40 C to +100 C.

These hoselines are comparable and interchangeable with the corresponding types of Aeroquip, Dunlop and Argus

and therefore shall be used with preference.

2 Designation examples (for further combinations see page 2, item 4)

Type A (from DN 6 to DN 40) Type B (from DN 6 to DN 8)

for welding cone couplings for solderless pipe couplings

Designation of a complete high-pressure Designation of a complete high-pressure

hoseline (4H), type A, of nominal size DN 16 hoseline (H), type B, of nominal size DN 6 for

and length of 1000 mm: outside pipe diameter d3 = 8 mm and length of 500 mm:

Hoseline SN 756 - 4HA 16 x 1000 Hoseline SN 756 - HB 6 x 8 x 500

Type C (from DN 12 to DN 40) Type D (from DN 12 to DN 40)

for SAE flanged connection 6000 psi for SAE flanged connection 6000 psi

Designation of a complete high-pressure Designation of a complete high-pressure

hoseline (4H), type C, of nominal size DN 20 hoseline (4SH), type D, of nominal size DN 25

and length of 1000 mm: and length of 1000 mm:

Hoseline SN 756 - 4HC 20 x 1000 Hoseline SN 756 - 4SHD 25 x 1000

Type E (from DN 12 to DN 40) Type F (from DN 6 to DN 32)

for SAE flanged connection 6000 psi for welding cone couplings

Designation of a complete high-pressure Designation of a complete high-pressure

hoseline (4SH), type E, of nominal size DN 32 hoseline (H), type F, of nominal size DN 8

and length of 1000 mm: and length of 1000 mm:

Hoseline SN 756 - 4SHE 32 x 1000 Hoseline SN 756 - HF 8 x 1000

Type G (from DN 6 to DN 32)

for welding cone couplings

Designation of a complete high-pressure hoseline (4H), type G, of nominal diameter DN 12 and length 1000 mm:

Hoseline SN 756 - 4HG 12 x 1000

For footnotes see page 4 Continued on pages 2 to 4

Bearbeitet:

Normung

The reproduction, distribution and utilization of this document as well as the disclosure of its content to others

without prior explicit written consent of SMS Demag AG is prohibited. Holder has to protect this document

against unauthorized withdrawal of third parties. Offenders will be held liable for the payment of damages.

All rights reserved in case of patent/utility model/trademark protection.

18.07.01

N

o

g

u

a

r

a

n

t

e

e

c

a

n

b

e

g

i

v

e

n

i

n

r

e

s

p

e

c

t

o

f

t

h

i

s

t

r

a

n

s

l

a

t

i

o

n

I

n

a

l

l

c

a

s

e

s

t

h

e

l

a

t

e

s

t

G

e

r

m

a

n

-

l

a

n

g

u

a

g

e

v

e

r

s

i

o

n

o

f

t

h

i

s

s

t

a

n

d

a

r

d

s

h

a

l

l

b

e

t

a

k

e

n

a

s

a

u

t

h

o

r

i

t

a

t

i

v

e

T

h

i

s

c

o

p

y

w

i

l

l

n

o

t

b

e

u

p

d

a

t

e

d

i

n

c

a

s

e

o

f

c

h

a

n

g

e

s

!

Page 2

SN 756 : 2005-02

3 Specification in bills of materials (please absolutely follow instructions below)

Complete hoselines are specified in the bill of materials on AP (order item) level. This means that the hoseline components

(hose and fittings, if necessary also heat protection hose) are specified only by the operations scheduling department on

AUP (order sub-item) level.

If hoselines are subsequently equipped with heat protection, the heat protection hose is specified in the bill of materials on AP

(order item) level with reference to the respective hoseline.

Hoselines of DN 40 cannot be attached (pressed) at SMS Demag AG and for this reason are ordered as complete units.

4 Overview of combinations of hose fittings

The following standardised combinations shall be used with preference at SMS Demag AG.

