Documente Academic

Documente Profesional

Documente Cultură

The Travels of A T-Shirt in The Global Economy Book Summary

Încărcat de

sreedeals0 evaluări0% au considerat acest document util (0 voturi)

201 vizualizări2 paginiTravels of a Tshirt2 - Few of the chapters

Titlu original

Travels of a Tshirt2

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentTravels of a Tshirt2 - Few of the chapters

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

201 vizualizări2 paginiThe Travels of A T-Shirt in The Global Economy Book Summary

Încărcat de

sreedealsTravels of a Tshirt2 - Few of the chapters

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

The Travels of a T-shirt in the Global

Economy; Book Summary

Chapter IV

Cotton growers have learned how to not spare any piece of the cotton, cottonseed, or even the

junk that goes with it to the gin. Only 24 percent of the material brought to the gin is cotton.

Forty percent of it is what everyone sees as junk, sticks and trash. They are able to mix the sticks

and trash with molasses and feed it to cattle. The seeds are 36 percent of what goes into the gin,

and all of the Bt cottonseeds are used as cattle feed as well. Regular cottonseeds however are

taken apart to make cottonseed oil, which is used as a replacement for corn syrup in a lot of

snack brands, seed meal, which is used as animal food, the seed hull, which is put in fertilizers,

and "linters", which are used in a lot of hard plastics and cushioning.

Growing cotton in other parts of the world is much harder than growing it in the U.S., not

because of the climates, but because of the prices. Farmers in the United States are usually paid 3

to 15 percent more than the average cotton price, but in places like West Africa farmers are

usually paid half of the average market price. Plus, in West Africa the crop yields per acre are

half that of Americas.

When the Bt cottonseed was introduced to China, farmers were able to reduce their

pesticide/herbicide usage from around 20, to about 8. Though, when pests that were minor

problems before became major problems because there was nothing to stop them from growing

and spreading, their pesticide/herbicide count went to around 18. With no one to tell them that

they needed to plant some regular cotton with the Bt cotton the farmers who used the Bt cotton in

China began losing money because they had to buy new seed every year.

Chapter V

American cotton usually leaves the compress in a truck, or by train. It is taken to the coast where

it is put onto a ship and sent to china. When it gets to China it is put in another truck, and driven

to a cotton yarn factory where it is cleaned and smoothed into a soft flat blanket. Then, it's

carded, and drawn into a rope about an inch in diameter, called a sliver. The slivers are wound

onto a can, and from the can are fed into the spindles and twisted into yarn. The yarn is spun onto

large bobbins and is then shipped to a garment factory. In the garment factory the yarn is woven

into long strips of fabric, which are cut into pieces that will soon be sleeves, fronts, backs, and

collars. Those pieces are sent to the sewing room, where they are sewn into the T-shirts that we

buy in our stores today.

As more and more of Americas T-shirts are made in China, their price has been going down, so

there has been some concern about how the shirts are made. Most people who have done in-

depth research about China's clothing production think that there are some concealed sweatshops

in China. Sweatshops are places where people work long hours for little money. They are illegal,

but whoever owns the sweatshop(s) make a lot of money because their prices and costs are lower

than all of their competitors.

Chapter VI

The first country to produce a smart system of making cotton cloth was China. They held the

lead until at least 1750. By the late 1700s Britain took the lead, and by creating new inventions

that made more cloth in the same amount of time they were able to hold the lead for quite a

while. They maintained the lead by keeping their cloth making technology a secret. They were so

determined to keep it a secret that they wouldn't even let skilled textile operatives leave the

country. Though, in 1810, Francis Cabot Lowell, an American, traveled to England with the

hope of bringing back the textile technology. He was successful, and America became the new

world leader in producing cotton cloth in 1820. By the 1930s Japan became the new leader, and

though it faltered during WWII, it remained the leader until the 1970s. Then, Hong Kong was the

largest exporter of clothing, but not for long because China was waking up from the Cultural

Revolution, and with much lower wages they were able to sell their clothing for less too. China

still leads in clothing exports today.

The reason that a country that had just received the textile technology after another country has

had it for years (ex: America and China) could become a world leader in the export of clothing is

because they can offer it for much cheaper, so people would buy it from them instead. This race

to make cheaper and cheaper clothing started in America, where the mill owners would give low

wages to women who were tired of farm life. That is why Japan became the next world leader in

clothing exports, because the mill owners were able to pay their employees less, so the clothing

was less, which in turn caused more demand for the cheap clothing. This is why there are

believed to be so many sweatshops in China.

