Documente Academic

Documente Profesional

Documente Cultură

5.itp For Construction Materials

Încărcat de

binunalukandamTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

5.itp For Construction Materials

Încărcat de

binunalukandamDrepturi de autor:

Formate disponibile

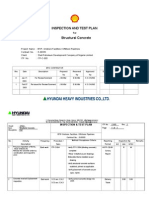

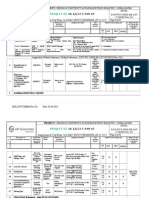

ITP:AAWRMTALITP700.Rev.

01

PROJECT NO: WRM/PTC/042/12/INF/LIWA

AGREEMENT NO: WRM/PTC/042/12/INF/LIWA

ITP NO: AA-WRM-TAL-ITP-700

REV: 01

INSPECTION AND TEST PLAN FOR CONSTRUCTION MATERIALS

PROJECT : MISCELLANEOUS DEVELOPMENT WORKS AT TAL MOREEB IN MADINAT LIWA, WESTERN REGION, EMIRATE OF ABUDHABI

CLIENT: WESTERN REGION MUNICIPALTY, EMIRATE OF ABU DHABI. U.A.E

H : HoldPoint - A designatedstoppingplaceduringtest or inspection, andthedatedsignatureor initial of theappropriate

ALTORATH CONSULTING ENGINEERS

ALASAB GENERAL TRANSPORT AND CONTRACTING EST.

PMC:

CONTRACTOR:

INSPECTION POINT

H : Hold Point A designated stopping place during test or inspection, and the dated signatureor initial of the appropriate

individuals is required before further work can be performed

W : Witness Point - Witness of the designated personnel. If the specified party is not present, the work shall not be continued.

W/S : Spot Witness - Spot witness of the designated personnel. If the specified party is not present, the work may continue.

R : ReviewPoint - Reviewof documents, drawingsor recordsfor theworks. Noformal notificationisrequired.

Rev

01

R : Review Point Review of documents, drawings or records for the works. No formal notification is required.

I : Inspection Point - Performthe activity of test or inspection. No formal notification is required.

ITL : Independent Third Party Lab

Revisions Record

Prepared by Revieved by Approved by ACE WRM

REVISION NO: DATE

CONTRACTOR PMC/CLIENT

Description and page No`s of Revisions

1-Sep-13 Pandiyarajan Santosh K srivastav Rahul kumar Moustafa Rashad

20-Oct-13 Pandiyarajan Santosh K srivastav Rahul kumar Moustafa Rashad page 1

0

1

Signature

AA ACE WRM

REMARKS

INSPECTION POINT

VERIFICATION

DOCUMENT

S.L NO

DESCRIPTION OF MATERIAL &

CRITERIA TO BE VERIFIED

CRITERIA CONTROLLING

DOCUMENTS

PROJECT REQUIRMENT AS

PER CONTROLLING

DOCUMENT

STANDARD TEST

PROCEDURE

FREQUENCY OF TEST

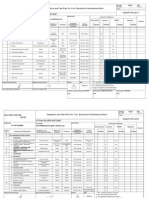

1 Filling and Embankment material

A Liquid Limit Project Specification Not specified

AS PER RELEVANT

Onceper 5000M T I T L Test Report H A LiquidLimit ProjectSpecification Notspecified

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

B PlasticLimit ProjectSpecification Notspecified

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

ASPER RELEVANT

C PlasticityIndex ProjectSpecification <10

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

D Grainsizedistribution ProjectSpecification Notspecified

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

E CBR ProjectSpecification Min15%at95%ofMDD

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

F Sandequivalent ProjectSpecification Notspecified

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

ASTM/ AASHTO

G Specificgravity ProjectSpecification Notspecified

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

H MDD & OMC Project Specification Not specified

AS PER RELEVANT

O 5000M T I T L T t R t H H MDD&OMC ProjectSpecification Notspecified

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

2 Subgrade material

Page1of8

ITP:AAWRMTALITP700.Rev.01

AA ACE WRM

REMARKS

INSPECTION POINT

VERIFICATION

DOCUMENT

S.L NO

DESCRIPTION OF MATERIAL &

CRITERIA TO BE VERIFIED

CRITERIA CONTROLLING

DOCUMENTS

PROJECT REQUIRMENT AS

PER CONTROLLING

DOCUMENT

STANDARD TEST

PROCEDURE

FREQUENCY OF TEST

ASPER RELEVANT

A. LiquidLimit ProjectSpecification Notspecified

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

B. PlasticLimit ProjectSpecification Notspecified

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

C. PlasticityIndex ProjectSpecification <10

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

D. Grainsizedistribution ProjectSpecification Notspecified

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H j p p

ASTM/ AASHTO

p p

E. CBR ProjectSpecification >25at95%ofMDD

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

ASPER RELEVANT

F. Sandequivalent ProjectSpecification Notspecified

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

G. Specificgravity ProjectSpecification Notspecified

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

H. MDD&OMC ProjectSpecification

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

3 Aggregate Sub Base - B

Sieveinmm%ofpassing

41.75100

25.470100

19.056090

ASPER RELEVANT

A. Gradation

9.534575

No.43060

No.102050

No.401030

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

No.200515

B. Los Angeles Abrasion ProjectSpecification 40%Max.

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

ASPER RELEVANT

C. Soundness (Sodium) ProjectSpecification 12%Max.

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

D. Soundness (Magnesium) ProjectSpecification 15%Max.

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

E. Sand Equivalent ProjectSpecification 25%Min.

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

F. Liquid Limit ProjectSpecification 35%Max.

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H q

ASTM/ AASHTO

p p

G. Plasticity Index ProjectSpecification 6.0%Max

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

ASPER RELEVANT

H. Sulphate Content ProjectSpecification 0.5%Max

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

I. Chloride Content ProjectSpecification 1.0%Max

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

J . Flakiness Index ProjectSpecification 35%Max.

