Documente Academic

Documente Profesional

Documente Cultură

Mini Tablesaw Router Shaper For Dremel Rotary

Încărcat de

boon1961Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Mini Tablesaw Router Shaper For Dremel Rotary

Încărcat de

boon1961Drepturi de autor:

Formate disponibile

http://www.instructables.

com/id/Mini-Tablesaw-Router-Shaper-for-Dremel-rotary-/

Home Sign Up! Browse Community Submit

All Art Craft Food Games Green Home Kids Life Music Offbeat Outdoors Pets Photo Ride Science Tech

Mini-Tablesaw / Router / Shaper for Dremel rotary tool

by sdudley on December 4, 2010

Table of Contents

License: Attribution Non-commercial Share Alike (by-nc-sa) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Intro: Mini-Tablesaw / Router / Shaper for Dremel rotary tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

step 1: Get templates here! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

File Downloads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

step 2: Material Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

step 3: Cut the wood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

step 4: Table Top and Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

step 5: Side Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

step 6: Brackets and Braces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

step 7: Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

step 8: Acrylic Cover Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

step 9: Fence for Tablesaw / Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

step 10: Optional - Table Extender and Rulers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Related Instructables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Advertisements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

http://www.instructables.com/id/Mini-Tablesaw-Router-Shaper-for-Dremel-rotary-/

License: Attribution Non-commercial Share Alike (by-nc-sa)

Intro: Mini-Tablesaw / Router / Shaper for Dremel rotary tool

Mini - Table Saw / Router / Shaper

for Dremel rotary tool.

step 1:Get templates here!

I am attaching a PDF that includes the templates I made for this project. Open the PDF and save it to your computer.

Print out the templates (I suggest using 100 pound card stock for the templates).

MAKE SURE... that you select None in the Page Scaling option when printing!

If you fail to do this the printer will scale the pages to a different size and the templates will not be correct.

File Downloads

http://www.instructables.com/id/Mini-Tablesaw-Router-Shaper-for-Dremel-rotary-/

Dremel_TablesawRouterShaper_plans.pdf (8 MB)

[NOTE: When saving, if you see .tmp as the file ext, rename it to 'Dremel_TablesawRouterShaper_plans.pdf']

step 2:Material Supply

You will need a Dremel rotary tool (obviously)...

I purchased the 4000-5/36H from Home Depot which has 5 attachments and 36 accessories for $99.00! This is by far one of the best deals available for the Dremel

products. I highly reccomend it.

Material Supply:

1 - 1x8x4 (I used top choice whitewood board)

1 - 1x2x4 (I used top choice whitewood board)

2 - Optix 8x10acrylic sheet (.080 thick)

1 bag- 3/4 two hole pipe strap - (sold in bags of 4)

2 - 1/4x 4-1/2 bolts

1 bag- 1/4 wing nuts - (sold in bags of 4)

1 section - 3/4 foam pipe insulation (sold in 6ft sections)

2 bags - Wood screw - #6 x 1-1/2 - (sold in bags of 10)

1 bag - Wood screw - #4 x 5/8 - (sold in bags of 12)

2 - 2 Spring Clamp

Attachments/Accessories/Tool List:

Dremel Rotary Tool (templates were designed for model 4000 but can be modified to fit any model)

Dremel - Mini Saw Attachment (model 670)

Dremel - Sanding Drum (either model 407 or 470 will work for this application)

5/32 Drill Bit

5/64 Drill Bit

7/64Drill Bit

1/4 Drill Bit

Phillips screw driver

Elmers glue

Utility knife (or other razor)

Optional Dremel Attachments/Accessories:

(only needed if you plan to build this project *exclusively with a Dremel Rotary Tool)

Dremel - Plunge Router Attachment (model 335-01) OR Multi Purpose Cutting Kit (model 565)

Dremel - Circle Cutter and Straight Edge Guide (model 678-01)

Dremel - Brad Point Drill Bit Set (model 631-01)

*Note: the top plate cover screws require a tapered 1/4 counter sink. The Dremel Brad Bits are not tapered and Dremel does not currently make a tapered 1/4 drill bit

with a 1/8 shank. This will require the need for an additional drill (preferably drill press) that can handle standard 1/4 drill bits or 1/4 tapered counter sink bits.

Image Notes

1. 1x8x4

http://www.instructables.com/id/Mini-Tablesaw-Router-Shaper-for-Dremel-rotary-/

Image Notes

1. 1x2x4

Image Notes

1. .080" is the optimal thickness for this sheet due to the size of the Dremel mini

saw blade. Lowes sells this in a thickness of .080" - this is important to remember!

