Documente Academic

Documente Profesional

Documente Cultură

SOR Road Works 2013

Încărcat de

vineetvcebDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

SOR Road Works 2013

Încărcat de

vineetvcebDrepturi de autor:

Formate disponibile

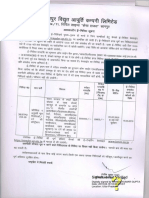

GOVERNMENT OF CHHATTISGARH

PUBLIC WORKS DEPARTMENT

SCHEDULE OF

RATES

FOR

ROAD WORKS

With Effect From 15

th

May , 2013

Issued By

ENGINEER-IN-CHIEF

SOR for Road Works, C.G,. P.W.D. w.e.f 1-04-2013

P.W.D., RAIPUR (C.G.)

INDEX

S.No. Particulars Page

1 FOREWORD 3

2 GENER! NO"ES # $ %

3 &'P"ER$1$ &RRIGE ND S(PP!) OF

*"ERI!

11 + 12

, &'P"ER$2$ SI"E &!ERN&E 13 + 1#

# &'P"ER$3$ ER"' WOR-. EROSION &ON"RO!

ND DRINGE

1/ + 1%

/ &'P"ER$,$ S(B$BSES. BSE &O(RSE

0NON$BI"(*INO(S1 ND S'O(!DERS

22 + 22

3 &'P"ER$#$ BSES ND S(RF&E &O(RSES

0BI"(*INO(S1

23 + 24

4 &'P"ER$/$ &E*EN" &ON&RE"E P5E*EN"S 2% + 32

% &'P"ER$3$ GEOS)N"'E"I&S ND

REINFOR&E*EN" ER"'

31 + 32

12 &'P"ER$4$ "RFFI& SIGNS. *R-INGS 6 O"'ER

ROD PP(R"ENN&ES

33 + ,1

11 &'P"ER$%$ PIPE &(!5ER"S ,2 + ,3

12 &'P"ER$12$ *IN"ENN&E OF RODS ,, + ,#

13 &'P"ER$11$ 'OR"I&(!"(RE ,/ + ,3

1, &'P"ER$12$ RBORI&(!"(RE 6

ROD BE("IFI&"ION

,4 + #2

1# !IS" OF (SEF(! S"NDRD "B!ES #1 + %#

1/ ROD *P OF &''""ISGR' S""E %3

OFFI&E OF "'E ENGINEER$IN$&'IEF. PWD

SIRP(R B'5N . RIP(R 0&.G.1

S&'ED(!E OF R"ES FOR ROD WOR-S IN P.W.D.&''""ISGR'

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page

No. /#212$,1,7W 7SOR713 Rai8ur. dated 1,72#72213

FOREWORD

1) The old schedule of rates for road works was prepared in 2010 and was in force w.e.f.

1/04/2010. Since then the rates of labour material and P.O.. ha!e chan"ed considerabl#.

$s such this schedule of rates has been re!ised takin" into consideration the current rates

for labour materials and P.O..

2) The %inistr# of &oad Transport and 'i"hwa#s has re!ised the specification for road (

brid"e works in $u"ust 2001 )*+th &e!ision1. 9Sta:dard Data Boo; <or :alysis o<

Rates9 of %inistr# of &oad Transport ( 'i"hwa#s, has also been published b# *ndian

&oads -on"ress. These specifications and SO& based on Standard .ata /ook are bein"

adopted "enerall# b# all the States of *ndia and hence the 0ew S.O.&. has been prepared

keepin" in !iew the specifications of &oad and /rid"e works )*+th &e!ision) and on the

basis of the Sta:dard Data Boo; o< *oR"6's.

1) This S.O.R. has been prepared on the basis of the 2Standard .ata /ook for $nal#sis of

&ates2 of %inistr# of &oad Transport ( 'i"hwa#s, published b# *ndian &oads -on"ress.

3ew of the *tems which do not find place in the Standard .ata /ook for $nal#sis of

&ates ha!e also been included in the new S.O.R. as these are re4uired and pro!ided in

the old S.O.R.

4) This Sc=edule o< Rates 0SOR1 for &oad works is brou"ht in force with effect from 1#

t=

*ay. 2213. This SO& shall be applicable for maintenance and construction of roads and

cul!erts in entire Public 5orks .epartment in -hhattis"arh.

6) Some items ha!e been modified in their nomenclature as per re4uirements. The

description of the items is kept accordin" to %inistr# of &oad Transport ( 'i"hwa#s,

7o!ernment of *ndia, 2Specifications for &oad and /rid"e works2 )*+th &e!ision)

published b# the *ndian &oads -on"ress.

8) Standard Tables "i!en in the specifications are anne9ed with the S.O.&., so as to

facilitate eas# reference to the specifications durin" e9ecution.

:) * would like to commend Er. D.-.gra>al -hief ;n"ineer, Er. -.-.Pi8ri -hief

;n"ineer, Er.5.-.Ru:i?=a ;9ecuti!e ;n"ineer and Er. (.S.5er@a $ssistant ;n"ineer

who ha!e contributed considerabl# towards brin"in" out this Schedule of &ates into

effect. * would also like to commend all those who ha!e helped a lot directl# or

indirectl# in brin"in" out this schedule of rates.

<) Su""estions, if an#, towards further impro!ement to this Schedule of &ates for &oad and

/rid"e works will be hi"hl# welcomed.

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page

GENERAL NOTES

1) )a) 2Specifications2 would refer to the 2Specifications for road and brid"e works2 )4

th

&e!ision) published b# the *ndian roads -on"ress $u"ust=2001, on behalf of the

7o!ernment of *ndia, %inistr# of &oad Transport ( 'i"hwa#.

)b) 2-lause2 would refer to clauses of the specifications referred to in note )a) abo!e.

)c) 2;n"ineer>in>char"e2 would refer to the ;9ecuti!e ;n"ineer of the di!ision for the

time bein".

)d) 2Table2 would refer to the table of the aforesaid specifications.

2) The rates of all items include element of settin" out and carr#in" out the work in narrow or

part width of road, where directed.

1) *n the absence of an# stipulation to the contrar#, unit rates for different items of works are

for completin" the works to the specifications i/c full compensation for all operations

detailed in the rele!ant sections of the specifications under 2&ates2. The rates are to be

considered as the full inclusi!e rate for the finished work co!erin" all labour, material,

ro#alties, lease, rent, wasta"e, temporar# work, plant, e4uipment, o!erhead char"es and

profit, unless specified otherwise.

4) %ode of measurements shall be as per pro!isions contained in the rele!ant clauses of the

specifications unless specified otherwise.

6) The rates are inclusi!e of the element of hire and runnin" char"es of all t#pes of plant,

machiner# and e4uipment re4uired to complete the work unless specified otherwise.

&o#alt#, octroi>dut#, commercial and all other ta9es are included in the rates.

8) )i) The rates include makin" arran"ement of traffic as per clause 0o.112 e9cept for

initial treatment to !er"e, shoulders and construction of di!ersion.

)ii) The rates do not include the work of borin" and trial pits, which are to be measured

and paid separatel#.

:) )i) -ost of drums would be char"ed e9tra in case of suppl# of bitumen in packed

drums at &s.160/> each and &s.400/> each for the drum of bitumen and emulsion

respecti!el# if these materials are supplied departmentall#.

)ii) /itumen and modified bitumen shall be obtained from appro!ed 7o!t. petroleum

refineries.

)iii) Onl# +7>10 "rade bitumen will be used in all bituminous works unless specified

otherwise.

)i!) ?5hen -ommercial +ehicles e9ceeds 2000 per da# per lane and the hi"hest dail#

mean temperature e9ceeds 40

o

-. +7>40 or modified bitumen of e4ui!alent

stiffness are recommended for /ituminous -oncrete and top la#ers of .ense

/ituminous %acadam.@ $s per note under Table>4 )selection criteria for "rade

modified bitumen) of *&-A 111>200B.

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page

<) $. Theoretical consumption of bitumen shall be worked out on the basis of the followin"

compacted densities of mi9 A

0i1 for /ituminous %acadam 2.20 "m/cc

0ii1 for ean /ituminous %acadam 2.00 "m/cc

)iii) for .ense /ituminous %acadam 2.10 "m/cc

)i!) for Semi>.ense /ituminous -oncrete 2.10 "m/cc

)!) for /ituminous -oncrete 2.18 "m/cc

/. .urin" construction, if the densit# of mi9 obtained b# Cob mi9 formula for items

mentioned in $)iii), $)i!) ( $)!) abo!e are found less, proportionate cost of bitumen,

at issue rate mentioned in SO& shall be reco!ered from the contractor.

B) 3or profile correcti!e course up to 60 mm thickness /ituminous %acadam with 7radin">2

material with 1.1D bitumen shall be pro!ided. /.E.S.7. shall be used in case the thickness

re4uired for profile correcti!e course is more than 60 mm.

10) The rates also include the element of testin" of samples of !arious materials brou"ht b# the

contractor for use on the work as well as other tests for items of work as stipulated in the

specifications as per clause B01 and its sub>clauses of specifications for road and brid"e

works of %O&T(' )4

th.

re!ision). 3re4uenc# of such tests to be carried out must not be

less than the prescribed fre4uencies. -opies from &e"isters containin" records of tests

shall ha!e to be presented alon" with runnin" account bills. $ record of actual

consumption of materials like , bitumen, cement, steel etc. be maintained at site and cop#

submitted alon" with each runnin" bills and the same should be cross checked with

theoretical consumption before makin" pa#ment. &e"ister )ori"inal) shall ha!e to be

submitted alon" with the final bill. Tests shall ha!e to be conducted for the contractor=s

material b# his ;n"ineers under the super!ision of the ;n"ineer>in>-har"e or his

authoriFed representati!es in the field laborator# established b# the contractor. 'owe!er,

the ;n"ineer>in>-har"e ma# direct to carr# out tests in the departmental laborator# or an#

appro!ed laborator# for which the testin" char"es will be paid b# the contractor or ma# be

deducted from bills. /efore makin" an# pa#ment it will be the responsibilit# of the officer

makin" pa#ment to ensure that all tests as per prescribed fre4uencies ha!e been carried out

and the results are well within the scope of permissible limits.

11) The Sectio:$%22 of the specification mentions 9as reAuired9 a"ainst some of the tests.

To sta!e off disputes the followin" fre4uencies are specified A>

)a) .eleterious material. One test per 600 -um. or part thereof.

)b) -./.&. >>>>>>>>> do >>>>>>>>

12) *t will not be obli"ator# on the part of the ;n"ineer>in>-har"e to pro!ide an# assistance in

obtainin" lease/permits for e9traction of minor minerals. The contractor will not be entitled

to an# e9cuse whatsoe!er on account of an# dela#s in obtainin" minor minerals to be used

on the work.

