Documente Academic

Documente Profesional

Documente Cultură

Team Chester BA

Încărcat de

sebast107Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Team Chester BA

Încărcat de

sebast107Drepturi de autor:

Formate disponibile

1

2

TABLE OF CONTENTS

Research and Development (R&D) ........................................................................ 2

Production ................................................................................................................. 5

Marketing.................................................................................................................. 7

Reminiscences and Reflections ............................................................................... 9

Appendix .................................................................................................................10

R&D .....................................................................................................................11

Production ...........................................................................................................12

Marketing ...........................................................................................................14

Research and Development (R&D)

The main function of R&D is to research and develop products that customers want.

Funding R&D is an investment in a company's future, and plays an important role in business.

3

R&D are investigative activities that a business chooses to conduct with the intention of making

a discovery that can either lead to the development of new products or procedures, or to the

improvement of those existing. More specifically, these activities consist of selling at the right

price, revising products at the correct age, choosing the ideal position and ensuring decent

reliability. When these criteria are met, customers are happy and product sales increase.

Chesters R&D department was chartered with the responsibility to monitor these criteria.

Team Chesters goal was to become a niche cost leader. Our objectives included keeping

cost low while still providing our customers with products that meet their expectations. Team

Chesters R&D department researched the profitability of the five segment products to determine

which would be most cost effective and economical to produce. R&D determined that the High

End and Performance segment products are fast moving and need revision every year. This

would turn out to be too costly not only for the revision, but they also require high caliber

workers demanding large wages plus expensive material to manufacture those products. In

addition, the Size segment product has a 1.5 year revision time frame and was appropriate to

produce and market but only for a few years while we earn the most profit possible. However our

cash positions were very strong to compare to the other teams and we decided to continue the

production up to round 8. After two rounds, we also realized that we had very strong

competitors, Andrews, Digby Erie and Ferris. For example, from Round 3 to Round 8, Ferris

was the leading company in the High End segment. Their performance increased from 10.6 to

16.7 while their size decreased from 14.8 to 3.4 in Round 8. In order to stay strong as a company

and have a successful financial future, Team Chester decided to concentrate on the all five

segments and try to have 20 % market share in every segments and we achieved overall market

share of 20.43%.

4

Chester determined that the Low End and Traditional products had longer revision time,

required lower labor costs, lower material costs and encouraged increased automation levels.

Considering these advantages, Team Chester decided to produce more on these two segments.

For the Traditional segment, we focused on its positioning to ensure it is close to its ideal spot on

the perceptual map. We monitored its age and tried to keep it at no more than two years. For

Round 1, Chester came first and Rounds 2, 3 4,5,6,8 and 7 came third in the Traditional segment

competing with Andrews and Erie. However, Chester always had lower prices than other

groups. In round 8, Chester came second in the Traditional segment with 2,475 Units sold. Our

low price of $24.00 per unit and 2900M promo- budget of gave us a competitive edge.

Unfortunately, the Age of our product did not meet the #1 Buying Criteria in these rounds

compare with other groups. For the Low End product, we focused heavily on keeping price

down since these customers place 53% importance on this criterion. We also monitored its

position to ensure it is close to its ideal spot and age. Reliability did not prove to be of high

importance (only 7%) for our customers thus we saved on material cost by keeping reliability

low. In comparing Round 1 and Round 2, Team Chester had the second lowest selling price for

both the Traditional and Low End segment products. Andrews was selling their Low end

product Acre at $21.50 a unit, Digby was selling dell at $22 a unit Erie was selling Ebb at $20 a

unit and we were selling Cedar at $21 a unit.

This strategy saved our company a lot of money for our future plans. We invested our

savings in revising in our products and automations. This strategy also allowed our company to

increase automation for our existing products. By doing so, we saw our material cost decrease

from $10.85 to $8.56 for our Traditional product Cake and material costs decrease from $7.05 to

5

$5.23 for our Low End product Cedar. By the end of Round 8 the dramatic decrease in material

cost led to increased productivity and profit (see Appendix - R&D A).