Home Depot sells this in either .050 (to thin) or .090 (to thick).

Image Notes

1. 3/4" two hole pipe strap

Image Notes

1. 5/32 Drill Bit / 5/64 Drill Bit / 7/64 Drill Bit / 1/4 Drill Bit / Phillips screw driver /

Utility knife (or other razor)

Image Notes

1. 1/4 x 4-1/2 bolts and 1/4 wing nuts - (bag of 4)

Image Notes

1. 3/4foam pipe insulation (sold in 6ft sections)

http://www.instructables.com/id/Mini-Tablesaw-Router-Shaper-for-Dremel-rotary-/

Image Notes

1. Wood screw - #6 x 1-1/2 (bag of 10) and Wood screw - #4 x 5/8 (bag of

12)

Image Notes

1. 2" Spring Clamp - sold at Home Depot for $0.99

step 3:Cut the wood

Step One - Cut the wood to proper length:

I suggest when purchasing the supplies, have the hardware store cut the wood for you. This will save time and assure clean straight cuts. The following are the cuts you

will need to make this table.

1x8x4:

2- 10in length(table top and back plate)

2 - 4in length(left and right side panels)

1 - 8in length(optional table extension)

1x2x4:

4 - 5-1/2 in length(braces and brackets)

2 - 12 in length(optional extension arms)

http://www.instructables.com/id/Mini-Tablesaw-Router-Shaper-for-Dremel-rotary-/

step 4:Table Top and Back Panel

Step Two - Cutting / Drilling the Table Top and Back Panel:

Once you have all the wood cut to length, print out the templates and look through them. For best results print the templates on 100 pound card stock.

Starting with the Table Top template you will notice a bold boarder, several faded dashed lines, some drill hole placements and a bold dashed line that represents the

cutout for the Dremel rotary tool and Mini Saw Attachment.

There is also a faded solid line that represents the pipe strap that will be mounted underneath the Mini Saw Attachment between its directional guide and coupling (see

Mini Saw Attachment operating instructions). The faded lines in each template represent items on the opposite side of the viewing perspective (as if the template were

transparent). Cut the template along the boarder and also cut along the dashed line for the Dremel and Mini Saw Attachment.

Select one of the 10 panels (cut from the 1x8x4) to be your table top and lay the template over it. Secure it with some scotch tape or simply hold it in place while tracing

the outline of the Dremel and Mini Saw Attachment (1) . Use a punch, nail, or screw to mark the drill holes. Put an indentation into the wood to help steady the drill bit

when you start to drill the holes.

Clamp the panel down and route out the area you traced using a Dremel Plunge Router or Dremel Multi Purpose Cutting Kit (follow the instructions for those tools using

appropriate routing techniques) (2) .

If you do not own one of these attachments, then use a jig saw or other means of cutting the wood. The template was designed so the Dremel tool and Mini Saw

accessory will fit snug, so continue working the edges until they are just able to slide through the top plate.

Once you are finished routing, drill the holes using the appropriate bits (labeled on the template). Note that if you are planning to build this project using only Dremel tools

and accessories you will need the Dremel Brad Point Drill Bit Set for the 5/32 and 1/4 drill holes / counter sinks.

Heres a tip - if you dont have access to a drill press to counter sink the holes, use the 1/4 drill bit to first drill into the wood just enough for the counter sink. Then

finish drilling the hole using the smaller drill bit.

Follow the above instructions for the Back Panel. No routing or cutting is necessary - only drilling.

Image Notes

1. 1

Image Notes

1. 2

step 5:Side Panels

Step Three - Side Panels:

The side panels are already the size we need for this project. However, you will notice on the template there is an optional decorative cut line. Feel free to use this if you

would like to dress up your project a bit. On the bottom of the side panel page you will find what I call a contour template . This is for the left side panel only. The right

side will need no additional cutting or shaping.

Cut out around the boarder and along the cut line. Fold along the lines and place the folded template directly over the top of the LEFT side panel (3) . Make sure the

side of the template labeled outside is on the side you want to be seen (one side of the wood usually looks nicer than the other). Trace the outline and use the Dremel

to shape the wood until the contour matches close to that of the line. DO NOT sand this down too much at this time! For now just get close to the outline and later you

can make for a perfect fit.