Shaded boxes indicate hoselines that have identical fittings at both hose ends.

Nipple 2

Type

A B C D E F G

A

HA 6 and 8

4 HA 12 to 20

4SHA 25 to 40

HAB 6x6 to 8

-

-

-

4 HAC 12 to 20

4SHAC 25 to 40

-

4 HAD 12 to 20

4SHAD 25 to 40

-

4 HAE 12 to 20

4SHAE 25 to 40

HAF 6 and 8

4 HAF 12 to 20

4SHAF 25 and 32

HAG 6 and 8

4 HAG 12 to 20

4SHAG 25 and 32

B

HB 6x6 to 8

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

C

-

4 HC 12 to 20

4SHC 25 to 40

-

4 HCD 12 to 20

4SHCD 25 to 40

-

4 HCE 12 to 20

4SHCE 25 to 40

-

4 HCF 12 to 20

4SHCF 25 and 32

-

4 HCG 12 to 20

4SHCG 25 and 32

D

-

4 HD 12 to 20

4SHD 25 to 40

-

4 HDE 12 to 20

4SHDE 25 to 40

-

4 HDF 12 to 20

4SHDF 25 and 32

-

4 HDG 12 to 20

4SHDG 25 and 32

E

-

4 HE 12 to 20

4SHE 25 to 40

-

4 HEF 12 to 20

4SHEF 25 and 32

-

4 HEG 12 to 20

4SHEG 25 and 32

F

HF 6 and 8

4 HF 12 to 20

4SHF 25 and 32

HFG 6 and 8

4 HFG 12 to 20

4SHFG 25 and 32

N

i

p

p

l

e

1

G

HG 6 and 8

4 HG 12 to 20

4SHG 25 and 32

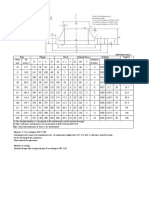

5 Technical data for hoselines

For types A, B, F, G (24 cone coupling connection)

Operating pressure

bar DN

Pipe

connection

d1

min.

d2

max.

d3

2)

d4

3)

d5

l4

- 8

l5

- 8

Bending

radius

rmin

s

dynamic static

4)

6 6 - - - -

8 8 - - - - 6

10

6,2 15,7

10 M18 x 1,5

21

22 39

100

22

400 600

H

8 12 7,7 17,3 12 M20 x 1,5 22 24 39 115 24 350 560

12 16 12,3 25,9 - M24 x 1,5 28 25 50 230 30 415 660

16 20 15,5 29,0 - M30 x 2 32 30 55 250 36 350 500 4H

20 (19) 25 18,6 33,0 - M36 x 2 37 34 63 300 46 350 500

25 30 25,0 39,9 - M42 x 2 48 41 80 340 50 380 550

32 (31) 38 31,4 47,1 - M52 x 2 57 52 98 460 60 350 500 4SH

40 (38) - 37,7 55,1 - M68 x 2 62 - - 560 80 290 420

For types C, D, E (with SAE connection)

Operating pressure

bar DN

SAE

connection

6000 psi

d1

min.

d2

max.

d5

l4

- 8

l5

- 8

Bending radius

rmin

dynamic static

4)

12 12,3 25,9 29 25 58 230 415 660

16

1/2

15,5 29,0 32 26 58 250 350 500 4H

20 (19) 3/4 18,6 33,0 38 30 66 300 350 500

25 1 25,0 39,9 49 39 78 340 380 550

32 (31) 31,4 47,1 57 53 105 460 350 500 4SH

40 (38)

1 1/2

37,7 55,1 62 58 115 560 290 420

For footnotes see page 4

Page 3

SN 756 : 2005-02

6 Special designations

The angular position on hoselines with elbow fittings at both ends (types D to G) is determined as described below.

Look along the hoseline with the rear fitting (the distant one) pointing upward.

Then specify the angle between the rear fitting and the front fitting going in

clockwise direction.