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

K. Elongation Index ProjectSpecification 35%Max.

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

ASTM/ AASHTO

L. Specific gravity ProjectSpecification 2.20Min.

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

M MaxDryDensity(M DD) Project Specification 2 10 g/cc Min

AS PER RELEVANT

Onceper 5000M T I T L Test Report H M. Max Dry Density (M.D.D) ProjectSpecification 2.10g/ccMin.

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

N. C.B.R. at 98% of M.D.D ProjectSpecification 80%Min.

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Test Report H

Page2of8

ITP:AAWRMTALITP700.Rev.01

INSPECTION POINT

VERIFICATION DESCRIPTION OF MATERIAL & CRITERIA CONTROLLING

PROJECT REQUIRMENT AS

STANDARD TEST

AA ACE WRM

REMARKS

VERIFICATION

DOCUMENT

S.L NO

DESCRIPTION OF MATERIAL &

CRITERIA TO BE VERIFIED

CRITERIA CONTROLLING

DOCUMENTS

PER CONTROLLING

DOCUMENT

STANDARD TEST

PROCEDURE

FREQUENCY OF TEST

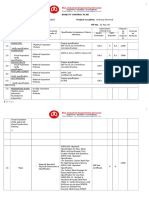

4 Geotextile Fabric-Type-1 yp

A. Fabric weight ProjectSpecification 100 gm/Sqm

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

B il h

ASPER RELEVANT

B. Tensile Strength ProjectSpecification 560 N

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

C. Elongation ProjectSpecification 20%

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

D. Puncture Strength ProjectSpecification 200 N

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

E. Muller Burst Strength ProjectSpecification 860 kpa

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

ASTM/ AASHTO

F. Tear Strength ProjectSpecification 80 N

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

G Permeablity Project Specification 001cm/s

AS PER RELEVANT

EachDelivery M T C H

Note1, Note2 of table

G. Permeablity ProjectSpecification 0.01 cm/s

ASTM/ AASHTO

Each Delivery M.T.C H

,

207.05

H. E.O.S - U.S STD SIEVE ProjectSpecification -

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

I. Strength Retention ProjectSpecification 560 N

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

J . Flow Rate ProjectSpecification 25 l/s/Sqm

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

5

Asphaltic concrete type-1

(Base course)

Sieve in mm % of passing

37.50 100 (+5)

25.0 92 (+5)

19.0 77 (+5)

1250 64 (+5)

A. Gradation ProjectSpecification

12.50 64 (+5)

9.50 55 (+5)

4.75 38 (+5)

2.36 27 (+4)

1.18 19(+4)

AS PER RELEVANT

ASTM/ AASHTO

Onceper Source M.T.C H

as per particular

specification

1.18 19 (+4)

600 Mic 13 (+4)

300 Mic 9 (+4)

150 Mic 6 (+4)

75 Mic 4 (+1.5)

B. Marshal Stability ProjectSpecification >1750 kg

AS PER RELEVANT

ASTM/ AASHTO

Onceper Source M.T.C H

C l

ASPER RELEVANT

C. Flow 0.25mm ProjectSpecification 8-16

AS PER RELEVANT

ASTM/ AASHTO

Onceper Source M.T.C H

D. OptimumBitumen Content ProjectSpecification <3.8%

AS PER RELEVANT

ASTM/ AASHTO

Onceper Source M.T.C H

E. VMA at Refusal Density ProjectSpecification <13%

AS PER RELEVANT

ASTM/ AASHTO

Onceper Source M.T.C H

F. Air Voids at Refusal density ProjectSpecification 2.0 - 4.0%

AS PER RELEVANT

ASTM/ AASHTO

Onceper Source M.T.C H

ASTM/ AASHTO

G. Min. Air Voids ProjectSpecification >1.5%

AS PER RELEVANT

ASTM/ AASHTO

Onceper Source M.T.C H

H Max VFB (voidsfilledwithbitumen) Project Specification <85%

AS PER RELEVANT

Onceper Source M T C H H. Max. VFB (voids filled with bitumen) ProjectSpecification <85%

ASTM/ AASHTO

Onceper Source M.T.C H

6

Asphaltic concrete type-2

(Wearing course)

Page3of8

ITP:AAWRMTALITP700.Rev.01

INSPECTION POINT

VERIFICATION DESCRIPTION OF MATERIAL & CRITERIA CONTROLLING

PROJECT REQUIRMENT AS

STANDARD TEST

AA ACE WRM

REMARKS

VERIFICATION

DOCUMENT

S.L NO

DESCRIPTION OF MATERIAL &

CRITERIA TO BE VERIFIED

CRITERIA CONTROLLING

DOCUMENTS

PER CONTROLLING

DOCUMENT

STANDARD TEST

PROCEDURE

FREQUENCY OF TEST

Sieve in mm % of passing

250 100 (+5) 25.0 100 (+5)

19.0 98 (+5)

12.50 88 (+5)

9.50 75 (+5)

4.75 52 (+5)

A. Gradation ProjectSpecification

( )

2.36 36 (+4)

1.18 26 (+4)

