Documente Academic

Documente Profesional

Documente Cultură

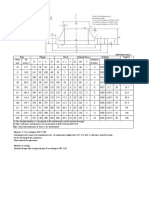

Dimensions, Sizes and Specification of ANSI ASME B 16.5 Flanges

Încărcat de

Simbu ArasanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Dimensions, Sizes and Specification of ANSI ASME B 16.5 Flanges

Încărcat de

Simbu ArasanDrepturi de autor:

Formate disponibile

ANTONG FITTING & FLANGES

Http://antongcorp.com

ANSI ASME B16.5 Forged Flanges

Dimensions, Sizes and Specication of ANSI ASME B 16.5 Flanges

p.com

r

co

/Antong

/

:

/Antong

/

:

p.com

r

co

ANTONG FITTING & FLANGES

Http://antongcorp.com

Mail: sales@antongcorp.com

Tel: 008631180763668

Ht

t

p

H

t

t

p

ANSI ASME

B16.5 Class150

CLASS150

Outside

Thk. of Diam.

Nominal Diam. Flange

of

of

Pipe

Min.

Hub

Flanges

Size

Unit : mm

Corner

LENGTH THROUGH HUB

BORE

Hub

Radius

O.D of

Thread Slip-on

Diam. Threaded

Welding of Bore Depth

of

Raised

of

Chamfer Slip-on Lapped Welding Length Socket Lapped Neck

Diam.

Face

Socket Lapped Socket of Bolt

Neck

of W.N Socket

Welding

Welding Flange

Welding

Circle

p.com

r

co

DRILLING

LENGTH OF STUD BOLTS

Machine

Stud Bolts

Diam.

Diam. of Bolts

Number

of Bolt

Bolts 0.06 in 0.06 in

of Bolts

Holes

(inch) Raised Raised Ring

Joint

Face Face

Y1

Y2

Y3

B1

B2

B3

89.0

11.2

30.2

35.1

21.3

15.7

15.7

47.8

15.7

22.4

22.9

15.8

3.0

9.7

60.5

15.8

1/2

50.8

57.2

20

98.5

12.7

38.1

42.9

26.7

15.7

15.7

52.3

15.7

27.7

28.2

20.8

3.0

11.2

69.9

15.8

1/2

50.8

63.5

25

108.0

14.2

49.3

50.8

33.5

17.5

17.5

55.6

17.5

34.5

35.1

26.7

3.0

12.7

79.3

15.8

1/2

57.2

63.5

76.2

32

117.5

15.7

58.7

63.5

42.2

20.6

20.6

57.2

20.6

43.2

43.7

35.1

4.8

14.2

88.9

15.8

1/2

57.2

69.9

82.6

40

127.0

17.5

65.0

73.2

48.3

22.4

22.4

62.0

22.4

49.5

50.0

40.9

6.4

15.8

98.6

15.8

1/2

63.5

69.9

82.6

50

152.5

19.1

77.7

91.9

60.5

25.4

25.4

63.5

25.4

62.0

62.5

52.6

7.9

17.5

120.7

19.1

5/8

69.9

82.6

95.3

65

178.0

22.4

90.4

104.6

73.2

28.4

28.4

69.9

28.4

74.7

75.4

62.7

7.9

19.1

139.7

19.1

5/8

76.2

88.9

101.6

80

190.5

23.9

108.0

127.0

88.9

30.2

30.2

69.9

30.2

90.7

91.4

78..0

9.7

20.6

152.4

19.1

5/8

76.2

88.9

101.6

90

216.0

23.9

122.2

139.7

101.6

31.8

31.8

71.4

31.8

103.4

104.1

90.2

9.7

177.8

19.1

5/8

76.2

88.9

101.6

100

228.5

23.9

134.9

157.2

114.3

33.3

33.3

76.2

33.3

116.1

116.8

102.4

11.2

190.5

19.1

5/8

76.2

88.9

101.6

125

254.0

23.9

163.6

185.7

141.2

36.6

36.6

88.9

36.6

143.8

144.5

128.3

11.2

215.9

22.4

3/4

82.6

95.3

108.0

150

279.5

25.4

192.0

215.9

168.4

39.6

39.6

88.9

39.6

170.7

171.5

154.2

12.7

241.3

22.4

3/4

82.6

101.6

114.3

200

343.0

28.4

246.1

269.7

219.2

44.5

44.5

101.6

44.5

221.5

222.3

202.7

12.7

298.5

22.4

3/4

88.9

108.0

120.7

250

406.5

30.2

304.8

323.9

273.1

49.3

49.3

101.6

49.3

276.4

277.4

254.5

12.7

362.0

25.4

12

7/8

101.6

114.3

127.0

/Antong

/

:

15

Ht

t

p

300

482.5

31.8

365.3

381.0

323.9

55.6

55.6

114.3

55.6

327.2

328.2

304.8

12.7

431.8

25.4

12

7/8

101.6

120.7

133.4

350

533.5

35.1

400.1

412.8

355.6

57.2

79.2

127.0

57.2

359.2

360.2

12.7

476.3

28.5

12

114.3

133.4

146.1

400

597.0

36.6

457.2

469.9

406.4

63.5

87.4

127.0

63.5

410.5

411.2

12.7

539.8

28.5

16

114.3

133.4

146.1

450

635.0

39.6

505.0

533.4

457.2

68.3

96.8

139.7

68.3

461.8

462.3

12.7

577.9

31.8

16

1 1/8

127.0

146.1

158.8

500

698.5

42.9

558.8

584.2

508.0

73.2

103.1

144.5

73.2

513.1

514.4

12.7

635.0

31.8

20

1 1/8

139.7

158.8

171.5

600

813.0

47.8

663.4

692.2

609.6

82.6

111.3

152.4

82.6

616.0

616.0

12.7

749.3

35.1

20

1 1/4

152.4

171.5

184.2

3. Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

4. The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out

according to MSS SP-9, without reducing thickness (C).

5. Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturers option.

