Documente Academic

Documente Profesional

Documente Cultură

Impact Test Lab Report

Încărcat de

aisyah mohamad othman85%(72)85% au considerat acest document util (72 voturi)

60K vizualizări5 paginithis experiment test two types of steel; mild steel and carbon steel with two different notch;u-notch and v-notch.

Titlu original

impact test lab report

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentthis experiment test two types of steel; mild steel and carbon steel with two different notch;u-notch and v-notch.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

85%(72)85% au considerat acest document util (72 voturi)

60K vizualizări5 paginiImpact Test Lab Report

Încărcat de

aisyah mohamad othmanthis experiment test two types of steel; mild steel and carbon steel with two different notch;u-notch and v-notch.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 5

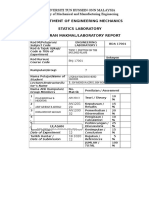

Objective:

1. To develop an understanding of fracture toughness.

2. To investigate the influence of the notch shape on the notched bar impact work.

3. To test ability of different types of spec impacts using two materials for impact test; mild

steel and carbon steel.

Theory:

Impact test is a test used in studying the toughness of material. The definition of

toughness is defined as the capacity of material to absorb energy and deform plastically

before fracturing. Toughness is associated with both ductility and strength of materials.

Since the amount of plastic deformation that occurs before fracture is a measure of the

ductility of the material and because the stress needed to cause fracture isa measure of

its strength, it follows that toughness is associated with both the ductility and strength of

the material. Impact test involves the sudden and dynamic application of the load. For this

purpose, in general, a pendulum is made to swing from a fixed height and strike the

standard impact specimen. There are two types of method to test impact test which is Izod

test and Charpy test. These two methods are different in placing the specimens. In Izod

test, the specimen is placed in vertical position and the notch area is facing the pendulum.

Meanwhile in Charpy test, the specimen is placed horizontally with unnotched area facing

the pendulum. Moreover, Izod impact specimen only has a V-notch specimen while

Charpy impact specimen has both U-notch and V-notch specimen. Charpy test result can

indicate how brittle the materials are. The most common method for the measurement of

impact strength that is Charpy tests is used in this experiment.

Specimen and Equipments:

1. Pendulum impact tester G.U.N.T.WP400

2. Vernier caliper

3. Impact specimens : mild steel (V and U-notch), carbon steel (V and U-notch)

Procedure:

1) The dimensions of the unnotched length and the thickness of the specimen are measured.

2) The pendulum is raised to the left until it indicates the maximum energy range on the upper

indicator unit.

3) The specimen is placed horizontally across supports with the notch away from the pendulum

4) Pendulum is released.

5) The indicated value from the indicator unit is recorded.

6) The brake is applied until the pendulum has returned to its stable hanging vertical position.

7) The specimen is removed from the testing area and failure surface is observed.

Results:

All the measurements of specimens are recorded in Table 1.

I. Thickness, h [mm]

II. Unnotched length, l [mm]

Specimen Dimension R1(mm) R2(mm) R3(mm) Average(mm)

Mild steel

U-notch

h 5.00 5.02 5.00 5.01

l 5.68 5.66 5.66 5.67

Mild steel

V-notch

h 5.02 5.00 5.00 5.01

l 8.02 8.00 8.00 8.01

Carbon steel

U-notch

h 5.02 5.00 5.00 5.01

l 5.90 5.88 5.90 5.89

Carbon steel

V-notch

h 5.00 5.00 5.00 5.00

l 7.46 7.50 7.48 7.48

Table 1: Measurement of Mild Steel and Carbon Steel

Specimen

Without specimen

Datum with

specimen

(Nm)

Impact value

(Nm)

Datum 1

(Nm)

Datum 2

(Nm)

Datum 3

(Nm)

Average

(Nm)

Mild steel

U-notch

4.90 5.00 5.00 4.97 25.40 20.43

Mild steel

V-notch

5.00 5.00 5.10 5.03 25.50 20.47

Carbon steel

U-notch

5.00 5.10 5.00 5.03 7.90 2.87

Carbon steel

V-notch

5.00 5.00 5.10 5.03 5.70 0.67

Table 2: Data of impact energy for Mild Steel and Carbon Steel

Discussion:

By comparing all the specimens used, it can be conclude that the best specimen that

gives highest impact energy is mild steel (v-notch). Mild steel is tougher than carbon steel as it

has lower carbon composition in it and the v-notch provides better performance against impact

as it gives bigger unnotched cross-section area compared to u-notch mild steel bar. Toughness

is a property, which is capacity of a material to resist fracture, when subjected to impact.