600 Mic 18 (+4)

300 Mic 12.0 (+4)

AS PER RELEVANT

ASTM/ AASHTO

Onceper Source M.T.C H

150 Mic 8.0 (+4)

75 Mic 5.0(+1.5)

ASPER RELEVANT

B. Marshal Stability ProjectSpecification >2000 kg

AS PER RELEVANT

ASTM/ AASHTO

Onceper Source M.T.C H

C. Flow 0.25mm ProjectSpecification 8-16

AS PER RELEVANT

ASTM/ AASHTO

Onceper Source M.T.C H

D. OptimumBitumen Content ProjectSpecification <4.5%

AS PER RELEVANT

ASTM/ AASHTO

Onceper Source M.T.C H

E. VMA at Refusal Density ProjectSpecification <12.5%

AS PER RELEVANT

ASTM/ AASHTO

Onceper Source M.T.C H

ASTM/ AASHTO

F. Air Voids at Refusal density ProjectSpecification 1.5-3.0%

AS PER RELEVANT

ASTM/ AASHTO

Onceper Source M.T.C H

G Min Air Voids Project Specification >15%

AS PER RELEVANT

Onceper So rce M T C H G. Min. Air Voids ProjectSpecification >1.5%

ASTM/ AASHTO

Onceper Source M.T.C H

H. Max. VFB (voids filled with bitumen) ProjectSpecification <85%

AS PER RELEVANT

ASTM/ AASHTO

Onceper Source M.T.C H

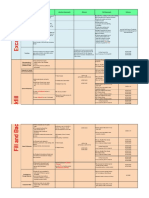

7 Prime Coat- M.C-70

A. Saybolt Furol Viscosity @ 50C ProjectSpecification 60-120 sec

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

B. Flash Point (Tag open cut) ProjectSpecification Min 38C

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

C

Residue fromDistillation to 360C in % by

Project Specification Min 55%

AS PER RELEVANT

EachDelivery M T C H C.

volume

ProjectSpecification Min. 55%

ASTM/ AASHTO

Each Delivery M.T.C H

Test on residue from distillation

ASPER RELEVANT

D. Penetration @25C,100g.,5sec ProjectSpecification Min. 120

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

E. Ductility, 25C ProjectSpecification 100 - 250 cm

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

F. Solublity in Trichloroethylene ProjectSpecification Min. 99% by weight

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

G. water content ProjectSpecification Max. 0.2%by weight

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

ASTM/ AASHTO

8 Tack Coat-SS-1H

A S b l l i i @

ASPER RELEVANT

A. Saybolt Furol Viscosity @ 50C ProjectSpecification 60-120 sec

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

B. Flash Point (Tag open cut) ProjectSpecification Min 38C

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

C.

Residue fromDistillation to 360C in % by

volume

ProjectSpecification Min. 55%

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

Test on residue from distillation

Page4of8

ITP:AAWRMTALITP700.Rev.01

INSPECTION POINT PROJECT REQUIRMENT AS

AA ACE WRM

REMARKS

INSPECTION POINT

VERIFICATION

DOCUMENT

S.L NO

DESCRIPTION OF MATERIAL &

CRITERIA TO BE VERIFIED

CRITERIA CONTROLLING

DOCUMENTS

PROJECT REQUIRMENT AS

PER CONTROLLING

DOCUMENT

STANDARD TEST

PROCEDURE

FREQUENCY OF TEST

ASPER RELEVANT

D. Penetration @25C,100g.,5sec ProjectSpecification Min. 120

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

E. Ductility, 25C ProjectSpecification 100 - 250 cm

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

F. Solublity in Trichloroethylene ProjectSpecification Min. 99% by weight

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

G. water content ProjectSpecification Max. 0.2%by weight

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

ASTM/ AASHTO

9 Curb Stone (All types)

A Dimension& Colour Asper ApprovedIFC Drawing Asper ApprovedIFC Drawing Visual EachDelivery

FormNo: AA-WRM-ITP-

H A. Dimension & Colour Asper Approved IFC Drawing Asper Approved IFC Drawing Visual Each Delivery

700-FM-1000

H

B.

Comp. Srength of concrete used in Curb

Stone making

ProjectSpecification Min. K250

AS PER RELEVANT

ASTM/ AASHTO

Onceper Source I.T.L Test Report H

10 Interlocking Tiles

A. Dimension & Colour Asper Approved IFC Drawing Asper Approved IFC Drawing Visual Each Delivery

FormNo: AA-WRM-ITP-

700-FM-1000

H

B.

Average Bulk density (after 48hrs of

immerson in water)

Project Specification >2.375 T/Cum

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery & onceper

5000 nos

M.T.C & I.T.L Report H Min. 4 out of 5 specimen

C

Minimum Bulk density (after 48hrs of

Project Specification 2.330T/Cum

AS PER RELEVANT

/

Each Delivery & onceper

M.T.C & I.T.L Report H Max. 1out of 5specimen C.

immerson in water)

Project Specification 2.330 T/Cum

ASTM/ AASHTO 5000 nos

M.T.C & I.T.L Report H Max. 1 out of 5 specimen

D.

Average Bulk/Apparent Density Ratio

(after 48hrs of immerson in water)

Project Specification >0.88

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery & onceper

5000 nos

M.T.C & I.T.L Report H Min. 4 out of 5 specimen

Min Bulk/Apparent DensityRatio (after ASPER RELEVANT EachDelivery& onceper

E.

Min. Bulk/Apparent Density Ratio (after

48hrs of immerson in water)

Project Specification 0.87

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery & onceper

5000 nos

M.T.C & I.T.L Report H Max. 1 out of 5 specimen

F.

Average Water Absorption (after 48hrs of

immerson in water)

Project Specification <5%

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery & onceper

5000 nos

M.T.C & I.T.L Report H Min. 4 out of 5 specimen

G.

Maximum. Water Absorption (after 48hrs

of immerson in water)

Project Specification 5.50%

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery & onceper

5000 nos

M.T.C & I.T.L Report H Max. 1 out of 5 specimen

H.