Http://antongcorp.com

+8631180763668

sales@antongcorp.com

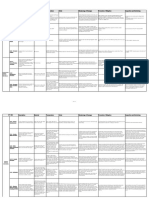

ANSI ASME

B16.5 Class300

CLASS300

Unit : mm

Corner

LENGTH THROUGH HUB

BORE

Outside

Hub

Radius

Thk. of Diam. O.D of

Threaded

Thread

Diam.

Diam.

Welding of Bore

Nominal

Slip-on

Flange

Raised

of

of

of

Chamfer Slip-on Lapped Welding Length Socket Lapped Neck

Pipe

Min.

Face

Hub

Socket Lapped

Neck

Socket

of W.N

Size Flanges

Welding

Welding Flange

Welding

Counter

DRILLING

Bore

Depth

Thread

of

ed

Socket Diam. Diam. Number Diam. of

Flange

Bolts

of Bolt of Bolt

of Bolts

Min.

(inch)

Circle Holes

0.06 in 0.06 in

Raised Raised

Face Face

Ring

Joint

Y1

Y2

Y3

B1

B2

B3

15

95.5

14.2

38.1

35.1

21.3

22.4

22.4

52.3

15.7

22.4

22.9

15.7

3.0

23.6

9.7

66.5

15.7

1/2

57.2

63.5

76.2

20

117.5

15.7

47.8

42.9

26.7

25.4

25.4

57.2

15.7

27.7

28.2

20.8

3.0

29.0

11.2

82.6

19.1

5/8

63.5

76.2

88.9

25

124.0

17.5

53.8

50.8

33.5

26.9

26.9

62.0

17.5

34.5

35.1

26.7

3.0

35.8

12.7

88.9

19.1

5/8

63.5

76.2

88.9

32

133.5

19.1

63.5

63.5

42.2

26.9

26.9

65.0

20.6

43.2

43.7

35.1

4.8

44.5

14.2

98.6

19.1

5/8

69.9

82.6

95.3

40

155.5

20.6

69.9

73.2

48.3

30.2

30.2

68.3

22.4

49.5

50.0

40.9

6.4

50.5

15.7

114.3

22.4

3/4

76.2

88.9

101.6

50

165.0

22.4

84.1

91.9

60.5

33.3

33.3

69.9

28.4

62.0

62.5

52.6

7.9

63.5

17.5

127.0

19.1

5/8

76.2

88.9

101.6

65

190.5

25.4

100.1

104.6

73.2

38.1

38.1

76.2

31.8

74.7

75.4

62.7

7.9

76.2

19.1

149.4

22.4

3/4

82.6

101.6

114.3

80

209.5

28.4

117.3

127.0

88.9

42.9

42.9

79.2

31.8

90.7

91.4

78.0

9.7

92.2

20.6

168.1

22.4

3/4

88.9

108.0

120.7

90

228.5

30.2

133.4

139.7

101.6

44.5

44.5

81.0

36.6

103.4

104.1

90.2

9.7

104.9

22.4

184.2

22.4

3/4

95.3

108.0

127.0

100

254.0

31.8

146.1

157.2

114.3

47.8

47.8

85.9

36.6

116.1

116.8

102.4

11.2

117.6

200.2

22.4

3/4

95.3

114.3

127.0

125

279.5

35.1

177.8

185.7

141.2

50.8

50.8

98.6

42.9

143.8

144.5

128.3

11.2

144.5

235.0

22.4

3/4

108.0

120.7

133.4

150

317.5

36.6

206.2

215.9

168.4

52.3

52.3

98.6

46.0

170.7

171.5

154.2

12.7

171.5

269.7

22.4

12

3/4

108.0

120.7

139.7

200

381.0

41.1

260.4

269.7

219.2

62.0

62.0

111.3

50.8

221.5

222.3

202.7

12.7

222.3

330.2

25.4

12

7/8

120.7

139.7

152.4

250

444.5

47.8

320.5

323.9

273.1

66.5

95.3

117.3

55.6

276.4

277.4

254.5

12.7

276.4

387.4

28.4

16

139.7

158.8

171.5

300

520.5

50.8

374.7

381.0

323.9

73.2

101.6

130.0

60.5

327.2

328.2

304.8

12.7

328.7

450.9

31.8

16

1 1/8

146.1

171.5

184.2

350

584.0

53.8

425.5

412.8

355.6

76.2

111.3

142.7

63.5

359.2

360.2

12.7

360.4

514..4

31.8

20

1 1/8

158.8

177.8

190.5

400

647.5

57.2

482.6

469.9

406.4

82.6

120.7

146.1

68.3

410.5

411.2

12.7

411.2

571.5

35.1

20

1 1/4

165.1

190.5

203.2

450

711.0

60.5

533.4

533.4

457.2

88.9

130.0

158.8

69.9

461.8

462.3

12.7

462.0

628.7

35.1

24

1 1/4

171.5 196..9 209.6

500

774.5

63.5

587.2

584.2

508.0

95.3

139.7

162.1

73.2

513.1

514.4

12.7

512.8

685.8

35.1

24

1 1/4

184.2

203.2

222.3

600

914.5

69.9

701.5

692.2

609.6

106.4

152.4

168.1

82.6

616.0

616.0

12.7

614.4

812.8

41.1

24

1 1/2

203.2

228.6

254.0

To be

specified

by

purchaser

/Antong

/

:

Stud Bolts

p.com

r

co

LENGTH OF STUD BOLTS

Machine

Bolts

Ht

t

p

3. Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

4. The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out

according to MSS SP-9, without reducing thickness (C).

5. Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturers option.

Http://antongcorp.com

+8631180763668

sales@antongcorp.com

ANSI ASME

B16.5 Class600

CLASS600

Corner

LENGTH THROUGH HUB

BORE

Outside

Hub

Radius

Thk. of Diam. O.D of

Threaded

Thread

Diam.

Diam.

Welding

of

Bore

Nominal

Slip-on

Flange

Raised

of

of

of

Chamfer Slip-on Lapped Welding Length Socket Lapped Neck

Pipe

Min.