S-ar putea să vă placă și

- The Travels of a T-Shirt in the Global Economy: An Economist Examines the Markets, Power, and Politics of World Trade. New Preface and Epilogue with Updates on Economic Issues and Main CharactersDe la EverandThe Travels of a T-Shirt in the Global Economy: An Economist Examines the Markets, Power, and Politics of World Trade. New Preface and Epilogue with Updates on Economic Issues and Main CharactersEvaluare: 3.5 din 5 stele3.5/5 (6)

- Travels of A Tshirt Summary4Document3 paginiTravels of A Tshirt Summary4sreedealsÎncă nu există evaluări

- Travels of A Tshirt Summary3Document3 paginiTravels of A Tshirt Summary3sreedeals0% (1)

- Travels of A Tshirt Summary - SampleDocument2 paginiTravels of A Tshirt Summary - SamplesreedealsÎncă nu există evaluări

- Porter Diamond Theory On ChinaDocument5 paginiPorter Diamond Theory On Chinagauravbansall56760% (5)

- Arguments Against Free Trade: Key EconomistsDocument3 paginiArguments Against Free Trade: Key EconomistsChristian Jay LimpangogÎncă nu există evaluări

- Trader Joe'sDocument10 paginiTrader Joe'sShiladitya SwarnakarÎncă nu există evaluări

- Dickens Global Shift NotesDocument15 paginiDickens Global Shift NotesTommy Ekundayo100% (1)

- Chapter 8 Multiple Choice Questions on Trade Policy InstrumentsDocument12 paginiChapter 8 Multiple Choice Questions on Trade Policy InstrumentsBill BennttÎncă nu există evaluări

- Krugman TB ch08Document11 paginiKrugman TB ch08Teresita Tan ContrerasÎncă nu există evaluări

- Accenture GCA Circular FashionTech Trend Report 2018Document48 paginiAccenture GCA Circular FashionTech Trend Report 2018GabrellaÎncă nu există evaluări

- International Islamic University Islamabad Faculty of Management SciencesDocument10 paginiInternational Islamic University Islamabad Faculty of Management SciencesArslanÎncă nu există evaluări

- Importsustituion Korea&brazilDocument58 paginiImportsustituion Korea&brazilAntonini de JiménezÎncă nu există evaluări

- The Myth of Asia's MiracleDocument15 paginiThe Myth of Asia's MiracleshamikbhoseÎncă nu există evaluări

- Starbucks Expansion in AsiaDocument9 paginiStarbucks Expansion in AsiaIvanto Hadiatma100% (1)

- Target Canada Paper - v3Document33 paginiTarget Canada Paper - v3dagreenman1850% (2)

- Globalization and Its Various PhasesDocument3 paginiGlobalization and Its Various Phasesmukesh chutani100% (2)

- Industrial Policy DebateDocument8 paginiIndustrial Policy Debateandinua9525Încă nu există evaluări

- Outside the Box: How Globalization Changed from Moving Stuff to Spreading IdeasDe la EverandOutside the Box: How Globalization Changed from Moving Stuff to Spreading IdeasEvaluare: 4 din 5 stele4/5 (4)

- Cola Wars - Peter ThaminDocument16 paginiCola Wars - Peter Thaminapi-312962821100% (1)

- Intel's Strategic Transition from Memory to MicroprocessorsDocument30 paginiIntel's Strategic Transition from Memory to MicroprocessorsBappa P M BaruaÎncă nu există evaluări

- 1Document3 pagini1prince395Încă nu există evaluări

- Princeton Economics Archive Three-Faces-Inflation PDFDocument3 paginiPrinceton Economics Archive Three-Faces-Inflation PDFadamvolkovÎncă nu există evaluări

- Political Economy Global CommodityDocument5 paginiPolitical Economy Global CommodityVaibhav VishalÎncă nu există evaluări

- The Fabric of Civilization: A Short Survey of the Cotton Industry in the United StatesDe la EverandThe Fabric of Civilization: A Short Survey of the Cotton Industry in the United StatesÎncă nu există evaluări

- Introduction to India's Textile IndustryDocument50 paginiIntroduction to India's Textile IndustryKuldip VyasÎncă nu există evaluări

- Textile IndustryDocument37 paginiTextile IndustryArun_Shankar_K_5239Încă nu există evaluări

- GopalDocument55 paginiGopalUday GowdaÎncă nu există evaluări

- King Cotton: How the South's Most Important Crop Shaped American HistoryDocument4 paginiKing Cotton: How the South's Most Important Crop Shaped American Historypraveen917Încă nu există evaluări