Customer satisfaction is the key for the success of any business. From Round 1 to Round

8, we managed to meet our customers expectations by keeping our prices competitively low

compared with all the other teams; we basically positioned our products correctly; we maintained

decent age and reasonable reliability. By doing so, we satisfied our customers needs, increased

sales, and enhanced our shareholder and company wealth. Additionally, we are proud to say our

company received 30 out of 40 stars which was the third highest and received AAA ratings from

S&P which had only two teams for the simulation based on the Capstone Round Analysis

Reports for all 8 rounds.

Production

As a strategy to achieve its goal of becoming the cost leader in the traditional and low

and segments, Team Chester has been closely monitoring each products capacity requirements

and inventory levels throughout the simulation to avoid stocking out and holding too much

inventory Team Chester has been closely monitoring each products capacity requirements and

inventory levels throughout the simulation to avoid stocking out and holding too much inventory.

The team is aware that these oversights have financial drawbacks. Every time the team stocked

out resulted a direct loss of potential sales that could have been used for plant and product

improvements. These missed sales also could have also utilized the period costs spent for the

year at no additional cost for the company. Excess inventories were company investments with

no returns that cost the company stocking fees that in turn increased the companys variable

costs. To minimize these mistakes, the team considered the industry demand and growth rates in

forecasting demand for its target segments, which in turn gave the least possible amount of

6

stocking costs and potential revenue loss. After cumulatively summing the excess inventories

for all the products per round for all teams for the eight rounds, Team Chester managed to keep

its average total carry over inventory level at the lowest level when compared to all teams. This

translates into Chester incurring the least amount of stocking expenses throughout the

competition. Team Chester total inventories were 3,549 units while the other teams ranged from

3,828 units to 16,889 units. Team Chester therefore averages the lowest with 443 units per

round for all eight rounds as the others teams average ranged from 481 units to 2107 units (see

Appendix - Production - A).

With the objective of becoming the cost leader in traditional and Low End

segments, the team used tactical adjustments such as reducing the price and produced more on

these segments. Team Chester used the strategy to steadily increase the automation levels

starting at 4 and ending at 10 for these segments. As Team Chester spent $4 per unit of capacity

for every unit increase of automation level, the team reduced labor costs by about 10% the

following year after the automation increase (see Appendix - Production - B). As for all the

segments that the team was focusing on, automation was kept at a constant level of 6 throughout

the rounds until the products gained market share of 20%. As a team we did not introduce any

new products in the market, nor purchased additional capacity, this decision was a mistake and it

did cost us. The team also utilized second shifts as necessary to ensure that customer demands

were met and labor costs were kept to its minimum. However as a result of increased automation,

overtime costs were offset. The team did not reduce automation in any rounds, thereby avoiding

retooling costs.

It was obvious that by round 4, as evidenced by a declining market shares, that there were

several teams eyeing the same market segments that Team Chester was focusing on. However,

7

the team was able to maintain healthy margins by keeping close watch of its contribution margin

and ensuring that it was at least 30%. The team managed to sustain a contribution margin that

ranged from 34.1% to 55.9% in seven of the eight rounds (see Appendix - Production - C). This

was done by keeping variable costs like labor, material, and stocking fees at minimal. Team

Chester had the Second lowest variable costs average of $99.5M among 6 the teams throughout

the competition while the other teams were averaging from $104.9M to $116.9M (see Appendix

- Production - D). Because the team was able to keep its variable costs to a minimum, which is

in this case the second lowest overall average, the team was able to compete in terms of product

prices and was thus able to achieve its goal of becoming the cost leader in the Traditional and

Low End segments and still be profitable. Team Chesters cost leadership will continue in the

coming years as long as healthy margins are maintained by keeping variable and period costs

minimal.