Face

Hub

Socket Lapped

Neck

of W.N Socket

Size Flanges

Welding

Welding Flange

Welding

Male &

Raised Female

Face

Ring

or

(0.25 Tongue Joint

&

Inch)

Groove

Y1

Y2

Y3

B1

B2

14.2

38.1

35.1

21.3

22.4

22.4

52.3

15.7

22.4

22.9

3.0

23.6

9.7

66.5

15.7

1/2

76.2

69.9

76.2

20

117.5

15.7

47.8

42.9

26.7

25.4

25.4

57.2

15.7

27.7

28.2

3.0

29.0

11.2

82.6

19.1

5/8

88.9

82.6

88.9

25

124.0

17.5

53.8

50.8

33.5

26.9

26.9

62.0

17.5

34.5

35.1

3.0

35.8

12.7

88.9

19.1

5/8

88.9

82.6

88.9

32

133.5

20.6

63.5

63.5

42.2

28.4

28.4

66.5

20.6

43.2

43.7

4.8

44.5

14.2

98.6

19.1

5/8

95.3

88.9

95.3

40

155.5

22.4

69.9

73.2

48.3

31.8

31.8

69.9

22.4

49.5

50.0

6.4

50.5

15.7

114.3

22.4

3/4

108.0 101..6 108.0

50

165.0

25.4

84.1

91.9

60.5

36.6

36.6

73.2

28.4

62.0

62.5

7.9

63.5

17.5

127.0

19.1

5/8

108.0

101.6

108.0

65

190.5

28.4

100.1

104.6

73.2

41.1

41.1

79.2

31.8

74.7

75.4

7.9

76.2

19.1

149.4

22.4

3/4

120.7

114.3

120.7

80

209.5

31.8

117.3

127.0

88.9

46.0

46.0

82.6

35.1

90.7

91.4

9.7

92.2

20.6

168.1

22.4

3/4

127.0

120.7

127.0

90

228.5

35.1

133.4

139.7

101.6

49.3

49.3

85.9

39.6

103.4

104.1

9.7

104.9

184.2

25.4

7/8

139.7

133.4

139.7

100

273.0

38.1

152.4

157.2

114.3

53.8

53.8

101.6

41.1

116.1

116.8

11.2

117.6

215.9

25.4

7/8

146.1

139.7

146.1

125

330.0

44.5

189.0

185.7

141.2

60.5

60.5

114.3

47.8

143.8

144.5

11.2

144.5

266.7

28.4

165.1

158.8

165.1

150

355.5

47.8

222.3

215.9

168.4

66.5

66.5

117.3

50.8

170.7

171.5

12.7

171.5

292.1

28.4

12

171.5

165.1

171.5

200

419.0

55.6

273.1

269.7

219.2

76.2

76.2

133.4

57.2

221.5

222.3

12.7

222.3

349.3

31.8

12

1 1/8

190.5

184.2

196.9

250

508.0

63.5

342.9

323.9

273.1

85.9

111.3

152.4

65.0

276.4

277.4

12.7

276.4

431.8

35.1

16

1 1/4

215.9

209.6

215.9

300

559.0

66.5

400.1

381.0

323.9

91.9

117.3

155.4

69.9

327.2

328.2

12.7

328.7

489.0

35.1

20

1 1/4

222.3

215.9

222.3

350

603.5

69.9

431.8

412.8

355.6

93.7

127.0

165.1

73.2

359.2

360.2

12.7

360.4

527.1

38.1

20

1 3/8

235.0

228.6

235.0

400

686.0

76.2

495.3

469.9

406.4

106.4

139.7

177.8

77.7

410.5

411.2

12.7

411.2

603.3

41.1

20

1 1/2

254.0

247.7

254.0

450

743.0

82.6

546.1

533.4

457.2

117.3

152.4

184.2

79.2

461.8

462.3

12.7

462.0

654.1

44.5

20

1 5/8

273.1

266.7

273.1

500

813.0

88.9

609.6

584.2

508.0

127.0

165.1

190.5

82.6

513.1

514.4

12.7

512.8

723.9

44.5

24

1 5/8

285.8

279.4

292.1

600

940.0

101.6

717.6

692.2

609.6

139.7

184.2

203.2

91.9

616.0

616.0

12.7

614.4

838.2

50.8

24

1 7/8

330.2

323.9

336.6

To be specified by purchaser.

O

95.5

/Antong

/

:

LENGTH OF STUD BOLTS

15

p.com

r

co

B3

Counter

DRILLING

Bore

Depth

Thread

of

ed

Socket Diam. Diam. Number Diam. of

Flange

of Bolt of Bolt

of Bolts Bolts

Min.

Circle Holes

Ht

t

p

3. Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

4. The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out

according to MSS SP-9, without reducing thickness (C).

5. Dimensions of sizes 1/2 through 3 1/2 are the same as for Class 400 Flanges.

6. Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturers option.

Http://antongcorp.com

+8631180763668

sales@antongcorp.com

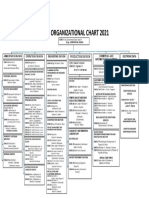

ANSI ASME

B16.5 Class900

CLASS900

Outside

Thk. of

Nominal Diam. Flange

of

Pipe

Min.

Size Flanges

Unit : mm

Corner Counter

LENGTH THROUGH HUB

BORE

DRILLING

LENGTH OF STUD BOLTS

Hub

Radius bore

Diam.

Male &

Thread

Diam.

of Bore Threadof

Raised Female

ed Diam. of Diam. of

of

Chamfer Threaded Lapped Welding Length Slip-on Lapped Welding

Diam. of

Hub

Number

Face

Ring

or

Neck

Neck Lapped Flange Bolt

of W.N Slip-on

Bolt

Bolts

of Bolts

(0.25 Tongue Joint

Flange Min.

