Documente Academic

Documente Profesional

Documente Cultură

Euro Trakker - Repair Manual - Electrical PDF

Încărcat de

FranciscoOliveira93%(40)93% au considerat acest document util (40 voturi)

15K vizualizări290 paginiTitlu original

EURO TRAKKER - REPAIR MANUAL - ELECTRICAL.pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

93%(40)93% au considerat acest document util (40 voturi)

15K vizualizări290 paginiEuro Trakker - Repair Manual - Electrical PDF

Încărcat de

FranciscoOliveiraDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 290

ELECTRIC/ELECTRONICSYSTEM 1 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

SECTION 16

Electric/Electronic system

Page

GENERAL WARNINGSFORELECTRICAL/

ELECTRONICCOMPONENTS 3 . . . . . . . . . . .

COMPONENT CODE 6 . . . . . . . . . . . . . . . . . . . .

MAIN CHANGES 11 . . . . . . . . . . . . . . . . . . . . . . . .

CAN LINES 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CAN LINEASSEMBLY DRAWING 17 . . . . . . . . . .

POWERNETWORK 18 . . . . . . . . . . . . . . . . . . . . . .

GROUNDPOINTS 19 . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL EQUIPOTENTIAL BRAID 20 . . . . . . .

ALTERNATOR 23 . . . . . . . . . . . . . . . . . . . . . . . . . .

STARTERMOTOR 25 . . . . . . . . . . . . . . . . . . . . . . .

JUNCTION CONNECTORS 27 . . . . . . . . . . . . . . .

DIAGNOSISCONNECTOR 77 . . . . . . . . . . . . . . .

BULKHEAD 79 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CENTRAL INTERCONNECTINGUNIT 84 . . . . . .

FUSE 85 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REMOTESWITCHES 87 . . . . . . . . . . . . . . . . . . . . .

FUSEASSEMBLY BODY CONTROLLER(IBC3) 89

SUPPLEMENTARY FUSES(70000) 90 . . . . . . . . . . .

INSTRUMENT BOARD 92 . . . . . . . . . . . . . . . . . . . .

CENTRAL DASHBOARDCONTROLS 93 . . . . . . .

CONTROLSON THESTEERINGWHEEL 94 . . . .

REARVIEW MIRRORSANDWINDOW

REGULATORCONTROL ADJUSTMENT 95 . . .

LEFT LIGHT CONTROL54033 96 . . . . . . . . . . . . .

ENGINEBRAKECONTROLANDINTARDER 99 .

GEARSELECTION FUNCTION 100 . . . . . . . . . . . . .

FUNCTION ENGAGINGEMERGENCY MODE

(LIMP HOME) 102 . . . . . . . . . . . . . . . . . . . . . . . . .

Aquila Trucks Centres

2 ELECTRIC/ELECTRONICSYSTEM TRAKKER EURO 4/5

Base - November 2006 Print 603.93.641

Page

CLUSTER 104 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLUSTER(PIN-OUT) 107 . . . . . . . . . . . . . . . . . . . . . .

BODY CONTROLLER(IBC3) 113 . . . . . . . . . . . . . . . .

BODY CONTROLLER 115 . . . . . . . . . . . . . . . . . . . . . .

- Linkingconnectors 115 . . . . . . . . . . . . . . . . . . . . . .

CHASSISELECTRONICMODULE(M.E.T.) 119 . . . . . .

S.W.I. (STEERINGWHEEL/

STEERVATORINTERFACE) 122 . . . . . . . . . . . . . .

SPIRALEDCONTACT 125 . . . . . . . . . . . . . . . . . . . . . .

STEERINGCOLUMN

(COMPONENT LOCATION) 126 . . . . . . . . . . . .

B.M. (BEDMODULE) 130 . . . . . . . . . . . . . . . . . . . . . . .

E.B.M. (BEDMODULEEASY) 131 . . . . . . . . . . . . . . . . .

TACHOGRAPH 133 . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDC (ECM) SYSTEMS 135 . . . . . . . . . . . . . . . . . . . . . .

SYSTEMCOMPONENTS 139 . . . . . . . . . . . . . . . . . . .

VCM(VEHICLECONTROLMODULE)

ELECTRONICCONTROL UNIT 163 . . . . . . . . . .

IMMOBILIZER 166 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ABS-EBL 168 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMMON COMPONENTS 171 . . . . . . . . . . . . . . . . .

Page

ECASSUSPENSIONS 178 . . . . . . . . . . . . . . . . . . . . . . .

EUROTRONIC AUTOMATIC TRANSMISSION 184 . .

LIMP - HOME 189 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRONICCONTROL UNIT 192 . . . . . . . . . . . . . .

TRANSMISSION ACTUATOR 194 . . . . . . . . . . . . . . . .

CLUTCH ACTUATOR 196 . . . . . . . . . . . . . . . . . . . . .

INTARDER 200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EM(EXPANSION MODULE) ELECTRONIC

CONTROL UNIT (PTO) 206 . . . . . . . . . . . . . . . .

AUTOMATIC AIRCONDITIONER 209 . . . . . . . . . . . .

MANUAL AIRCONDITIONER 224 . . . . . . . . . . . . . . .

HYDRONICD10WATERHEATER 228 . . . . . . . . . . .

SCR(SELECTIVECATALYTIC REDUCTION)

SYSTEM- DENOX 2 235 . . . . . . . . . . . . . . . . . . .

CENTRALLOCKINGWITH REMOTE

CONTROL 238 . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSTIC 240 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CIRCUIT CHARTS 245 . . . . . . . . . . . . . . . . . . . . . . . . .

Aquila Trucks Centres

!

Do not ever disconnect thebatteriesfromthesystemwiththeenginerunning.

Do not start theenginewithout first havingconnectedthebatteriesinapermanent manner.

!

Keystorageproceduresareaffectedbyelectromagnetic disturbancessuchascell phonesandthelike.

Therefore, duringkeymemorization:

1. Ensurethereareno sourcesof disturbanceinthecabor closeto thekeys.

2. Keysnot insertedinthepanel must beat adistanceof at least 1meter.

!

When working on electronic control units, plug connections and electrical connections to the components,

measurementscanbemadeonlyonsuitabletestinglines,bymeansofspecial plugsandplug-typebushes.Donot under

anycircumstancesmakeuseof improper devicessuchasmetal wires, screwdrivers,clipsandthelike.Inadditiontothe

riskofcausingashortcircuit,thismightdamageplug-typeconnectionsandthiswouldthengiverisetocontactproblems.

ELECTRIC/ELECTRONICSYSTEM 3 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

GENERAL WARNINGS FOR ELECTRICAL/ELECTRONIC COMPONENTS

- Beforeworkingonthevehicle, immobilisethewheelswithchocks.

- Donotusefastchargerstostarttheengine.Enginestartingcanbeperformedeitherbymeansofseparatebatteriesorbymeans

of aspecial truck.

- Incorrect polarisationof thepower supplyvoltagefor theelectroniccontrol units(e.g. erroneousbatterypolarisation) may

damagethecomponentsirreversibly.

- If youhavetodisconnect thebatteriesfromthesystem,alwaysdisconnect theframegroundcablefromthenegativeterminal

of thebatteriesfirst.

- Beforeconnectingthebatteriesto thesystem, makesurethat thesystemissuitablyinsulated.

- Disconnect thebatteriesfromthesystembeforerechargingthembymeansof anexternal unit.