Marketing

Chester sets out to produce and market products tailored for the all five segments. Our

marketing goal was to ensure we market products that the customer wants. Our strategies to

accomplish such objectives encompass providing customers with products that are of the lowest

price since price is 53% important for our Low End segment customers, ensuring adequate

awareness and accessibility of our products through ideal promo and sales budgets, effectively

positioned our products to match its ideal age inside its segment circle since age is 47%

important to our Traditional segment customers and providing products with acceptable quality.

In addition, we also strive to build a strong sustainable customer base by nurturing mutual

relationships and long term loyalty with them. By incorporating these strategies, our marketing

department was armed to provide growth and success for our company.

8

One of our competitive strengths was to control our price to be the lowest amongst our

competitors. The price range for Traditional product is from $19.50 to $29.50. Chester

marketed its Traditional products at the lowest price of $24.00 in Round 8. This price was not in

the lower third of the range as outlined in our strategy but it was certainly the lowest amongst all

teams. Our Low End products were being marketed for $17.00. Again this was the lowest price

offered for this product and as such it was not necessary to sell in the lower third price range.

From these statistics, we can conclude that we did excellent in keeping our price below all of our

competitors. See Appendix Marketing chart and graph A for price comparison of the

Traditional and Low End segments for all teams.

Our strategic plan includes increasing our customer awareness for our Traditional product

to 70% and awareness for Low End product to 60% by year 8. To accomplish these projections,

we invested a total of $4.6M in promo budget and achieved 87% awareness of Traditional and

for Low End products. Other teams did not do better than us. Andrews invested $1.725M in

promoting Able and achieved 80% awareness in round 8. It is logical to conclude that an

increase in promo budget would result an increase in customer awareness. As customer

awareness increases so is the potential for increased sales.

We also projected to achieve and sustain 70% customer accessibility by the end of Round

5. During Round 5, we invested $2.4M in Traditional sales budget and achieved 70% customer

accessibility. We invested $2.5M in Low End sales budget and achieved 73% accessibility on

our Low End products. Judging these results we can conclude we basically achieved our 5 year

goal for awareness and accessibility. We observed that other companies that invested more in

their sales budget achieved more accessibility. Erie invested $1..09M in their Egg sales budget

9

and was awarded with 900% accessibility. An increase in accessibility therefore tends to

increase product sales.

Reminiscences and Reflections

Looking back at this simulation, we must conclude that it was a wonderful and

challenging experience even though stressful at times. However Team Chester bond together to

in a cohesive way to build and managed a successful and profitable company. We strategically

decided on a plan to manufacture and market in all five segments products and we were pleased

with our results. Sometimes we were off our target ratios or not matching our production with

capacity or forecast. Sometimes we did not invest adequately in the detail diversity section of

our promo and sales budgets. Sometimes we were spending too much in areas that wouldnt

have been cost effective. However, we were quick to observe our mistakes and took prompt

corrective actions. Our understanding of the competitive simulation increased with each round

and this adds to our enthusiasm. We have achieved some critical success during our simulation.

We earned 30 stars. We marketed the lowest cost Traditional and Low End segment products.

Despite that we produced and marketed the least variety of products; we made decent profits and

never had a need for an emergency loan.

Something we could have done differently to beat the competition would have been to

phase out the products we were not interested much faster, purchase plant and equipment

capacity earlier and introduced more alternative products in our targeted segments. We could

have invested more in our automation to reduce our labor cost and we could have better

forecasting that would help to stop the stock outs our products. These steps can be implemented

10

moving forward. However, overall Team Chester was very pleased with the way we managed

Chester Inc.