Circle Holes

(inch)

&

Inch)

X

A

Y1

Y2

Y3

T

B1

B2

B3

r

Q

Groove

120.7

22.4

38.1

21.3

31.8

31.8

60.5

22.4

22.4

22.9

3.0

23.6

82.6

22.4

3/4

108.0

101.6

108.0

20

130.0

25.4

44.5

26.7

35.1

35.1

69.9

25.4

27.7

28.2

3.0

29.0

88.9

22.4

3/4

114.3

108.0

114.3

25

149.4

28.4

52.3

33.5

41.1

41.1

73.2

28.4

34.5

35.1

3.0

35.8

101.6

25.4

7/8

127.0

120.7

127.0

32

158.8

28.4

63.5

42.2

41.1

41.1

73.2

30.2

43.2

43.7

4.8

44.5

111.3

25.4

7/8

127.0

120.7

127.0

40

177.8

31.8

69.9

48.3

44.5

44.5

82.6

31.8

49.5

50.0

6.4

50.5

124.0

28.4

139.7

133.4

139.7

50

215.9

38.1

104.6

60.5

57.2

57.2

101.6

38.1

62.0

62.5

7.9

63.5

165.1

25.4

7/8

146.1

139.7

146.1

65

244.3

41.1

124.0

73.2

63.5

63.5

104.6

47.8

74.7

75.4

7.9

76.2

190.5

28.4

158.8

152.4

158.8

80

241.3

38.1

127.0

88.9

53.8

53.8

101.6

41.1

90.7

91.4

9.7

92.2

190.5

25.4

7/8

146.1

139.7

146.1

100

292.1

44.5

158.8

114.3

69.9

69.9

114.3

47.8

116.1

116.8

11.2

117.6

235.0

31.8

1 1/8

171.5

165.1

171.5

125

349.3

50.8

190.5

141.2

79.2

79.2

127.0

53.8

143.8

144.5

11.2

144.5

279.4

35.1

1 1/4

190.5

184.2

190.5

381.0

55.6

235.0

168.4

85.9

85.9

139.7

57.2

12.7

171.5

317.5

31.8

12

1 1/8

190.5

184.2

196.9

219.2

101.6

114.3

162.1

63.5

38.1

12

1 3/8

222.3

215.9

222.3

276.4

277.4

235.0

/Antong

/

:

p.com

r

co

150

200

469.9

63.5

298.5

170.7

221.5

171.5

222.3

250

546.1

69.9

368.3

273.1

108.0

127.0

184.2

71.4

300

609.6

79.2

419.1

323.9

117.3

142.7

200.2

76.2

327.2

328.2

350

641.4

85.9

450.9

355.6

130.0

155.4

212.9

82.6

359.2

360.2

400

704.9

88.9

508.0

406.4

133.4

165.1

215.9

85.9

410.5

450

787.4

101.6

565.2

457.2

152.4

190.5

228.6

88.9

500

857.3

108.0

622.3

508.0

158.8

209.6

247.7

600

1041.4

139.7

749.3

609.6

203.2

266.7

292.1

To be specified by Purchaser.

O

15

12.7

222.3

393.7

12.7

276.4

469.9

38.1

16

1 3/8

235.0

228.6

12.7

328.7

533.4

38.1

20

1 3/8

254.0

247.7

254.0

12.7

360.4

558.8

41.1

20

1 1/2

273.1

266.7

279.4

411.2

12.7

411.2

616.0

44.5

20

1 5/8

285.8

279.4

292.1

461.8

462.3

12.7

462.0

685.8

50.8

20

1 7/8

323.9

317.5

336.6

91.9

513.1

514.4

12.7

512.8

749.3

53.8

20

349.3

342.9

362.0

101.6

616.0

616.0

12.7

614.4

901.7

66.5

20

2 1/2

438.2

431.8

457.2

Ht

t

p

3. Dimensions of size 1/2 through 2 1/2 are the same as for class 1500 flanges.

4. Socket Welding flange may be provided in NPS 1/2 through 2 1/2 using 1500 dimensions.

Http://antongcorp.com

+8631180763668

sales@antongcorp.com

ANSI ASME

B16.5 Class1500

CLASS1500

Outside

Unit : mm

Corner

LENGTH THROUGH HUB

BORE

Hub

Radius

Thk. of Diam.

Thread Slip-on

Diam. Threaded

Welding of Bore

of

of

Chamfer Slip-on Lapped Welding Length Socket Lapped Neck

Hub

Socket Lapped

Neck

of W.N Socket

Welding

Welding

Flange

Welding

Nominal Diam. Flange

of

Pipe

Min.

Size Flanges

LENGTH OF STUD BOLTS

Male &

Raised Female

Diam.

Diam. of

Number

Face

or

of Bolt

Bolts

of Bolts

(0.25 Tongue

Holes

(inch)

&

Inch)