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page

11) 3or comprehensi!e items, 4uantities of a""re"ates, screenin"s, "ranular materials and

bindin" materials etc. indicated in the specifications are loose. 0o e9tras on account of

an# !oids or bulka"es etc. will be paid separatel#. 5here it is proposed onl# to suppl#,

transport and stack the mineral a""re"ates for use in pa!ement courses, the 4uantities

indicated in the specifications shall be supplied but pa#ment for the same shall be

re"ulated on the basis of !olumes to be computed after deductions specified in -lause

614.6. The stackin" will ha!e to be in a trapeFoidal section ha!in" base 1.60 %., top width

0.60 %. and hei"ht 0.60 %. The len"th should be as lon" as con!enientl# possible.

14) 3or items 7ranular Sub>base, 5./.%., /.E.S.7., Surface .ressin" and Seal -oat t#pe>$

the a""re"ates shall be stacked at site b# the contractor which will be recorded in the

%easurement /ook and 100D check will be affected b# the Sub>.i!isional Officer prior

to their use on work. 0o separate pa#ment shall be made for stackin" as the same is

deemed to be inclusi!e in the rate of these items.

16) 3or construction of reinforced earth retainin" wall, back fillin" shall be paid separatel# as

per -hapter>1 2;arth work, erosion control and draina"e2

18) %etal to be used for all bituminous courses and cement concrete shall be crushed in

mechanical crushers.

1:) *f an# work is found to be sub>standard, but the ;n"ineer>in>-har"e is of the opinion that

the same can be accepted at a reduced rate, then the ;n"ineer>in>-har"e shall submit

proposals for the same, supported b# an anal#sis i.e. Custification of such reduction,

throu"h a ..O. letter to the Superintendin" ;n"ineer concerned, to obtain his appro!al

e9peditiousl# )ordinaril# within 16 da#s). The appro!ed anal#sis alon" with orders of the

Superintendin" ;n"ineer should be appended to the final bill of the contractor.

1<) &ota!ator or similar appro!ed e4uipment capable of mi9in" the material to the desired

de"ree is compulsor# for mi9in" the "raded material.

1B) The -./.&. for Sub>"rade soil )600 mm below the Sub>base ) shall not be less than 6D.

20) The use of !ibrator# roller is essential for all the items where e!er

compaction/consolidation is to be done with rollers unless specified otherwise. 3or narrow

and restricted areas plate compactors shall be used for compaction to achie!e the desired

densit#.

21) The surface re"ularit# of the completed Sub>"rade, Sub>base, /ase courses, widenin" of

surfaces and /ituminous courses in the lon"itudinal and trans!erse directions shall be

within the tolerances indicated in the Table B00>1 of the Specifications. 3or checkin",

Specifications -lause B02 shall appl#. 3ailure to rectif# the same will call for similar

action as pro!ided for in note 1: abo!e.

22) "=e >or; o< s=oulders @ust 8recede t=e >or; o< SuB$Base a:d Base courses a:d

succeed t=e Bitu@i:ous courses a:d &e@e:t &o:crete 8aCe@e:t.

21) The rates for shoulders includes the operation of cleanin" and scrappin" of deleterious

material and preparin" of surface in 4D camber before la#in" of material for construction

of shoulders.

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page

24) &ates for the items of Semi>.ense /ituminous -oncrete, /ituminous -oncrete and .ense

/ituminous %acadam are based on the bitumen percenta"e in these items. $dditional

bitumen re4uired as per Cob mi9 formula will ha!e to be taken into account and be

accommodated b# the contractors in their tender rates. 0o separate pa#ment shall be made

on this account.

26) Onl# cement of re4uired specifications at the rate of 2D b# wei"ht of total a""re"ate will

be used as filler for Semi>.ense /ituminous -oncrete, /ituminous -oncrete and .ense

/ituminous %acadam is mandator#. ime will not be used as filler.

28) a) &ates of items would appl# for work order/piece work s#stem also.

b) &ates pa#able for an# work to be done departmentall# on work order/piece work

ma# either be at>par or below rates in this SO&.

2:) &ates for Transportation in -hapter 0o. 1 of 2-arria"e of %aterial2 include A>

i) oadin" and unloadin" into transport !ehicle with incidental leads up to 100 %. at

each place and all lifts.

ii) Stackin" at suitable places as directed b# the ;n"ineer>in>-har"e, the wei"hts of

the container of an# material shall be i"nored.

2<) The measurements of rock e9ca!ation are to be done as per -lause 101.<. 'owe!er, if the

e9ca!ated rock is utiliFed b# con!ersion into a""re"ates also, then a deduction at the rate

of 46D shall be made from the stacked 4uantit# of a""re"ates. To compute the !olumes of

rock e9ca!ation siFe of the stacks should be as lar"e as con!enient.

2B) &ubble a!ailable from e9ca!ation of hard rock shall be used for con!ersion into coarse

a""re"ates or for other constructions and shall be issued to the contractor at &s.200 per

cubic meter of rock e9ca!ated.

10) 5here!er an e9istin" boulder solin" or 5/% pa!ement is re4uired to be e9ca!ated, it

shall be presumed that the followin" 4uantities of rubble and coarse a""re"ates would be

a!ailable for re>use and issued to the contractor at the rate indicated a"ainst each A>

a) &ubble A> 1 -ubic meter of rubble for e!er# cubic meter of e9ca!ated boulder

solin" G&s.186 per cubic meter of solin".

b) -oarse $""re"ateA > 1.10 -ubic meter for e!er# cubic meter of e9ca!ated 5/%

G &s.200 per cubic meter of e9ca!ated 5/%. );9ca!ated 5/% should be

screened to se"re"ate metal from moorum before re>use).

11) The -ontractor will carr# out dismantlin" of utilities under the super!ision of the

concerned department with prior information to the users.

12) The actual 4uantities of materials shall be as per Cob mi9 formula for bituminous works.

11) The pa!ement camber or cross fall shall be pro!ided as per pro!isions of *&-A :1>1B<0.

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page

14) The Prime coat must be used o!er all "ranular surface before the use of tack coat.

16) The "irth of trees shall be measured at 1.00 meter )One meter) abo!e "round le!el.

18) &ates of site clearance include Cun"le clearance le!elin" and dressin".

1:) $ll wood obtained from the tree cuttin" shall be propert# of the "o!ernment and shall be

deposited at P.5... store as per direction of ;n"ineer>in>-har"e.

1<) atest *.&.-. -odes shall be followed.

1B) *n case of an# contradiction in the pro!isions of the Specifications and this Schedule of

&ates, the pro!isions of the SO& would take precedence.

40) The /asic rates at site for important materials considered in this SO& are as follows A

)a) /itumen +7>40 &s. ,%222.22 per %.T.

)b) /itumen +7>10 &s. ,%%#2.22 per %.T.

)c) /itumen +7>10 &s. ,4132.22 per %.T.

)d) /itumen ;mulsion )&S "rade) &s. ,/222.22 per %.T.

)e) /itumen ;mulsion )SS "rade) &s. ,,1%2.22 per %.T.

)f) -&%/>80 &s. #,144.22 per %.T.

41) *tem 0o. 6.20 ( 6.21 of -hapter>6 are applicable for the works of /astar Hone and these

items can be e9ecuted onl# with the prior written permission of -hief ;n"ineer.

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page

&'P"ER$ 1

&RRIGE ND S(PP!) OF *"ERI!S

Ite@

No.

Descri8tio:s (:it Rate

05olu@e to Be co@8uted as 8er 8roCisio:s i: clause #1,1

1.1 "ra:s8ortatio: o< @etal i7c loadi:g 0By @ec=a:ical

@ea:s1 6 u:loadi:g

i1 3or a lead upto 1 Im. &u@. #4.22

ii1 /e#ond 1 Ims. and upto 10 Ims. )$dd for e!er# 1 Im.) &u@. 2.#2

iii1 /e#ond 10 Ims. and upto 20 Ims. )$dd for e!er# 1 Im.) &u@. 2.22

iC1 /e#ond 20 Ims. and upto 60 Ims. )$dd for e!er# 1 Im.) &u@. 2.22

C1 /e#ond 60 Ims. )$dd for e!er# 1 Im.) &u@. 1.22

1.2 "ra:s8ortatio: o< di<<ere:t ot=er @aterial i7c loadi:g 6

u:loadi:g

&ate as Da"e of metal

transportation rates

a1 3la" Stone/cut stone &u@. ,2D aBoCe

B1 %asonr# stones &u@. 3#D aBoCe

c1 &ubble &u@. 1#D aBoCe

d1 oose moorum/sand/earth/surkhi/cement/stone dust/hot mi9

asphalt material

&u@. 12D Belo>

e1 ;9ca!ated/compacted ordinar# ( other soil measured as per

clause 101.<, 104.4 and 106.<

&u@. 22D aBoCe

<1 ;9ca!ated ordinar# rock measured as per clause 104.4 &u@. %2D aBoCe

g1 -oal/fuel wood/*ron work/steel/7.*. Sheets/ pipes/

lime/machiner# etc.

*.". 3.#D Belo>

=1 160 mm dia ballies R.*. 1.#D o< @etal

i1 :6/100 mm diameter ballies R.*. 2.3#D o< @etal

?1 Tar/paints/bitumen etc. *.". #D aBoCe

;1 'ume pipe/0P4

i) 1000mm dia R.*. 42D o< @etal

ii) 1200mm dia R.*. 112D o< @etal

1.3 "ra:s8ortatio: By truc;s o: =ire

i1 Trucks hired for full load e9cludin" loadin"/unloadin" and

stackin" for items not co!ered abo!e for distancesA

a) Ep to 10 kms. Per Im. 24.22

b) /e#ond 10 Ims. and up to 60 Ims. add e9tra o!er a)

abo!e

Per Im. 22.22

c) /e#ond 60 Ims. add e9tra o!er b) abo!e. Per Im. 14.22

ii1 oadin" of trucks )b# manual means) &u@. /3.22

iii1 Enloadin" of trucks and stackin" )b# manual means) &u@. /3.22

1., 'ire c=arges <or @ac=i:eries E

i1 Tractor with trolle# 'our 232.22

ii1 Tractor mounted water tanker 'our ,#/.22

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 10

iii1 Truck mounted water tanker 'our 423.22

Ite@

No.