- Disconnect theexternal rechargingunit fromthepower mainsbefore removing the units pliers from the battery terminals.

- At temperaturesof over 80 C (drier ovens), take down the ECUs.

- At theconnectionstage, tightentheflangednutsof theconnectors(temperatureandpressuresensors, etc.) to herequired

torque. Checktheexact polarityof thebatteryterminalswhenstartingtheenginebymeansof theauxiliarytruck.

- Before working on the vehicles electrical/electronicsystemdisconnect thepositivepoleof thebattery.

- Beforedisconnectingtheconnector fromanelectroniccontrol unit, isolatethesystem.

- Do not causesparksto checkwhether acircuit islive.

- Do not useatest bulbto checkthecontinuityof acircuit. Onlyusetheappropriatetestingdevices.

- Do not directlypower thecomponentsassociatedwithelectroniccontrol unitswiththenominal power ratingof thevehicle.

- Makesurethatthewiringsofelectronicdevices(length,typeofcable,location,grouping,connectionofscreenbraiding,earthing,

etc.) conformwiththeIVECO systemandthat theyare carefullyrestoredafter repair or maintenancework. To avoidthe

possiblemalfunctioningof theelectronicsystemsonboard, thewiringsof additional devicesmust followadifferent paththan

that of theabove-mentionedsystems.

- Do not connect thenegativeterminalsof additional systemsto thenegativeterminalsof electronicsystems.

- Intheevent of electric weldingonthevehicle, disconnect all theelectroniccontrol unitsand/or disconnect thepower cable

fromthebatterypositiveterminal andconnect it to theframeearth.

- Connectorsareviewedfromthecableside.

Aquila Trucks Centres

Inorder to prevent damageor short-circuitingof theon-boardelectroniccontrol units, thefollowingoperationsmust

bealwayscarriedout beforestartinganyweldingoperationonthechassis.

- If electricweldinghasto bedoneonthevehicle,

isolatetheelectricsystemasfollows:

a) disconnect thepower leadfromthebatterypositiveterminal andconnect it to thechassisearth;

b) disconnect thepower leadfromthebatterynegativeterminal;

c) disconnect theelectroniccontrol unit connectors, takingcaretoavoidtouchingthecontrol unit connector pins.

- Moreover:

a) shouldit benecessaryto carryout weldingoperationscloseto thecontrol unit, removeit fromitslocation.

b) whenever possible, earththeweldingmachinedirectlyto thepiecethat hasto bewelded.

112514

InthecaseofvehiclesequippedwithaDTCOdigital tachograph,donotdisconnectthebatteryleadsandthenconnect

thembyjumpersto reset theelectronic systems.

Thisoperationshouldbeavoided, asit couldcausepermanent damageto theDTCO tachographCARDor other

on-boardelectronic systems.

To reset theelectronic systemwithout runningrisks, disconnect thevehiclebatteryandwait for 10minutes.

It isstrictlyforbiddentocarryout anymodificationsor connectionstotheelectroniccontrol unitwiring;inparticular,

thelineinterconnectingdatabetweenthecontrol units(CAN line) must beconsideredasuntouchable.

Diagnostic and maintenance operations can onlybe carried out by authorised personnel with IVECO approved

equipment.

4 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

Aquila Trucks Centres

ELECTRIC/ELECTRONICSYSTEM 5 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

Practical tips

Thenegativeleadsconnectedto asystemgroundingpoint must beas short as possible and connected to one another in star

configuration; makesurethat theyaretightenedinanorderlyandadequatemanner (Figure1, ref. M).

Furthermore, for electroniccomponents, theinstructionsto befollowedverycarefullyare:

- ECUs must be connected to the system ground if they are provided with a case.

- ECUnegativecablesmust beconnectedbothtoasystemgroundingpoint,suchasfor instancethedashcompartment ground

(with no serial or chain connections) and to the negativeterminal(s) of thebattery/batteries.

- Eventhoughtheyarenot connectedto thesystemground/batterynegativeterminals, analoguegroundelements(sensors)

musthaveexcellentinsulation.Asaresult,specialcaremustbedevotedtotheeddyresistancesofthecableterminals:oxidation,

seam-foldingdefects, etc.

- Themetal braidof shieldedcircuitsmust beinelectrical contact at either endwithsystemcomponents.

- Onlyoneendof theshieldingbraidmust beconnectedto thesystemground.

- In the presence of jointingconnectors, the non-shielded portion, d, must be as short as possible in the proximityof the

connectors(Figure1).

- Thecablesmust bearrangedsoastorunparallel to thereferenceplane,i.e., ascloseaspossibletotheframe/bodystructure.

- Additional electromechanical systemsmustbeconnectedwiththegreatest caretothesystemgroundandmust not beplaced

alongsidethecablesof electroniccomponents.

SHIELDINGBY MEANSOFA METAL BRAIDOFA CABLELEADINGTO AN ELECTRONICCOMPONENT -

C. CONNECTOR- d. DISTANCE! 0.

Figure1

88039

Aquila Trucks Centres

6 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

COMPONENT CODE

03000 Self-rectifyingalternator withbuilt involtageregulator

08000 Starter Motor

12015 Motor for outsideair intakedoor

12023 Windowshademotor

12032 Cabhydraulic releasepumpmotor

20000 Starter battery

22000 Horn

25200 Relayfor starter

25201 Relay, preheating

25202 Relay, G.C.R. energizing

25203 Relay, G.C.R. opening

25204 Relay, remotestartingenablement, cabunlatched

25205 Relay, enginestopping

25206 Relay, richmixturecontrol

25207 Relay, alternator D+earthing

25208 Relay, remotestart enablement, gear engaged

25209 Relayfor cuttingoff variouscomponentsduringstartingstage

25210 Relay, startingenablement withtransmissioninneutral

25211 Relaywithdelayedopeningcontact for keepingG.C.R energized

25212 Relaywithdelayedclosingcontact for keepingRTE energized

25213 Relayfor supplyof usersconnectedto ignitionswitch throughbatterypositive

25222 Relayfor allowingconnectionof thermal starter

25310 Relayfor allowingconnectionof internal heatingwithpower loadinhibitingrelay

25322 Relayfor connectionof auxiliaryheater (1st speed)

25327 Relayfor connectionof air-conditioningsystem

25332 Relayfor connectionof air-conditioningsystem

25544 Topflapenginepolarityreversecontactor for LD

25545 Topflapopen/closecomandcontactor for LD

25722 Cabhydraulic releasepumpswitch(lowering)

25723 Cabhydraulic releasepumpswitch(raising)

25866 Relayfor terminal 58

25874 Relayfor connectionof power loadswithenginerunning

25897 Relayfor connectionof sidetransmissionpower takeoff

25898 Relayfor connectionof rear transmissionpower takeoff

25900 General current relay

25924 EDC connecting relay Main Relay

30001 Dippedandmainbeamheadlampwithsidelight

30011 Foglight

32002 Front directionindicator

33001 Sidedirectionindicator

34000 Multifunctional rear light

34011 Trailer light

35000 Number platelight

37000 Front/rear dimensionslight

37001 Front dimensionslight

39003 Courtesylight for steps

39009 Courtesylight for readinglights

39017 Courtesylight for adjustablecabininterior light

39030 Cabsideopeninglightinglamp

39034 Whiteandredinternal light unit

40011 ElectronicTachograph

Aquila Trucks Centres

ELECTRIC/ELECTRONICSYSTEM 7 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