Average Comp. Strength (after 48hrs of

immersoninwater)

Project Specification >52 N/Sqmm

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery & onceper

5000nos

M.T.C & I.T.L Report H Min. 4 out of 5 specimen

immerson in water) ASTM/ AASHTO 5000 nos

I.

Min.Comp. Strength (after 48hrs of

immerson in water)

Project Specification 47N/Sqmm

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery & onceper

5000 nos

M.T.C & I.T.L Report H Max. 1 out of 5 specimen

VolumeLossshall not have

J . Arasion Resistance Project Specification

VolumeLoss shall not have

greater than 15cc/50Sqcm&

Avg thickeness loss Shall not

Exceed 3mm

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

ASPER RELEVANT

K. Average Flexural Strength Project Specification >5 N/Sqmm

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H Min. 4 out of 5 specimen

L. Min. Flexural Strength Project Specification 4.5 N/Sqmm

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H Max. 1 out of 5 specimen

11 Ready Mix Concrete

A. Mix. Proportion Approved M.A.R As per Approved M.A.R Visual Each Delivery Batch Report H A. p pp p pp y p

B. MinimumCement content Project Specification

K140 - 220 kg/Cum

K250 - 300 kg/Cum

K415 - 425 kg/Cum

Visual Each Delivery Batch Report H

C. Water Cement ratio Project Specification

K140 - 0.5 Max

K250 - 0.45Max

K415 - 0.42 Max

Visual Each Delivery Batch Report H

Page5of8

ITP:AAWRMTALITP700.Rev.01

AA ACE WRM

REMARKS

INSPECTION POINT

VERIFICATION

DOCUMENT

S.L NO

DESCRIPTION OF MATERIAL &

CRITERIA TO BE VERIFIED

CRITERIA CONTROLLING

DOCUMENTS

PROJECT REQUIRMENT AS

PER CONTROLLING

DOCUMENT

STANDARD TEST

PROCEDURE

FREQUENCY OF TEST

K140 60 120mm

D. Slump Range Project Specification

K140 - 60-120mm

K250 - 60-120mm

K415 - 60-120mm

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery

FormNo: AA-WRM-MS-

ITP-707-FM-1001

H

ASPER RELEVANT FormNo: AA WRM MS

E. Temperature Project Specification <32Cwhenplacing

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery

FormNo: AA-WRM-MS-

ITP-707-FM-1002

H

K140 - 100 kg/Sqcm

ASPER RELEVANT

OneSampleper50 cumof

concretefor ecahgrade&

F. MinimumCrushing Strength at 7 Days Project Specification K250 - 185 kg/Sqcm

K415 - 310 kg/Sqcm

AS PER RELEVANT

ASTM/ AASHTO

concretefor ecah grade&

Min. onesample(6 cubes)

for every day

H

K140- 140kg/Sqcm

ASPER RELEVANT

OneSampleper50 cumof

f h d &

G. MinimumCrushing Strength at 28 Days Project Specification

K140 140 kg/Sqcm

K250 - 250 kg/Sqcm

K415 - 415 kg/Sqcm

AS PER RELEVANT

ASTM/ AASHTO

concretefor ecah grade&

Min. onesample(6 cubes)

for every day

H

12 R i f t St l b 12 Reinforcement Steel bars

A.

All reinforcement steel required under this

Contract shall be epoxy-coated

i f l

AASHTO M284

(ASTM D3963)

As per AASHTO M284

(ASTM D3963

AASHTO T-68

(ASTM M/E8)

Each Delivery M.T.C H

reinforcement steel

( ) ( ( )

B. Grade Project Specification Grade60

AASHTO T-68

(ASTM M/E8)

Each Delivery M.T.C H

All Ph i l M h i l & Ch i l AASHTOM284 A AASHTOM284 AASHTOT 68 M T C & F N AA

C.

All Physical, Mechanical & Chemical

Properties

AASHTO M284

(ASTM D3963)

As per AASHTO M284

(ASTM D3963

AASHTO T-68

(ASTM M/E8)

Each Delivery

M.T.C & FormNo: AA-

WRM-ITP-700-FM-1000

H

13 Ready Mix Grout M.A.R As per M.A.R

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

14

Road marking paint

(Thermoplastic)

A. Pavement Marking Material AASHTO M249

should comply with AASHTO

M249

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

Glass Beads

A. shape Project Specification Spherical

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

U.S Sieve % of passing

20 100

B. Gradation Project Specification

20 100

30 75-95

50 15-35

100 0-5

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

C.

Index of Refraction @25C by immersion

method

Project Specification Atleast 1.65

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

D.

Imperfections (the dark & irregular shape

material & scratchesonsurfacesof beads)

Project Specification

shall not bemorethan 20% by

weight

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

material & scratches on surfaces of beads) weight ASTM/ AASHTO

E. Chemical Stability Project Specification

As per Federal |Specification

TT-B-1325A

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

when tested at an angleof

F. Reflectivity Project Specification

incidenceof 0and an angleof

divergenceof 1/3 degreeshall

beatleast 2.0

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

15 15

A. Sign Post Project Specification

As per Given in Shop

Drawings

visual Each Delivery M.T.C H

Page6of8

ITP:AAWRMTALITP700.Rev.01

INSPECTION POINT PROJECT REQUIRMENT AS

AA ACE WRM

REMARKS

INSPECTION POINT

VERIFICATION

DOCUMENT

S.L NO

DESCRIPTION OF MATERIAL &

CRITERIA TO BE VERIFIED

CRITERIA CONTROLLING

DOCUMENTS

PROJECT REQUIRMENT AS

PER CONTROLLING

DOCUMENT

STANDARD TEST

PROCEDURE

FREQUENCY OF TEST

B i

Asper Project Specification ASPER RELEVANT

B. Sign Face Project Specification

As per Project Specification

and Approved M.A.R

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

16

Pavement Marker (Heavy duty

Road Stud)