For example, front fitting at 140 (this angle is specified in the bill of materials),

angle tolerance 5.

Hoseline SN 756 - 4SHDE 32 x 800 - turned by 140

7 Standard lengths for hoselines

DN l1

6 315

8

400

12

500

16

630

20 (19)

800

25

1000

32 (31)

1250

40 (38)

1400 1600 1800 2000 2500 3150 4000

Permissible length deviations as in DIN 20066

l1

up to 630

above 630

to 1250

above 1250

to 2500

above 2500

to 8000

above 8000

DN25

+ 7

- 3

+12

- 4

+20

- 6

DN32 + DN40

+12

- 4

+20

- 6

+25

- 6

+ 1,5%

- 0,5%

+ 3%

- 1%

8 Weights

Basic weights of hoselines with corresponding connections

Weight in kg per 1000 mm of length

Type

H6x6 H6x8 H6x10 H8 4H12 4H16 4H20 4SH25 4SH32 4SH40

A - - 0,510 0,580 1,27 1,77 2,47 3,40 4,63 6,22

B 0,430 0,500 - - - - - -

C 1,17 1,61 2,05 3,28 4,59 6,02

D 1,26 1,61 2,21 3,32 4,79 6,32

E

- - - -

1,29 1,81 2,27 3,60 4,91 7,04

F 1,31 1,85 2,39 3,92 5,41

G

- - 0,510 0,600

1,29 1,83 2,37 3,80 5,19

-

Page 4

SN 756 : 2005-02

Referenced standards

DIN 20066 Fluid power systems; hose assemblies, dimensions, requirements

Further standards

SN 532-1 SAE flanges with flanged welding neck, 3000 PSI and 6000 PSI; flanged joint, flange coupling

SN 532-2 SAE flange, semiflanges, solid flange, flanged welding necks, blind collar

SN 544 Low-pressure hoselines

SN 757 High-pressure hoselines; hoses

SN 758 High-pressure hoselines; hose fittings, types A to G

SN 759 High-pressure hoselines; male studs, weld-on sockets

Revision of February 2005 Previous editions

Addition of temperature range. SN 543, sheet 1: 1965-05

Editorial revision. SN 756: 1967-09, 1969-12, 1971-09, 1974-02,

1975-08, 1976-04, 1978-01, 1979-12,

1989-01, 1994-04, 1994-12, 1998-02,

2002-02, 2002-07, 2002-10, 2003-11,

2004-10

1)

The length is specified as appropriate, but with due regard to the standard lengths.

2)

For solderless pipe couplings with cutting rings, please refer to SN 456.

3)

For male studs and weld-on sockets, please refer to SN 759.

4)

Use of static operating pressure is allowed only in case of power fluids with high water contents which are predominantly

exposed to static loads.

S-ar putea să vă placă și

- AG Quick Release ENProDocument4 paginiAG Quick Release ENProNatalia WinataÎncă nu există evaluări

- SN884 2006-12 SAP eDocument3 paginiSN884 2006-12 SAP eChristopher LloydÎncă nu există evaluări

- Straight-Way Type Valves SN 469: Provided With Progressive Ferrule Compression Couplings On Either SideDocument2 paginiStraight-Way Type Valves SN 469: Provided With Progressive Ferrule Compression Couplings On Either SideChristopher LloydÎncă nu există evaluări

- SN757 2005-05 eDocument4 paginiSN757 2005-05 ehasan_676489616Încă nu există evaluări

- E SN759Document2 paginiE SN759hasan_676489616Încă nu există evaluări

- Part List Rga-2315h1jt-11 2-La4-E1 (GB Cv05)Document4 paginiPart List Rga-2315h1jt-11 2-La4-E1 (GB Cv05)restu yanuar salamÎncă nu există evaluări

- Round Washers SN 808: July 2000Document1 paginăRound Washers SN 808: July 2000Maurício Duarte de AndradeÎncă nu există evaluări