This contour will brace the body of the Dremel Rotary tool and help hold it in place. If you own a Dremel or rotary tool other than the model 4000, you will need to shape

this area to fit the contour of your Dremel model. For the whitewood board used in this project a sanding drum will suffice when shaping the contour (4) . If you wish to

use a harder wood, you may need to use a different dremel accessory for this step.

http://www.instructables.com/id/Mini-Tablesaw-Router-Shaper-for-Dremel-rotary-/

Image Notes

1. 3

Image Notes

1. 4

step 6:Brackets and Braces

Step Four - Brackets and Braces:

There are two brackets and two braces (for use with rotary tool in vertical position). The two brackets will clamp the tool in place while the top and bottom braces will

simply keep the tool from moving as you apply pressure when routing / shaping a work piece (5) .

Follow the same procedure for these four pieces as you did when shaping the rotary tool contour for the left side panel. When drilling the 1/4 holes for the brackets,

make sure they align nicely with the 1/4 holes you drilled in the back panel (6) . You may even want to set them in place and mark them using the holes in the back

panel.

Remember the rule - measure twice, cut once (in this case drill). It is recommended to use a drill press for this procedure. If you do not have access to a drill press,

start by using a small drill bit first making sure to get good alignment, then increase the hole in steps until you reach 1/4.

Image Notes

1. 5

Image Notes

1. 6

step 7:Assembly

Step Five - Assembly:

Once all of the pieces are cut, drilled, and shaped, its time to put it together.

Using the #6 x 1-1/2 screws, screw the side panels, top brace and bottom brace to the back panel. It is a good idea to drill pilot holes to keep from splitting the wood

(the 5/64 drill bit should work nicely for this) (7) . Before you can set the Table Top in place you will need to attach the 3/4 pipe strap to the bottom of the Table Top

using two #4 x 5/8 screws. The 5/64 holes have been previously drilled so the center of the strap should line up very nicely over the cut out for the Dremel Mini Saw

Attachment (8) .

When you turn the Table Top over and try to set it in place, you should notice the strap will not allow the top to sit level. The edge of the strap overlaps the back panel.

The easiest solution for this is to use a sanding drum to groove out a place on the back panel for the edge of the strap to sit into (9) . Now screw the table top in place

and assembly is complete.

Note that if you try and set the Dremel rotary tool and Mini Saw Attachment in place, the Mini Saw Attachment will not sit level with the Table Top (10) . Cut a 2-1/4

section of foam pipe insulation. Squeeze it together then bend it so it is shaped as if it is smiling at you (11a) . Place it into the cavity of the Mini Table Saw attachment

turning it so the folded side is down (11b) . Now when you place the Dremel rotary tool and Mini Saw Attachment

in place you should have to push it down to hold it level with the Table Top.

Now go back and finish the left side panel contour for your rotary tool. Set the Dremel rotary tool and Mini Saw Attachment in place (the on/off switch should be facing

the front of the table saw and facing slightly downward).

Hold the tool in place making sure the Mini Saw Attachment is level with the table and look to see how high the rotary tool sits above the table. Using a sanding drum,

sand down a little of the side panel contour and check it again. Continue shaping and contouring the side panel until the rotary tool sits just below the surface (12) . You

will need to repeat this process for the brackets and braces so the rotary tool is centered when in the vertical position. Remove just enough of the contoured areas of the

brackets and braces to glue in place some foam insulation where the Dremel rotary tool will sit.

http://www.instructables.com/id/Mini-Tablesaw-Router-Shaper-for-Dremel-rotary-/

Image Notes

1. 7

Image Notes

1. 8

Image Notes

1. 9

Image Notes

1. 10

Image Notes

1. 11a

Image Notes

1. 11b

http://www.instructables.com/id/Mini-Tablesaw-Router-Shaper-for-Dremel-rotary-/

Image Notes

1. 12

step 8:Acrylic Cover Plates

Step Six - Table Saw and Router/Shaper Cover Plates:

When configured as a mini table saw, the cover is used to hold the rotary tool and Mini Saw Attachment in place. The acrylic sheets are 8x10 so they will need to be

trimmed down to fit the table top.

To do this, simply measure and mark a line at 8 inches and score the acrylic with a utility knife (run the utility knife along a straight edge or ruler) (13) . Move the acrylic

to the edge of a table or board and snap it off (14) .

Once the acrylic sheets are the correct size, follow the templates to make the covers for the Table Saw and Router / Shaper respectively.

Image Notes

1. 13

Image Notes

1. 14

step 9:Fence for Tablesaw / Router

Step Seven - Fence for Table Saw / Router:

To make the fence simply follow the same instructions for the Brackets and Braces. One side of the fence can be used when configured as a router, and the other side

can be used when configured as a table saw.

http://www.instructables.com/id/Mini-Tablesaw-Router-Shaper-for-Dremel-rotary-/

step 10:Optional - Table Extender and Rulers

NOTE: This instructable only covers the original table. There are additional instructions to add an extension and rulersto the table top.