Descri8tio:s (:it Rate

iC1 -rane for liftin"

a) 40 T capacit# 'our 3#1.22

b) <0 T capacit# 'our 112/.22

!) '#draulic e9ca!ator of 1.0 -um bucket 'our <<2.00

Ci1 &oad rollers A

)a) Smooth wheeled roller < T 'our 3,2.22

)b) Tandem &oad roller 'our 4,%.22

)c) Pneumatic &oad roller 'our %22.22

)d) +ibrator# roller 'our 11,3.22

Cii1 Tipper 'our 232.22

Ciii1 Truck 'our 21,.22

iF1 7enerators A

a) 11 I+$ 'our 232.22

b) 81 I+$ 'our 23/.22

c) 100 I+$ 'our #,/.22

d) 260 I+$ 'our 1222.2#

F1 Pa!er 3inisher %echanical 'our 323.3#

1.# Su88ly o< @i:eral aggregate li;e Bro;e: sto:e7crus=ed

sto:e 0crus=ed i: @ec=a:ical crus=er1 as 8er clause #1, at

road site i:cludi:g all lead a:d stac;i:g etc. co@8lete.

i1 :6 mm standard siFe broken stone &u@. 3/2.22

ii1 81 mm standard siFe broken stone &u@. 41,.22

iii1 46 mm standard siFe broken stone &u@. 4#4.22

iC1 46 mm standard siFe -rushed stone &u@. 1113.22

C1 22.4 mm standard siFe -rushed stone &u@. 1123.22

Ci1 11.2 mm standard siFe -rushed stone &u@. 1214.22

Cii1 11.2 mm standard siFe -rushed stone &u@. 1214.22

Ciii1 8.: mm standard siFe -rushed stone &u@. #%4.22

1./ Su88ly as 8er clause #.1, i:cludi:g all lead a:d stac;i:g

etc. co@8lete

i1 -rusher stone dust )clause 60:.2.1) &u@. #,/.22

ii1 Sand/Shin"le/Ianker/aterite &u@. #,/.22

iii1 %oorum &u@. 3/,.22

Note

E

*n case of suitable bindin" material ha!in" a P.*. +alue of less

than 8 is not a!ailable within reasonable distances. The

contractor )at his own cost) ma# add an admi9ture of lime to

lower down the P.*. to brin" it within the abo!e ran"e. $

factor of safet# of 2 should be applied to the results of

laborator# to decide the percenta"e of lime to be added.

1.3 Suppl# transportation and stackin" of hot premi9ed

bituminous macadam usin" crushed a""re"ate of "radin" >1

confirmin" to clause 604 with binder content 1.1D b# wei"ht

of from hot mi9 plant site to site inclusi!e of all leads. )3or

this item prior permission of -.;. shall be obtained)

&u@. ##%2.22

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 11

&'P"ER + 2

SI"E &!ERN&E

Ite@

No.

Descri8tio:s (:it Rate 0Rs.1

2.1 &utti:g o< trees, includin" cuttin" of trunks, branches and

remo!al of stumps, roots, stackin" of ser!iceable material with all

lifts and up to a lead of 1000 mtrs and earth fillin" in the

depression/pit and as per rele!ant clauses of section>200 for A>

i1

7irth from 100 mm to 800 mm Eac=. 1,2.22

ii1

7irth be#ond 800 mm to B00 mm Eac=. 2#3.22

iii1

7irth be#ond B00 mm to 1<00 mm Eac=. ,4%.22

iC1

7irth abo!e 1<00 mm Eac=. %1/.22

2.2 &leari:g Grass a:d Re@oCal o< RuBBis= )clearin" "rass and

remo!al of rubbish up to a distance of 60 meters outsite the

peripher# of the area)

'ectare. %1//.22

2.3 &leari:g a:d gruBBi:g road land includin" uprootin" rank

!e"etation, "rass, bushes, shrubs, saplin"s and trees "irth up to 100

mm, remo!al of stumps of trees cut earlier and disposal of

unser!iceable materials and stackin" of ser!iceable material to be

used or auctioned up to a lead of 1000 meters includin" remo!al

and disposal of top or"anic soil not e9ceedin" 160 mm in thickness

if re4uired and as per rele!ant clauses of section>200.

$

*n area of li"ht Cun"le 'ectare. 23423.22

/ *n area of thorn# Cun"le

'ectare. 33233.22

2., Dis@a:tli:g o< eFisti:g structures like cul!erts, brid"es,

retainin" walls and other structure comprisin" of masonr#, cement

concrete, wood work, steel work, includin" T(P and scaffoldin"

where!er necessar#, sortin" the dismantled material, disposal of

unser!iceable material and stackin" the ser!iceable material with

all lifts and lead up to 1000 meters and as per rele!ant clauses of

section>200 in

0i1 !i@e 7 &e@e:t &o:crete

ime -oncrete, cement concrete "rade %>10 and below

&u@. 213.22

B -ement -oncrete 7rade %>16 ( %>20

&u@. 2,%.22

& Pre>stressed / &einforced cement concrete "rade %>20 ( abo!e

&u@. /22.22

0ii1 Bric; 7 "ile >or;

*n lime mortar

&u@. 13%.22

B *n cement mortar

&u@. 13/.22

& *n mud mortar

&u@. 12#.22

D .r# brick pitchin" or brick solin"

&u@. 113.22

0iii1 Sto:e *aso:ry

&ubble stone masonr# in lime mortar

&u@. 1#,.22

B &ubble stone masonr# in cement mortar.

&u@. 13/.22

& &ubble Stone %asonr# in mud mortar.

&u@. 13%.22

D .r# rubble masonr#

&u@. 132.22

E Stone pitchin"/ dr# stone spalls.

&u@. 12#.22

F /oulders laid in wire crates includin" openin" of crates and

stackin" dismantled materials.

&u@. 13%.22

Ite@ Descri8tio:s (:it Rate 0Rs.1

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 12

No.

0iC1 5ood work wrou"ht framed and fi9ed in frames of trusses upto a

hei"ht of 6 m abo!e plinth le!el.

&u@. 2%3.22

0C1 Steel work in all t#pes of sections up to a hei"ht of 6 m abo!e

plinth le!el e9cludin" cuttin" of ri!et.

*ncludin" dismemberin" "o:e. 332.22

B ;9cludin" dismemberin". "o:e. ##3.22

& ;9tra o!er item 0o) + ) $ and) + ) / for cuttin" ri!ets. Eac=. #.22

0Ci1 Scra8i:g o< Bric;s dis@a:tled <ro@ Bric; >or; i:cludi:g

stac;i:g.

*n lime/-ement mortar 1222No. /,2.22

B *n mud mortar 1222No. 22%.22

0Cii1 Scra8i:g o< Sto:e <ro@ dis@a:tled sto:e @aso:ry

*n cement and lime mortar &u@. 2#3.22

B *n %ud mortar &u@. ##.22

0Ciii1 Scra8i:g 8laster i: li@e or ce@e:t @ortar <ro@ Bric;7 sto:e

@aso:ry

SA@. 4.22

0iF1 &emo!in" all t#pe of hume pipes and stackin" within a lead up to

1000 meters includin" earthwork and dismantlin" of masonr#

works around pipes.

Ep to 1000 mm dia *eter. 233.22

B $bo!e 1000 mm dia *eter. 3/3.22

2.# Dis@a:tli:g o< <leFiBle 8aCe@e:ts and disposal of dismantled

materials up to a lead of 1000 meters, stackin" ser!iceable and

unser!iceable materials separatel# and as per rele!ant clauses of

section>200.

$ /ituminous courses &u@. 3%1.22

/ 7ranular courses &u@. 24,.22

2./ Dis@a:tli:g o< ce@e:t concrete pa!ement i/c breakin" to pieces

not e9ceedin" 0.02 cum in !olume and stock pilin" at desi"nated

locations and disposal of dismantled materials up to a lead upto

1000 meters, stackin" ser!iceable and unser!iceable materials

separatel# and as per rele!ant clauses of section>200.

&u@. %22.22

2.3 Dis@a:tli:g guard rails b# manual means and disposal of

dismantled material with all lifts and up to a lead upto 1000

meters, stackin" ser!iceable materials and unser!iceable materials

separatel# and as per rele!ant clauses of section>200.

*eter. ,3.22

2.4 Dis@a:tli:g ;erB sto:e b# manual means and disposal of

dismantled material with all lifts and up to a lead upto 1000 meter

and as per rele!ant clauses of section>200.

*eter. %.22

2.% Dis@a:tli:g ;erB sto:e c=a::el b# manual means and disposal

of dismantled material with all lifts and up to a lead upto 1000

meter and as per rele!ant clauses of section>200

.

*eter. 13.22

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 11

Ite@ No. Descri8tio:s (:it Rate 0Rs.1

2.12 Dis@a:tli:g o< ;ilo@eter sto:e includin" cuttin" of earth,

foundation and disposal of dismantled material with all lifts

and lead upto 1000 m and back fillin" of pit.

6th I% stone

Eac=. 222.22

B

Ordinar# I% Stone

Eac=. 122.22

&

'ectometer Stone

Eac=. 2,.22

2.11 Dis@a:tli:g o< BarBed >ire <e:ci:g7 >ire @es= <e:ci:g

includin" posts, foundation concrete, back fillin" of pit b#

manual means includin" disposal of dismantled material with

all lifts and up to a lead of 1000 meters, stackin" ser!iceable

material and unser!iceable material separatel#.

*eter. 2#.22

2.12 Dis@a:tli:g o< &I >ater 8i8e li:e 800 mm dia includin"

disposal with all lifts and lead up to 1000 meters and stackin"

of ser!iceable material and unser!iceable material separatel#

under super!ision of concerned department.

*eter. /3.22

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 14

&'P"ER$ 3

ER"' WOR-. EROSION &ON"RO! ND DRINGE

Ite@ No. Descri8tio:s (:it Rate

3.1 EFcaCatio: i: Soil 0By *a:ual *ea:s.1

;9ca!ation for roadwa# in soil usin" includin" loadin" in

tipper for carr#in" of cut earth to embankment site and

unloadin" with all lifts and lead upto1000 meters as per

rele!ant clauses of section 100.

&u@. 12/.22

3.2 EFcaCatio: i: Soil 0By *ec=a:ical *ea:s.1

;9ca!ation for roadwa# in soil usin" includin" loadin" in

tipper for carr#in" of cut earth to embankment site and

unloadin" with all lifts and lead upto 1000 meters as per

rele!ant clauses of section 100.

&u@. ,2.22

3.3 EFcaCatio: i: ordi:ary roc; includin" loadin" in a truck and

carr#in" of e9ca!ated material to embankment site with in all

lifts and leads upto 1000 meters as per rele!ant clauses of

section 100.

&u@. 12%.22

3., EFcaCatio: i: 'ard Roc; )re4uirin" blastin") with disposal

upto 1000 meters );9ca!ation for roadwa# in hard rock

)re4uirin" blastin") b# drillin", blastin" and breakin",

trimmin" of bottom and side slopes in accordance with

re4uirements of lines, "rades and cross sections, loadin" and

disposal of cut road with in all lifts and leads up to 1000 meters

as per rele!ant clauses of section 100.

&u@. 1%2.22

3.# EFcaCatio: i: 'ard Roc; 0Blasti:g 8ro=iBited1 );9ca!ation

for roadwa# in hard rock )blastin" prohibited) with rock

breakers includin" breakin" rock, loadin" in tippers and

disposal within all lifts and lead upto 1000 meters, trimmin"

bottom and side slopes in accordance with re4uirements of

lines, "rades and cross sections as per rele!ant clauses of

section 100.