- SN430-2 2006-12 SAP eDocument3 paginiSN430-2 2006-12 SAP eChristopher LloydÎncă nu există evaluări

- Fittings Din11852 Din11850Document14 paginiFittings Din11852 Din11850dingobk1Încă nu există evaluări

- Iso 16028 1999Document9 paginiIso 16028 1999MussardÎncă nu există evaluări

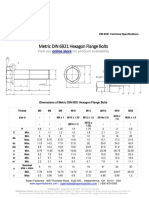

- Metric DIN 6921 Hexagon Flange Bolts: Visit Our For Product AvailabilityDocument5 paginiMetric DIN 6921 Hexagon Flange Bolts: Visit Our For Product AvailabilityJaganÎncă nu există evaluări

- RJR PMMTDocument16 paginiRJR PMMTArun PrasadÎncă nu există evaluări

- Sealing DIN 3670 - 5Document2 paginiSealing DIN 3670 - 5Tobajasz HermaniuszÎncă nu există evaluări

- Din 3357-4-1981Document5 paginiDin 3357-4-1981олегÎncă nu există evaluări

- DIN 3015 ClampsDocument17 paginiDIN 3015 ClampsBalderas Rosas WilibaldoÎncă nu există evaluări

- 1 2312 PDFDocument4 pagini1 2312 PDFFrancisco CarrascoÎncă nu există evaluări

- SN428Document2 paginiSN428T Mathew Tholoor100% (1)

- Din 2616 PDFDocument2 paginiDin 2616 PDFTahresÎncă nu există evaluări

- ErmetoDocument14 paginiErmetoJavier VespaÎncă nu există evaluări

- Parallel Key Calculation According To DIN 6892Document21 paginiParallel Key Calculation According To DIN 6892zahirshah1436923Încă nu există evaluări

- SC470-P Four Inch STUB Cyclone 2016Document2 paginiSC470-P Four Inch STUB Cyclone 2016Tobias De Somer100% (1)

- DIN 2076 vs. ASTM A 877Document1 paginăDIN 2076 vs. ASTM A 877tobypadfieldÎncă nu există evaluări

- Conical Seat Spherical Washer Is 4297Document6 paginiConical Seat Spherical Washer Is 4297Rajasekaran Murugan0% (1)

- Toaz - Info Iso 8062-3-2007 Casting Tolerancepdf PRDocument1 paginăToaz - Info Iso 8062-3-2007 Casting Tolerancepdf PRdineshramya190% (1)

- Fittings - DIN 2616: VL Code 731Document2 paginiFittings - DIN 2616: VL Code 731RatheeshÎncă nu există evaluări

- Din 6798 ADocument3 paginiDin 6798 ADuong BachÎncă nu există evaluări

- Din Flange Din 2627: (Dimensions in MM.)Document12 paginiDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönÎncă nu există evaluări

- Din 2576 PDFDocument1 paginăDin 2576 PDFSabka PanayotovaÎncă nu există evaluări

- 복사본 볼트규격표Document20 pagini복사본 볼트규격표임동섭Încă nu există evaluări

- SN200 2010-09 eDocument131 paginiSN200 2010-09 eÜmit UçakÎncă nu există evaluări

- Iso 228 1 2000Document9 paginiIso 228 1 2000Ulvi NebiyevÎncă nu există evaluări

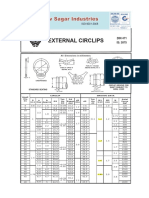

- External CirclipDocument2 paginiExternal CirclipDivyang MistryÎncă nu există evaluări

- ASGEpg187 PDFDocument3 paginiASGEpg187 PDFbkprodhÎncă nu există evaluări

- Types of Steel and StandardsDocument2 paginiTypes of Steel and Standardsewva12Încă nu există evaluări

- Pins and KeysDocument12 paginiPins and KeysSam GillilandÎncă nu există evaluări