You will need todownload theoriginal PDF on the intro page for the templates and full instructions.

I hope this will give some inspiration for creating some great Dremel craft and hobby projects!

Image Notes

1. Table Top Extension - allows the table to extend to a full 12" on either side!

Related Instructables

My basement

workshop

(slideshow) by

gscott69

Dremel Micro

Mini Disc

Sander (video)

by riseabove

How to Make a

Router Circle

Cutting Jig by

tashiandmo

My 10 X 14

basement

workshop

(slideshow) by

marlinhendricks

Workshop

pegboard by

kerns

Router Case

(slideshow) by

Tap33

Advertisements

Comments

50 comments Add Comment view all 52 comments

toastdore says: Dec 9, 2010. 3:58 PM REPLY

WOW WOW WOW

I'll make one

TOAST

hairybaroque says: Dec 9, 2010. 1:46 PM REPLY

What a beautifully presented project! More like a section of a magazine than your usual Instructable. I intend to make one when the frost gets out of my

workshop!

Thank you; this is a great facilitator for artistically trained people like me with enthusiasm but no mechanical design skills or training.

marcgoovaerts says: Dec 9, 2010. 12:28 PM REPLY

Sublime,

I was breaking my head over this for some time now. Thanks for the solution !

Only pitty for us in Europe the whole world doesn't use the metric system by now (I'm living in Belgium)

Dragontrap says: Dec 9, 2010. 11:50 AM REPLY

Okay not only is this the coolest thing ever, it allows you to use your Dremel to MAKE the freaking thing. When I get the chance, I am totally doing this

(because I adore my dremel way too much to not try this out).

evil_fish says: Dec 6, 2010. 2:47 AM REPLY

sdudley

You are a genius!

http://www.instructables.com/id/Mini-Tablesaw-Router-Shaper-for-Dremel-rotary-/

sdudley says: Dec 6, 2010. 3:14 AM REPLY

Well thank you very much but I'd be lying if I tried to claim that it was etirely my idea. So... I must give credit where credit is due.

I was originally going to purchase the mini router table from Dremel when I found a project to make your own here:

http://www.woodmagazine.com/woodworking-plans/routing/mini-router-table/

I also wanted a mini tablesaw and have been looking at some online. They are either too expensive or not powerful enough to do the job I want. Also I

am very limited in space (garage is FULL). I decided to redesign the above idea to incorporate the two and make it a combo table.

The tablesaw is limited however as it is not adjustable and it can only saw workpieces up to 3/4" thickness - you must turn the workpiece over and make

a second pass (as seen in the video).

evil_fish says: Dec 9, 2010. 11:19 AM REPLY

A man with talent and modest! I almost forgot to say THANK YOU VERY MUCH for sharing this amazing project!

ps:

sorry about my bad English, I am from China. I wish you can understand. :)

Flipper_118 says: Dec 6, 2010. 2:51 PM REPLY

Very nice writeup! Just a quick question. You say you can rip workpieces up to 3/4" with a double sided cut...is that a typo? I thought max cutting

depth with that saw was 1/4" which would lead to a 1/2" double cut.

I think I'll have to try my hand at a design like this. I very much like your dual purpose design!

sdudley says: Dec 6, 2010. 6:46 PM REPLY

Was 3/4" a typo? Well... yes and no.

I knew I was saying 3/4" but it wasn't until after I posted the comment that I realized it won't cut 3/4". I have no excuse - I'm a loser who can't add.

Actually, it won't really cut 1/2" thickness due to the thickness of the cover plate.

Sorry about the misinformation. Thanks for the correction though! :)

Flipper_118 says: Dec 7, 2010. 1:54 PM REPLY

Hehe, no worries amigo! Still an awesome guide...so much in fact that last night I went out and purchased a slightly larger saw (4" blade) that

I will be converting into a table saw for some precision work I do.

Thanks again!

leshall says: Dec 9, 2010. 10:38 AM REPLY

Easily the best instructable I have ever watched. The final product is excellent too. Kudos.

mosquitoloco says: Dec 9, 2010. 10:36 AM REPLY

Excellent! Copy paste copy paste! jajaja Ill do it!!!

werejag says: Dec 9, 2010. 8:51 AM REPLY

i like the concept but i dont like the idea of screwing and unscrewing the top plastic plate as the wood shall not hold up for long

ill probly build one and move to creating modified version

sdudley says: Dec 9, 2010. 10:15 AM REPLY

This is good, the kind of stuff I like to hear. Thanks for the suggestions.