11

Appendix

R&D

A. Material Costs

Product Segment Rd 1 Rd 2 Rd 3 Rd 4 Rd 5 Rd 6 Rd 7 Rd 8

Cake Traditional $10.85 $10.66 $10.26 $9.25 $8.28 $8.08 $7.92 $8.56

Cedar Low $7.05 $5.76 $4.81 $4.81 $4.55 $5.05 $4.25 $5.23

Cid High $15.96 $14.87 $15.22 $14.85 $14.00 $13.96 $13.70 $13.43

Coat Performance $15.53 $15.34 $15.43 $14.20 $13.58 $13.34 $13.15 $12.94

Cure Size $13.73 $13.54 $13.27 $12.00 $11.45 $11.22 $11.03 $10.83

Total $63.12 $60.17 $58.99 $55.11 $51.86 $51.65 $50.05 $50.99

0

2

4

6

8

10

12

14

16

18

R

o

u

n

d

1

R

o

u

n

d

2

R

o

u

n

d

3

R

o

u

n

d

4

R

o

u

n

d

5

r

o

u

n

d

6

R

o

u

n

d

7

R

o

u

n

d

8

Cake

Cedar

Cid

Coat

Cure

12

Production

A.Contrib. Margins in%

0

10

20

30

40

50

60

Round1 Round2 Round3 Round4 Round5 Round6 Round7 Round8

Andrews

Baldwin

Chester

Digby

Erie

Ferris

Andrews Baldwin Chester Digby Erie Ferris

Round1 28.2% 28.5% 28.5% 33.1% 29.0% 32.9%

Round2 38.9% 21.0% 33.2% 32.2% 31.41% 31.7%

Round3 40.2% 12.2% 30.4% 28.9% 28.1% 27.0%

Round4 43.3% 26.7% 34.12% 33.0% 35.0% 28.5%

Round5 48.0% 24.6% 43.2% 33.5% 40.3% 30.9%

Round6 49.1% 2.9% 43.7% 34.2% 43.4% 29.65%

Round7 52.6% 12.9% 58.8% 35.4% 49.5% 34.4%

Round8 56.1% 4.3% 55.9% 29.7% 46.3% 25.6%

13

B.Excess Inventory Units for all Teams by Round

0

500

1000

1500

2000

2500

3000

3500

4000

4500

Andrews Baldwin Chester Digby Erie Ferris

Round1

Round2

Round3

Round4

Round5

Round6

Round7

Round8

Unit of Excess Inventory

Company Rd 1 Rd 2 Rd 3 Rd 4 Rd 5 Rd 6 Rd 7 Rd 8 Average Total

Andrews 943 590 977 1228 1714 3430 1417 1590 1486 11889

Baldwin 1640 4140 3554 1691 1046 1750 1144 1894 2107 16859

Chester 1557 277 505 400 129 582 1 98 443 3549

Digby 391 409 914 1031 1510 1204 0 936 799 6395

Erie 457 321 291 433 523 1247 0 581 481 3853

Ferris 514 349 647 517 1060 1197 0 904 648 5188

C. Automation Compared to Direct Labor Cost by Round

Automation Direct Labor Costs

Round Cake Cedar Cid Coat Cure

Rd 1 4 5 3 3 3 $39,100

Rd 2 4 5 3 3 3 $34,505

Rd 3 4 5 3 3 3 $41,883

Rd 4 6 6 6 6.1 6.1 $52,144

Rd 5 6 6 6 6.1 6.1 $40,140

Rd 6 10 10 6 10 10 $40,209

Rd 7 10 10 6 10 10 $12,754

Rd 8 10 10 6 10 10 $20,959

14

Variable Cost for all Teams by Round

0

20000

40000

60000

80000

100000

120000

140000

160000

180000

Round0 Round2 Round4 Round6 Round8

Andrews

Baldwin

Chester

Digby

Erie

Ferris

Variable Costs (Labor,Material,Carry)