- KAT-A 2014-EA RIKO-EA Edition11 04-12-2012 ENDocument7 paginiKAT-A 2014-EA RIKO-EA Edition11 04-12-2012 ENpalanaruvaÎncă nu există evaluări

- 1DIN 6921-10.9 Hex Flange Bo.Document2 pagini1DIN 6921-10.9 Hex Flange Bo.Sunil BaliÎncă nu există evaluări

- DOZNA - 6000 KN - DIN-6319 PDFDocument4 paginiDOZNA - 6000 KN - DIN-6319 PDFzoranmiskovicÎncă nu există evaluări

- 10 1092Document39 pagini10 1092ThinkProgressÎncă nu există evaluări

- Material Comparisons For Astm and JisDocument2 paginiMaterial Comparisons For Astm and JisNitesh GargÎncă nu există evaluări

- Din 2616 PDFDocument2 paginiDin 2616 PDFmiguelfpintoÎncă nu există evaluări

- DIN StandardDocument2 paginiDIN StandardViiee Chauhaan33% (3)

- Chinese To DinDocument7 paginiChinese To DinDamla KaymakçıÎncă nu există evaluări

- Mil STD 40007Document19 paginiMil STD 40007engine100% (2)

- Aluminium - Specifications, Properties, Classifications and Classes, Supplier Data by AalcoDocument2 paginiAluminium - Specifications, Properties, Classifications and Classes, Supplier Data by Aalcowongtathong1987Încă nu există evaluări

- Din 2616 PDFDocument2 paginiDin 2616 PDFALEKSANDARÎncă nu există evaluări

- Chemical ChartDocument6 paginiChemical ChartAnurag SarkarÎncă nu există evaluări

- SLG-0001-1b Flange Designation Chart PDFDocument2 paginiSLG-0001-1b Flange Designation Chart PDFMohd Shafuaaz KassimÎncă nu există evaluări

- Grade Chemical Composition (% by Mass - Max Unless Stated) Ferritic SteelsDocument15 paginiGrade Chemical Composition (% by Mass - Max Unless Stated) Ferritic SteelsSenthil KumarÎncă nu există evaluări

- Schallater Gaas80 Gaa100 DownloadDocument4 paginiSchallater Gaas80 Gaa100 DownloadRakesh SrivastavaÎncă nu există evaluări

- Circlip Data PDFDocument6 paginiCirclip Data PDFRay FaiersÎncă nu există evaluări

- Din 3015Document17 paginiDin 3015Mohammed Eljammal100% (1)

- SENTRON LV36 Complete English 2014Document284 paginiSENTRON LV36 Complete English 2014charlonÎncă nu există evaluări

- Equalent Material GradesDocument16 paginiEqualent Material GradesLesle GpÎncă nu există evaluări

- Safety Data Sheet MSDS - Vanadium-Electrolyt-Lösung2014-10-20Document9 paginiSafety Data Sheet MSDS - Vanadium-Electrolyt-Lösung2014-10-20XaviAlonsoÎncă nu există evaluări

- Din 7977Document1 paginăDin 7977zorghi1Încă nu există evaluări

- About Axial Displacement Pump A4VSoDocument68 paginiAbout Axial Displacement Pump A4VSomrkadu_61Încă nu există evaluări

- A4VSODocument64 paginiA4VSORock Saybolt100% (1)

- 3100 Series and 3200 Heavy Duty Series: Compact OEM Pressure TransmittersDocument5 pagini3100 Series and 3200 Heavy Duty Series: Compact OEM Pressure TransmittersAlejandro CagideÎncă nu există evaluări

- زندگی پنهان مادر ترزاDocument10 paginiزندگی پنهان مادر ترزاChristopher LloydÎncă nu există evaluări

- Comparison of Jet Aeration Systems vs. Diffused Aeration SystemsDocument8 paginiComparison of Jet Aeration Systems vs. Diffused Aeration SystemsChristopher LloydÎncă nu există evaluări