I have quite a few other ideas to make it better but the goal was to make a very inexpensive and easy project that someone can throw together on a

Saturday with a little free time.

One example of cheap and easy is the fence. I had planed on using some aluminum T-track with a miter gauge and so on, but then I thought about it and

decided on a piece of wood (scrap from the 1x2x4) and a couple cheap clamps.

I also wanted to write an instructable where people don't have to do a lot of searching to find the parts to put the project together. Just grab a list and

head to the hardware store.

I would love nothing more than to see some other people modify it and watch it grow into a really nice little mini-combo workshop (maybe even built into a

small roll around table).

I got the router/shaper idea from someone else and added a tablesaw... now let's see some more modifications! :)

werejag says: Dec 9, 2010. 10:19 AM REPLY

yeah i have ideas. thank you for this article.

http://www.instructables.com/id/Mini-Tablesaw-Router-Shaper-for-Dremel-rotary-/

srilyk says: Dec 9, 2010. 9:34 AM REPLY

It wouldn't take much to put some wood anchors or t-nuts as mods. That should take care of it.

gabrielsan says: Dec 9, 2010. 8:03 AM REPLY

I think I missed it, but, how you put it on the table? I cant tell by the pictures. I mean, How do you lock the router on the table?

sdudley says: Dec 9, 2010. 8:34 AM REPLY

Now that you mention it, I guess I neversaid how it clamps to the table- DUH!

It's meant to be clamped via a bench vice. You can either clamp it on the side or the table top. Further down the comments sectionI posted a link to the

original project where I got my idea.

Here is the link again:

http://www.woodmagazine.com/woodworking-plans/routing/mini-router-table/

He is much more clear about clamoing it to the bench vice.

sdudley says: Dec 9, 2010. 8:37 AM REPLY

QUOTE: "He is much more clear about clamoing it to the bench vice"

Sorry, I hit the "o" instead of the "p"... I meant "clamping "!

Edgar says: Dec 9, 2010. 7:20 AM REPLY

Great piece of work!

Subscribed you, so I keep seeing these.

fyavorsky says: Dec 9, 2010. 7:02 AM REPLY

The video production with fast motion and music is as brilliant as the project. Even if I never build the mini-tablesaw/router/sander, I enjoyed watching.

Thanks!

kidproquo says: Dec 9, 2010. 5:45 AM REPLY

This is truly an excellent instructable. I'm an architecture student and spend hours on a mini table saw cutting small pieces for models. This will be a great

supplement.

TheWaddleWaaddle says: Dec 7, 2010. 6:01 PM REPLY

I was typing up a really good complement but my computer randomly restarted, and I lost all of my comment work. Long story short, this thing is awesome!

-TheWaddleWaaddle

Barrionuevo says: Dec 7, 2010. 5:44 PM REPLY

Great!!!!!

Thanks to share!!

xboogerx says: Dec 6, 2010. 5:33 AM REPLY

this is awesome.

thank you for sharing with the world.

a very well documented share as well.

sdudley says: Dec 6, 2010. 5:54 AM REPLY

Thanks. I tried very hard to create an instructable that people could make with one trip to the hardware store and complete in a weekend.

I just hope I didn't over explain what is supposed to be a very simple project. I tend to do that!

abrannan says: Dec 7, 2010. 2:42 PM REPLY

There is no such thing as over-explaining. Under-explaining? Absolutely. But yoiu can never give too much detail into the hows and whys of a project.

It allows others to more easily build (and improve) on your design. Your combination of the Instructable (with excellent photos) and the video make

this one of the, if not the, best Instructables I've ever read.

rimar2000 says: Dec 7, 2010. 10:43 AM REPLY

Excellent job!

I'll make one like it.

http://www.instructables.com/id/Mini-Tablesaw-Router-Shaper-for-Dremel-rotary-/

WARLOCK76 says: Dec 7, 2010. 10:25 AM REPLY

A winner ...No doubt...*****

RTChoke says: Dec 6, 2010. 3:18 PM REPLY

Nice work! but I have one suggestion on technique in the vid -- when you are doing the edge routing, have the workpiece between the fence and the bit can

lead to some serious kickback on the workpiece. Might not be such an issue with a little Dremel as it does not have that much torque, but if you try that with a

big router -- well, don't try that with a big router. Put the bit up next to the fence and run your workpiece along the fence, which will also keep the cut uniform

as it can not go into the workpiece any further than the bit is from the fence.