&u@. 21#.22

3./ EFcaCatio: i: 'ard Roc; 0co:trolled Blasti:g1 with

disposal upto 1000 meters );9ca!ation for roadwa# in hard

rock with controlled blastin" b# drillin", blastin" and breakin",

trimmin" of bottom and side slopes in accordance with

re4uirements of lines, "rades and cross sections, loadin" and

disposal of cut road with in all lifts and leads up to 1000 meters

as per rele!ant clauses of section 100.

&u@. 2%4.22

3.3 EFcaCatio: i: *ars=y Soil );9ca!ation for roadwa# in

marsh# soil with h#draulic e9ca!ator 0.B cum bucket capacit#

includin" cuttin" and loadin" in tippers and disposal with in all

lifts and lead upto 1000 meters, trimmin" of bottom and side

slopes in accordance with re4uirements of lines, "rades and

cross sections.)

&u@. 3#.22

3.4 Re@oCal o< (:serCiceaBle Soil with .isposal up to 1000

meters )&emo!al of unser!iceable soil includin" loadin" and

disposal up to 1000 meters lead but e9cludin" replacement b#

suitable soil which shall be paid separatel# as per clause 106.)

&u@. 31.22

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 16

Ite@ No. Descri8tio:s (:it Rate

3.% Scari<yi:g EFisti:g Gra:ular Surface to a .epth of 60 mm

)Scarif#in" the e9istin" "ranular road surface to a depth of 60

mm and disposal of scarified material within all lifts and leads

up to 1000 meters. )

SA@. 1,.22

3.12 Scari<yi:g eFisti:g Bitu@i:ous surface to a depth of 60 mm

)Scarif#in" the e9istin" bituminous road surface to a depth of

60 mm and disposal of scarified material with in all lifts and

lead up to 1000 meters.)

SA@. 22.22

3.11 $dd e9tra o!er item 1.1to 1.2 ( 1.: to 1.10 abo!e for

transportation for disposal be#ond 1.0 Im lead.

&u@. 5ide ite@

No. 1.1 6

1.2 o<

&=a8ter$1

3.12 &o:structio: o< e@Ba:;@e:t 7 suB$grade >it= *aterial

OBtai:ed <ro@ Borro> Pits )-onstruction of embankment

with appro!ed material/selected soil ha!in" -./.&. J 6 )unless

specified otherwise in the contract) obtained from borrow pits

with all lifts and leads, transportin" to site, spreadin", "radin"

to re4uired slope and compactin" to meet re4uirement of table

100>2)

&u@. 1,#.22

3.13 &o:structio: o< E@Ba:;@e:t >it= *aterial De8osited

<ro@ Road>ay &utti:g )-onstruction of embankment with

appro!ed materials ha!in" -./.&. J 6 )unless specified

otherwise in the contract) deposited at site from roadwa#

cuttin" and e9ca!ation from drain and foundation of other

structures "raded and compacted to meet re4uirement of table

100>2)

&u@. 3,.22

3.1, &o@8acti:g Origi:al Grou:d

0 i 1 &o@8acti:g Origi:al Grou:d su88orti:g suB$grade

oosenin" of the "round upto a le!el of 600 mm below the

sub"rade le!el , watered, "raded and compacted in la#ers to

meet re4uirement of table 100>2 for sub "rade construction

.

&u@. ,3.22

0 ii 1 &o@8acti:g Origi:al Grou:d su88orti:g e@Ba:;@e:t

oosenin", le!elin" and compactin" ori"inal "round to

facilitate placement of first la#er of embankment, scarified to a

depth of 160 mm, mi9ed with water at O.%.-. and then

compacted b# rollin" so as to achie!e minimum dr# densit# as

"i!en in table 100>2 for embankment construction.

&u@. 2/.22

3.1# Sur<ace Drai:s i: Soil )-onstruction of unlined surface drains

of a!era"e cross sectional area 0.40 s4m in soil to specified

lines, "rades, le!els and dimensions to the re4uirement of

clause 101 and 10B. ;9ca!ated material to be used in

embankment within a lead of 60 meters )a!era"e lead 26

meters)

*eter. ,1.22

3.1/ Sur<ace Drai:s i: Ordi:ary Roc; )-onstruction of unlined

surface drain of a!era"e cross sectional area 0.4 s4m in

ordinar# rock to specified lines, "rades, le!els and dimensions

as per appro!ed desi"n and to the re4uirement of clause 101 to

10B. ;9ca!ated material to be used in embankment at site.)

*eter. 43.22

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 18

Ite@ No. Descri8tio:s (:it Rate

3.13 SuB Sur<ace Drai:s >it= Per<orated Pi8e )-onstruction of

subsurface drain with perforated pipe of 100 mm internal

diameter of cement concrete closel# Cointed, perforations

ran"in" from 1 mm to 8 mm dependin" upon siFe of material

surroundin" the pipe, with 160 mm beddin" below the pipe and

100 mm cushion abo!e the pipe, cross section of e9ca!ation

460 9 660 mm. ;9ca!ated material to be utiliFed in roadwa# at

site )

*eter. ,,2.22

3.14 ggregate SuB$ Sur<ace Drai:s )-onstruction of a""re"ate

sub surface drain 100 mm 9 460 mm with a""re"ates

conformin" to table 100>4, e9ca!ated material to be utiliFed in

roadwa# )

*eter. 44.22

3.1% &o:structio: o< R&& o8e: drai:

0i1 &o:structio: o< R&& o8e: drai: 1.2@ F 1.2@ i:side

di@e:sio: lined with 160 mm thick &-- %>20 walls, 160 mm

thick -- %>20 foundation, o!er 100 mm thick )$!) le!elin"

course in P-- %>16 includin" e9ca!ation , dressin" of sides

and bottom, pro!ision of 'KS. reinforcement consistin" 10

mm dia horiFontal bars G 160 mm c/c and >shaped 10 mm

dia !ertical bars G 160 mm c/c )L1400 mm) includin" cuttin"

, bendin" and bindin" wire, placin" in position ,pro!idin"

shutterin" and concretin" b# usin" concrete mi9er, compaction

b# !ibration etc complete as per drawin"s and technical

specifications.

*eter. 3331.22

0ii1 &o:structio: o< R&& o8e: drai: 2./2@ F 2./2@ i:side

di@e:sio: lined with 120 mm thick &-- %>20 walls, 120 mm

thick -- %>20 foundation, o!er 100 mm thick )$!) le!elin"

course in P-- %>16 includin" e9ca!ation , dressin" of sides

and bottom, pro!ision of 'KS. reinforcement consistin" <

mm dia horiFontal bars G 160 mm c/c and >shaped < mm dia

!ertical bars G 160 mm c/c )L <00 mm) includin" cuttin" ,

bendin" and bindin" wire, placin" in position , pro!idin"

shutterin" and concretin" b# usin" concrete mi9er, compaction

b# !ibration etc complete as per drawin"s and technical

specifications.

*eter. 22/2.22

0iii1 Pro!idin" and la#in" 16 cm ) $!era"e ) thickness hammered

dressed dr# stone +>shaped road side surface drains as per

%O&T('s specifications with all leads and lifts complete.

) &efer to %anual for 'ill &oads *&-ASPA4<>1BB<.)

SA@. 32#.22

3.22 &o:structio: o< Roc; <ill E@Ba:;@e:t )-onstruction of

rock fill embankment with broken hard rock fra"ments

obtained from roadwa# e9ca!ation of siFe not e9ceedin" 100

mm laid in la#ers not e9ceedin" 600 mm thick includin" fillin"

of surface !oids with stone spalls, blindin" top la#er with

"ranular material, rolled with !ibrator# road roller, all complete

as per clause 111)

&u@. ,3.22

3.21 E@Ba:;@e:t &o:structio: >it= Fly as=7Po:d as= aCailaBle

<ro@ coal or lig:ite Bur:i:g "=er@al Pla:ts as >aste

@aterial. )-onstruction of embankment with fl# ash

conformin" to table 1 of *&-ASPA6<>2001 obtained from coal

or li"nite burnin" thermal power stations as waste material,

spread and compacted in la#er of 200mm thickness each at

&u@. 21/.22

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 1:

O%-, all as specified in *&-ASPA6<>2001 and as per appro!ed

plans.)

Ite@ No. Descri8tio:s (:it Rate

3.22 ProCidi:g a:d layi:g aggregate a:d sa:d coCer <or

aggregate drai:s with all leads and lifts as per clause 10B.1.8

) onl# a""re"ate crushed in mechanical crusher shall be used

and measurement from outer ends of sand co!er.)

&u@. /3,.22

3.23 ProCidi:g &=ute drai:s consistin" of 0P>2 &-- half round,

100 mm dia pipes , laid o!er block of -.-. 1A1A8 ) 20mm and

down a""re"ates ) siFe 460 mm 9 286 mm laid o!er filter

media ) measured and paid separatel# ) includin" all false work

etc. complete.

*eter. 1,#/.22

3.2, &o:structio: o< R&& Drai:7&oCer7&=a@Ber

0i1 EFcaCatio: <or drai: );arth work in e9ca!ation for

drain/chamber as per drawin" and technical specification,

includin" settin" out, construction of shorin" and bracin",

remo!al of stumps and other deleterious matter, dressin" of

sides and bottom and backfillin" with appro!ed material.)

&u@. 12/.22

0ii1 -onstruction of &-- drain/co!er/chamber placin" in position,

pro!idin" shutterin" and concretin" b# usin" concrete mi9er,

compaction b# !ibration etc complete as per drawin"s and

technical specifications e9cludin" reinforcement.

with &-- %>20

&u@. ,22,.22

0iii1 Suppl#in", 3ittin" and Placin" un>coated 'KS. bar

&einforcement in drain/co!er/chamber complete as per

.rawin" and Technical Specifications.

*". ,43/2.22

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 1<

&'P"ER + ,

S(B$BSES. BSES 0 NON$ BI"(*INO(S1 ND S'O(!DERS

Ite@ No. Descri8tio:s (:it Rate

,.1 Gra:ular SuB$Base as 8er "aBleE$ ,22$1

-onstruction of "ranular sub>base b# pro!idin" close "raded

%aterial, , carria"e of mi9ed %aterial to work site, spreadin" in

uniform la#ers with motor "rader on prepared surface waterin",

rollin" and compactin" with !ibrator# power roller at O%- to

achie!e the desired densit#, complete as per clause 401

Pla:t @iF @et=od )with %echanicall# crushed stone onl#)

0i1 for "radin"> * %aterial &u@. 1221.22

0ii1 for "radin"> ** %aterial &u@. 11%,.22

0iii1 for "radin">*** %aterial &u@. %%4.22

B By *iF i: 8lace @et=od

.isinte"rated rock i.e moorum ha!in" -/& !alue not less than

20 and P.*. and .. not more than 8 and 20 respecti!el#.