40032 Sender unit for tachometer andtachograph

40046 Inductivetypechassisheight sensor (rear axle)

40047 Inductivetypechassisheight sensor (front axle)

42030 Sender unit for engineoil pressuregauge

42045 Sender unit for outdoor temperaturegauge

42102 Switchsignallinghandbrakeapplied

42108 Switchfor trailer retarder signal

42111 Switchsignallingtrailer brakingsystemfailure

42116 Switchfor lowair pressureindicator inEBSsystem

42200 Switchsignallingpneumatic suspensionsystemfailure

42351 Switchsignallingair filter blocked

42374 EDC clutchswitch

42381/A DriveaxleRH pressuresensor (ECAS)

42382/a Lift axleRH pressuresensor (ECAS)

42389 Air pressuresensor onthirdaxlepneumaticliftingsystem

42551 Switchsignallingoil filter blocked

42608 Coolant pressuresignalling3-switchassembly

42700 Fuel filter cloggedindicator switch

44031 Fuel level gaugesender unit withreserver warninglight contact

44035 Insufficient windscreenwasher fluidlevel gaugecontrol

44036 Insufficient radiator coolant level gaugecontrol

44037 Insufficient power assistedsteeringfluidlevel gaugecontrol

44043 Engineoil level gaugesender unit

47032 Sender unit for engineoil temperaturethermometer

47041 Water temperaturesender for retarder control unit

47042 Fuel temperaturesensor

47043 Enginefantemperaturesensor

48035 Enginerpmsensor

48042 Enginerpmsensor (ontiminggear)

48043 Turbocharger speedsensor

50005 Multiplexinstrumentsunit module

52005 Switchwithbuilt inw/l for heatedrear viewmirrors

52009 Switchwithbuilt inw/l for trailer light

52024 Switchwithbuilt inw/l for additional headlamps

52056 Switchwithbuilt-inw/lampfor ASRcutout

52059 Automatic transmissionspeedselector

52070 Switchfor engagingsidepower takeoff

52071 Switchfor engagingrear power takeoff

52090 Suspensionlevellingswitch(ECAS)

52092 Switchfor engineor cabheater

52093 Switchfor tail hatchlockingsafety

52093 Switchfor tail hatchlockingsafety

52094 Switchfor spot light

52200 Switchfor electric or pneumatichorns

52302 Switchwithbuilt inw/l for hazardwarninglights

52304 Switchfor foglightsandrear foglightsinhibitor

52307 Switchfor exterior lights

52312 Switchcontrollingheadlampalignment adjustment

52324 Enginebrakeconnectingswitch

52326 Whiteandredinternal lightsswitch

52502 Ignitionswitchfor serviceswithstarting

53006 Switchfor startingfromenginecompartment

53007 Switchfor stoppingenginefromenginecompartment

Aquila Trucks Centres

8 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

53030 Switchfor controllingstartingassistance

53061 Cabhydraulicreleaseconsensusswitch

53062 Cabhydraulic releasepumpswitch(lowering)

53063 Cabhydraulic releasepumpswitch(raising)

53300 Switch for drivers side electric window

53302 Switchfor passenger sideelectricwindow

53053 Test pushbuttoncoupling, automatic transmission

53054 Limit switchbuttononsidedoors

53055 Unstableswitchfor interior lights

53306 Switchcontrollingsunroof motor

53309 Switchfor 3rdaxleraisingsystem

53311 Switchfor controllingwindowblind

53315 Switchwithbuilt intelltaleto turnonfoglights

53316 Current general contactor switch

53501 Switchsignallingvehiclestopped

53503 Switchsignallingreversinglights

53507 Switchsignallingreducedgearsengaged

53508 Switchfor antistartingwithreducedgears

53509 Switchfor switchingoninterior lights

53510 Switchfor switchingonsteplights

53511 Switchsignallingcabinunlatched

53512 Switchfor antistartingenginedevicewithhandbrakeoff

53521 Switchfor signallinglongitudinal differential lock

53547 Switchfor secondarysignal frombrakepedal to EDC control unit

53567 Switchfor signallingsidepower takeoff engaged

53568 Switchfor signallingrear power takeoff engaged

53591 Switchfor signallingfailureof thehydrauliccircuit withauxiliarysteeringthirdaxle

53593 Switchto light cabsideopeninglamp

53593 Tool compartment light switch

53602 Switchindicatingincompletesunshadeclosing

53801 SwitchsignallingRockwell axledifferential lockengaged

53802 SwitchsignallingRockwell axledifferential lockengaged(3rdaxle)

54030 4functionsteeringcolumnswitchunit

54033 6functionsteeringcolumnswitchunit

61011 3A 1-diodeholder container

61104 Air brakingsystemdrier resistor

61121 Resistancefor enginepreheating

61126 Terminationresistor for CAN bus

64000 Electric windscreenwasher pump

68000 Radio equipment

68001 Speaker

68003 Preamplifier

68005 Feeder 24V 12V

68007 CityBand(C.B.)

70000 6fusecarrier

70058 1-way20A fusecarrier

70601 6-fuseholder

70602 6-fuseholder

70603 6-fuseholder

70604 6-fuseholder

70605 6-fuseholder

72006 Couplingwith7polesfor electrical connectionof trailer ABS

72010 15-polecouplingfor electrical connectionto trailer

72021 30-poleconnector for theelectrical connectionto thediagnosticequipment locatedoutsidethevehicle

72025 2-pole12Vconnectionfor general power supply

Aquila Trucks Centres

ELECTRIC/ELECTRONICSYSTEM 9 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