Groove

Ring

Joint

Y1

Y2

Y3

B1

B2

22.4

38.1

21.3

31.8

31.8

60.5

22.4

22.4

22.9

3.0

23.6

9.7

82.6

22.4

3/4

108.0

101.6

108.0

20

130.0

25.4

44.5

26.7

35.1

35.1

69.9

25.4

27.7

28.2

3.0

29.0

11.2

88.9

22.4

3/4

114.3

108.0

114.3

25

149.4

28.4

52.3

33.5

41.1

41.1

73.2

28.4

34.5

35.1

3.0

35.8

12.7

101.6

25.4

7/8

127.0

120.7

127.0

32

158.8

28.4

63.5

42.2

41.1

41.1

73.2

30.2

43.2

43.7

4.8

44.5

14.2

111.3

25.4

7/8

127.0

120.7

127.0

40

177.8

31.8

69.9

48.3

44.5

44.5

82.6

31.8

49.5

50.0

6.4

50.5

15.7

124.0

28.4

139.7

133.4

139.7

50

215.9

38.1

104.6

60.5

57.2

57.2

101.6

38.1

62.0

62.5

7.9

63.5

17.5

165.1

25.4

7/8

146.1

139.7

146.1

65

244.3

41.1

124.0

73.2

63.5

63.5

104.6

47.8

74.7

75.4

7.9

76.2

19.1

190.5

28.4

158.8

152.4

158.8

80

266.7

47.8

133.4

88.9

73.2

117.3

91.4

9.7

203.2

31.8

1 1/8

177.8

171.5

177.8

100

311.2

53.8

162.1

114.3

90.4

124.0

116.8

11.2

241.3

35.1

1 1/4

196.9

190.5

196.9

125

374.7

73.2

196.9

141.2

104.6

155.4

144.5

11.2

292.1

41.1

1 1/2

247.7

241.3

247.7

150

393.7

82.6

228.6

168.4

119.1

171.5

171.5

12.7

317.5

38.1

12

1 3/8

260.4

254.0

266.7

200

482.6

91.9

292.1

219.2

142.7

212.9

222.3

12.7

393.7

44.5

12

1 5/8

292.1

285.8

323.9

250

584.2

108.0

368.3

273.1

177.8

254.0

277.4

12.7

482.6

50.8

12

1 7/8

336.6

330.2

342.9

300

673.1

124.0

450.9

323.9

218.9

282.4

328.2

12.7

571.5

53.8

16

374.7

368.3

387.4

749.3

133.4

495.3

355.6

241.3

298.5

635.0

60.5

16

2 1/4

406.4

400.1

425.5

406.4

260.4

311.2

66.5

16

2 1/2

444.5

438.2

469.9

462.3

12.7

774.7

73.2

16

2 3/4

495.3

489.0

527.1

/Antong

/

:

400

825.5

146.1

552.5

360.2

411.2

To be specified by Purchaser.

O

120.7

350

DRILLING

15

p.com

r

co

B3

Counter

bore

Depth

Threadof

ed

Socket Diam.

Flange

of Bolt

Min.

Circle

12.7

12.7

704.9

Ht

t

p

914.4

162.1

596.9

457.2

276.4

327.2

500

984.3

177.8

641.4

508.0

292.1

355.6

514.4

12.7

831.9

79.2

16

539.8

533.4

565.2

600

1168.4 203.2

762.0

609.6

330.2

406.4

616.0

12.7

990.6

91.9

16

3 1/2

616.0

609.6

647.7

450

NOTE : B = Bore size to be specified by customer

Http://antongcorp.com

+8631180763668

sales@antongcorp.com

ANSI ASME

B16.5 Class2500

CLASS2500

Outside

Thk. of

Nominal Diam. Flange

of

Pipe

Min.

Size Flanges

Diam.

of

Hub

Unit : mm

Corner Counter

LENGTH THROUGH HUB

BORE

DRILLING

LENGTH OF STUD BOLTS

Hub

Radius bore

Male &

Thread

Diam.

of Bore ThreadRaised Female

ed

of

Chamfer Threaded Lapped Welding Length Lapped Welding

Diam. of Diam. of

Diam. of

Number

Face

Ring

or

Neck

Neck Lapped Flange

of W.N

Bolt

Bolt

Bolts

of Bolts

(0.25 Tongue Joint

Min.

Flange

Circle

Holes

(inch)

&

Inch)

A

Y1

Y2

Y3

T

B1

B2

r

Q

Groove

133.4

30.2

42.9

21.3

39.6

39.6

73.2

28.4

22.9

3.0

23.6

88.9

22.4

3/4

120.7

114.3

120.7

20

139.7

31.8

50.8

26.7

42.9

42.9

79.2

31.8

28.2

3.0

29.0

95.3

22.4

3/4

127.0

120.7

127.0

25

158.8

35.1

57.2

33.5

47.8

47.8

88.9

35.1

35.1

3.0

35.8

108.0

25.4

7/8

139.7

133.4

139.7

32

184.2

38.1

73.2

42.2

52.3

52.3

95.3

38.1

43.7

4.8

44.5

130.0

28.4

152.4

146.1

152.4

40

203.2

44.5

79.2

48.3

60.5

60.5

111.3

44.5

50.0

6.4

50.5

146.1

31.8

1 1/8

171.5

165.1

171.5

50

235.0

50.8

95.3

60.5

69.9

69.9

127.0

50.8

62.5

7.9

63.5

171.5

28.4

177.8

171.5

177.8

65

266.7

57.2

114.3

73.2

79.2

79.2

142.7

57.2

75.4

7.9

76.2

196.9

31.8

1 1/8

196.9

190.5

203.2

80

304.8

66.5

133.4

88.9

91.9

168.1

91.4

9.7

228.6

35.1

1 1/4

222.3

215.9

228.6

100

355.6

76.2

165.1

114.3

108.0

190.5

116.8

11.2

273.1

41.1

1 1/2

254.0

247.7

260.4

125

419.1

91.9

203.2

141.2

130.0

228.6

144.5

11.2

323.9

47.8

1 3/4

298.5

292.1

311.2

150

482.6

108.0

235.0

168.4

152.4

273.1

171.5

12.7

368.3

53.8

342.9

336.6

355.6

200

552.5

127.0

304.8

219.2

177.8

317.5

222.3

12.7

438.2

53.8

12

381.0

374.7

393.7

250

673.1

165.1

374.7

273.1

228.6

419.1

277.4

12.7

539.8

66.5

12

2 1/2

489.0

482.6

508.0

300

762.0

184.2

441.5

323.9

254.0

463.6

328.2

12.7

619.3

73.2

12

2 3/4

539.8

533.4

558.8

/Antong

/

:

p.com

r

co

To be specified by Purchaser.

O

15

NOTE : B = Bore size to be specified by customer

Ht

t

p

Http://antongcorp.com

+8631180763668

sales@antongcorp.com

More Information, please visit our website:

Http://antongcorp.com

Antong

/

/

ong

/Ant:

/

:

p.com

r

co

p.com

r

co

ANTONG FITTING & FLANGES

Http://antongcorp.com

Mail: sales@antongcorp.com

Tel: 008631180763668

Ht

t

p

H

t

t

p

S-ar putea să vă placă și

- Welding Bevel Design 3.1 Bevels For Other Than GTAW Root PassDocument2 paginiWelding Bevel Design 3.1 Bevels For Other Than GTAW Root PassaezeadÎncă nu există evaluări

- Welded Joint DesignDocument5 paginiWelded Joint Designscott2355Încă nu există evaluări

- Conversion Table - Decimal, Hexadecimal, Octal, BinaryDocument3 paginiConversion Table - Decimal, Hexadecimal, Octal, BinaryPingthong LingÎncă nu există evaluări

- Tapping Torque Values PDFDocument1 paginăTapping Torque Values PDFNitin AggarwalÎncă nu există evaluări