&u@. #,#.22

,.2 !i@e StaBiliGatio: <or I@8roCi:g SuB$grade )a#in" and

spreadin" a!ailable soil in the sub>"rade on a prepared surface,

pul!eriFin", mi9in" the spread soil in place with rota!ator with

1D slaked lime ha!in" minimum content of :0D of -aO,

"radin" with motor "rader and compactin" with the road roller

at O%- to the desired densit# to form a la#er of impro!ed sub>

"rade)

&u@. 324.22

,.3 !i@e "reated Soil <or SuB$Base )Pro!idin", la#in" and

spreadin" soil on a prepared sub>"rade, pul!eriFin", mi9in" the

spread soil in place with rota!ator with 1 D slaked lime with

minimum content of :0D of -aO, "radin" with motor "rader

and compactin" with the road roller at O%- to achie!e at least

B<Dof the ma9 dr# densit# to form a la#er of sub base.)

&u@. 341.22

,., &e@e:t "reated Soil SuB$Base7 Base )Pro!idin", la#in" and

spreadin" soil on a prepared sub>"rade, pul!eriFin", addin" the

desi"ned 4uantit# of cement to the spread soil, mi9in" in place

with rota!ator, "radin" with the motor "rader and compactin"

with the road roller at O%- to achie!e the desired unconfined

compressi!e stren"th and to form a la#er of sub>base/base.)

&u@. #32.22

,.# &e@e:t "reated &rus=ed Roc; or co@Bi:atio: as 8er

clause ,23.2 a:d taBle ,22., i: SuB$Base7 Base )Pro!idin",

la#in" and spreadin" %aterial on a prepared sub>"rade, addin"

the desi"ned 4uantit# of cement to the spread %aterial, mi9in"

in place with rota!ator, "radin" with the motor "rader and

compactin" with the road roller at O%- to achie!e the desired

unconfined compressi!e stren"th and to form a la#er of sub>

base/base.)

0i1 3or Sub>/ase course &u@. 1#%4.22

0ii1 3or /ase course &u@. 1,14.22

,./ *a;i:g #2 @@ F #2 @@ Furro>s )%akin" 60 mm 9 60 mm

furrows, 26mm deep, 460 mm to the center line of the road and

at one meter inter!al in the e9istin" thin bituminous wearin"

coarse includin" sweepin" and disposal of e9ca!ated material

within 1000 meters lead)

)i) 26 mm deep furrow cuttin" SA@ ,.22

)ii) 60 mm deep furrow cuttin" SA@ 4.22

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 1B

Ite@ No. Descri8tio:s (:it Rate

,.3 I:Certed &=o;e )-onstruction of in!erted choke b# pro!idin",

la#in", spreadin" and compactin" screenin" / t#pe/ coarse

sand of specified "rade in uniform la#er on a prepared surface

with motor "rader and compactin" with power roller etc)

&u@ #/%.22

,.4 Water Bou:d *acada@ )Pro!idin", la#in", spreadin" and

compactin" stone a""re"ates of specific siFes to water bound

macadam specification includin" spreadin" in uniform

thickness, hand packin", rollin" with !ibrator# roller <>10

tonnes in sta"es to proper "rade and camber, appl#in" and

broomin" re4uisite t#pe of screenin"/ bindin" %aterials to fill

up the interstices of coarse a""re"ate, waterin" and compactin"

to the re4uired densit#.)

Gradi:g$ II 0(si:g Scree:i:g &rus=aBle ty8e suc= as

*ooru@ or GraCel1

0i1 Esin" Screenin" -rushable t#pe such as %oorum or 7ra!el &u@ 13#4.22

0ii1 Esin" Screenin" T#pe>$ )11.2mm $"".) &u@ 1,#2.22

0iii1 Esin" Screenin" T#pe>/ )11.2mm $"".) &u@ 1#2#.22

B Gradi:g$ III 0(si:g Scree:i:g &rus=aBle ty8e suc= as

*ooru@ or GraCel1

0i1 Esin" Screenin" -rushable t#pe such as %oorum or 7ra!el &u@ 13#4.22

0ii1 Esin" Screenin" T#pe>/ )11.2mm $"".) &u@ 1#2#.22

,.% &rus=ed &e@e:t &o:crete SuB$Base 7 Base )/reakin" and

crushin" of material obtained b# breakin" dama"ed cement

concrete slabs to siFe ran"e not e9ceedin" :6 mm as specified

in table 400.: transportin" the a""re"ates obtained from

breakin" of cement concrete slabs., la#in" and compactin" the

same as sub base/ base course, constructed as 5/% to clause

404 e9cept the use of screenin" or bindin" %aterial.)

&u@ 14/.22

,.12 Pe:etratio: &oat OCer "o8 !ayer o< &rus=ed &e@e:t

&o:crete Base )Spra#in" of bitumen o!er cleaned dr# surface

of crushed cement concrete base at the rate of 26 k" per 10 s4m

b# a bitumen pressure distributor, spreadin" of ke# a""re"ates

at the rate of 0.11 cum per 10 s4m b# a mechanical "ritter and

rollin" the surface as per clause 608.1.<)

SA@ 14.22

,.11 Wet *iF *acada@ )Pro!idin", la#in", spreadin" and

compactin" "raded stone a""re"ate to wet mi9 macadam

specification includin" premi9in" the %aterial with water at

O%- in mechanical mi9 plant carria"e of mi9ed %aterial b#

tipper to site, la#in" in uniform la#ers with pa!er in sub> base /

base course on well prepared surface and compactin" with

!ibrator# roller to achie!e the desired densit#.)

&u@ 1243.22

,.12 &o:structio: o< *edia: a:d Isla:d >it= Soil "a;e: <ro@

Road>ay &utti:g )-onstruction of %edian and *sland abo!e

road le!el with appro!ed material deposited at site from

roadwa# cuttin" and e9ca!ation for drain and foundation of

other structures, spread, "raded and compacted as per clause>

40:

&u@ 13,.22

,.13 &o:structio: o< *edia: a:d Isla:d >it= Soil "a;e: <ro@

Borro> reas )-onstruction of median and *sland abo!e road

le!el with appro!ed material brou"ht from borrow pits, spread,

sloped and compacted as per clause>40:)

&u@ 2,2.22

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 20

Ite@ No. Descri8tio:s (:it Rate

,.1, &o:structio: o< S=oulders )-onstruction of shoulders as per

clause 40: with selected soil from borrow pits / borrow areas

ha!in" -/& not less than 12 and shall ha!e .. and P.*. not

more than 26D and 8D respecti!el#, inclusi!e of all leads and

lifts, includin" clearin" and scrappin" of e9istin" surface,

pro!idin" 4D camber, compactin". waterin" rollin" and ro#alt#

char"es etc. complete.

$ 5ith !ibrator# roller &u@ 1%3.22

/ 5ith smooth wheeled roller &u@ 13%.22

,.1# ProCidi:g 222 @@ t=ic; 0 Cerage 1 sto:e 8aCi:g to

s=oulders includin" dressin", le!elin" to camber and

compactin" the base etc. with A

0i1 'ammer dressed stones, "aps to be filled with spalls hammered

and ri!er sand.

SA@ ,/,.22

0ii1 /ricks )laid in 100 to 112 mm thickness) of crushin" stren"th

not less than :0 k"/cm

2

when tested to *ndian Standards with

Coints filled with ri!er sand.

SA@ 32,.22

,.1/ Foot8at=s a:d Se8arators )-onstruction of footpath/separator

b# pro!idin" a 160 mm compacted "ranular sub base as per

clause 401 and 26 mm thick cement concrete "rade %>16, o!er

laid with precast concrete tiles in cement mortar 1A1 includin"

pro!ision of all draina"e arran"ements but e9cludin" kerb

channel..)

SA@ 1#34.22

,.13 ProCidi:g a:d <iFi:g guard sto:es 200 9 200 9 B00 mm made

of precast &-- %>20 "rade fi9ed at 100 mm into the "round in

P.-.-. 1A1A8 blocks of siFe 400 9 400 9 400 mm and "i!en two

coats of paint with white and black bands includin" e9ca!ation.

Eac= ,13.22

,.14 ProCidi:g a:d <iFi:g ;erB sto:es 100 mm thick and 800 mm

wide chisel dressed cut stones fi9ed in -- 1A1A8 )block siFe

260 9 226 mm) includin" all e9ca!ation.

R* 232.22

,.1% ProCidi:g #2 @@ t=ic; <lag sto:e <loori:g includin"

beddin" in -% 1A8 o!er 100 mm thick -- 1A1A8 includin"

cement pointin" 1A1 dressin" of stones and all e9ca!ation.

SA@ #%2.22

,.22 !i@e. Fly as= staBiliGed soil suB$Base )-onstruction of Sub>

base usin" lime>fl# ash admi9ture with "ranular soil, free from

or"anic matter/ deleterious material or cla#e# silts and low

plasticit# cla#s ha!in" P* between 6 and 20 and li4uid limit

less than 26 and commercial dr# lime, slaked at site or pre>

slaked with -aO content not less than 60D, fl# ash to conform

to "radation as per clause 4.1 of *&-A <<>1B<4, lime M fl# ash

content ran"in" between 10 to 10D, the minimum un>confined

compressi!e stren"th and -/& !alue after 2< da#s curin" and 4

da#s soakin" to be :.6k"/cm

2

and 26D respecti!el#, all as

specified in *&-A <<A1B<4. )

&u@ 34,.22

&'P"ER$ #

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 21

BSES ND S(RF&E &O(RSES 0BI"(*INO(S1

Ite@ No. Descri8tio:s (:it Rate

#.1 Pri@e coat )Pro!idin" and appl#in" primer coat with bitumen

emulsion )SS>1) on prepared surface of "ranular /ase

includin" clearin" of road surface and spra#in" primer at the

rate of 0.<6 k"/s4m usin" mechanical means)

SA@ ,,.22

#.2 "ac; coat Pro!idin" and appl#in" tack coat with bitumen

emulsion )&S>1) usin" emulsion pressure distributor on the

prepared bituminous/"ranular surface cleaned with mechanical

broom and as per clause 601 of section 600

0i1 0ormal bituminous surface G 0.26 k" / S4m SA@ 1,.22

)ii) .r# and hun"r# bituminous surfaces/ "ranular surfaces

treated with primes G 0.10 k" / S4m

SA@ 13.22

0iii1 )0on>bituminous surface) 7ranular base not SA@ 22.22

primed G 0.40 k" / S4m

0iC1 )0on>bituminous surface) -ement concrete G 0.16 k"/

S4m

SA@ 1%.22

#.3 "ac; coat Pro!idin" and appl#in" tack coat with bitumen

usin" pressure distributor on the prepared bituminous/"ranular

surface cleaned with mechanical broom.