Safety!

I was thinking too, a set of files to run these parts out on the CNC machine...

RTChoke says: Dec 7, 2010. 6:28 AM REPLY

Looks like you might have used something to generate the pdf plans, those could be used to make dxf files that could be used to generate gcode for the

CNC machine

sdudley says: Dec 6, 2010. 7:05 PM REPLY

Ok you busted me! I'm not really experienced with wood working tools. In my defense however, I did know that is not good practice and I don't ever recall

seeing anyone use a router that way (for reasons which you pointed out).

I was just experimenting with different things while running the video and I just went with it. I was hoping people would not notice my flaws, but it is nice

to know people are paying attention!

Interestingly I mention in the plans to follow proper safety proceedures for tablesaws and routers - then I turn around and give a bad example!

Thanks for the saftey tip.

Files for a CNC machine?

RTChoke says: Dec 7, 2010. 6:21 AM REPLY

Good judgment comes from experience, experience comes from bad judgment. I have some good experience! And good judgment now!

If you (or I suppose I, or anyone else) were to commit these plans to electronic format using a CAD program, it would be easy to bang out a fairly

precise set of parts (at least the ones that involve various cuts) using a CNC machine, but that might be overkill.

blackslax says: Dec 7, 2010. 6:03 AM REPLY

Probably one of the best Instructable I've ever seen.

You 'da man sdudley.

sdudley says: Dec 7, 2010. 5:18 AM REPLY

Thanks everyone for the very kind comments about this project. I wanted to keep it as simple as possible for this instructable in hopes that others would give

suggestions for improvements.

Fortunately several of you have given great suggestions and I also read some good suggestions for improvement on a few blog sites that have posted it.

I will definitely be adding some more videos showing a project or two that I make with it, as well as a few improvements to the design (one of which is a way

to adjust the height of the Dremel when in the vertical position).

I will wait until the contest is over to do this since I have already submitted this into the contest.

bradsprojects says: Dec 7, 2010. 1:46 AM REPLY

This is such a cool project!

Very well presented and absolutely love the video!

CementTruck says: Dec 6, 2010. 9:55 AM REPLY

Great idea!

If you use the spiral saw bits while the tool is in the vertical router configuration you could use this as a "Scroll Saw" too.

bobby sissom says: Dec 6, 2010. 7:00 PM REPLY

this particular comment cinched the deal i will be making one now for i have wanted a scroll saw for years

CementTruck says: Dec 6, 2010. 8:16 PM REPLY

Bobby,

I don't know what your wood working skills are like but have to throw this out just in case, keep in mind that it will be a "Pseudo Scroll Saw". There is

no replacement for the real thing.

A spiral saw can make very intricate cuts, but the gap it leaves is as wide as its bit (1/8" or so).

A scroll saw takes very little wood off, which is why it is used to make tight fitting puzzle pieces, etc.

http://www.instructables.com/id/Mini-Tablesaw-Router-Shaper-for-Dremel-rotary-/

sdudley says: Dec 6, 2010. 11:32 AM REPLY

Hey that's a great addition to it's usefulness. Maybe I can update the video showing that (giving you credit of course). Thanks for the suggestion.

CrLz says: Dec 6, 2010. 6:23 PM REPLY

That is a seriously awesome set-up. Thanks for all the hard work!

hightekrednek2396 says: Dec 6, 2010. 4:29 PM REPLY

im gonna make one tonight could of used this for a ling time

BlueWeasel says: Dec 6, 2010. 1:45 PM REPLY

This is exactly what I need. I figure this easily substitutes for $500+ in other

machines of the same size/scope.

I've got a heavy duty flex shaft dremel so it'll require some reengineering

to make sure the shaft isn't in a bind.

sdudley says: Dec 6, 2010. 2:22 PM REPLY

I would have used the flex shaft if I had one. You might find that will be easier. The Mini Saw Attachment is held in place by the pipe strap, and held

down by the cover plate (aluminum would make a better choice for the cover plate if you want to spend the money). The Dremel is simply resting on the

left side panel.

Keep us posted on how well the flex shaft works for this.

Adeline says: Dec 6, 2010. 2:00 PM REPLY

This is brilliant!

danner says: Dec 6, 2010. 1:36 PM REPLY

very nice just what I need to build thank you for the plains very well done

Jodex says: Dec 6, 2010. 12:34 PM REPLY

I'm speechless. This is awesome, I'm gonna make this.

hajosmulders says: Dec 6, 2010. 9:20 AM REPLY

This is SO much exactly what I need. I often end up setting up full size a table saw or router table (I have a small shop; so I need to set up a tool when I need

it; they are not permanently ready).