Project Specification

As per Project Specification &

Approved M.A.R

As per Project Specification

& Relevant ASTM/

AASHTO

Each Delivery M.T.C H

Road Stud)

pp

AASHTO

17

Chain Link Fence with Pedestrian

gate

ASPER RELEVANT

A. Chemical properties Project specification As per Project specification

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

B. Mechanical properties Project specification As per Project specification

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

18

Ornamental Fence with

Decorative Panel

A. Chemical properties Project specification As per Project specification

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

ASTM/ AASHTO

B. Mechanical properties Project specification As per Project specification

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

19 B T G d R il 19 Beam Type Guard Rail

A. Chemical properties Project specification As per Project specification

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

B. Mechanical properties Project specification As per Project specification

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

20 Cable Warning Tap

A. Material Project Specification

Acid & Alkali Polyethylene

Film

Visual Each Delivery M.T.C H

B Widthof film Project Specification Min 15cm

AS PER RELEVANT

EachDelivery M T C H B. Width of film Project Specification Min. 15 cm

ASTM/ AASHTO

Each Delivery M.T.C H

C. Thickeness Project Specification 150 Microns

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

ASPER RELEVANT

D. Tensile Strength - lengthwise Project Specification Min. 125Kg/Sqmm

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

E. Tensile Strength - crosswise Project Specification Min. 105Kg/Sqmm

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

F. Elongation factor Project Specification 350%

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

Utility Colour

1Electrical Cables Red

G. Colour Project Specification

1Electrical Cables Red

2TelephoneCables Green

3Water Lines Blue

4Sewer/Irrigation Yellow

pipelines

Visual Each Delivery M.T.C / Check sheet H

pp

5.Trafficcontroll Orange

system

21 Concrete Cable Cover Tiles

A. concrete mix proportion Project Specification

1:1.5:3

Visual Each Delivery M.T.C H

B. Mechanical properties Project Specification & WED As per WED & M.A.R

AS PER RELEVANT

ASTM/ AASHTO

1 Batch (12 nos) per 2000

tiles and then 1 Batch for

every 4000 tiles

I.T.L Test Report

M.T.C

H

Page7of8

ITP:AAWRMTALITP700.Rev.01

REMARKS

INSPECTION POINT

VERIFICATION

DOCUMENT

S.L NO

DESCRIPTION OF MATERIAL &

CRITERIA TO BE VERIFIED

CRITERIA CONTROLLING

DOCUMENTS

PROJECT REQUIRMENT AS

PER CONTROLLING

DOCUMENT

STANDARD TEST

PROCEDURE

FREQUENCY OF TEST

AA ACE WRM

DOCUMENT

22 Concrete Repair Mortar

A.

All Physical, Chemical & Mechanical

Properties

M.A.R As per Approved M.A.R

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C /I.T.L Report H

B. Date of Expiry M.A.R As per Approved M.A.R Visual Each Delivery

FormNo: AA-WRM-ITP-

700-FM-1000

H

23 Expansion Preformed Joint Filler Project Specification

Shall comply with

AASHTO M-33

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

24 Expansion Joint Sealant Project Specification Asper ApprovedM A R

AS PER RELEVANT

EachDelivery M T C H 24 Expansion Joint Sealant Project Specification As per Approved M.A.R

ASTM/ AASHTO

Each Delivery M.T.C H

25 Curb stone Paint

ASPER RELEVANT

A. Colour Project Specification White, Red, Yellow&Block

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

B. Density Project Specification 1.5 Kg/Ltr

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

C. Solid Content Project Specification .+50% by volume

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

26

Water Proofing Memberane Type-

Project Specification Asper ApprovedM A R

AS PER RELEVANT

EachDelivery M T C H 26

A, Type-B

Project Specification As per Approved M.A.R

ASTM/ AASHTO

Each Delivery M.T.C H

27 Electrical Cables

Project Specification

/Approved M.A.R

As per Approved M.A.R

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

j S ifi i AS A

28 Street Light Poles for all height

Project Specification

/Approved M.A.R

As per Approved M.A.R

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

29 Lanterns

Project Specification

/Approved M.A.R

As per Approved M.A.R

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

30 P.V.C, U.P.V.C, GRP Ducts

A.

All Physical, Chemical & Mechanical

P i

Project Specification /M.A.R As per Approved M.A.R

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C /I.T.L Report H A.

Properties

oject Spec cat o / . . spe pp oved . .

ASTM/ AASHTO

ac e vey . .C / . . epo t

31 P.V.C,HORSE RACE TRACK M.A.R As per Approved M.A.R

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C H

32 All other Special & New Items Project Specification /M.A.R As per Approved M.A.R

AS PER RELEVANT

ASTM/ AASHTO

Each Delivery M.T.C / I.T.L Report H

33

Bedding Sand (for laying interlocking

33

tiles)

A. Gradation Project Specification

U.S Sieve % of passing

1/4" (6.25mm) 100

50(03mm) 0-35

AS PER RELEVANT

ASTM/ AASHTO

Onceper 5000 M.T I.T.L Report H

50 (0.3mm) 0 35

100 (0.150mm) 0-10

ASTM/ AASHTO

Page8of8

S-ar putea să vă placă și

- ITP C 005 (Structural Concrete)Document4 paginiITP C 005 (Structural Concrete)segun ajibolaÎncă nu există evaluări

- Ibb Mcup & Modification of K-12 Building: Safco/Ibb Mobile Coating Unit PojectDocument19 paginiIbb Mcup & Modification of K-12 Building: Safco/Ibb Mobile Coating Unit PojectShewale PravinÎncă nu există evaluări