0i1 0ormal bituminous surface G 0.16 k" / S4m SA@ 22.22

0ii1 7ranular surfaces treated with primes G 0.46 k" / S4m SA@ 2/.22

)iii) )0on>bituminous surface) -ement concrete G 0.60

k" /S4m

SA@ 24.22

#., Bitu@i:ous *acada@ )Pro!idin" and la#in" bituminous

macadam with minimum 40>80 TP' capacit# hot mi9 plant

usin" crushed a""re"ates of specified "radin" premi9ed with

bituminous binder, transported to site, laid o!er a pre!iousl#

prepared surface with pa!er finisher to the re4uired "rade, le!el

and ali"nment and rolled as per clauses>601.8 and 601.: to

achie!e the desired compaction)

Wit= se:sor 8aCer <i:is=er

0i1 for 7radin" * )40 mm nominal siFe, bitumen content 1.26D ) &u@ #%21.22

0ii1 for 7radin" ** )1B mm nominal siFe, bitumen content 1.40D) &u@ /2,,.22

B Wit= @ec=a:ical 8aCer <i:is=er

0i1 for 7radin" * )40 mm nominal siFe, bitumen content 1.26D ) &u@ #43%.22

0ii1 for 7radin" ** )1B mm nominal siFe, bitumen content 1.40D) &u@ /222.22

#.# ProCidi:g a:d layi:g leCeli:g course 7 8ro<ile correctiCe

course >it= Bitu@i:ous @acada@

5ith minimum 40>80 TP' capacit# hot mi9 plant usin"

crushed a""re"ates of 7radin">1 premi9ed with bituminous

binder G 1.1D transported to site and laid o!er a pre!iousl#

prepared surface with pa!er finisher to the re4uired "rade, le!el

and ali"nment and rolled as per clause>601.8 and 601.: to

achie!e the desired compaction complete in all respect and as

per rele!ant clause section 600.

5ith sensor pa!er finisher &u@ #3%%.22

B 5ith mechanical pa!er finisher &u@ #3/1.22

Ite@ No. Descri8tio:s (:it Rate

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 22

#./ Bitu@i:ous Pe:etratio: *acada@ )-onstruction of

penetration macadam o!er prepared /ase b# pro!idin" a la#er

of compacted crushed coarse a""re"ate usin" chips spreader

with alternate applications of bituminous binder and ke#

a""re"ates and rollin" with a smooth wheeled steel roller <>10

tonne capacit# to achie!e the desired de"ree of compaction)

0i1 60 mm thick SA@ 3/2.22

0ii1 :6 mm thick SA@ ,%2.22

#.3 Built$(8$S8ray Grout )Pro!idin", la#in" and rollin" of built>

up>spra# "rout la#er o!er prepared base consistin" of a two

la#er composite construction of compacted crushed coarse

a""re"ates usin" motor "rader for a""re"ates. ke# stone chips

spreader ma# be used with application of bituminous binder

after each la#er, and with ke# a""re"ates placed on top of the

second la#er to ser!e as a /ase conformin" to the line, "rades

and cross>section specified, the compacted la#er thickness

bein" :6 mm)

SA@ 24,.22

#.4 Built$(8$S8ray Grout )Pro!idin", la#in" and rollin" of built>

up>spra# "rout la#er o!er prepared base for profile correcti!e

course/ le!elin" course)

&u@ 3343.22

#.% De:se Graded Bitu@i:ous *acada@ )Pro!idin" and la#in"

dense bituminous macadam with minimum 40>80 TP'

capacit# '%P usin" crushed a""re"ates of specified "radin",

premi9ed with bituminous binder G 4.0 to 4.6D b# wei"ht of

total mi9 of mi9 and filler, transportin" the hot mi9 to work

site, la#in" with a h#drostatic pa!er finisher to the re4uired

"rade, le!el and ali"nment, rollin" with smooth wheeled,

!ibrator# and tandem rollers to achie!e the desired compaction

as per %O&T' specification clause 0o. 60: complete in all

respects.)

Wit= se:sor 8aCer <i:is=er

0i1 for 7radin" * )40 mm nominal siFe, bitumen content 4.26D) &u@ 3,4%.22

0ii1 for 7radin" ** )1B mm nominal siFe bitumen content 4.60D) &u@ 34,3.22

Wit= @ec=a:ical 8aCer <i:is=er

0i1 for 7radin" * )40 mm nominal siFe, bitumen content 4.26D) &u@ 3,,%.22

0ii1 for 7radin" ** )1B mm nominal siFe bitumen content 4.60D) &u@ 342#.22

#.12 Se@i$De:se Bitu@i:ous &o:crete )Pro!idin" and la#in"

semi>dense bituminous concrete with minimum 40>80 TP'

capacit# usin" crushed a""re"ates of specified "radin",

premi9ed with bituminous binder G 4.60 to 6 D of mi9 and

filler, transportin" the hot mi9 to work site, la#in" with a

h#drostatic pa!er finisher with sensor control to the re4uired

"rade, le!el and ali"nment, rollin" with smooth wheeled,

!ibrator# and tandem rollers to achie!e the desired compaction

as per %O&T(' specification clause 0o. 60< complete in all

respects)

Wit= se:sor 8aCer <i:is=er

0i1 for 7radin" * )11 mm nominal siFe) with bitumen 4.6 D &u@ 342/.22

Ite@ No. Descri8tio:s (:it Rate

0ii1 for 7radin" * )11 mm nominal siFe) with -&%/ 80> 4.6 D &u@ 42%%.22

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 21

0iii1 for 7radin" ** )10 mm nominal siFe) with bitumen 6.0 D &u@ 4,/1.22

0iC1 for 7radin" ** )10 mm nominal siFe) with -&%/ 80 > 6.0D &u@ %212.22

B Wit= @ec=a:ical 8aCer <i:is=er

0i1 for 7radin" * )11 mm nominal siFe) with bitumen 4.6 D &u@ 33/2.22

0ii1 for 7radin" * )11 mm nominal siFe) with -&%/ 80> 4.6 D &u@ 42##.22

0iii1 for 7radin" ** )10 mm nominal siFe) with bitumen 6.0 D &u@ 4,14.22

0iC1 for 7radin" ** )10 mm nominal siFe) with -&%/ 80 > 6.0D &u@ 4%//.22

#.11 Bitu@i:ous &o:crete )Pro!idin" and la#in" bituminous

concrete with minimum 40>80 TP' capacit# hot mi9 plant

usin" crushed a""re"ates of specified "radin", premi9ed with

bituminous binder G 6.0 to 8.0D of mi9 and filler, transportin"

the hot mi9 to work site, la#in" with a h#drostatic pa!er

finisher with sensor control to the re4uired "rade, le!el and

ali"nment, rollin" with smooth wheeled, !ibrator# and tandem

rollers to achie!e the desired compaction as per %O&T'

specification clause 0o. 60B complete in all respects)

Wit= se:sor 8aCer <i:is=er

0i1 for 7radin">*)1B mm nominal siFe) with bitumen 6.6 D &u@ %232.22

0ii1 for 7radin" *)1B mm nominal siFe) with -&%/ 80> 6.6 D &u@ %4,2.22

0iii1 for 7radin" ** )11 mm nominal siFe) with bitumen 8.0 D &u@ %423.22

0iC1 for 7radin" ** )11 mm nominal siFe) with -&%/ 80> 8.0 D &u@ 12,/%.22

B Wit= @ec=a:ical 8aCer <i:is=er

0i1 for 7radin" * )1B mm nominal siFe) with bitumen 6.6 D &u@ %144.22

0ii1 for 7radin" *)1B mm nominal siFe) with -&%/ 80> 6.6 D &u@ %3%3.22

0iii1 for 7radin" ** )11 mm nominal siFe) with bitumen 8.0 D &u@ %3#%.22

0iC1 for 7radin" ** )11 mm nominal siFe) with -&%/ 80> 8.0 D &u@ 12,2,.22

#.12 Sur<ace Dressi:g )Pro!idin" and la#in" surface dressin" as

wearin" course in sin"le coat usin" crushed stone a""re"ates of

specified siFe on a la#er of bituminous binder laid on prepared

surface and rollin" with <>10 tonne smooth wheeled steel

roller)

0i1 1B mm nominal siFe chippin" SA@ 122.22

0ii1 11 mm nominal siFe chippin" SA@ 42.22

#.13 O8e: $ Graded Pre@iF Sur<aci:g )Pro!idin", la#in" and

rollin" of open > "raded premi9 surfacin" of 20 mm thickness

composed of 11.2 mm to 6.8 mm a""re"ates either usin"

bitumen or cut>back or emulsion to re4uired line, "rade and

le!el to ser!e as wearin" course on a pre!iousl# prepared base,

includin" mi9in" in a suitable plant, la#in" and rollin" with a

smooth wheeled roller <>10 tonne capacit#, finished to re4uired

le!el and "rades.)

0i1 -ase N *A> %echanical method usin" /itumen and minimum

40>80 TP' capacit# hot mi9 plant.

$ 5ith sensor pa!er finisher SA@ 11%.22

/ 5ith mechanical pa!er finisher SA@ 114.22

0ii1 -ase N** A> Open>7raded Premi9 Surfacin" usin" cationic

/itumen ;mulsion

SA@ 1,2.22

Ite@ No. Descri8tio:s (:it Rate

#.1, &lose Graded Pre@iF Sur<aci:g 7 *iFed Seal Sur<aci:g

)%echanical means usin" minimum 40>80 TP' '%P of

appropriate capacit# not less than 16 tonnes/hour. Pro!idin",

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 24

la#in" and rollin" of close>"raded premi9 surfacin" material of

20 mm thickness usin" bitumen to the re4uired line, "rade and

le!el to ser!e as wearin" course on a pre!iousl# prepared base,

includin" mi9in" in a suitable plant, la#in" and rollin" with a

Smooth wheeled roller <>10 tonne capacit#, and finishin" to

re4uired le!el and "rade. )

I. Wit= se:sor 8aCer <i:is=er

5ith bitumen

i1 T#pe $ ) 11.2 mm to 0.0B mm siFe a""re"ates ) SA@ 1/1.22

ii1 T#pe / ) 11.2 mm to 0.0B mm siFe a""re"ates ) SA@ 1,,.22

B 5ith -&%/>80

i1 T#pe $ ) 11.2 mm to 0.0B mm siFe a""re"ates ) SA@ 132.22

ii1 T#pe / ) 11.2 mm to 0.0B mm siFe a""re"ates ) SA@ 1#3.22

II. Wit= @ec=a:ical 8aCer <i:is=er

5ith bitumen

i1 T#pe $ ) 11.2 mm to 0.0B mm siFe a""re"ates ) SA@ 1/2.22

ii1 T#pe / ) 11.2 mm to 0.0B mm siFe a""re"ates ) SA@ 1,3.22

B 5ith -&%/>80

i1 T#pe $ ) 11.2 mm to 0.0B mm siFe a""re"ates ) SA@ 131.22

ii1 T#pe / ) 11.2 mm to 0.0B mm siFe a""re"ates SA@ 1#2.22

#.1# Seal &oat )Pro!idin" and la#in" seal coat sealin" the !oids in a

bituminous surface laid to the specified le!els, "rade and cross

fall usin" T#pe $ and / seal coats)

0i1 T#pe $ SA@ /2.22

0ii1 T#pe / )Pro!idin" and la#in" of premi9 sand seal coat with

minimum 40>80 TP' '%P of appropriate capacit# not less

than 16 tonnes/ hours usin" crushed stone chippin" 8.: mm

siFe and bitumen.)