For a lot of small parts this is an ideal tool that I can just leave on the workbench at all times.

You have my vote for the "What can you do with a dremel tool" contest!

Hajo

gedda says: Dec 6, 2010. 8:27 AM REPLY

Quite possibly the most clearly written 'ible' I've ever read. * * * * *

And it couldn't come at a better - at least for me - as I just received my first Dremel (a 4000, no less) this past weekend. It seems very fitting that my first

project would be to make this table.

Thanks for the great Instructable!

ZaitsevScope says: Dec 6, 2010. 7:28 AM REPLY

Amazing design, I'll try to build it with your plans, many thanks :)

view all 52 comments

S-ar putea să vă placă și

- Shut Up and Take My Money - The Motoped - RideApartDocument8 paginiShut Up and Take My Money - The Motoped - RideApartboon1961100% (1)

- Buck, Pearl S. - Fourteen Stories (Pocket Books, 1963)Document239 paginiBuck, Pearl S. - Fourteen Stories (Pocket Books, 1963)EnglishSmj100% (2)

- Model Aircraft 2012-11Document84 paginiModel Aircraft 2012-11bobbyb121223486% (7)

- LRTDocument1 paginăLRTboon1961Încă nu există evaluări

- Beginners Method To Solving The 3x3 Rubiks CubeDocument8 paginiBeginners Method To Solving The 3x3 Rubiks Cubeboon1961100% (1)

- WessexDocument120 paginiWessexboon1961100% (1)

- Canoe SailDocument11 paginiCanoe Sailboon1961100% (1)

- Pallet Coffee Table From Reclaimed WoodDocument14 paginiPallet Coffee Table From Reclaimed Woodboon1961Încă nu există evaluări

- 6 Tips For Cutting Complex Curves On A BandsawDocument8 pagini6 Tips For Cutting Complex Curves On A Bandsawboon1961Încă nu există evaluări

- Stain PVC Any Color You Like - MAKEDocument13 paginiStain PVC Any Color You Like - MAKEboon1961Încă nu există evaluări

- Bench Lathe 3 in 1 Lathe Sander GrinderSharpenerDocument13 paginiBench Lathe 3 in 1 Lathe Sander GrinderSharpenerboon1961100% (1)

- Make A Sharpening System With A Sharpening Stone ADocument5 paginiMake A Sharpening System With A Sharpening Stone Aboon1961100% (1)

- Drill Press LatheDocument13 paginiDrill Press Latheboon1961Încă nu există evaluări

- The Bare Minimum DIY LatheDocument5 paginiThe Bare Minimum DIY Latheboon1961100% (1)

- Woodturning With A Drill PressDocument18 paginiWoodturning With A Drill Pressboon1961Încă nu există evaluări

- Fishing Tackle TubeDocument6 paginiFishing Tackle Tubeboon1961Încă nu există evaluări

- Gas Beating Electric Race KartDocument9 paginiGas Beating Electric Race Kartboon1961Încă nu există evaluări

- Make An Open Kayak From Recycled BottlesDocument8 paginiMake An Open Kayak From Recycled Bottlesboon1961Încă nu există evaluări

- Turn Your Office Into A KayakDocument9 paginiTurn Your Office Into A Kayakboon1961Încă nu există evaluări

- DIY RC Foamboard PlaneDocument44 paginiDIY RC Foamboard Planeboon1961Încă nu există evaluări

- Tennis Ball Launcher 2Document48 paginiTennis Ball Launcher 2boon1961Încă nu există evaluări

- Table Saw Sled For Precise Angled CutsDocument7 paginiTable Saw Sled For Precise Angled Cutsboon1961Încă nu există evaluări

- Gypsy Wagon BuildingDocument20 paginiGypsy Wagon Buildingboon1961Încă nu există evaluări

- DIY Human Powered Hydrofoil The "Hydrothopter"Document15 paginiDIY Human Powered Hydrofoil The "Hydrothopter"boon1961Încă nu există evaluări

- Building A Threaded Pipe Steadi CamDocument11 paginiBuilding A Threaded Pipe Steadi Camboon1961Încă nu există evaluări

- Small Foldable Tripod DollyDocument8 paginiSmall Foldable Tripod Dollyboon1961Încă nu există evaluări

- Easy Paracord USB Flash Drive CaseDocument9 paginiEasy Paracord USB Flash Drive Caseboon1961Încă nu există evaluări