Tougher materials such as mild steel need higher energy or impact to break or fracture. So, this

means that it can absorb more energy applied on it. So, hypothesis that can be made from this

experiment is the more energy absorbed by the specimen, the more toughness the materials

will be. The actual results obtained from the experiment showed that the hypothesis is similar to

the result obtained. It is stated that mild steel is tougher than carbon steel and the result from

the experiment also shows the same as mild steel absorb more energy compared to carbon

steel. This is because mild steel is more ductile than carbon steel and carbon steel is a more

brittle as the composition of carbon is higher in carbon steel.

In this experiment, carbon steel specimens broke completely into two parts with

smoother broken surface while mild steel only undergo plastic deformation and did not

fractured. This is because mild steel is more ductile than carbon steel. Besides that, u-notch

specimen of carbon steel gives smoother surface of fracture compared to the v-notch specimen

while u-notch specimen of mild steel bend more than the v-notch specimen. So, it can be said

that u-notch specimens cannot absorb high energy produce by the pendulum during the impact

as u-notch specimen has smaller unnotched cross-section area. Smaller unnotched cross-

section area can only absorb small amount of energy from the impact. The correlation that could

be made is a higher toughness material will absorb more energy upon impact and will therefore

result in a high height to which the pendulum arm will swing to following impact and gives high

impact value reading. Specimen with lowest absorbed energy means its brittle and has least

toughness which can break easily and cannot withstand the sudden high loads. Specimen with

highest absorbed energy means its ductile and has highest toughness which can withstand the

sudden high loads upon collision.

Factors that can affect the impact energy value obtained could come from two aspects in

this experiment which are error because of the specimens condition and also the equipment

used. The specimen used in this experiment rust a little so it may affect the plastic deformation

or fracture condition result. The pendulum impact tester used in the experiment is old and does

not in it most effective condition where it cannot give precise reading. This condition is proven

right based on Table 2 where the average datum readings give some value of impact. If the

pendulum impact tester is in a good condition, the reading should be zero as there is no

collisions occur.

Charpy test is widely used during construction of pressure vessels and also in

constructions of bridge which is very important to determine which material is the most suitable

against air factor and load on it.

Conclusion:

Impact is a high force or shock applied over a short time period. Such a force or

acceleration can sometimes have a greater effect than a lower force applied over a

proportionally longer time period. At normal speeds, during a collision, an object struck by a

projectile will deform, and this deformation will absorb most, or even all, of the force of the

collision. However, these deformations cannot occur instantaneously. A high velocity collision

(an impact) does not provide sufficient time for these deformations to occur. Thus, the struck

material behaves as if it were more brittle than it is, and the majority of the applied force goes

into fracturing the material. From the Charpy impact test that we have done, carbon steel

undergoes brittle fracture while the mild steel undergoes ductile fracture but because of low

energy supply from the pendulum, the mild steel just undergoes plastic deformation. More

energy is absorbed by mild steel shows that it is more suitable to be use in the structural

construction that expose to high load and high impact collision such as vehicles body.

S-ar putea să vă placă și

- MECE 221 Lab Manual - Torsion of Rods & TubesDocument6 paginiMECE 221 Lab Manual - Torsion of Rods & TubesSam Hitchens Lesenyamotse100% (1)

- Experiment 1-Tensile TestDocument7 paginiExperiment 1-Tensile Testhazriel83% (6)

- Impact Test ReportDocument7 paginiImpact Test Reportgammoora92% (25)

- S3-Deflection in Beam and CantileverDocument97 paginiS3-Deflection in Beam and CantileverBruh100% (1)

- Hardness Test Lab Report PDFDocument9 paginiHardness Test Lab Report PDFKalKatu MaLam76% (42)

- Aircraft Painting & FinishingDocument19 paginiAircraft Painting & Finishingali amr100% (2)

- Hardness TestDocument8 paginiHardness TestSyahirah JuhariÎncă nu există evaluări

- Tensile Test Lab ReportDocument10 paginiTensile Test Lab Reportkingzarip67% (3)

- Charpy Impact Test - Lab ReportDocument18 paginiCharpy Impact Test - Lab ReportChitra Nadia100% (1)

- CVE 230. Lab Report 4 (Torsion Testing) .Document4 paginiCVE 230. Lab Report 4 (Torsion Testing) .Juan Villa100% (1)