- Nawaz Khan - Civil InspectorDocument4 paginiNawaz Khan - Civil InspectormlÎncă nu există evaluări

- Contractor Quality Control Plan For Civil WorkDocument6 paginiContractor Quality Control Plan For Civil WorkUday PratapÎncă nu există evaluări

- Method Statement For BuildingDocument2 paginiMethod Statement For BuildinglahiruÎncă nu există evaluări

- QC PROCEDURESDocument37 paginiQC PROCEDURESRen Salazar100% (2)

- RAFT Foundation FDocument30 paginiRAFT Foundation F10bcl016100% (3)

- Inspection and Test Plan: (Project Name)Document1 paginăInspection and Test Plan: (Project Name)Muhammad Setyo RahutomoÎncă nu există evaluări

- PQP Flow ChartDocument1 paginăPQP Flow ChartFIRMANSYAHÎncă nu există evaluări

- Dinesh Qa-Qc EngineerDocument6 paginiDinesh Qa-Qc EngineerDinesh SomwanshiÎncă nu există evaluări

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFDocument53 paginiA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONÎncă nu există evaluări

- Right Factorz Projects PVT LTD Checklist For Cable InstallationDocument9 paginiRight Factorz Projects PVT LTD Checklist For Cable InstallationRajesh RaghunathanÎncă nu există evaluări

- Construction QC PlanDocument13 paginiConstruction QC PlanAbdallah YounisÎncă nu există evaluări

- Types of Waterproofing Methods in ConstructionDocument7 paginiTypes of Waterproofing Methods in ConstructionNino Celso AstilleroÎncă nu există evaluări

- Inspection Test PlanDocument3 paginiInspection Test Planfabin100% (3)

- QES PEVC-ENG237 - Checklist For PSS Fencing DetailsDocument2 paginiQES PEVC-ENG237 - Checklist For PSS Fencing DetailsRupesh Khandekar100% (1)

- ITP Fencing Rev - 00 PDFDocument3 paginiITP Fencing Rev - 00 PDFanon_987276020Încă nu există evaluări

- Excavation and Backfill Inspection PlanDocument9 paginiExcavation and Backfill Inspection PlanShewale PravinÎncă nu există evaluări

- MS For Rehabilitation of Clear Water ReserviorDocument3 paginiMS For Rehabilitation of Clear Water ReserviorMhando IgnasÎncă nu există evaluări

- Check List For Backfilling WorksDocument2 paginiCheck List For Backfilling WorksYash SharmaÎncă nu există evaluări

- Structural Steel Work Check ListDocument1 paginăStructural Steel Work Check ListAhmad BilalÎncă nu există evaluări

- Method Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01Document9 paginiMethod Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01hammad21100% (1)

- Itp For Painting WorksDocument28 paginiItp For Painting WorksAhmed saberÎncă nu există evaluări

- 011 Itp Culvert Works 1Document3 pagini011 Itp Culvert Works 1MikiRoniWijayaÎncă nu există evaluări

- Surface GI Conduit Installation Method StatementDocument4 paginiSurface GI Conduit Installation Method StatementJaneÎncă nu există evaluări

- Epoxy Method 2Document11 paginiEpoxy Method 2Mohamed BadrÎncă nu există evaluări

- Field ITP Civil Rev-8after Lump-Sump.Document17 paginiField ITP Civil Rev-8after Lump-Sump.Echik Kici100% (3)

- Method Statement - Concreting WorkDocument4 paginiMethod Statement - Concreting WorkArnold Roy ManaloÎncă nu există evaluări

- CHECKLIST For Installation of Electrical UPVC DuctsDocument1 paginăCHECKLIST For Installation of Electrical UPVC DuctskevinÎncă nu există evaluări

- Gril Engineer URS Engineer: Manufacturer Guideline/QMS Protected Against Rain, Humidity, Dew Fall and DustDocument17 paginiGril Engineer URS Engineer: Manufacturer Guideline/QMS Protected Against Rain, Humidity, Dew Fall and Dustjitendra100% (1)

- Method Statement FOR Concreting Work: ProjectDocument6 paginiMethod Statement FOR Concreting Work: ProjectKelvin LauÎncă nu există evaluări

- Precast Building ChecklistDocument4 paginiPrecast Building ChecklistSasala Raju100% (1)

- 33 05 13 Manholes and Structures 10Document4 pagini33 05 13 Manholes and Structures 10salamÎncă nu există evaluări

- Itp S8 CivilDocument12 paginiItp S8 CivilAnonymous G3jRndEbVÎncă nu există evaluări

- Method Statement for Formwork, Reinforcement bars and Ready Mix Concrete عامDocument20 paginiMethod Statement for Formwork, Reinforcement bars and Ready Mix Concrete عامM.ZEKEBA0% (1)

- INSPECTION & TEST PLAN FOR FLUE GAS AND AIR DUCTSDocument1 paginăINSPECTION & TEST PLAN FOR FLUE GAS AND AIR DUCTStreyÎncă nu există evaluări

- 02 Pre Concreting Inspection RequestDocument2 pagini02 Pre Concreting Inspection RequestAlmira raiza BustamanteÎncă nu există evaluări

- CEMENT PLASTERING CHECKLISTDocument1 paginăCEMENT PLASTERING CHECKLISTsankuj5354Încă nu există evaluări

- CH-Engineering ITP for Backfilling WorksDocument2 paginiCH-Engineering ITP for Backfilling WorksYash SharmaÎncă nu există evaluări

- ITP For Concrete Paving WorkDocument15 paginiITP For Concrete Paving WorkShewale PravinÎncă nu există evaluări

- ITP AllDocument1 paginăITP AllMuhammadIqbalMughalÎncă nu există evaluări

- MasterSeal 550Document38 paginiMasterSeal 550Ahmad ElghazolyÎncă nu există evaluări