SA@ ,/.22

#.1/ *astic s8=alt )Pro!idin" and la#in" 2#@@ t=ic; mastic

asphalt wearin" course with pa!in" "rade bitumen meetin" the

re4uirements "i!en in table 600>2B, prepared b# usin" mastic

cooker and laid to re4uired le!el and slope after cleanin" the

surface, includin" pro!idin" antiskid surface with bitumen pre>

coated fine>"rained hard stone chippin" of 11.2 mm nominal

siFe at the rate of 0.006cum per 10 s4m and at an appro9imate

spacin" of 10 cm center to center in both directions, pressed

into surface when the temperature of surfaces not less than

100

0

-, protrudin" 1 mm to 4 mm o!er mastic surface, all

complete as per clause>616.)

SA@ ,44.22

#.13 *astic s8=alt )Pro!idin" and la#in" 12@@ t=ic; mastic

asphalt wearin" course with pa!in" "rade bitumen meetin" the

re4uirements "i!en in table 600>2B, prepared b# usin" mastic

cooker and laid to re4uired le!el and slope after cleanin" the

surface, includin" pro!idin" antiskid surface with bitumen pre>

coated fine>"rained hard stone chippin" of B.6 mm nominal

siFe at the rate of 0.006cum per 10 s4m and at an appro9imate

SA@ 24,.22

Ite@ No. Descri8tio:s (:it Rate

spacin" of 10 cm center to center in both directions, pressed

into surface when the temperature of surfaces not less than

100

0

-, protrudin" 1 mm to 4 mm o!er mastic surface, all

complete as per clause>616.)

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 26

#.13 Slurry Seal Pro!idin" and la#in" slurr# seal consistin" of a

mi9ture of fine a""re"ates, Portland cement filler, bituminous

emulsion and water on a road surface includin" cleanin" of

surface, mi9in" of slurr# seal in a suitable mobile plant, la#in"

and compactin" to pro!ide e!en ridin" surface)

0i1 1.6 mm thickness SA@ 2%.22

0ii1 1 mm thickness SA@ ,4.22

0iii1 6 mm thickness SA@ /4.22

#.14 Fog S8ray 0Pro!idin" and appl#in" low !iscosit# bitumen

emulsion for sealin" cracks less than 1 mm wide or incipient

frettin" or disinte"ration in an e9istin" bituminous surfacin" )

SA@ ,2.22

$dd e9tra in case it is decided b# the en"ineer to blind the fo"

spra#.

SA@ #.22

#.1%

&rac; PreCe:tio: &ourses

0i1 Stress BsorBi:g *e@Bra:e 0S*1 crac; >idt= less t=a: /

@@ )Pro!idin" and la#in" of a stress absorbin" membrane

o!er a cracked road surface, with crack width below 8 mm

after cleanin" with a mechanical broom, usin" modified binder

compl#in" with clause>621, spra#ed at the rate of B k" per 10

s4m and spreadin" 6.8 mm crushed stone a""re"ates G 0.11

cum per 10 s4m with h#draulic chip spreader, sweepin" the

surface for uniform spread of a""re"ates and surface finished

to conform to clause>B02.)

SA@ /2.22

0ii1 Stress BsorBi:g *e@Bra:e 0S*1 >it= crac; >idt= / @@

to % @@ )Pro!idin" and la#in" of a stress absorbin" membrane

o!er a cracked road surface, with crack width 8 to B mm after

cleanin" with a mechanical broom, usin" modified binder

compl#in" with clause>621, spra#ed at the rate of 11 k" per 10

s4m and spreadin" 11.2 mm crushed stone a""re"ates G 0.12

cum per 10 s4m, sweepin" the surface for uniform spread of

a""re"ates and surface finished to conform to clause>B02.)

SA@ 3%.22

0iii1 Stress BsorBi:g *e@Bra:e 0S*1 crac; >idt= aBoCe %

@@ a:d crac;ed area aBoCe #2 D )Pro!idin" and la#in" a

sin"le coat of a stress absorbin" membrane o!er a cracked road

surface, with crack width abo!e B mm and cracked area abo!e

60 D after cleanin" with a mechanical broom, usin" modified

binder compl#in" with clause>621, spra#ed at the rate of 16 k"

per 10 s4m and spreadin" 11.2 mm crushed stone a""re"ates G

0.12 cum per 10 s4m, sweepin" the surface for uniform spread

of a""re"ates and surface finished to conform to clause>B02.)

SA@ 12/.22

0iC1 Bitu@e: I@8reg:ated GeoteFtile )Pro!idin" and la#in" a

bitumen impre"nated "eote9tile la#er after cleanin" the road

surface, "eote9tile conformin" to re4uirements of clause>:04.1,

laid o!er a tack coat with 1.06 k" per s4m of pa!in" "rade

bitumen <0/100 penetration and constructed to the re4uirement

of clause>:04.4.6)

SA@ 24,.22

Ite@ No. Descri8tio:s (:it Rate

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 28

#.22 O8e:$Graded Pre@iF Sur<aci:g 0By @a:ual @ea:s1

)Pro!idin", la#in" and rollin" of open>"raded premi9 surfacin"

of 20 mm thickness composed of 11.2 mm to 6.8 mm

a""re"ates usin" bitumen to re4uired line, "rade and le!el to

ser!e as wearin" course on a pre!iousl# prepared base,

includin" mi9in", la#in" and rollin" with a smooth wheeled

roller <>10 tonne capacit#, finished to re4uired le!el and

"rades.)

SA@ 114.22

#.21 Seal &oat "y8e$B 0By @a:ual @ea:s1

)Pro!idin" and la#in" seal coat sealin" the !oids in a

bituminous surface laid to the specified le!els, "rade and cross

fall usin" T#pe>/ seal coat usin" crushed stone chippin" 8.:

mm siFe and bitumen.)

SA@ ,#.22

#.22 Bitu@i:ous &old *iF 0i:cludi:g GraCel E@ulsio:1

)Pro!idin", la#in" and rollin" of bituminous cold mi9 on

prepared base consistin" of a mi9ture of unheated mineral

a""re"ate and emulsified or cutback bitumen, includin" mi9in"

in a plant of suitable t#pe and capacit#, transportin", la#in",

compactin" and finishin" to specified "rades, le!els and

ali"nment, rollin" with smooth wheeled, !ibrator# and tandem

rollers to achie!e the desired compaction as per %O&T('

specification clause 0o. 61B complete in all respects)

Wit= se:sor 8aCer <i:is=er

)i) Esin" bitumen emulsion and B.6 mm or 11.2 mm siFe

a""re"ate

&u@ 12/1/.22

)ii) Esin" bitumen emulsion and 1B mm or 28.6 mm nominal siFe

a""re"ate

&u@ 12/23.22

Wit= @ec=a:ical 8aCer <i:is=er

)i) Esin" bitumen emulsion and B.6 mm or 11.2 mm siFe

a""re"ate

&u@ 12232.22

)ii) Esin" bitumen emulsion and 1B mm or 28.6 mm nominal siFe

a""re"ate

&u@ 12#41.22

&'P"ER$ /

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 2:

&E*EN" &ON&RE"E P5E*EN"S

Ite@ No. Descri8tio:s (:it Rate

/.1 Dry !ea: &e@e:t &o:crete SuB$Base )-onstruction of dr#

lean cement concrete Sub>base o!er a prepared sub>"rade with

coarse and fine a""re"ate conformin" to *SA 1<1, the siFe of

coarse a""re"ate not e9ceedin" 26 mm, a""re"ate cement ratio

not to e9ceed 16A1, a""re"ate "radation after blendin" to be as

per table 800>1, cement content not to be less than 160 k"/

cum, optimum moisture content to be determined durin" trial

len"th construction, concrete stren"th not to be less than 10

%pa at : da#s, mi9ed in a batchin" plant, transported to site,

laid with a pa!er with electronic sensor, compactin" with <>10

tonnes !ibrator# roller, finishin" and curin".)

&u@ 2114.22

/.2 &e@e:t &o:crete PaCe@e:t 0Grade *$,21 )-onstruction of

un>reinforced, dowel Cointed, plain cement concrete pa!ement

o!er a prepared sub base with minimum cement G 400 k" per

cum, coarse and fine a""re"ate conformin" to *SA1<1,

ma9imum siFe of coarse a""re"ate not e9ceedin" 26 mm,

mi9ed in a batchin" and mi9in" plant as per appro!ed mi9

desi"n, transported to site, laid with a fi9ed form or slip form

pa!er, spread, compacted and finished in a continuous

operation includin" pro!ision of contraction, e9pansion,

construction and lon"itudinal Coints, Coint filler, separation

membrane, sealant primer, Coint sealant, debondin" strip, dowel

bar, tie rod, admi9tures as appro!ed, curin" compound,

finishin" to lines and "rades as per drawin")

&u@ ,,#1.22

/.3 &e@e:t &o:crete PaCe@e:t 0Grade *$,21 )-onstruction of

un>reinforced, cement concrete pa!ement o!er a prepared sub

base with minimum cement G 400 k" per cum, coarse and fine

a""re"ate conformin" to *SA1<1, ma9imum siFe of coarse

a""re"ate not e9ceedin" 26 mm, mi9ed as per appro!ed mi9

desi"n, transported to site, laid, spread, !ibrated, compacted

and finished in a continuous operation includin" pro!ision of

contraction, e9pansion, construction and lon"itudinal Coints,

Coint filler, separation membrane, sealant primer, Coint sealant,

de>bondin" strip, dowel bar, tie rod, admi9tures as appro!ed,

curin" compound, finishin" to lines and "rades as per

drawin".)

&u@ ,,34.22

/., Rolled &e@e:t &o:crete Base )-onstruction of rolled cement

concrete base course with coarse and fine a""re"ate

conformin" to *SA1<1, the siFe of coarse a""re"ate not

e9ceedin" 26 mm with minimum, a""re"ate cement ratio 16A1

and minimum cement content of 200 k"/cum, a""re"ate

"radation to be as per tableA 800>4 after blendin", mi9in" in

batchin" plant at optimum moisture content, transportin" to

site, la#in" with a pa!er with electronic sensor, compactin"

with <>10 tonnes smooth wheeled !ibrator# roller to achie!e,

the desi"ned fle9ural stren"th, finishin" and curin".)