Round Andrews Baldwin Chester Digby Erie Ferris

Round 0 $72,513 $72,513 $72,513 $72,513 $72,513 $72,513

Round 1 $95,398 $80,787 $93,816 $76,922 $77,957 $74,813

Round 2 $94,610 $59,473 $80,850 $116,372 $82,321 $104,787

Round 3 $86,290 $41,090 $94,678 $140,409 $112,060 $138,573

Round 4 $95,174 $48,324 $110,826 $155,305 $102,451 $135,490

Round 5 $91,750 $27,197 $97,629 $116,930 $108,955 $110,353

Round 6 $94,087 $18,999 $98,110 $131,553 $97,723 $92,613

Round 7 $108,161 $27,731 $60,196 $137,446 $75,169 $86,020

Round 8 $95,196 $20,899 $87,658 $170,433 $110,193 $117,252

Average $104,147 $49,626 $99,534 139,735 $104,917 $116,551

Total $833,179 $397,013 $796,276 $1,117,883 $839,342 $932,414

15

Marketing

A.Traditional and Low End Segment Price Comparison

Traditional Segment

Low End

Segment

Price Comparison

Price Comparison

Able $ 24.00

Acre $ 19.5

Baker $ 27.50

Cedar $ 17.00

Cake $ 24.00

Dell $ 19.5

Daze $ 25.50

Eat $ 18.5

Echo $24.00

Ebb $ 17.00

Egg $ 24.00

$

22

23

24

25

26

27

28

Able Baker Cake Daze Echo Egg

Price

Low End Segment Price comparison

15.5

16

16.5

17

17.5

18

18.5

19

19.5

Acre Cedar Dell Eat Ebb

Price

16

S-ar putea să vă placă și

- Capstone Industry - 602 Team AndrewsDocument17 paginiCapstone Industry - 602 Team AndrewsPeshwa BajiraoÎncă nu există evaluări

- Capsim Report - Digby TeamDocument17 paginiCapsim Report - Digby Teamparamjit badyal100% (1)

- Capsim StrategyDocument2 paginiCapsim Strategyhtshot2350% (2)

- BS Digby ReportDocument12 paginiBS Digby ReportAlok PathakÎncă nu există evaluări

- Capsim TipsDocument4 paginiCapsim TipsTomi Chan100% (3)

- Chester Capsim Report I Professor FeedbackDocument8 paginiChester Capsim Report I Professor Feedbackparamjit badyal100% (1)

- Master of Business Administration (MBA-CORE)Document4 paginiMaster of Business Administration (MBA-CORE)Anish Dalmia100% (1)

- Comp XM Examination GuideDocument15 paginiComp XM Examination Guidesarathusha100% (1)

- CapSim Demonstration - Student NotesDocument7 paginiCapSim Demonstration - Student NotesKarthik HegdeÎncă nu există evaluări

- Capsim FinalDocument24 paginiCapsim FinalTanvi Mudhale100% (1)

- Digby Corp 2021 Annual ReportDocument13 paginiDigby Corp 2021 Annual ReportwerfsdfsseÎncă nu există evaluări

- Capsim ReportDocument23 paginiCapsim Reportamanmessi50% (2)

- Comp-XM Examination GuideDocument15 paginiComp-XM Examination GuideJacquesMeyer100% (2)

- Capstone Situation AnalysisDocument5 paginiCapstone Situation AnalysisHerbert Ascencio0% (1)

- Capstone RehearsalDocument14 paginiCapstone RehearsalRaakesh RajanÎncă nu există evaluări

- Capsim Business Simulation - Key Learnings - FinalDocument26 paginiCapsim Business Simulation - Key Learnings - Finalvin100% (2)

- CAPSIM DecisionDocument4 paginiCAPSIM DecisionJenniferÎncă nu există evaluări

- RTS Company AndrewsDocument26 paginiRTS Company Andrewsasia0312Încă nu există evaluări

- Capstone Courier Round 5Document13 paginiCapstone Courier Round 5AkashÎncă nu există evaluări

- CapsimDocument7 paginiCapsimakarsh jainÎncă nu există evaluări

- Simulation SlidesDocument46 paginiSimulation SlidesMalick Toguyeni100% (2)