- NUI PHAO MINING BRICK WALL INSPECTIONDocument1 paginăNUI PHAO MINING BRICK WALL INSPECTIONHongducBuiÎncă nu există evaluări

- MS Site and FenceDocument11 paginiMS Site and FenceSahabzada AamirÎncă nu există evaluări

- Request For Inspection Civil Concrete Pre-PouringDocument2 paginiRequest For Inspection Civil Concrete Pre-PouringProject m707Încă nu există evaluări

- Traffic Signage Installation ITPDocument1 paginăTraffic Signage Installation ITPmoytabura96Încă nu există evaluări

- 027 ITP For Pre Cast Concrete PDFDocument27 pagini027 ITP For Pre Cast Concrete PDFlinga2014Încă nu există evaluări

- Inspection and Tests Plan: OPGW 60mm, 24coresDocument3 paginiInspection and Tests Plan: OPGW 60mm, 24coresErika Rafani WibowoÎncă nu există evaluări

- Saes A 114Document2 paginiSaes A 114Nino Celso AstilleroÎncă nu există evaluări

- P1066-CTD-QAC-ITP-002-B-Inspe... of Structural Steel WorkDocument4 paginiP1066-CTD-QAC-ITP-002-B-Inspe... of Structural Steel WorkEILA545 QAQCÎncă nu există evaluări

- 01 ITP TemplateDocument6 pagini01 ITP TemplateHelsy FuentesÎncă nu există evaluări

- Sewerage and WWTP measures in the city of Korca“ project testing proceduresDocument9 paginiSewerage and WWTP measures in the city of Korca“ project testing proceduresJohnny RamboÎncă nu există evaluări

- ML-KW-MST-001 R1 False Ceiling WorksDocument7 paginiML-KW-MST-001 R1 False Ceiling WorksprithivirajÎncă nu există evaluări

- Checklist For Terrace WaterproofingDocument2 paginiChecklist For Terrace WaterproofingSantosh YadavÎncă nu există evaluări

- Water RecDocument9 paginiWater RecToyEn MEgatÎncă nu există evaluări

- ITP For Piping WorksDocument3 paginiITP For Piping WorksOrlando1949100% (3)

- A05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C DDocument14 paginiA05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C Dbingmin100% (4)

- Dodsal Pte Ltd Q-Chem Project Doha Qatar Job No 7979 Welder Qualification RecordDocument1 paginăDodsal Pte Ltd Q-Chem Project Doha Qatar Job No 7979 Welder Qualification Recordproxywar100% (1)

- 026-Itp For Structural Steel PDFDocument18 pagini026-Itp For Structural Steel PDFKöksal Patan100% (11)

- Itp For Main SteelaaaaaaDocument4 paginiItp For Main SteelaaaaaaaymanmalahÎncă nu există evaluări

- NOTE-Spec. For Ductile Iron Pipes1 K9-K12Document32 paginiNOTE-Spec. For Ductile Iron Pipes1 K9-K12binunalukandamÎncă nu există evaluări

- Classic Range Dn60 To 2000Document48 paginiClassic Range Dn60 To 2000binunalukandamÎncă nu există evaluări

- AVM Pipes Fittings CatalogueDocument41 paginiAVM Pipes Fittings CataloguebinunalukandamÎncă nu există evaluări

- Retained Marshall Stability Test ProcedureDocument2 paginiRetained Marshall Stability Test ProcedurebinunalukandamÎncă nu există evaluări

- EXW-P015-0000-QM-LNT-IT-00066 Rev CADocument4 paginiEXW-P015-0000-QM-LNT-IT-00066 Rev CAbinunalukandamÎncă nu există evaluări

- Classic Range Dn60 To 2000Document48 paginiClassic Range Dn60 To 2000binunalukandamÎncă nu există evaluări

- AVM Pipes Fittings CatalogueDocument41 paginiAVM Pipes Fittings CataloguebinunalukandamÎncă nu există evaluări

- Hse Risk Assessment - 006 Ra - Hdpe Duct LayingDocument7 paginiHse Risk Assessment - 006 Ra - Hdpe Duct Layingbinunalukandam83% (12)

- Glass BeadsDocument20 paginiGlass BeadsbinunalukandamÎncă nu există evaluări

- Marshall Immersion Test ProcedureDocument2 paginiMarshall Immersion Test ProcedurebinunalukandamÎncă nu există evaluări

- EXW-P015-0000-QM-LNT-IT-00066 Rev CBDocument5 paginiEXW-P015-0000-QM-LNT-IT-00066 Rev CBbinunalukandamÎncă nu există evaluări

- TRA-Street Light Foundation Installation WorkDocument5 paginiTRA-Street Light Foundation Installation WorkbinunalukandamÎncă nu există evaluări

- Volume 2 Cover PagesDocument3 paginiVolume 2 Cover PagesbinunalukandamÎncă nu există evaluări

- Pages From 02b. Specifications-Concrete MixDocument1 paginăPages From 02b. Specifications-Concrete MixbinunalukandamÎncă nu există evaluări

- Almasaoodd Prestige OfficialDocument5 paginiAlmasaoodd Prestige OfficialbinunalukandamÎncă nu există evaluări

- Pages From 02b. Specifications-Concrete MixDocument1 paginăPages From 02b. Specifications-Concrete MixbinunalukandamÎncă nu există evaluări

- 5.itp For Construction MaterialsDocument8 pagini5.itp For Construction Materialsbinunalukandam100% (1)

- Volume 2 Cover PagesDocument3 paginiVolume 2 Cover PagesbinunalukandamÎncă nu există evaluări