72026 2-pole12Vconnectionfor telephone

78016 Enginefansolenoidvalve

78050 Enginebrakesolenoidvalve

78052 ABS/EBSsolenoidvalve

78053 ASRsolenoidvalve

78054 Solenoidvalvefor engagingretarder

78055 Solenoidvalvefor retarder oil accumulator

78057 EBSfront axleair pressurecontrol proportional valve

78058 EBStrailer air pressurecontrol proportional valve

78059 Duplexvalvefor EBS

78060 Solenoidvalveto excludethird-axlebrakingwithASR

78061 Redundant solenoidvalvefor rear-axlebrakingintheevent of EBScontrol unit failure

78203 Solenoidvalvefor pneumatic horns

78227 Solenoidvalvefor radiator water recirculation

78238 Rear axlesolenoidvalveassemblyfor chassisalignment

78239 Front axlesolenoidvalveassemblyfor chassisalignment

78243 Rear axleelectropneumatic distributor

78247 Solenoidvalvefor electronic injection

78248 Solenoidvalvefor variablegeometryturbineorder

72049 3-polecouplingfor rear-viewmirror motor

72050 Unipolar current outlet

78251 Solenoidvalvefor engagingtransmissionsidepower takeoff

78252 Solenoidvalvefor engagingtransmissionrear power takeoff

80000 Motor for right electricwindow

80001 Motor for left electricwindow

82000 Windscreendefrostingcontrol unit

82005 Auxiliaryair heater

82010 Air-conditioningsystemelectroniccontrol unit

84000 Water boiler

84009 Internal temperaturesensor

84010 Meteringdevice

84019 Electromagneticpulley

85000 Cigar lighter

85001 Cigar lighter outlet

85003 Heatedrearviewmirror (trailer)

85004 Heatedrearviewmirrot (wheel)

85005 Heatedrearviewmirror

85006 Electricallyadjustableheatedrear viewmirror

85007 Wheel electricallyadjustableheatedrear viewmirror

85008 Trailer electricallyadjustableheatedrear viewmirror

85010 Rear viewmirror control

85023 Electric latch

85065 Remotecontrol for aligningsuspensionsandraising3rdaxle

85150 EDC MS6control unit

85152 Accelerator loadsensor (EDC)

85153 Coolant temperaturesensor (EDC)

85154 Turbofanair temperaturesensor (EDC)

85155 Turbofanair temperaturesensor (EDC)

85158 Turbofanair temperaturesensor (EDC)

85159 Temperatureandambient air pessuresensor for E.D.C.

86002 Sensorsfor front brakeshoewear

86003 Sensorsfor rear brakeshoewear

86004 Automatic transmissionelectroniccontrol unit

86013 Sensor for signallingwater infuel filter

86015 Retarder electroniccontrol unit

86023 Vehicleraising/loweringcontrol unit Ecas

86030 Sensor detectingheat irradiation

Aquila Trucks Centres

10 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

86053 Multiplexcontrol andsignal unit frombedpositions

86116 Multiplexbodycomputer control unit

86117 Multiplexfront framecomputer control unit

86118 Multiplexrear framecomputer control unit

86119 MultiplexDriver Door ModuleControl Unit

86120 MultiplexPassenger Door ModuleControl Unit

86123 Multiplexcontrol unit for interfacewithsteeringcontrol shaft

86124 Cabwithmultiplexfunctionelectronic control unit

86125 Electroniccontrol unit for VDI (VehicleDatainterface)

86126 Electroniccontrol unit for EM(Expansionmodule)

86127 Electroniccontrol unit for DMI (DataManagement Interface)

86128 Electroniccontrol unit for M.E.T. chassis(chassiselectronicmodule)

86129 Electroniccontrol unit for MC-NET (MobileCommunicationNetwork)

86130 Electroniccontrol unit for navigator

86131 Electroniccontrol unit for telematic

86132 VCMcontrol unit (VehicleControl Module)

88000 ABSsystemelectronic control unit

88001 ABSsystemsensor

88005 Electroniccontrol unit for EBSsystem

88006 EBSrear axleair pressurecontrol modulator

88007 Potentiometric sensor for front wheel shoepositionindicator

88008 Potentiometric sensor for rear wheel shoepositionindicator

88010 Rear axlebrakeapplicationpressuresensor

88011 Potentiometric sensor for thirdaxleskidwear signalling

88012 SASsensor (=SteeringAngleSensor) for EBS

88013 ESCmodule(=ElectronicStabilityControl) for EBS

89000 Fridge

89010 Foodwarmer

Aquila Trucks Centres

ELECTRIC/ELECTRONIC SYSTEM 11 TRAKKER EURO 4/5

Print 603.93.641 Base - November 2006

MAIN CHANGES

For vehicleswithEuro 4enginetheelectric/electronic systemissubject to important variations.

Inorder to handletheincreasedcomplexityof Euro 4operationsdemandedto theenginecontrol systemextrahardwareand

softwareresources, the VCM(VehicleComputer Module) hasbeenaddedso that vehiclefunctionscanbereallocatedonit,

whichupto Euro3hadbeencarriedout bytheEDCenginecontrol unit,thereforemoredevelopment flexibilityisavailablefor

vehiclefunctions. Theimmobilizer functionhasbeenalso integratedonthisunit.

The New BodyController (IBC3) unlike the BodyComputer (BC) distributes direct positives and key-locked, protected by

external fuses(replaceable) orinternal (resettable).InthechassisthereistheMETcontrol unit (chassiselectronicmodule) which

controlsthechassispower devices, thusreplacingtheFFC andRFC control units.

For theautomatedtransmissiononthenewEuro 4vehiclerangethegear selector hasbeenremoved. Itsfunctionsarecarried

out fromthecontrol pushbuttonslocatedonthedashboardcenter panel combinedwiththepower steeringlever.

The EMcontrol unit (ExpansionModule) replacestheDMI (DataManagement Interface). It controlsthepower takeoffsand

makes it possible to implement complex applications and connections to different devices through the CAN-open line. It

communicateswiththeother control unitsthroughtheCAN DVBline.

TheSCR(SelectiveCatalyticReduction) - Denox2isontheentireAverage/HeavyEuro4RangewiththeUreaDosingSystem

(UDS) positionedonthelower sideof theframe.

TheENGINEECM(EngineControl Module) replacesEDC MS6.2.

ThenewCluster ismonochromewithmorefunctionscomparedto thepreviousone.

Theintroductionof thenewunitsandthechangeof thepreviousonesrequirechangesof thevehiclesystemstructure.

ThefollowingCAN linesareontheVCMunit:

- VDB- VehicleDataBus

- ECB- EngineControl Bus

- FMB- FuhrparkManagement Bus

Figure2

112584

UDS

VCM

ECM

EM

IBC3

CLUSTER

MET

Aquila Trucks Centres

12 ELECTRIC/ELECTRONIC SYSTEM TRAKKER EURO 4/5

Base- November 2006 Print 603.93.641

CAN LINES

DialoguebetweentheEasyMuxsystem, vehiclesystems, engine control unit, SCRsystem, radio andvarioussettersiscarried

out bymeansof theCAN lines:

- BCB- BodyControl Bus

- VDB- VehicleDataBus

- ECB- EngineControl Bus

- IDB- Infotainment DataBus

- FMB- FuhrparkManagement Bus

BCB (Body Control Bus) communication line

It enablesthecommunicationbetweentheIBC3andMET control unitsof theEasyMuxsystemandtheother control unitsof

thedifferent servicesonboard.

Technical features

- Datatransmissionspeed 62.500(BIT/SEC)

- Color of thewire Grey

List of Units

Ref. Description

IBC3

DDM

PDM

BM

MET

AHT-A

AHT-W

BodyController

Driver Door Modulecontrol unit

Passenger Door Modulecontrol unit

BedModule

MET chassiscontrol unit

Air heater

Water heater

Figure3

112585

IBC3

BM DDM

PDM AHT_A

BCB

MET

AHT_W

Aquila Trucks Centres

ELECTRIC/ELECTRONIC SYSTEM 13 TRAKKER EURO 4/5

Print 603.93.641 Base - November 2006

VDB (Vehicle Data Bus) Communication Line

Allowstheelectronicsystemsonthevehicletodialogue.Theunitsconnectedto it are:EurotronicTransmission,Retarder,ABS,

Ecas, Diagnosisconnector, VCM, Tachograph, ACC, SWI, EM, (Mc Net).

Thislinealso dialogueswiththeCluster andtheBodyComputer.

Features

- Datatransmissionspeed 250.000(BIT/SEC)

- Color of thewire Black

List of Units

Ref. Description

MTCO

DTCO

VCM

IC

IBC3

SWI

Diagnostic Connector

ABS

McNet

RETARDER

ECASII

EUROTRONIC II

ALLISON TCM

ACC

Tachograph

Digital tachograph

VehicleControl Modulecontrol unit

Cluster

BodyController

SteeringWheel Interfacecontrol unit

30-polediagnosisconnector

ABScontrol unit

Electronic control unit for MobileCommunicationNetwork

Intarder control unit

Air suspensioncontrl unit

Eurotronic II automatic gearboxcontrol unit

Allisonautomatic gearboxcontrol unit

Radar ACC (AdaptiveCruiseControl) control unit

Figure4

112597

SWI

MTCO/DTCO

RETARDER ABS

Diagnostic

Connector

ECAS II

VDB

IBC3

VCM

EM MCNet

ETC

ALLISON TCM/

EUROTRONIC II

IC ACC

Aquila Trucks Centres

14 ELECTRIC/ELECTRONIC SYSTEM TRAKKER EURO 4/5

Base- November 2006 Print 603.93.641

ECB (Engine Control Bus) communication line

Allowstheunitsandtheenginecontrol sensorsto dialoguetogether. Theunitsconnectedto it are::EDC, VCM, DCU15and

theOBDconnector.