- CAPSIM Course Assignment 1Document1 paginăCAPSIM Course Assignment 1Anup DhanukaÎncă nu există evaluări

- Notes CapsimDocument6 paginiNotes CapsimElinorWang0% (1)

- Capstone 5 Year StrategyDocument11 paginiCapstone 5 Year Strategyberetta92f100% (1)

- Basic Capsim StrategiesDocument8 paginiBasic Capsim StrategiesRachel YoungÎncă nu există evaluări

- Good Info CapsimDocument11 paginiGood Info Capsimmstephens1Încă nu există evaluări

- Capstone StrategiesDocument13 paginiCapstone Strategiesrns116Încă nu există evaluări

- Capsim Success MeasuresDocument10 paginiCapsim Success MeasuresalyrÎncă nu există evaluări

- Capsimstrategy Blogspot Com AuDocument5 paginiCapsimstrategy Blogspot Com AuCahyo EdiÎncă nu există evaluări

- Ferris-Foundation Niche DifferentiationDocument5 paginiFerris-Foundation Niche DifferentiationAlexandra Karastathi50% (2)

- CAPSIM - Digby PresentationDocument20 paginiCAPSIM - Digby PresentationKrishna SaraswatÎncă nu există evaluări

- Comp XM Examination GuideDocument15 paginiComp XM Examination GuideSunil Singh50% (8)

- CompXM Study GuideDocument1 paginăCompXM Study GuidePrashant KapoorÎncă nu există evaluări

- CapSim Demonstration Student Notes SP13Document8 paginiCapSim Demonstration Student Notes SP13NRLDCÎncă nu există evaluări

- CAPSIMDocument4 paginiCAPSIMJie ChengÎncă nu există evaluări

- Capsim Predict v9Document11 paginiCapsim Predict v9ABHISHEK100% (2)

- Team Digby Capsim Final ReportDocument49 paginiTeam Digby Capsim Final Reportmiranjd100% (3)

- Comp-Xm® Inquirer WordDocument37 paginiComp-Xm® Inquirer WordAnonymous TAV9RvÎncă nu există evaluări

- Capsim Expert GuideDocument61 paginiCapsim Expert Guideniroson88% (8)

- Andrews AnalysisDocument11 paginiAndrews Analysisapi-334753705Încă nu există evaluări

- Capsim Capstone Introductory QuizDocument1 paginăCapsim Capstone Introductory Quizreformedgamer100% (1)

- Sample Strategic Plan 2Document5 paginiSample Strategic Plan 2ibrahimaktan100% (1)

- Capstone Round 3Document43 paginiCapstone Round 3Vatsal Goel100% (1)

- Capsim Decisions AssistDocument68 paginiCapsim Decisions AssistRose KÎncă nu există evaluări

- Capstone Excel WOrksheetDocument3.304 paginiCapstone Excel WOrksheetOrgan Beh60% (5)

- Strategy Guide CapsimDocument4 paginiStrategy Guide Capsimhummer12345100% (2)

- Comp XMDocument785 paginiComp XMAnkit Chaturvedi0% (1)

- SAP Case Analysis PDFDocument1 paginăSAP Case Analysis PDFshivrinderÎncă nu există evaluări

- CAPSIM Capstone Strategy 2016Document21 paginiCAPSIM Capstone Strategy 2016Khanh MaiÎncă nu există evaluări

- 500 - Capsim Team Member GuideDocument28 pagini500 - Capsim Team Member GuideJaspreetÎncă nu există evaluări

- Presentation Example For Markstrat Final PresentationDocument11 paginiPresentation Example For Markstrat Final PresentationemilhagglundÎncă nu există evaluări

- Markstrat Report - Company I - Nigel Quah - Yuanxin Gao - Zille HussnainDocument7 paginiMarkstrat Report - Company I - Nigel Quah - Yuanxin Gao - Zille HussnainZillay Hussnain BasijiÎncă nu există evaluări