- Flexural Test Lab ReportDocument6 paginiFlexural Test Lab Reportaisyah mohamad othman80% (20)

- Charpy Impact Test AssigmDocument13 paginiCharpy Impact Test AssigmFaiz Sufyan0% (1)

- Deflection of Beam Lab ReportDocument23 paginiDeflection of Beam Lab ReportJayle Pengiran Francis69% (16)

- Bending in Beam: Lab ReportDocument30 paginiBending in Beam: Lab ReportLa'ibah KamalÎncă nu există evaluări

- BOQ Electrical L&T IrrumDocument6 paginiBOQ Electrical L&T IrrumRAVEENDRAÎncă nu există evaluări

- Tensile Test Lab ReportDocument9 paginiTensile Test Lab ReportTan Xuennie0% (1)

- Complete Impact Test PDFDocument9 paginiComplete Impact Test PDFKalKatu MaLam86% (22)

- Tensile Test Parameters for MetalsDocument9 paginiTensile Test Parameters for MetalsJasanta Jinor50% (2)

- Tensile Test Lab ReportDocument12 paginiTensile Test Lab ReportXuan Wang100% (1)

- Torsion Test Lab ReportDocument17 paginiTorsion Test Lab Reportlong0% (2)

- TOPIC 5 - Friction On The Inclined Plane 1Document17 paginiTOPIC 5 - Friction On The Inclined Plane 1Muhammad Amir Bin Kunhammad100% (5)

- Anchor Weight CalculationDocument4 paginiAnchor Weight CalculationSuresh DÎncă nu există evaluări

- Hardness Test A4Document9 paginiHardness Test A4aisyah mohamad othmanÎncă nu există evaluări

- Interior FinishesDocument45 paginiInterior FinishesBradley TaylorÎncă nu există evaluări

- Strength of Material Experiment 3 (Torsion Test)Document20 paginiStrength of Material Experiment 3 (Torsion Test)Atikah Mohd57% (7)

- Tensile Report Group7Document21 paginiTensile Report Group7muhd hariz100% (1)

- Rockwell Hardness Testing of Metallic Materials Lab ReportDocument5 paginiRockwell Hardness Testing of Metallic Materials Lab ReportEmıły WınıfredÎncă nu există evaluări

- Material Science Hardness Test Lab ReportDocument4 paginiMaterial Science Hardness Test Lab ReportJeremy Lim Choon Keat67% (21)

- Shear Force Variation Beam Point Load LabDocument16 paginiShear Force Variation Beam Point Load LabAlif Bukhari Imran Naim57% (7)

- Complete Material Science Experiment 3 (The Jominy End-Quench Test)Document14 paginiComplete Material Science Experiment 3 (The Jominy End-Quench Test)izzat razali100% (1)

- Impact Test Lab ReportDocument9 paginiImpact Test Lab ReportRedzuan KamarudinÎncă nu există evaluări

- Impact TestDocument7 paginiImpact Testwaysh100% (4)

- Torsion Test Determines Shear PropertiesDocument15 paginiTorsion Test Determines Shear PropertiesHilman Hazmi33% (3)

- Introduction to Metallographic Analysis of Steel MicrostructureDocument20 paginiIntroduction to Metallographic Analysis of Steel Microstructureshuhada sulaiman86% (7)

- Lab Report - Impact TestingDocument13 paginiLab Report - Impact Testingapi-404653452100% (1)

- Deflection of A Simply Supported BeamDocument15 paginiDeflection of A Simply Supported Beamshuqing heongÎncă nu există evaluări

- Properties of Concrete Fifth Edition A. M. Neville PDFDocument2.866 paginiProperties of Concrete Fifth Edition A. M. Neville PDFlalaÎncă nu există evaluări

- Reaction Beam LabDocument26 paginiReaction Beam LabAzhar Marzuki83% (6)

- Torsion Report PDFDocument31 paginiTorsion Report PDFKalKatu MaLam100% (22)

- 101 Mcqs On Textile ScienceDocument19 pagini101 Mcqs On Textile Sciencesandip kumar mishra100% (1)

- Impact TestDocument5 paginiImpact TestGolden ChanÎncă nu există evaluări

- TOPIC 4 - Principle of Moments Lab ReportDocument19 paginiTOPIC 4 - Principle of Moments Lab ReportMuhammad Amir Bin Kunhammad43% (7)

- Mechanical Properties of SteelDocument27 paginiMechanical Properties of SteelMuhd Farhan Bin Ibrahim100% (1)