- WO2017037540A1Document29 paginiWO2017037540A1Christopher LloydÎncă nu există evaluări

- Experimental Evaluation of Ball Bar Standard ThermDocument12 paginiExperimental Evaluation of Ball Bar Standard ThermChristopher LloydÎncă nu există evaluări

- Venturi Scrubber ProjectDocument1 paginăVenturi Scrubber ProjectChristopher LloydÎncă nu există evaluări

- EVE 402 Air Pollution Generation and Control: Wet CollectorsDocument8 paginiEVE 402 Air Pollution Generation and Control: Wet CollectorsChristopher LloydÎncă nu există evaluări

- Modelling of The Pressure Drop in Tangential Inlet Cyclone SeparatorsDocument10 paginiModelling of The Pressure Drop in Tangential Inlet Cyclone SeparatorsChristopher LloydÎncă nu există evaluări

- Energy and Exergy of Electric Arc Furnace PDFDocument26 paginiEnergy and Exergy of Electric Arc Furnace PDFChristopher LloydÎncă nu există evaluări

- Water Mist Systems in Tunnels: Some Unanswered QuestionsDocument10 paginiWater Mist Systems in Tunnels: Some Unanswered QuestionsChristopher LloydÎncă nu există evaluări

- Description of Thermal Oxidizers PDFDocument5 paginiDescription of Thermal Oxidizers PDFChristopher LloydÎncă nu există evaluări

- Fire Safety Enginering For An Auditorium Analysis: M. Filimon D. Diaconu-Șotropa C. P. OlariuDocument8 paginiFire Safety Enginering For An Auditorium Analysis: M. Filimon D. Diaconu-Șotropa C. P. OlariuChristopher LloydÎncă nu există evaluări

- Normal To Real Flow Rate and FAD Flow RateDocument25 paginiNormal To Real Flow Rate and FAD Flow RateChristopher LloydÎncă nu există evaluări

- TBS Case Study Train LoadoutDocument1 paginăTBS Case Study Train LoadoutChristopher LloydÎncă nu există evaluări

- Normal Conditions at 100% Barometer Amb Temp,°C Inlet Capacity: Ist StageDocument1 paginăNormal Conditions at 100% Barometer Amb Temp,°C Inlet Capacity: Ist StageChristopher LloydÎncă nu există evaluări

- Notes On Sizing of Horizontal Ceiling Vents With Traditional Flow ModelDocument7 paginiNotes On Sizing of Horizontal Ceiling Vents With Traditional Flow ModelChristopher LloydÎncă nu există evaluări

- Sound Pressure LevelDocument38 paginiSound Pressure LevelChristopher Lloyd100% (1)

- Combustion. Adiabatic Flame Temperature - Jeff MunicDocument56 paginiCombustion. Adiabatic Flame Temperature - Jeff MunicChristopher LloydÎncă nu există evaluări

- Spherical Particle Drag CoefficientDocument8 paginiSpherical Particle Drag CoefficientChristopher LloydÎncă nu există evaluări

- Mechanical Ventilation For Individual Pen Calf Barn CalculatorDocument3 paginiMechanical Ventilation For Individual Pen Calf Barn CalculatorChristopher LloydÎncă nu există evaluări

- Ps BallDocument5 paginiPs BallChristopher LloydÎncă nu există evaluări

- Astm D 2014 - 97 (2010)Document5 paginiAstm D 2014 - 97 (2010)alexander guerraÎncă nu există evaluări

- Hufcor 632 Paired F4149FDocument6 paginiHufcor 632 Paired F4149Fdoody.dpujaÎncă nu există evaluări

- Table UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3Document7 paginiTable UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3MechanicalÎncă nu există evaluări

- 02-Crystal Titan ContainersDocument16 pagini02-Crystal Titan Containersinammurad12Încă nu există evaluări