Features

- Datatransmissionspeed 250.000(BIT/SEC)

- Color of thewire Yellow

List of Units

Ref. Description

VCM

EDC7

DCU15

OBD II Connector

VehicleControl ModuleUnit

Enginecontrol unit

SCRpumpingmoduleunit

16poleconnector for OBD (onborddiagnose)

VCM

ECB

EDC7

OBDII

Connector

DCU15

Figure5

112280

Aquila Trucks Centres

ELECTRIC/ELECTRONIC SYSTEM 15 TRAKKER EURO 4/5

Print 603.93.641 Base - November 2006

I.D.B. (Infotainment Data Bus) communication line

AllowscommunicationbetweentheCluster andtheRadio. Themessagessent areshownontheCLUSTER.

Technical features

- Datatransmissionspeed 100.000(BIT/SEC)

- Color of thewire Blue

List of Units

Ref. Description

Radio

McNet

Radio

Electronic control unit for MobileCommunicationNetwork

Figure6

IDB McNet

RADIO

112586

Aquila Trucks Centres

16 ELECTRIC/ELECTRONIC SYSTEM TRAKKER EURO 4/5

Base- November 2006 Print 603.93.641

F.M.B. (Fuhrpark Managemant Bus) communication line

Allowscommunicationbetweenthedifferent electronicsystems(accessories) onthevehicle,, FMS(Telephone) connector and

VCMunit.

Technical features

- Datatransmissionspeed 250.000(BIT/SEC)

- Color of thewire White

List of Units

Ref. Description

VCM

FMS

VehicleControl ModuleUnit

Connector FMS

FMB

FMS

Connector

VCM

Figure7

112283

Aquila Trucks Centres

ELECTRIC/ELECTRONIC SYSTEM 17 TRAKKER EURO 4/5

Print 603.93.641 Base - November 2006

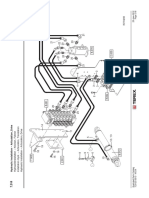

CAN LINE ASSEMBLY DRAWING

Figure8

112587

Aquila Trucks Centres

GROUND POINT OFBATTERIESON LEFT

SIDEMEMBER

STARTERMOTORANDENGINEGROUNDPOINT

6633

6632

M1

M2

Figure9

Figure10

!

Neverdisconnectthebatteriesfromthesystemwith

theenginerunning.

Beforeconnectingthebatteriestothesystem,make

surethat thesystemiswell insulated.

Disconnect the batteries from the system when

chargingthem.

18 ELECTRIC/ELECTRONIC SYSTEM TRAKKER EURO 4/5

Base- November 2006 Print 603.93.641

POWER NETWORK

The purpose of the electric systemisto generate, regulate,

storeanddistributethe energyneededto makethevehicle

componentswork.

For this reason the supply of the base electric systemis

ensuredbyagenerator(28V- 60A -90A alternator) andtwo

batteries,eachwith12V170Ah(opt 220Ah) connectedin

series.

Amobilefuseholdercontaininga20Ampfuseislocatedclose

to thebatteries. Thisfusesupplies:

- Fuseholder 70605/1

- BodyController (A07)

- Refrigerator

- ACC presetting

Thisfuseisnot present ontheADRversion.

Power cable section:

- batterydirect cable = 16mm

2

- fusecables = 4mm

2

Attain to what detected on the vehicle for the remaining

sections.

Negative network

The batteries are connected to the frame ground with a

brown 70 mm

2

cable, at ground point M1 on the left

sidemember (Figure9).

The starter motor is connected to the frame ground(M2)

througha70mm

2

cable, fastenedontheright sidemember

near theactual motor.

Thesamecableservesfor connectingthewholeengineunit

to theframeground.

Aquila Trucks Centres

ELECTRIC/ELECTRONICSYSTEM 19 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

GROUND POINTS

91664

M1. Batteryground- M2. Starter motor ground- M3. Upper cabground- M4. Right inner cabground-

M5. Left inner cabground- M6. Front right frameground- M7. Engineground- T1- T2. Equipotential braid

Figure11

Aquila Trucks Centres

20 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ELECTRICAL EQUIPOTENTIAL BRAID

Thoughgenerallyprotectedagainst theinfluenceof on-boardequipment voltage,electroniccomponentsneverthelessremainpar-

ticularlysensitiveelectromagnetic compatibilityissues, of different naturesuchas:

- generatedbythevehicles

- external.

A suitablesizeflexibleelectrolyticcopper braidhasbeenprovidedonthevehiclestominimizethesephenomenaandreturnmain

cabandframestructuresto theequipotential state.

Checkthat thebraidisproperlyattachedto theframeandthecab, intheevent of defectivecabgrounding.

74201

T1

T2

Figure12

Aquila Trucks Centres

ELECTRIC/ELECTRONICSYSTEM 21 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

49846

GROUNDPOINT ON THELEFT FRONT FRAME

49844

GROUNDPOINT ON THERIGHT FRONT FRAME

M6

T2

Figure13

Figure14

Aquila Trucks Centres

22 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

49849

GROUNDPOINT BEHINDTHEBODY COMPUTER

73754

GROUNDPOINT BEHINDTHECLUSTER

M4

M5

Figure15

Figure16

Aquila Trucks Centres

7998

8000

8002

8003

ALTERNATORCURRENT DELIVERY CURVE

Characteristics

WIRINGDIAGRAM

A. Alternator B. Voltageregulator

Ratedvoltage 28V

Ratedpower 90A

Current at environment temperature1800RPM/40A

At 25C andratedvoltage 6000RPM/90A

Directionof rotation clockwise, seenfrompulley

Weight 7.8kg

S

03000

L(D+)

IG(15)

B+

TECHNICAL VIEW

B

A

VOLTAGEREGULATORTEMPERATURE

CHARACTERISTICS(6000RPM)

Figure17

Figure18

Figure19

Figure20

ELECTRIC/ELECTRONICSYSTEM 23 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

28V - 40A 90 A BOSCHALTERNATOR

Aquila Trucks Centres

24 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

Ref. Function

Cablecolour

code

L To F.F.C. center clampJ2/B24 7009

15(IG) To remoteswitch25213clamp87(viafuseF6-70601) 8876

S Positive(+30) 7777

B+ ClampSalternator Positive+30power positive 7777

+30positiveto starter motor 7777

Positive+30 7777

8535

PERSPECTIVEVIEW WITH CORRESPONDINGELECTRICAL CONNECTIONS

B

A

A

B+

Figure21

Aquila Trucks Centres

Ratedpower

Systemvoltage

Engagement system

Adjustedtime

Directionof rotation

Weight

Operatingvoltage

Water resistance

CHARACTERISTIC CURVES

4958

Characteristics Characteristics Test cond.

Specific Power

(20 C)

TECHNICAL VIEW

WIRINGDIAGRAM

4956

4957

5.5kW

24V

Positiveapproachcontrol

30sec.

clockwise, seenfromend

of pinion

approx. 10.5kg

16VMAX. (20 C)

Water spraytest to JIS

D0203 SI

Loadless 23V 120A MAX (3800rpmMIN.)