- Homemade PlasticDocument11 paginiHomemade Plasticboon1961Încă nu există evaluări

- Bungee BazookaDocument35 paginiBungee Bazookaboon1961Încă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Elements of Metric Gear TechnologyDocument60 paginiElements of Metric Gear TechnologyforuozanmehrÎncă nu există evaluări

- MP 2014AD (D247) Parts CatalogDocument99 paginiMP 2014AD (D247) Parts CatalogArySenoWibowoÎncă nu există evaluări

- Spare Parts Manual CP30 - Edition Nov-2014Document184 paginiSpare Parts Manual CP30 - Edition Nov-2014Sunny Sethi67% (3)

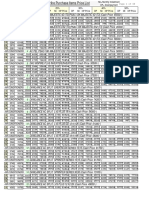

- PriceListHirePurchase Normal28thapril2020Document68 paginiPriceListHirePurchase Normal28thapril2020kjhfjkfhgjkdfhgjdkfÎncă nu există evaluări

- Fitting Elbow JisDocument2 paginiFitting Elbow JisHarry laksanaÎncă nu există evaluări

- SIP 2011 CatalogueDocument44 paginiSIP 2011 CatalogueDave StewartÎncă nu există evaluări

- 787 (r01)Document86 pagini787 (r01)AndresÎncă nu există evaluări

- Coiled Tubing CourseDocument15 paginiCoiled Tubing CourseShehzad khanÎncă nu există evaluări

- ME6402 Manufacturing Technology IIDocument10 paginiME6402 Manufacturing Technology IIprasanthprpÎncă nu există evaluări

- Shengzhou Imadel Trade Co LTD - COMPOSTABLE TABLEWAREDocument13 paginiShengzhou Imadel Trade Co LTD - COMPOSTABLE TABLEWAREavinashn1984Încă nu există evaluări

- H&H Shotguns 2023 Q1Document29 paginiH&H Shotguns 2023 Q1Anonymous MwulYRw2LÎncă nu există evaluări

- LG ThermaV Fault Codes UKDocument20 paginiLG ThermaV Fault Codes UKSesko123100% (1)

- Infinity Army ListDocument2 paginiInfinity Army ListFrederik RasaliÎncă nu există evaluări

- Circle Support GD825A-2Document2 paginiCircle Support GD825A-2Uhanto BaikÎncă nu există evaluări

- Price ListDocument12 paginiPrice ListAgung Pramu AjiÎncă nu există evaluări

- Hand Arm Vibration RatingsDocument1 paginăHand Arm Vibration RatingsSophie-Louise MercedesÎncă nu există evaluări

- Work, Power, & MachinesDocument37 paginiWork, Power, & Machinesashfaq ahmedÎncă nu există evaluări

- Interbellum RPG - Playtest TablesDocument7 paginiInterbellum RPG - Playtest TablesPatryk ObrębskiÎncă nu există evaluări

- Parts ListDocument2 paginiParts ListOFFICE DANACÎncă nu există evaluări

- Project Report: SamsungDocument15 paginiProject Report: SamsungDaniel Morales FernándezÎncă nu există evaluări

- Spare Parts ListDocument20 paginiSpare Parts ListАлександр ДлинныйÎncă nu există evaluări

- Gear Grinding: Software UpdateDocument92 paginiGear Grinding: Software UpdategrazianogirottoÎncă nu există evaluări

- Technology of Machine Tools: Metal-Cutting SawsDocument20 paginiTechnology of Machine Tools: Metal-Cutting SawsAnibal DazaÎncă nu există evaluări

- Bar Parts and LayoutDocument8 paginiBar Parts and LayoutCassandra Noreen Pacayra SantosÎncă nu există evaluări

- Knife Skills Powerpoint New 5-1-2016Document61 paginiKnife Skills Powerpoint New 5-1-2016Tobi MM0% (1)

- Smaller Design: 2-Way High Pressure Ball ValvesDocument4 paginiSmaller Design: 2-Way High Pressure Ball ValvesLevi BriceñoÎncă nu există evaluări

- sd8 Valve Cut SectionDocument1 paginăsd8 Valve Cut SectionVEERAMANIÎncă nu există evaluări

- Cirque Twist Ballpoint Pen Kit: Gluing Blanks To TubesDocument2 paginiCirque Twist Ballpoint Pen Kit: Gluing Blanks To TubesCheryl QuaidÎncă nu există evaluări

- Hand ToolsDocument4 paginiHand Toolsayessa evangelistaÎncă nu există evaluări

- SanitaryDocument4 paginiSanitaryNurul IslamÎncă nu există evaluări