- Cordial Adhesive PresenationDocument42 paginiCordial Adhesive Presenationomermeric bilginÎncă nu există evaluări

- Tensile Test Lab ReportDocument11 paginiTensile Test Lab ReportRedzuan Kamarudin56% (9)

- Compression Test Analysis (CTADocument7 paginiCompression Test Analysis (CTASim Hong Yi44% (9)

- Torsion Test (Experiment 2)Document19 paginiTorsion Test (Experiment 2)Nirmal Chandra0% (3)

- Impact Tests: Charpy vs IzodDocument9 paginiImpact Tests: Charpy vs Izodonkod1Încă nu există evaluări

- CEGE Thesis Manuscript Template and InstructionsDocument34 paginiCEGE Thesis Manuscript Template and InstructionsStephanie GonzalesÎncă nu există evaluări

- Buckling Lab ReportDocument16 paginiBuckling Lab ReportYu Wan100% (5)

- Lab Report!!!Document10 paginiLab Report!!!Dharshanaa Babu0% (1)

- Bending Moment in A Beam Lab Report - Green MechanicDocument9 paginiBending Moment in A Beam Lab Report - Green Mechanicmohdiqbal93Încă nu există evaluări

- Buckling of Strut ReportDocument9 paginiBuckling of Strut ReportYamada Takeshi80% (5)

- Charpy TestDocument10 paginiCharpy TestAsad AliÎncă nu există evaluări

- Expt 2 (A) - Impact Test On Metal SpecimenDocument5 paginiExpt 2 (A) - Impact Test On Metal Specimenjyoti swaroop repaka100% (2)

- CE-2108 Lab Manual on Slender Column TestDocument6 paginiCE-2108 Lab Manual on Slender Column TestAsad UzzamanÎncă nu există evaluări

- Test Slender Column Strength & Buckling LoadsDocument6 paginiTest Slender Column Strength & Buckling LoadsAsad UzzamanÎncă nu există evaluări

- ME 457 Experimental Solid Mechanics (Lab) Torsion Test: Solid and Hollow ShaftsDocument5 paginiME 457 Experimental Solid Mechanics (Lab) Torsion Test: Solid and Hollow Shaftsanon-735529100% (2)

- Experiment 7Document13 paginiExperiment 7Malik Ainuddin50% (2)

- Lab ReportDocument21 paginiLab ReportMuhammad YasirÎncă nu există evaluări

- Structure Lab Critical Load On StrutsDocument13 paginiStructure Lab Critical Load On StrutsNurin Adlina67% (3)

- Torsion Test Discussion by ShanDocument4 paginiTorsion Test Discussion by Shanshangovinna_1078109050% (8)

- BENDING LAB 3..latestDocument28 paginiBENDING LAB 3..latestKabuki Mask100% (2)

- Impact Test Ravi Agarwal 09003017 Group GDocument8 paginiImpact Test Ravi Agarwal 09003017 Group GRavi Agarwal100% (1)

- Lab Impact TestDocument11 paginiLab Impact TestAmalinaAznanÎncă nu există evaluări

- Impact Test Measures Material Toughness in 40 CharactersDocument5 paginiImpact Test Measures Material Toughness in 40 CharactersKamal JayarajÎncă nu există evaluări

- Impact-Test-On Metal Specimen Lab-ReportDocument5 paginiImpact-Test-On Metal Specimen Lab-ReportJubaer RabbyÎncă nu există evaluări

- Material Science ExperimentDocument7 paginiMaterial Science ExperimentGan Kwang YongÎncă nu există evaluări

- Objective: Theory/ Literature ReviewDocument16 paginiObjective: Theory/ Literature ReviewsathiashekarÎncă nu există evaluări

- Lab Report Impact Test (Strength Material)Document13 paginiLab Report Impact Test (Strength Material)Redzuan Kamarudin0% (1)

- Chapter 3 - Crop Water NeedsDocument32 paginiChapter 3 - Crop Water Needsaisyah mohamad othman100% (1)

- How To Convert RGB To Grayscale Pic If: The Input Image I Can Be of Class Uint8Document3 paginiHow To Convert RGB To Grayscale Pic If: The Input Image I Can Be of Class Uint8aisyah mohamad othmanÎncă nu există evaluări

- 3308lecture 1 - Introduction Hydraulics and HydrologyDocument42 pagini3308lecture 1 - Introduction Hydraulics and Hydrologyaisyah mohamad othmanÎncă nu există evaluări