- Compresor EinhellDocument1 paginăCompresor Einhellmih4iÎncă nu există evaluări

- Weld SymbolsDocument8 paginiWeld SymbolsM.IBRAHEEMÎncă nu există evaluări

- Welding Inspection: Welding Symbols Course Reference WIS 5Document52 paginiWelding Inspection: Welding Symbols Course Reference WIS 5Joerge Ryan MaramotÎncă nu există evaluări

- English 4 Twisted DrillDocument6 paginiEnglish 4 Twisted DrillBozkurt EkinÎncă nu există evaluări

- 65 Monitoring and Measuring Plate Flatness During LappingDocument8 pagini65 Monitoring and Measuring Plate Flatness During Lappingkztro066100% (1)

- NPT Thread Chart - NPT & NPS Fittings Dimensions & SizesDocument2 paginiNPT Thread Chart - NPT & NPS Fittings Dimensions & SizesMarc EdwardsÎncă nu există evaluări

- ESAB Consumable PDFDocument165 paginiESAB Consumable PDFbond8031Încă nu există evaluări

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 paginiQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Încă nu există evaluări

- Instrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard RatingDocument5 paginiInstrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard Ratinggohjh80Încă nu există evaluări

- NPT Thread ChartDocument1 paginăNPT Thread ChartFredy Alvarez LucasÎncă nu există evaluări

- Orbitical WeldingDocument16 paginiOrbitical WeldingchianqiaoÎncă nu există evaluări

- WEP Standard For Reference OnlyDocument37 paginiWEP Standard For Reference OnlyKiran NikateÎncă nu există evaluări

- Adapter Sleeve: Adapter Sleeve Weight ISO Dimensions Locking Nut Locking DeviceDocument8 paginiAdapter Sleeve: Adapter Sleeve Weight ISO Dimensions Locking Nut Locking Devicekets1mechÎncă nu există evaluări

- Brosur Katalog Valve Flange Fitting Elbow Reducer Tee JakartaDocument13 paginiBrosur Katalog Valve Flange Fitting Elbow Reducer Tee JakartaAlvindo Catur SentosaÎncă nu există evaluări

- Welding Procedure Specification (WPS)Document1 paginăWelding Procedure Specification (WPS)Daniel ChewÎncă nu există evaluări

- Inch Thread PlugDocument10 paginiInch Thread PlugAizen SousukeÎncă nu există evaluări

- Weld SymbolsDocument14 paginiWeld SymbolsSureshraaviÎncă nu există evaluări

- MKMB 2603 Materials Testing and Quality Control: Yap Pui Yee MKM 171013Document12 paginiMKMB 2603 Materials Testing and Quality Control: Yap Pui Yee MKM 171013Penny YapÎncă nu există evaluări

- Grades of Steel ChartDocument3 paginiGrades of Steel ChartKimÎncă nu există evaluări

- Calculate Weld Metal VolumeDocument7 paginiCalculate Weld Metal VolumeChris De La Torre0% (1)

- 03 Automatic Submerged Arc Welding Air Liquide Welding 5347173341045849449Document14 pagini03 Automatic Submerged Arc Welding Air Liquide Welding 5347173341045849449daemsal100% (1)

- HeliCoil Insert Specs ImperialDocument1 paginăHeliCoil Insert Specs ImperialAce Industrial SuppliesÎncă nu există evaluări

- ButtWelding Is 11790 1986Document11 paginiButtWelding Is 11790 1986kathir1965Încă nu există evaluări

- Nickel Alloy Based Filler MetalDocument1 paginăNickel Alloy Based Filler MetaljoehodohÎncă nu există evaluări

- Din Flange Din 2627: (Dimensions in MM.)Document12 paginiDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönÎncă nu există evaluări

- Ecoline EST 150-300 FBDocument7 paginiEcoline EST 150-300 FBRicardo BarrosÎncă nu există evaluări

- JIS B2311 Steel Butt Welding Pipe Fittings For Ordinary UseDocument24 paginiJIS B2311 Steel Butt Welding Pipe Fittings For Ordinary Usense mcxÎncă nu există evaluări

- Weld GaugesDocument15 paginiWeld GaugessojeckÎncă nu există evaluări

- Check For Weld Between 50dia & Rainforcement PadDocument8 paginiCheck For Weld Between 50dia & Rainforcement PadUmer AziqÎncă nu există evaluări

- Ptfe Torque Chart Aps KitsDocument2 paginiPtfe Torque Chart Aps KitsJo KingsÎncă nu există evaluări

- Hydro Aluminium - AlSi7Mg0.6Document2 paginiHydro Aluminium - AlSi7Mg0.6Raj PrasanthÎncă nu există evaluări

- S.No SL - No Mogura Deuma Two Tee's One I Two Tee's Du. No Web TCK, MM Flange TCK, MM Width, MM Length, MMDocument12 paginiS.No SL - No Mogura Deuma Two Tee's One I Two Tee's Du. No Web TCK, MM Flange TCK, MM Width, MM Length, MMRajiv DamodarÎncă nu există evaluări

- Part 1 (Final 2022-11-21)Document28 paginiPart 1 (Final 2022-11-21)saraÎncă nu există evaluări

- Swagelok Tubing DataDocument8 paginiSwagelok Tubing DataSyahirul Alim100% (1)

- GMAWDocument12 paginiGMAWsushant47Încă nu există evaluări

- Weld Acceptance Criteria1Document1 paginăWeld Acceptance Criteria1sankarÎncă nu există evaluări

- ASME P NumbersDocument1 paginăASME P NumbersFahri Risfa ZulfiÎncă nu există evaluări

- What Is The Difference Between A Weldolet and A SockoletDocument3 paginiWhat Is The Difference Between A Weldolet and A SockoletWaqas Waqas100% (3)

- Drawing Design: EngineeringDocument25 paginiDrawing Design: Engineeringsukarlan98Încă nu există evaluări

- DWG ST 418-20 - Sockolets - WeldoletDocument11 paginiDWG ST 418-20 - Sockolets - WeldoletLis RincónÎncă nu există evaluări