Load 16V (49N-m) 690A MAX. (900rpmMIN.)

Stall 6V 1260A MAX. (73.5N-mMIN.)

08000

Figure22

Figure23 Figure24

ELECTRIC/ELECTRONICSYSTEM 25 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

24V - 5.5 KW NIPPONDENSO STARTER MOTOR

Aquila Trucks Centres

6658

PERSPECTIVEVIEW WITH ASSOCIATED ELECTRICAL CONNECTIONS

+30

Figure25

26 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

Connector Function

Cablecolour

code

+30 +30positivefor starter motor power frombatterypositiveclamp(viatheT.G.C.) 7777

+30 +30positiveto thealternator 7777

+30 +30positiveto remoteswitchfor enginepreheat onconsent 7777

+50 +50positivefor keyswitch 8888

Aquila Trucks Centres

ST06A

ST06B

ST07D

ST08A

ST08B

ST31

ST31L

ST37

ST79A

ST79B

ST79D

STY1

ST02

ST12

ST21

ST30

ST11

ST35/1

ST35/2

ST39

ST44

ST56

ST63

ST05

ST07B

ST07C

ST09A

ST10

ST13

ST20

ST31B

ST31C

ST31R

ST34

ST36

ST07A

ST19

ST09B

ST14A

ST14B

ST24

ST25

ST26A

ST31A

ST42

ST14

ST26B

ST14C

ST48

ST03

ST23

ST01

ST

ST28

ST15

ST40

ST45

ST06C

Figure26

113406

ELECTRIC/ELECTRONICSYSTEM 27 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

JUNCTION CONNECTORS

Location of the junction connectors - cab

Thelocationof theconnectors(cab- chassis) couldchangeto suit wiringneeds.

Aquila Trucks Centres

Figure27

113407

ST72

ST54

ST65

ST64

ST70

ST73/1

ST87

ST91

ST92

ST93

ST82

ST55A

ST55B

ST67

ST68

ST81A

ST80

ST69

ST83

ST73/2

ST73/3

ST73/4

ST86

ST75A

ST75B

28 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

Location of the junction connectors - chassis

Aquila Trucks Centres

ELECTRIC/ELECTRONICSYSTEM 29 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

List of connectors

Name Description

ST 01 Connectionfor startingcommutator

ST 02 Connectionfor steeringcolumn

ST 03 Connectionfor speedlimiter / Cruisecontrol set

ST 05 Connectionfor Eurotronic

ST 06A Connectionfor roof panel wingsdevicesonthedriver side

ST 06B Connectionfor tachograph

ST 06C Connectionfor Toll Collect

ST 07A Connectionfor roof panel wingsdevicesonthepassenger side

ST 07B Connectionfor navigationandfor IT tools

ST 07C Connectionfor heatablewindscreen

ST 07D Connectionfor rotatingheadlights

ST 08A Connectionfor DDMcontrol unit

ST 08B Connectionfor driver sidedoor

ST 09A Connectionfor PDMcontrol unit

ST 09B Connectionfor passenger sidedoor

ST 10 Connectionfor toolslighting

ST 11 Connectionfor trailer retarder brake

ST 12 Connectionfor ABS/EBStractor andtrailer electrical connection

ST 13 Connectionfor auxiliaryair heater CAN line

ST 14 Connectionfor Ecasbodybuilders(cab)

ST 14A Connectionfor bodybuilders(cab)

ST 14B Connectionfor bodybuilders(cab)

ST 14C Connectionfor set updevices(Allison)

ST 15 Connectionfor couplingsinthehighroof

ST 19 Connectionfor heater

ST 20 Connectionfor air- conditioner

ST 21 Connectionfor radiator water recirculationsolenoidvalve

ST 23 Connectionfor Immobilizer antenna

ST 24 Connectionfor air conditioningsystemcontrol unit CAN line

ST 25 Connectionfor Intarder

ST 26A Connectionfor Ecas

ST 26B Connectionfor ABS/EBS

ST 28 Connectionfor rotatingheadlights

ST 30 Connectionfor ADR(tachograph) provision

ST 31 Connectionfor ECASremotecontrol

ST 31A Connectionfor cabrear

ST 31B Connectionfor auxiliaryair heating

ST 31C Connectionfor auxiliaryair heatingtemperaturesensor

ST 31L Connectionfor pneumatic heatedseat

ST 31R Connectionfor pneumatic heatedseat

ST 34 Connection for ACC provision / simple H gearbox control

ST 35/1 Connectionfor air conditioner withmanual control

ST 35/2 Connectionfor air conditioningwithmanual control

ST 36 Connectionfor T.G.C. / I.G.C.

ST 37 Connectionfor Toll Collect

ST 39 Connectionfor differential lock

ST 40 Connectionfor navigationandfor IT tools

ST 42 Connectionfor DDM/PDMsupplies

Aquila Trucks Centres

30 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

Name Description

ST 44 Connectionfor centralizedclosingwithremotecontrol

ST 45 Connectionfor 24Vradio

ST 48 Connectionfor DMI / EMcontrol unit for PTO

ST 49 Connectionfor Allisonsetup

ST 54 Connectionfor ACC provision

ST 55A Connectionfor SCRsystem(Urea)

ST 55B Connectionfor SCRsystem(Urea)

ST 56 Connectionfor ADR(15) Alternator

ST 59 Connectionfor ECASbreakdownswitch/longitudinal blockageof 2

nd

front axle(8x8)

ST 63 Connectionfor auxiliarywater heater CAN line(BCB)

ST 64 Connectionfor 15-polescurrent output freepins

ST 65 CAN lineconnectionfor trailer (PTO withEM)

ST 67 Connectionfor ureadosingmodulesolenoidvalve

ST 68 Connectionfor Ureatemperaturesensor

ST 69 Connectionfor Intarder

ST 70 Connectionfor ASRsolenoidvalve

ST 72 Connectionfor 35axlesfor shoeswear andtear / transversedifferential blocking

ST 73/1 Connectionfor indicating1st front axlewear (right)

ST 73/2 Connectionfor indicating1st front axlewear (left)

ST 73/3 Connectionfor indicating2ndfront axlewear (right)

ST 73/4 Connectionfor indicating2ndfront axlewear (left)

ST 77 Connectionfor right handsideSMLindicator lamp(SideMarker Lamp)

ST 78 Connectionfor left handsideSMLindicator lamp(SideMarker Lamp)

ST 79A Connectionfor external cabfront

ST 79B Connectionfor windshieldwasher andwarninghornunit

ST 79D Connectionfor brakepedal switch(ABS)

ST 80 Connectionfor mechanic gearbox

ST 81A Connectionfor front lights

ST 82 Connectionfor componentsontheengine

ST 83 Connectionfor componentsonengine

ST 85L Connectionfor left handsideplatelight

ST 85R Connectionfor right handsideplatelight

ST 86 Connectionfor T.G.C. / I.G.C.