- Cotton Sales and Production in The Era of The American Civil WarDocument13 paginiCotton Sales and Production in The Era of The American Civil Warmegob15Încă nu există evaluări

- A Project Report On BRFLDocument62 paginiA Project Report On BRFLGeethika K Marar0% (1)

- Word CottonessayDocument6 paginiWord Cottonessayapi-253493808Încă nu există evaluări

- Oxfam Education: About CottonDocument3 paginiOxfam Education: About CottonSwatiShelarÎncă nu există evaluări

- Cotton - A Natural Fiber: Free Days. The Most Important Cotton-Growing Countries Are The USA, China, India, PakistanDocument3 paginiCotton - A Natural Fiber: Free Days. The Most Important Cotton-Growing Countries Are The USA, China, India, PakistancieloypiedraÎncă nu există evaluări

- Textile 302 TheoryDocument43 paginiTextile 302 Theorymt khanÎncă nu există evaluări

- Evolution of the Hosiery IndustryDocument12 paginiEvolution of the Hosiery Industry21MCO004 Ajay Kumar K SÎncă nu există evaluări

- NCERT Solutions For Class 10 History Chapter 5 - The Age of IndustrialisationDocument5 paginiNCERT Solutions For Class 10 History Chapter 5 - The Age of Industrialisationᴊᴊ ᴇᴅɪᴛꜱÎncă nu există evaluări

- Suicide Deaths and The Quality of Indian CottonDocument10 paginiSuicide Deaths and The Quality of Indian CottonABGÎncă nu există evaluări

- Textile Industry AnalysisDocument101 paginiTextile Industry Analysisrsaboji60% (10)

- Class 10 History CH 5Document9 paginiClass 10 History CH 5Anirudh RoyalÎncă nu există evaluări

- Chapter - 2 History of Indian Cotton Textile Industry (Pre-Indipendence Period)Document15 paginiChapter - 2 History of Indian Cotton Textile Industry (Pre-Indipendence Period)rohini soniÎncă nu există evaluări

- ScriptDocument3 paginiScriptR RÎncă nu există evaluări

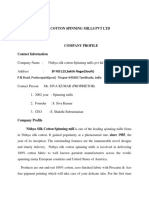

- Nithya Silk Cotton Spinning Mills Pvt Ltd Company ProfileDocument14 paginiNithya Silk Cotton Spinning Mills Pvt Ltd Company ProfileananthakumarÎncă nu există evaluări

- Cotton Hai YeDocument7 paginiCotton Hai Yerahul0751Încă nu există evaluări

- Indian Textile Industry: A History of Innovation and Global TradeDocument54 paginiIndian Textile Industry: A History of Innovation and Global TradeChhaya GahlotÎncă nu există evaluări

- Textile IndustryDocument80 paginiTextile Industryankitmehta23Încă nu există evaluări

- Weavers and Colonialism in IndiaDocument2 paginiWeavers and Colonialism in IndiaGauri GuptaÎncă nu există evaluări

- Industry Profile and ChallengesDocument62 paginiIndustry Profile and ChallengesMukesh kannan MahiÎncă nu există evaluări

- Textile Industry InformationDocument6 paginiTextile Industry InformationJasvinder SinghÎncă nu există evaluări

- The History of FabricDocument15 paginiThe History of FabricAdita AgarwalÎncă nu există evaluări

- Term Paper OF BT CottonDocument16 paginiTerm Paper OF BT CottonVikal RajputÎncă nu există evaluări

- SivanesanDocument42 paginiSivanesanKp PrakashÎncă nu există evaluări

- TextileDocument19 paginiTextileMarc Christian M BaguioÎncă nu există evaluări

- History of Cotton IndustryDocument17 paginiHistory of Cotton IndustryankiahujaÎncă nu există evaluări

- Knitted Fabric ManufcaturingDocument67 paginiKnitted Fabric ManufcaturingShathish VadiveluÎncă nu există evaluări

- Internship Report On Cotton IndustryDocument28 paginiInternship Report On Cotton IndustryTariq Saleem83% (6)

- Cotton Trash ProjectDocument30 paginiCotton Trash Projectapi-318706036Încă nu există evaluări

- History Chapter 6 (Changing The Pattern of Industrialisation Under The BrtishersDocument5 paginiHistory Chapter 6 (Changing The Pattern of Industrialisation Under The BrtishersAdhibhav MaheshwariÎncă nu există evaluări