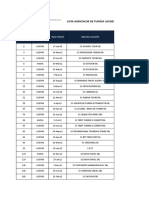

- LISTA AGENTIILOR DE TURISM LICENTIATE Actualizare 14.08.2018Document356 paginiLISTA AGENTIILOR DE TURISM LICENTIATE Actualizare 14.08.2018Năstasă Alexandru-GeorgeÎncă nu există evaluări

- Block Shear Failure of S275 and S690 Steel Angles With Single-LineDocument14 paginiBlock Shear Failure of S275 and S690 Steel Angles With Single-LineMaryam Al-SalmiyahÎncă nu există evaluări

- Opgw: Optical Cables Optical Ground WireDocument3 paginiOpgw: Optical Cables Optical Ground WireMilagros Mercedes Olmos CervantesÎncă nu există evaluări

- Casing Spacer - CompressedDocument12 paginiCasing Spacer - Compressedmoch ardiansyahÎncă nu există evaluări

- Epoxy-Primer Tds Rev2Document2 paginiEpoxy-Primer Tds Rev2antecristorodriguezÎncă nu există evaluări

- Visvesvaraya Technological University: Jnana Sangama, Belgaum, KarnatakaDocument23 paginiVisvesvaraya Technological University: Jnana Sangama, Belgaum, Karnatakayaligarumashankar89Încă nu există evaluări

- DS Granipan R03Document1 paginăDS Granipan R03faridÎncă nu există evaluări

- 2-Types of Road FailuresDocument12 pagini2-Types of Road FailuresthirangaÎncă nu există evaluări

- Structural Materials PDFDocument27 paginiStructural Materials PDFCheng Por Eng100% (1)

- Ultrafine GGBS and Calcium Nitrate As Concrete Admixtu - 2018 - Construction andDocument9 paginiUltrafine GGBS and Calcium Nitrate As Concrete Admixtu - 2018 - Construction andTunLinNaingÎncă nu există evaluări

- Brochure Orevac-T Avril-2012Document6 paginiBrochure Orevac-T Avril-2012Le MinhÎncă nu există evaluări

- Test Certificate JSW CHD W. No. 43 With 28 DayDocument1 paginăTest Certificate JSW CHD W. No. 43 With 28 DayAbhishek SinghÎncă nu există evaluări

- Freudenberg Xpress - Standard MaterialsDocument1 paginăFreudenberg Xpress - Standard MaterialsAndrewFranciscoÎncă nu există evaluări

- Proforma For Concrete MixDocument3 paginiProforma For Concrete Mixmp SinghÎncă nu există evaluări

- PLASTOMEXDocument2 paginiPLASTOMEXAbdullah AldabbabÎncă nu există evaluări

- Sika® Fibermesh®-150: Product Data SheetDocument3 paginiSika® Fibermesh®-150: Product Data SheetVikram ManeÎncă nu există evaluări

- Ultrathin, Flexible and Sandwich-Structured PHBVSilver Nanowire Films For High-Efficiency Electromagnetic Interference ShieldingDocument27 paginiUltrathin, Flexible and Sandwich-Structured PHBVSilver Nanowire Films For High-Efficiency Electromagnetic Interference Shieldingreza mirzakhaniÎncă nu există evaluări

- RO4400 Series Bondply Data Sheet - RO4450F and RO4460G2 BondplyDocument2 paginiRO4400 Series Bondply Data Sheet - RO4450F and RO4460G2 BondplySantiago Martin SondonÎncă nu există evaluări

- Safety Net Product Data Sheet PDFDocument1 paginăSafety Net Product Data Sheet PDFIgit SiswantoÎncă nu există evaluări

- BYK-A 535: Silicone-Free Air Release Additive For Solvent-Borne and Solvent-Free Epoxy and Polyurethane SystemsDocument2 paginiBYK-A 535: Silicone-Free Air Release Additive For Solvent-Borne and Solvent-Free Epoxy and Polyurethane Systemssriatul2006Încă nu există evaluări

- 2013 - Dolomite, Wollastonite and Calcite As Different CaO Sources in Anorthite-Based PorcelainDocument8 pagini2013 - Dolomite, Wollastonite and Calcite As Different CaO Sources in Anorthite-Based PorcelainFURY FURIONÎncă nu există evaluări

- 5-Aircraft Fabric Covering TextDocument2 pagini5-Aircraft Fabric Covering TextJecah Angelu S. SaquianÎncă nu există evaluări