ST 88 Connectionfor trailer connectors

ST 91 Connectionfor PTO1(DMI)

ST 92 Connectionfor PTO2(DMI)

ST 93 Connectionfor PTO3(DMI)

ST 99 Connectionfor rear axleECAS

ST Connectionfor ECAS

STY/1 Connectionfor switchonclutch

Aquila Trucks Centres

107169

Figure28

KEY SIDECONNECTORVIEW

1 2 3 1 2 3

Figure29

KEY SIDECONNECTORVIEW

107538

ELECTRIC/ELECTRONICSYSTEM 31 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

Junction connector ST01(black) - turn on key

Pin Function

Cablecolour

code

1 Positive+30for ignitionkey 7777

2 Terminal 15ignitionkey 8887

3 Terminal 50ignitionkey 8888

ST02(green) - connection for steeringcolumn

Pin Function

Cablecolour

code

1 CAN Lline(ICB) Green

2 CAN Hline(ICB) White

3 Ground 0000

4 Negativefor warninghorn 1116

5 Positive+15fromignitionkey(15) 8887

6 Positivefor steeringcolumnswitchunit symbolslighting 4442

7 Positive(+30) 7906

8 Positivefromignitionkey(50) 8888

9 Speedlimiter signal 9968

10 Ground 0000

11 - -

12 - -

Aquila Trucks Centres

Figure30

101525

KEY SIDECONNECTORVIEW

32 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST03junction connector - speed limiter signal / Cruise Control Set

Pin Function

Cablecolour

code

1 Speedlimiter signal 9968

2 - -

Aquila Trucks Centres

107545

Figure31

KEY SIDECONNECTORVIEW

107538

Figure32

KEY SIDECONNECTORVIEW

ELECTRIC/ELECTRONICSYSTEM 33 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

ST05junction connector (green) - Eurotronic II

Pin Function

Cablecolour

code

1 CAN VDBLine(L) Green

2 CAN VDBLine(H) White

3 CAN VDBLine(L) Green

4 CAN VDBLine(H) White

5 Klineautomaticgearbox 2297

6 Automatic gearboxsystempower supply(Positive+15) 8102

7 Positivesymbolslighting 4442

8 Negativesignal forwardgear withautomatic gearbox 0127

9 VCMcontrol unit pin- X3/24 0125

10 Negativesignal fromneutral positionof theautomatic gearbox 0147

11 Negativesignal reversegear withautomaticgearbox 0128

12 VCMcontrol unit pin- X3/41 0126

13 Automatic gearboxsystempower supply(Positive+30) 7101

14 Ground 0000

15 Speedlimiter signal 9968

ST06A junction connector (yellow) - roof panel wings devices on the driver side

Pin Function

Cablecolour

code

1 Positiveleft loudspeaker (preamplifier) 1188

2 Negativeleft loudspeaker (preamplifier) 1186

3 Slidingroof closingcontrol power supply 7011

4 Slidingroof openingcontrol power supply 7010

5 Positivefor warninghornsolenoidvalve 1133

6 CAN line(IDB) H White

7 CAN line(IDB) L Green

8 Positivesymbolslighting 4442

9 Positive+15 8871

10 - -

11 - -

12 - -

Aquila Trucks Centres

107545

Figure33

KEY SIDECONNECTORVIEW

Figure34

KEY SIDECONNECTORVIEW

107538

34 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST06B junction connector (yellow) - tachograph

Pin Function

Cablecolour

code

1 Isolatednegativetachographtransmitter 0058

2 Speedsignal tachographtransmitter 5517

3 Invertedsignal tachographtransmitter 5516

4 Tachographtransmitter power supply 5514

5 Speedpulsefor EDC 5155

6 CAN VDBLine(H) White

7 CAN VDBLine(L) Green

8 - -

9 Ground 0000

10 Tachographpower supply(Positive+15) 8871

11 Positivesymbolslighting 4442

12 Tachographpower supply(batterypositive+Batt) after fuse70058 7768

13 Kline 2997

14 Tachographsignal distance- travelledfor Cluster 5518

15 - -

ST06C junction connector (yellow) - Toll Collect

Pin Function

Cablecolour

code

1 Positive+30 7772

2 Positivesymbolslighting 4442

3 Positive+15 8871

4 Speedsignal (tachograph) 5541

5 Earth 0000

6 Positivesymbolslighting 4444

7 - 2222

8 CAN line Yellow

9 CAN line Red

10 - 6666

11 Positive+30 7777

12 Earth 0000

Aquila Trucks Centres

107545

Figure35

KEY SIDECONNECTORVIEW

107531

Figure36

KEY SIDECONNECTORVIEW

ELECTRIC/ELECTRONICSYSTEM 35 TRAKKEREURO 4/5

Print 603.93.641 Base - November 2006

ST07A junction connector (yellow) - roof panel wings devices on the passenger side

Pin Function

Cablecolour

code

1 Positivefor front end-outlinemarker lamps 3339

2 Positivefor voltagereducer 7772

3 Loudspeaker signal (preamplifier) 1184

4 Loudspeaker signal (preamplifier) 1183

5 Positivefor readinglights(12V) 7712

6 Positive12V 7712

7 Positivefor overheadlight (whitelight) 4423

8 Positivesteplighting 4445

9 Positivefor overheadlight (bluelights) 4410

10 Positivefor overheadlight (redlights) 4422

11 Negativefor sunshadecurtain 0974

12 Sunshadecurtainclosingsignal 8065

13 Positivefor sunshadecurtainmotor 8063

14 Positivefor sunshadecurtainmotor 8064

15 - -

ST07B junction connector (yellow) - navigation and it tools

Pin Function

Cablecolour

code

1 Positive+30after TGC 7772

2 Positive+15 8871

3 Speedsignal for navigator 5541

4 - -

5 CAN L line(FMB) Green

6 CAN H line(FMB) White

7 Positivefor instrumentslighting 4442

8 Reversegear signal 2268

9 - -

Aquila Trucks Centres

Figure37

KEY SIDECONNECTORVIEW

101529

105228

Figure38

KEY SIDECONNECTORVIEW

36 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST07C junction connector (black) - heatable windshield

Pin Function

Cablecolour

code

1 Power supplyto heatablewindshield 8020

2 Power supplyto heatablewindshield 8020

ST07D junction connector- rotating headlights

Pin Function

Cablecolour

code

1 Positivefor left handsiderotatingheadlight 1108

2 Groundfor rotatingheadlight 0000

3 Positivefor right handsiderotatingheadlight 1115

Aquila Trucks Centres

107538

Figure39

KEY SIDECONNECTORVIEW

107188

Figure40

KEY SIDECONNECTORVIEW

ELECTRIC/ELECTRONICSYSTEM 37 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

ST08A junction connector (blue) - DDM control unit

Pin Function

Cablecolour

code

1 Positive(+30) for control unit power supply 7991

2 Ground 0000

3 Signal for loudspeaker (roof panel) 1188

4 Signal for loudspeaker (roof panel) 1186

5 Klinefor diagnosis 2991

6 CAN Hline(BCB) White

7 CAN Lline(BCB) Green

8 Centralisedlockingcontrol signal - opening 0064

9 Centralisedlockingcontrol signal - closing 0065

10 Signal (+) external temperaturesensor 7573

11 Driver sideelectrical lockbolt 0003

12 External temperaturesensor ground 0550

Jointingconnector ST08B (blue) - driver side door

Pin Function

Cablecolour

code

1 Connection2betweensidewindowregulator switches 8862

2 Connection1betweensidewindowregulator switches 8002

3 Mirror heatingsupply 8830

4 Positive+30(presetting) 7990

5 - -

6 - -

Aquila Trucks Centres

107538

Figure41

KEY SIDECONNECTORVIEW

Figure42

KEY SIDECONNECTORVIEW

101529

38 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST09A junction connector (blue) - PDM control unit