- Weld History SheetDocument2 paginiWeld History SheetAjin S100% (1)

- Design, Fabrication and Inspection of Welded JointsDocument58 paginiDesign, Fabrication and Inspection of Welded Jointsbaca88Încă nu există evaluări

- Product Data Sheet OK Tigrod 316L: W 'Tungsten Inert Gas Arc Welding'Document2 paginiProduct Data Sheet OK Tigrod 316L: W 'Tungsten Inert Gas Arc Welding'soft4gsmÎncă nu există evaluări

- Ss Pipe WeldingDocument3 paginiSs Pipe WeldingshridharbshenoyÎncă nu există evaluări

- Dynamic Balancing MachineDocument4 paginiDynamic Balancing Machine.x100% (1)

- JCM Split Tee and Weld On Outlets For Industrial ServiceDocument1 paginăJCM Split Tee and Weld On Outlets For Industrial ServiceochableÎncă nu există evaluări

- Weight For Bolt With Nut PDFDocument1 paginăWeight For Bolt With Nut PDFRam RajaramanÎncă nu există evaluări

- Quantity Unit Tools Description RemarksDocument2 paginiQuantity Unit Tools Description RemarksnashÎncă nu există evaluări

- Ladder Rung Calc.Document1 paginăLadder Rung Calc.Azwan ShahÎncă nu există evaluări

- DistortionDocument62 paginiDistortionSharad AtraheÎncă nu există evaluări

- Measuring Length of Pipe in BendsDocument1 paginăMeasuring Length of Pipe in Bendsamacathot06100% (1)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDe la EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryÎncă nu există evaluări

- Dimensions, Sizes and Specification of ANSI ASME B 16.5 FlangesDocument8 paginiDimensions, Sizes and Specification of ANSI ASME B 16.5 FlangesAndres Nicolas Bouvier100% (1)

- Dimensions, Sizes and Specification of ANSI ASME B 16.36 Orifice Flanges PDFDocument8 paginiDimensions, Sizes and Specification of ANSI ASME B 16.36 Orifice Flanges PDFisaac2408Încă nu există evaluări

- Dimensions, Sizes and Specification of LONG WELDING NECK Flanges PDFDocument9 paginiDimensions, Sizes and Specification of LONG WELDING NECK Flanges PDFbalramkinageÎncă nu există evaluări

- Dimensions, Sizes and Specification of JIS B2220 Standard Steel FlangesDocument8 paginiDimensions, Sizes and Specification of JIS B2220 Standard Steel FlangesdjvhÎncă nu există evaluări

- Mitsui Engineering & Shipbuilding Asia Pte. LTD.: Name: DateDocument4 paginiMitsui Engineering & Shipbuilding Asia Pte. LTD.: Name: DateSimbu ArasanÎncă nu există evaluări

- TWI Welding Training 4Document36 paginiTWI Welding Training 4Simbu Arasan100% (1)

- OPES2024 Brochure V7Document12 paginiOPES2024 Brochure V7Simbu ArasanÎncă nu există evaluări

- Serag4000 NotesDocument19 paginiSerag4000 NotesSimbu ArasanÎncă nu există evaluări

- My Desk: Time Is GoldDocument22 paginiMy Desk: Time Is GoldSimbu ArasanÎncă nu există evaluări

- 510 - May 2017 Jan 2018 - PublicationsEffectivity - Final 12 05 16 PDFDocument1 pagină510 - May 2017 Jan 2018 - PublicationsEffectivity - Final 12 05 16 PDFshakeelahmadjsrÎncă nu există evaluări

- Steam Turbine Q & ADocument47 paginiSteam Turbine Q & Asrikanth9555100% (1)

- Uts, Utn, Dry - Weld History Sheet - MasterDocument461 paginiUts, Utn, Dry - Weld History Sheet - MasterSimbu ArasanÎncă nu există evaluări

- BHEL Earthing SystemDocument8 paginiBHEL Earthing SystemSimbu ArasanÎncă nu există evaluări

- CSWIP-WI-6-92 13th Edition July 2015 PDFDocument17 paginiCSWIP-WI-6-92 13th Edition July 2015 PDFjaisonaeroÎncă nu există evaluări

- Pipe Schedule PDFDocument1 paginăPipe Schedule PDFSrinivasan SeenuÎncă nu există evaluări

- Fe-C Phase DiagramDocument34 paginiFe-C Phase DiagramYoung-long Choi100% (1)

- XtrasDocument3 paginiXtrasSimbu ArasanÎncă nu există evaluări

- 571 SummaryDocument3 pagini571 SummarySimbu Arasan100% (1)

- Fe-C Phase DiagramDocument34 paginiFe-C Phase DiagramYoung-long Choi100% (1)

- 003 - Standard Procedure For Coating and WrappingDocument6 pagini003 - Standard Procedure For Coating and WrappingSimbu ArasanÎncă nu există evaluări

- 004 - Standard Procedure For Surface Preparation and PaintingDocument9 pagini004 - Standard Procedure For Surface Preparation and PaintingSimbu ArasanÎncă nu există evaluări

- TATA PROJECTS LIMITED, SBU-Utility Services: Material Requisition Cum Issue Voucher (MRIV)Document4 paginiTATA PROJECTS LIMITED, SBU-Utility Services: Material Requisition Cum Issue Voucher (MRIV)Simbu ArasanÎncă nu există evaluări

- 001 - Standard Procedure For Hydrostatic Pressure Test of PipingDocument8 pagini001 - Standard Procedure For Hydrostatic Pressure Test of PipingSimbu Arasan0% (1)

- 006 CBCRDT Tata ProjectsDocument3 pagini006 CBCRDT Tata ProjectsSimbu ArasanÎncă nu există evaluări

- Electrode Backing RegisterDocument4 paginiElectrode Backing RegisterSimbu Arasan100% (1)

- SaarnaDocument3 paginiSaarnagueridiÎncă nu există evaluări

- UF NF Dispatch Master Data 04-11-15Document47 paginiUF NF Dispatch Master Data 04-11-15Simbu ArasanÎncă nu există evaluări