- Capsim Sample ReportDocument15 paginiCapsim Sample ReportParas Jain67% (3)

- Team No.15 - Erie - Assignment No - 1Document6 paginiTeam No.15 - Erie - Assignment No - 1dipraj.dhuri22Încă nu există evaluări

- GC Student Report en enDocument13 paginiGC Student Report en enMTORREYÎncă nu există evaluări

- A CompanyDocument18 paginiA CompanyPhương Trần ThuÎncă nu există evaluări

- TEAM ANDREWS (Group 8) C116161: Cross-Functional Simulation ReportDocument5 paginiTEAM ANDREWS (Group 8) C116161: Cross-Functional Simulation ReportSURBHI MITTALÎncă nu există evaluări

- Final Paper Company A Startsim SimulationDocument9 paginiFinal Paper Company A Startsim SimulationPaul OroneÎncă nu există evaluări

- BSG Game StrategyDocument1 paginăBSG Game StrategyMarlenSapazhanovÎncă nu există evaluări

- Week 8 - Team Erie Final PaperDocument14 paginiWeek 8 - Team Erie Final PaperSamantha TedejaÎncă nu există evaluări

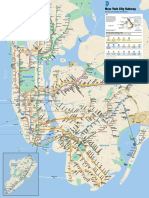

- New York Subway Map PDFDocument1 paginăNew York Subway Map PDFSzabÎncă nu există evaluări

- Thank You.Document1 paginăThank You.sebast107Încă nu există evaluări

- Issues in Nursing OrganizationsDocument6 paginiIssues in Nursing Organizationssebast107Încă nu există evaluări

- Issues in Nursing OrganizationsDocument6 paginiIssues in Nursing Organizationssebast107Încă nu există evaluări

- Role of APN - An Interview1Document7 paginiRole of APN - An Interview1sebast107Încă nu există evaluări

- Issues in Nursing OrganizationsDocument6 paginiIssues in Nursing Organizationssebast107Încă nu există evaluări

- Final Exam20Document6 paginiFinal Exam20sebast107Încă nu există evaluări

- Final Exam20Document6 paginiFinal Exam20sebast107Încă nu există evaluări

- Final Exam20Document6 paginiFinal Exam20sebast107Încă nu există evaluări

- Final Exam20Document6 paginiFinal Exam20sebast107Încă nu există evaluări

- How Germ Theory Brings Changes Into PracticeDocument1 paginăHow Germ Theory Brings Changes Into Practicesebast107Încă nu există evaluări

- Ford Motor Company-GlobalizationDocument10 paginiFord Motor Company-Globalizationsebast107100% (1)

- Staff Analyst Newyork Job1Document1 paginăStaff Analyst Newyork Job1sebast107Încă nu există evaluări

- Describe The Five Discoveries of Self-Directed LearningDocument7 paginiDescribe The Five Discoveries of Self-Directed Learningsebast107Încă nu există evaluări

- Self Control Is The Ability To Remain Composed in Spite of Our Emotional StateDocument2 paginiSelf Control Is The Ability To Remain Composed in Spite of Our Emotional Statesebast107Încă nu există evaluări

- Personal Statement SDDocument1 paginăPersonal Statement SDsebast107Încă nu există evaluări

- Capgemini 3Document40 paginiCapgemini 3Sai PragnaÎncă nu există evaluări

- M001-21 Abhinav MittalDocument22 paginiM001-21 Abhinav MittalAbhinav MittalÎncă nu există evaluări

- Penang Companies 2018Document31 paginiPenang Companies 2018陈桉琳Încă nu există evaluări

- Samsung Sustainability Reports 2014Document69 paginiSamsung Sustainability Reports 2014nicholasdeleoncircaÎncă nu există evaluări

- Kaplan & Norton BSC Report - 2003 - BSC and InnovationDocument16 paginiKaplan & Norton BSC Report - 2003 - BSC and InnovationRenato GutierrezÎncă nu există evaluări