&u@ 2,23.22

Ite@ No. Descri8tio:s (:it Rate

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 2<

/.# &o:structio: o< Base7SuB$Base o< 8aCe@e:t >it= lea:

co:crete+<ly as=. )-onstruction of /ase/sub>base usin"

cement, sand, fl# ash and coarse a""re"ates proportioned as per

table>4 of *&-A:4A1B:B and with water content ratio, slump and

compressi!e stren"th as defined in the said table, mi9 prepared

in a batchin" and mi9in" plant and compacted with a !ibrator#

roller <>10 tonnes capacit# within the time limit laid down !ide

clause :.8.1 of *&-A:4A1B:B, construction Coints properl#

formed at the end of da#=s work, cured for 14 da#s, all as

specified in *&-A:4A1B:B and as per appro!ed plans.)

&u@ 22/4.22

/./ &e@e:t+Fly as= co:crete 8aCe@e:t. )-onstruction

reinforced>reinforced, dowel Cointed, plain cement concrete

pa!ement o!er a prepared sub base with cement, coarse and

fine a""re"ate conformin" to *SA1<1, ma9imum siFe of coarse

a""re"ate not e9ceedin" 26 mm, replacin" cement b# fl# ash to

the e9tent of 16D and sand b# 10D, mi9ed in a batchin" and

mi9in" plant as per appro!ed mi9 desi"n, transported to site,

laid with a fi9ed form or slip form pa!er, spread, compacted

and finished in a continuous operation includin" pro!ision of

contraction, e9pansion, construction and lon"itudinal Coints,

Coint filler, separation membrane, sealant primer, Coint sealant,

debondin" strip, dowel bar, tie rod, admi9tures as appro!ed,

curin" compound, finishin" to lines and "rades as per

drawin".)

&u@ ,3#3.22

/.3 ProCidi:g a:d layi:g ce@e:t co:crete for plain concrete/

reinforced concrete i/c form work, shutterin" complete in as

per drawin"s and specifications.) 3or +illa"e roads)

0i1 P.-.-. %>10 &u@ 2341.22

0ii1 P.-.-. %>16 &u@ 333#.22

0iii1 P.-.-. %>20 &u@ ,141.22

0iC1 P.-.-. %>26 &u@ ,343.22

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 2B

&'P"ER$ 3

GEOS)N"'E"I&S ND REINFOR&ED ER"'

Ite@ No. Descri8tio:s (:it Rate

3.1 SuB$Sur<ace Drai: >it= GeoteFtiles

-onstruction of sub surface drain 200 mm dia usin" "eote9tiles

treated with carbon black with ph#sical properties as "i!en in

clause :02.2.1 formed in to a stable network and a planar

"eocomposite structure, Coints wrapped with "eote9tile to

pre!ent in"ress of soil, all as per clause :02 and appro!ed

drawin"s includin" e9ca!ation and backfillin"

R* //,.22

3.2 Narro> Filter SuB$Sur<ace Drai:

-onstruction of a narrow filter sub>surface drain consistin"

of porous or perforated pipe laid in narrow trench

surrounded b# a "eote9tile filter fabric, with a minimum of

460 mm o!erlap of fabric and installed as per clause :02.1

and 10B.1.6 includin" e9ca!ation and backfillin"

R* /1#.22

3.3 !ayi:g PaCi:g FaBric Be:eat= a PaCe@e:t OCerlay

)Pro!idin" and la#in" pa!in" fabric with ph#sical re4uirements

as per tableA :04>2 o!er a tack coat of pa!in" "rade /itumen>

80/:0 penetration, laid at the rate of 1 k"/ s4m o!er thorou"hl#

cleaned and repaired surface to pro!ide a water resistant

membrane and crack retardin" la#er. Pa!in" fabric to be free of

wrinklin" and foldin" and to be laid before coolin" of tack

coat, broomin" and rollin" of surface with pneumatic roller to

ma9imiFe pa!in" fabric contact with pa!ement surface)

SA@ 13/.22

3., !ayi:g Boulder 8ro: i: &rates o< Sy:t=etic Geogrids

)Pro!idin", preparin" and la#in" of "eo"rid crated apron 1 m 9

6 m, 800 mm thick includin" e9ca!ation and backfillin" with

baffles at 1.0 meter inter!al, made with "eo"rids ha!in"

characteristics as per clause :04.2, Coinin" sides with

connectors/rin" staples, top corners to be tie tensioned, placin"

of suitable cross inter!al ties in la#ers of 100 mm connectin"

opposite side with lateral braces and tied with pol#mer braids

to a!oid bul"in", constructed as per clause :04.1. filled with

stone with minimum siFe of 200 mm and specific "ra!it# not

less than 2.86, packed with stone spalls, ke#ed to the

foundation recess in case of slopin" "round and laid o!er a

la#er of "eote9tile to pre!ent mi"ration of fines, all as per

clause :04 and laid as per clause 2601.1 and appro!ed desi"n.)

&u@ 32/3.22

3.# Rei:<orced Eart= Retai:i:g Wall )&einforced earth retainin"

walls ha!e four main components as underA a) ;9ca!ation for

foundation, foundation concrete and cement concrete "roo!ed

seatin" in the foundation for facin" elements )facia material).

b) 3acia material and its placement. c) $ssemblin", Coinin"

with facin" elements and la#in" of the reinforcin" elements.

d) ;arth fill with "ranular material which is to be retained b#

the wall.)

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 10

Ite@ No. Descri8tio:s (:it Rate

01 $ssemblin" Coinin" and la#in" of reinforcin" elements with

0i1 7al!aniFed carbon steel strips *eter ,32.22

0ii1 -opper Strips *eter 3,3.22

0iii1 $luminum Strips *eter 2,,.22

0iC1 Stainless steel strips *eter ,1#.22

0C1 7lass reinforced pol#mer/fibre reinforced pol#mer/pol#meric

strips

*eter #2#.22

0Ci1 S#nthetic "eo"rids / "eote9tiles SA@ 32#.22

0B1 3acin" elements of &-- SA@ 122%.22

Note: The compacted earth filling to be retained shall form part of

embankment and the same is to be worked out and provided

separately as per clause 305.

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 11

&'P"ER$ 4

"RFFI& SIGNS. *R-INGS 6 O"'ER ROD PP(R"ENN&ES

Ite@ No. Descri8tio:s (:it Rate

4.1 &ast i: Situ &e@e:t &o:crete *22 ;erB )-onstruction of

cement concrete kerb with top and bottom width 116 and 186

mm respecti!el#, 260 mm hi"h in %20 "rade P-- on %10

"rade foundation 160 mm thick, foundation ha!in" 60 mm

proCection be#ond kerb stone, kerb stone laid with kerb la#in"

machine, foundation concrete laid manuall#, all complete as

per clause 40<)

*eter 1%2.22

4.2 &ast i: Situ &e@e:t &o:crete *22 -erB >it= &=a::el

)-onstruction of cement concrete kerb with channel with top

and bottom width 116 and 186 mm respecti!el#, 260 mm hi"h

in %20 "rade P-- on %10 "rade foundation 160 mm thick,

kerb channel 100 mm wide, 60 mm thick in P-- %20 "rade,

sloped towards the kerb, kerb stone with channel laid with kerb

la#in" machine, foundation concrete laid manuall#, all

complete as per clause 40<)

*eter 3#4.22

4.3 Pri:ti:g :e> letters a:d <igures of an# shade. )Printin" new

letters and fi"ures of an# shade with s#nthetic enamel paint,

/lack or other appro!ed colour to "i!e an e!en shade.

)i) 'indiA ) %atras, -omas and the like not to be measured and

paid for half letter shall be counted as half letter.

per cm

'ei"ht

per

letter

2.#2

)ii) ;n"lish and &oman A) '#phens and the like not to be

measured)

per cm

'ei"ht

per

letter

2.32

4., Retro$ re<lectroriGed "ra<<ic sig:s )Pro!idin" and fi9in" of

retro> reflectroriFed cautionar#, mandator# and informator#

si"n as per *&-A8:>2012 made of encapsulated lens t#pe

reflecti!e sheetin" !ide clause <01.1, fi9ed o!er aluminum

sheetin", 1.6 mm thick supported on a mild steel frame of siFe

40 9 40 9 6 mm and mild steel an"le iron post :6 mm 9:6 mm

9 8mm firml# fi9ed to the "round b# means of properl#

desi"ned foundation with %16 "rade cement concrete 46 cm 9

46cm 9 80cm, 80 cm below "round le!el as per appro!ed

drawin")

0 i 1 B0 cm e4uilateral trian"le Eac= 3%2%.22

0 ii 1 80 cm e4uilateral trian"le Eac= 2#3%.22

0 iii 1 80 cm circular Eac= 3,31.22

0 iC 1 <0 cm 9 80 cm rectan"ular Eac= ,423.22

0 C 1 80 cm 9 46 cm rectan"ular Eac= 33,3.22

0Ci 1 80 cm 9 80 cm s4uare Eac= 3%33.22

0 Cii 1 B0 cm hi"h octa"on Eac= /133.22

SOR for Road Works, C.G,. P.W.D. w.e.f 15-05-2013 Page 12

Ite@ No. Descri8tio:s (:it Rate

4.# Directio: a:d Place Ide:ti<icatio: sig:s u8to 2.% sA@ siGe

Board. )Pro!idin" and erectin" direction and place

identification retro>reflectoriFed si"n as per *&-A8:>2012 made

of encapsulated lens t#pe reflecti!e sheetin" !ide clause <01.1,

fi9ed o!er aluminum sheetin", 2 mm thick with area not

e9ceedin" 0.B s4m supported on a mild steel sin"le an"le iron

post :6 9 :6 9 8 mm firml# fi9ed to the "round b# means of

properl# desi"ned foundation with %16 "rade cement concrete

46 9 46 9 80cm, 80cm below "round le!el as per appro!ed

drawin")

SA@ 4/1,.22

4./ Directio: a:d Place Ide:ti<icatio: sig:s >it= siGe @ore t=a:

2.% sA@ siGe Board. )Pro!idin" and erectin" direction and

place identification retro> reflectoriFed si"n as per *&-A8:>

2012 made of encapsulated lens t#pe reflecti!e sheetin" !ide

clause <01.1, fi9ed o!er aluminum sheetin", 2 mm thick with

area e9ceedin" 0.B s4m supported on a mild steel an"le iron

post :6mm 9 :6mm 9 8mm, 2 0os. firml# fi9ed to the "round

b# means of properl# desi"ned foundation with %16 "rade