- UF Membrane Storage & PreservationDocument1 paginăUF Membrane Storage & PreservationSimbu ArasanÎncă nu există evaluări

- Structural Tank Instructions 11967-ADocument22 paginiStructural Tank Instructions 11967-Aiftikhar_khalid_1Încă nu există evaluări

- 2645r - Waterproofing Compounds For Concrete and Cement MortarsDocument13 pagini2645r - Waterproofing Compounds For Concrete and Cement MortarsSimbu ArasanÎncă nu există evaluări

- PF Withdrawl Forms 10cDocument5 paginiPF Withdrawl Forms 10cArun AbÎncă nu există evaluări

- Hot Forming/Bending: Material BS 806 ANSI B 31.1 DIN 17175 MannessmanDocument3 paginiHot Forming/Bending: Material BS 806 ANSI B 31.1 DIN 17175 Mannessmandnageshm4n244Încă nu există evaluări

- SWRO-Mobile Plant Requirements: S.No Item Previous Qty Changed / Required QtyDocument2 paginiSWRO-Mobile Plant Requirements: S.No Item Previous Qty Changed / Required QtySimbu ArasanÎncă nu există evaluări

- DO's & Dont'sDocument5 paginiDO's & Dont'sSimbu ArasanÎncă nu există evaluări

- Washout Valve and Air Valve SizingDocument3 paginiWashout Valve and Air Valve SizingA.AÎncă nu există evaluări

- Piping and Plumbing Fitting - WikipediaDocument16 paginiPiping and Plumbing Fitting - Wikipediaramthecharm_46098467Încă nu există evaluări

- Moody DiagramDocument18 paginiMoody DiagramWilson JustinoÎncă nu există evaluări

- You Might Also Like: Currently UnavailableDocument1 paginăYou Might Also Like: Currently UnavailableChia Sze KiatÎncă nu există evaluări

- Typical VALVES - K VALUEDocument1 paginăTypical VALVES - K VALUEKarthikeyan SankarrajanÎncă nu există evaluări

- Parryware Sanitarywares Pricelist PDFDocument41 paginiParryware Sanitarywares Pricelist PDFahmad shajeeÎncă nu există evaluări

- Mto Valve: CHKD Appd Appd Date DEC DSP/PPN REV Date Description BYDocument4 paginiMto Valve: CHKD Appd Appd Date DEC DSP/PPN REV Date Description BYAnonymous 6S9tcbhÎncă nu există evaluări

- Unidad Hidráulica PF1019Document2 paginiUnidad Hidráulica PF1019Juan Carlos Lopez TorresÎncă nu există evaluări

- Jaxworks Small Business Spreadsheet FactoryDocument66 paginiJaxworks Small Business Spreadsheet Factorypalpat.cmgÎncă nu există evaluări

- Owner's Manual: 404 Moravian Valley Road Waunakee, Wisconsin 53597 Phone: 608-849-3050 - Fax 608-849-7398Document28 paginiOwner's Manual: 404 Moravian Valley Road Waunakee, Wisconsin 53597 Phone: 608-849-3050 - Fax 608-849-7398Greg Reyneke0% (1)

- Vestpak SpiralWound v001 01 2016 PDFDocument19 paginiVestpak SpiralWound v001 01 2016 PDFSaadEddine AtifÎncă nu există evaluări

- Chapter 7: Basic Plumbing Tools For Drainage Pipes and FittingsDocument12 paginiChapter 7: Basic Plumbing Tools For Drainage Pipes and FittingsRhey LuceroÎncă nu există evaluări

- 5 ADM PLUMBING GRADE 9 1st QuarterDocument28 pagini5 ADM PLUMBING GRADE 9 1st QuarterMelnard AlcaydeÎncă nu există evaluări

- Sheet (7) Viscous Flow in PipesDocument4 paginiSheet (7) Viscous Flow in PipesABDELRHMAN ALIÎncă nu există evaluări

- SATRDocument1 paginăSATRAhmed BoraeyÎncă nu există evaluări

- A1A2Document6 paginiA1A2Tommy ArjanggiÎncă nu există evaluări

- Method Statement PlumbingDocument8 paginiMethod Statement Plumbinggvs raoÎncă nu există evaluări

- Ibr Calculation Boiler Integral PipingDocument25 paginiIbr Calculation Boiler Integral PipingP s Jagatheesan100% (1)

- Inspection Requirements of FlangesDocument20 paginiInspection Requirements of FlangesCaspian DattaÎncă nu există evaluări

- BOQ-ValvesDocument4 paginiBOQ-ValvesGourav SharmaÎncă nu există evaluări

- MSS SP 99 WeldoletDocument11 paginiMSS SP 99 WeldoletKailasÎncă nu există evaluări

- Icws Organizational Chart 2021: Production Division Electronic Data Processing DivisionDocument1 paginăIcws Organizational Chart 2021: Production Division Electronic Data Processing Divisionjanuary3196 :DÎncă nu există evaluări

- D11Document1 paginăD11liviu_dovaÎncă nu există evaluări

- R2 - RevADocument12 paginiR2 - RevAChirag ShahÎncă nu există evaluări

- Automatic Drinking Water Saving System For Municipal Water ProjectsDocument46 paginiAutomatic Drinking Water Saving System For Municipal Water ProjectsShanmugam Ramasamy0% (2)

- Gas Flotation Package (Asbea-A-2703) 32294 Ponticelli - Al Shaheen PWTDocument54 paginiGas Flotation Package (Asbea-A-2703) 32294 Ponticelli - Al Shaheen PWTTĩnh Hồ TrungÎncă nu există evaluări

- Exam1 SolutionsDocument6 paginiExam1 SolutionsAriel GamboaÎncă nu există evaluări

- ASPE PSD - CleanoutsDocument2 paginiASPE PSD - CleanoutsNiong DavidÎncă nu există evaluări

- Calculo de Dimension Cajon OverDocument7 paginiCalculo de Dimension Cajon OverJonathan Romero AlfaroÎncă nu există evaluări

- Model 42 Operator ManualDocument28 paginiModel 42 Operator ManualMuzammil AbbasÎncă nu există evaluări