- 2015 Global-Manufacturing-Outlook-KPMG PDFDocument36 pagini2015 Global-Manufacturing-Outlook-KPMG PDFivan jessicaÎncă nu există evaluări

- Questions AnswersDocument13 paginiQuestions Answersgagafik100% (1)

- Innovation and Product Innovation in MarDocument25 paginiInnovation and Product Innovation in MarMohammed AlkhaldiÎncă nu există evaluări

- Hierarchical Evidential Reasoning-Based AssessmentDocument13 paginiHierarchical Evidential Reasoning-Based Assessmentسارة قاسم كاظمÎncă nu există evaluări

- Case Study Week 01Document3 paginiCase Study Week 01Steven WijayaÎncă nu există evaluări

- HTCDocument12 paginiHTCMaryam DurraniÎncă nu există evaluări

- Kinegic Proposal 150623 v1Document34 paginiKinegic Proposal 150623 v1Rajeev VenegallaÎncă nu există evaluări

- CefipraDocument7 paginiCefiprachelam101Încă nu există evaluări

- Dikris Koyuncu Annotation4Document1 paginăDikris Koyuncu Annotation4tsarwaÎncă nu există evaluări

- Integration of Products and ServicesDocument8 paginiIntegration of Products and ServicesCamilo Andres Lopez DiazÎncă nu există evaluări

- Journal of Cleaner Production: Yixuan Wang, Xiangyun Chang, Zhigao Chen, Yongguang Zhong, Tijun FanDocument11 paginiJournal of Cleaner Production: Yixuan Wang, Xiangyun Chang, Zhigao Chen, Yongguang Zhong, Tijun FanCarmen ArgüellesÎncă nu există evaluări

- Group Facebook Case Study 2 AnswerDocument10 paginiGroup Facebook Case Study 2 AnswerNCTÎncă nu există evaluări

- Marketing AuditDocument20 paginiMarketing AuditpsivathmikaÎncă nu există evaluări

- Breaking Up With PlasticDocument6 paginiBreaking Up With PlasticunitedmanticoreÎncă nu există evaluări

- Victoria's New China Strategy - Partnerships For ProsperityDocument40 paginiVictoria's New China Strategy - Partnerships For ProsperityDaniel Andrews100% (1)

- Chapter01Sol 6e2005fDocument42 paginiChapter01Sol 6e2005fThu HươngÎncă nu există evaluări

- ECE Laws (Revised)Document93 paginiECE Laws (Revised)Alvin RullÎncă nu există evaluări

- Europe 2020 From Indicators and Targets To Performance and DeliveryDocument9 paginiEurope 2020 From Indicators and Targets To Performance and DeliveryMarkÎncă nu există evaluări

- Raising Productivity Growth in Australian Agriculture: November 2009Document22 paginiRaising Productivity Growth in Australian Agriculture: November 2009Christos VoulgarisÎncă nu există evaluări

- Influence of The Project Manager's Technical Skills On Research and Development Project Outputs in Kenya Industrial Research and Development InstituteDocument11 paginiInfluence of The Project Manager's Technical Skills On Research and Development Project Outputs in Kenya Industrial Research and Development InstituteAdera AmolloÎncă nu există evaluări

- Supply Chain - PharmaceuticalsDocument17 paginiSupply Chain - Pharmaceuticalsabdullah2020Încă nu există evaluări

- Geopolitics Assignment-SYB AG07Document36 paginiGeopolitics Assignment-SYB AG07Prisha BhatiÎncă nu există evaluări

- Gradually Internationalizing Born Global' Firms: An Oxymoron?Document19 paginiGradually Internationalizing Born Global' Firms: An Oxymoron?skavi_2702Încă nu există evaluări

- Hero HondaDocument46 paginiHero Hondamaisha_nsuÎncă nu există evaluări

- Costreduction PDFDocument50 paginiCostreduction PDFharish puÎncă nu există evaluări