- Bar ElementDocument14 paginiBar ElementprakashÎncă nu există evaluări

- BMP - Powder MetallurgyDocument71 paginiBMP - Powder Metallurgymantra2010Încă nu există evaluări

- I S S U E T W O 1 9 9 7: Mount Rushmore Parking Garage - USADocument16 paginiI S S U E T W O 1 9 9 7: Mount Rushmore Parking Garage - USADrPadipat ChaemmangkangÎncă nu există evaluări

- Bomba Vacio C Lateral FPZ TDDocument52 paginiBomba Vacio C Lateral FPZ TDchristian_ignacioÎncă nu există evaluări

- Modeling The Hysteretic Response of Mechanical Connections For Wood StructuresDocument11 paginiModeling The Hysteretic Response of Mechanical Connections For Wood StructuresSheff_studentÎncă nu există evaluări

- 3 Faze ConverterDocument22 pagini3 Faze ConverterCristi Chihaia100% (1)

- Productsheet Diesel Particulate Filter CleaningDocument2 paginiProductsheet Diesel Particulate Filter CleaningEhtıram SeyıdovÎncă nu există evaluări

- Sae J217-2016Document3 paginiSae J217-2016tiramisuweitaoÎncă nu există evaluări

- BASF 3A DatasheetDocument2 paginiBASF 3A DatasheetGernot FeldbacherÎncă nu există evaluări

- Agitation Experiment ManualDocument5 paginiAgitation Experiment Manualsimonatics08Încă nu există evaluări

- Soot BlowersDocument279 paginiSoot BlowersLALCHAND RAWANI100% (2)

- Winter Camouflage Painting - Episode 1 Slightly Weathered: by Roman VolchenkovDocument9 paginiWinter Camouflage Painting - Episode 1 Slightly Weathered: by Roman VolchenkovBENo100% (1)

- 645295-P56790A-0154 - 01 Acoustic Insulation PDFDocument18 pagini645295-P56790A-0154 - 01 Acoustic Insulation PDFAnsar AliÎncă nu există evaluări

- 2ND Periodical Test in Tle 6-IaDocument3 pagini2ND Periodical Test in Tle 6-IaElsie NogaÎncă nu există evaluări

- Sb70491atosh9 PDFDocument1 paginăSb70491atosh9 PDFCarlosÎncă nu există evaluări

- Aluminium and CorrosionDocument12 paginiAluminium and CorrosionMehman NasibovÎncă nu există evaluări

- Work Shoppractice Laboratory Manual I/II Semester (WSL16/26)Document75 paginiWork Shoppractice Laboratory Manual I/II Semester (WSL16/26)VIPAN KUMARÎncă nu există evaluări

- Effects of High Chlorine in Biomass FuelDocument16 paginiEffects of High Chlorine in Biomass FuelJaideepMannÎncă nu există evaluări

- ANUBISPapercraft Maskby NtanosDocument12 paginiANUBISPapercraft Maskby NtanosandrescardonaÎncă nu există evaluări

- Ensinger - TecapeekDocument2 paginiEnsinger - TecapeekPaul ScottÎncă nu există evaluări

- KS Series Master Format CSI SpecificationDocument14 paginiKS Series Master Format CSI SpecificationMohammad Maher AlSafariniÎncă nu există evaluări

- Heat Detector PDFDocument1 paginăHeat Detector PDFKiran VankudreÎncă nu există evaluări

- Asm-35-2000 Aluminum Sheet Metal Work in Building ConstructionDocument31 paginiAsm-35-2000 Aluminum Sheet Metal Work in Building ConstructionSamuel Yu LiuÎncă nu există evaluări

- Section 2: Insulation Materials and PropertiesDocument10 paginiSection 2: Insulation Materials and PropertiesJersey PerlasÎncă nu există evaluări

- 02 Generic - Types - Grade1Document34 pagini02 Generic - Types - Grade1Aravind BabuÎncă nu există evaluări