- Volume 2 Cover PagesDocument3 paginiVolume 2 Cover PagesbinunalukandamÎncă nu există evaluări

- Volume 2 Cover PagesDocument3 paginiVolume 2 Cover PagesbinunalukandamÎncă nu există evaluări

- AttachementDocument63 paginiAttachementbinunalukandamÎncă nu există evaluări

- AttachementDocument63 paginiAttachementbinunalukandamÎncă nu există evaluări

- Pages From 02b. Specifications-Concrete MixDocument1 paginăPages From 02b. Specifications-Concrete MixbinunalukandamÎncă nu există evaluări

- ChatGPT Traffic SignsDocument4 paginiChatGPT Traffic SignsRobert Arifin HardjasaputraÎncă nu există evaluări

- Kansas Driving Handbook - 2013Document72 paginiKansas Driving Handbook - 2013DMV_exam_GUIDE_comÎncă nu există evaluări

- MDOT-Material Source Guide Qualified Products 84764 7Document23 paginiMDOT-Material Source Guide Qualified Products 84764 7Georges Abi SaadÎncă nu există evaluări

- Final Project Report on Design and Construction of Six Lane Highway from Vasad to BagodaraDocument53 paginiFinal Project Report on Design and Construction of Six Lane Highway from Vasad to BagodaraMananÎncă nu există evaluări

- Jeppesen Chart LegendDocument117 paginiJeppesen Chart Legendindiannightjar100% (4)

- 4 - Traffic ControlsDocument14 pagini4 - Traffic ControlsJorge LuizÎncă nu există evaluări

- Test - API 1169 - QuizletDocument13 paginiTest - API 1169 - QuizletAkram Alhaddad0% (1)

- Astm D2911 PDFDocument16 paginiAstm D2911 PDFjcamilo200100% (1)

- ADM - Traffic Control Devices Manual - Version 2.0 (November 2014) PDFDocument157 paginiADM - Traffic Control Devices Manual - Version 2.0 (November 2014) PDFRavi Teja Polisetti13% (8)

- Lane/Shoulder Standards and Typical Highway Cross SectionsDocument24 paginiLane/Shoulder Standards and Typical Highway Cross Sectionsjazzfan52100% (1)

- Sample Particular Specification For Road MarkingsDocument10 paginiSample Particular Specification For Road Markingsmalaya tripathyÎncă nu există evaluări

- Identification of Street Hydrants For Firefighting PurposesDocument19 paginiIdentification of Street Hydrants For Firefighting PurposesAbdul Rahman HilmiÎncă nu există evaluări

- Bs 3262 3Document11 paginiBs 3262 3Hamid Naveed100% (1)

- DPWH Road Signs and Pavement Markings May 2011 CompleteDocument360 paginiDPWH Road Signs and Pavement Markings May 2011 CompleteJan McZeal Bandao83% (53)

- (WMC-035) MCA Facility Road Improvements - Plan Set 4.6.21Document23 pagini(WMC-035) MCA Facility Road Improvements - Plan Set 4.6.21Brandon Buffalo EverhartÎncă nu există evaluări

- What Is A Road Safety AuditDocument5 paginiWhat Is A Road Safety AuditNal Bikram ThapaÎncă nu există evaluări

- CHAPTER 5 (Part3 RSA) PDFDocument88 paginiCHAPTER 5 (Part3 RSA) PDFVictoria JungÎncă nu există evaluări

- QAP For Bitumen JobDocument2 paginiQAP For Bitumen JobSasanka SekharÎncă nu există evaluări

- Government of Telangana Roads & Buildings DepartmentDocument43 paginiGovernment of Telangana Roads & Buildings Departmentsaikumar yellankiÎncă nu există evaluări

- Irc 66 PDFDocument20 paginiIrc 66 PDFsafetydmrcÎncă nu există evaluări

- As 4049.2-2005 Paints and Related Materials - Pavement Marking Materials Thermoplastic Pavement Marking MaterDocument8 paginiAs 4049.2-2005 Paints and Related Materials - Pavement Marking Materials Thermoplastic Pavement Marking MaterSAI Global - APAC100% (1)

- Saw Cut GroovesDocument4 paginiSaw Cut GroovesDevrim GürselÎncă nu există evaluări

- Driving Instruction ManualDocument59 paginiDriving Instruction ManualAlaa Al MarashlyÎncă nu există evaluări

- Glowing Roads Report FinalDocument14 paginiGlowing Roads Report FinalChintoo KalyanadurgamÎncă nu există evaluări

- Road Safety AuditDocument22 paginiRoad Safety AuditSujeet DubeyÎncă nu există evaluări

- Manual On Uniform Traffic Control Devices, Dec 2000Document983 paginiManual On Uniform Traffic Control Devices, Dec 2000m0172Încă nu există evaluări

- Road Safety Education - Why ?: V.Ramalingam Environment Education Cell State Training Centre PuducherryDocument75 paginiRoad Safety Education - Why ?: V.Ramalingam Environment Education Cell State Training Centre PuducherryRamalingam VaradarajuluÎncă nu există evaluări

- Pembaikan Cerun2 JLN KK-SDK (Pakej 2) - S Curve - May 2019 - Rationalized MPR 21 - EOT NO.1Document153 paginiPembaikan Cerun2 JLN KK-SDK (Pakej 2) - S Curve - May 2019 - Rationalized MPR 21 - EOT NO.1Tony JamesÎncă nu există evaluări

- Road Marking PaintDocument4 paginiRoad Marking PaintAnish PanchalÎncă nu există evaluări

- MUTCD PT 2 Traffic Control Devices For General Use PDFDocument176 paginiMUTCD PT 2 Traffic Control Devices For General Use PDFbanga bangaÎncă nu există evaluări