Pin Function

Cablecolour

code

1 Positive(+30) control unit power supply 7990

2 Ground 0000

3 Positiveright handsideloudspeaker 1184

4 Negativeright handsideloudspeaker 1183

5 Klinefor diagnosis 2290

6 CAN Hline(BCB) White

7 CAN Lline(BCB) Green

8 Centralisedlockingcontrol signal - opening 0064

9 Centralisedlockingcontrol signal - closing 0065

10 - -

11 Passenger sideelectrical lockbolt 0003

12 Free -

Jointing connector ST09B (white) - passenger side door

Pin Function

Cablecolour

code

1 Connection2betweensidewindowregulator switches 8862

2 Connection1betweensidewindowregulator switches 8002

Aquila Trucks Centres

Figure43

KEY SIDECONNECTORVIEW

Figure44

KEY SIDECONNECTORVIEW

107531

101525

ELECTRIC/ELECTRONICSYSTEM 39 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

ST10junction connector (green) - Instruments lighting

Pin Function

Cablecolour

code

1 Positivefor instrumentslighting 4442

2 Positivefor instrumentslighting 4442

3 Positivefor commutator for thirdaxlelifting. 4442

4 Positivefor switchwithincorporatedwarninglight for heatablewindshieldenabling 4442

5 Positivefor switchwithincorporatedwarninglight for heatedrear viewmirrors 4442

6 Positivefor switchwithincorporatedwarninglight for A.S.R. disabling 4442

7 Positivefor instrumentslighting 4442

8 Positivefor instrumentslighting 4442

9 Positivefor instrumentslighting 4442

Connector of junction ST11- trailer retarder brake

Pin Function

Cablecolour

code

1 Groundfromtrailer brakehandwheel switch(brakelight) 0927

2 Groundfor trailer brakehandwheel switch(brakelight) 0000

Aquila Trucks Centres

Figure45

KEY SIDECONNECTORVIEW

Figure46

107188

KEY SIDECONNECTORVIEW

101531

40 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST12junction connector (green) - tractor and trailer ABS/EBS

Pin Function

Cablecolour

code

1 - -

2 - -

3 - -

4 - -

5 Positivepressedpedal signal (ABS) 8153

6 Positivefor stoplights(ABS) 8158

ST13junction connector (black) - auxilliary air heater

Pin Function

Cablecolour

code

1 CAN BCBLine(L) Green

2 CAN BCBLine(H) White

Aquila Trucks Centres

ELECTRIC/ELECTRONICSYSTEM 41 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

ST14junction connector - ECAS bodybuilders (cab)

Pin Function

Cablecolour

code

1 Power supplyto liftableaxleloweringor liftingswitch 8445

ST14A junction connector (blue) - for bodybuilders(cab)

Pin Function

Cablecolour

code

1 Enginestart-upsignal input 8892

2 Engineturningoff signal input 0151

3 Stoplightssignal for bodybuilders 1165

4 Vehiclenot inoperationsignal output 5515

5 Parkingbrakeengagedsignal output 6656

6 - -

7 Speedsignal fromtachograph 5155

8 Enginecondition(output signal) 0Venginenot inoperation/ 24Vengineinoperation 7778

9 Gearboxinneutral positionsignal 8050

10 Reversegear signal 2268

11 Positive+15 8871

12 Provisionfor CruiseControl SET + 8156

13 Provisionfor CruiseControl SET - 8157

14 Provisionfor CruiseControl OFF 8154

15 Provisionfor CruiseControl RESUME 8155

16 ProvisionCruiseControl (internal /external choice) 0158

17 Ground 0000

18 Provisionfor P.T.O. 1control signal 0131

19 Provisionfor P.T.O. 2control signal 0132

20 Provisionfor P.T.O. 3control signal 0123

21 Positive+30 7772

Figure47

Figure48

KEY SIDECONNECTORVIEW

101523

KEY SIDECONNECTORVIEW

107554

Aquila Trucks Centres

Figure49

KEY SIDECONNECTORVIEW

107531

KEY SIDECONNECTORVIEW

Figure50

107538

42 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST14B junction connector (blue) - for bodybuilders(cab)

Pin Function

Cablecolour

code

1 Signal for thesecondspeedlimiter 0172

2 - -

3 Clutchstatussignal 9963

4 Programmablespeedthresholdindicator signal (PTS) 5542

5 Hazardlight signal 1113

6 - -

7 - -

8 Enginerpmsignal 5584

9 External light signal 3333

ST14C junction connector (grey) - for set up devices(Allison)

Pin Function

Cablecolour

code

1 Neutral signal for PTO 145

2 Steppingswitchsignal 123

3 - -

4 PTO signal active 143

5 PTO signal active 130

6 - -

7 - -

8 Automaticneutral signal 117

9 Automaticneutral signal 101

10 Digital earth 103

11 Zoneindicator signal 113

12 - -

Aquila Trucks Centres

107538

Figure51

KEY SIDECONNECTORVIEW

ELECTRIC/ELECTRONICSYSTEM 43 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

ST15- ST19junction connector

ST15(yellow) - Connection for couplings in the high roof

Pin Function

Cablecolour

code

1 Ground 0000

2 Positivefor slidingroof closing 7011

3 Positivefor slidingroof opening 7010

4 Positivefor readinglight 4412

5 Positivefor overheadlights(whitelight) 4423

6 Positivefor overheadlights(redlights) 4422

7 - -

8 Left handsideloudspeaker 1186

9 Left handsideloudspeaker 1188

10 Right handsideloudspeaker 1183

11 Right handsideloudspeaker 1184

12 -- -

ST19(green) - connection for heating

Pin Function

Cablecolour

code

1 Kline 2295

2 Positivesymbolslighting 4442

3 withST 20- 3 0506

4 withST 20- 4 8087

5 Positivefor 1st speedauxiliaryheatingenabling(remotecontrol switch) 8884

6 Positivefor heater motor water recirculationenabling(remotecontrol switch) 7778

7 Lockedpositive 8871

8 - -

9 Ground 0000

10 Negativefor auxiliaryheater enabling 0501

11 Positivewithstarter upengine 7786

12 - -

Aquila Trucks Centres

107552

Figure52

KEY SIDECONNECTORVIEW

44 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST20junction connector (green) - air conditioning system

Pin Function

Cablecolour

code

1 Kline 2296/2295

2 Positiveinstrumentslighting 4442

3 withST 19- 3 0506

4 withST 19- 4 8087

5 Positivefor 1st speedheater enabling(remotecontrol switch) 8884

6 Remotecontrol switchsignal for compressor enabling(frompressureswitches) 9933

7 Remotecontrol switchsignal for compressor enabling(fromcontrol unit) 9933

8 Positivewithstarter upengine 7778

9 Ground 0000

10 Positivecompressor control 9993

11 Positive+15 8871

12 Positiveafter TGC 7551

13 Positiveafter TGC 7551

14 - -

15 Negative(fromcontrol unit) for solenoidvalveradiator water recirculation 9552

16 Positivefor solenoidvalveradiator water recirculation 7550

17 - -

18 - -

Aquila Trucks Centres

101531

Figure53

KEY SIDECONNECTORVIEW

Figure54

KEY SIDECONNECTORVIEW

107169

1 2 3 1 2 3

ELECTRIC/ELECTRONICSYSTEM 45 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

ST21junction connector (black) - solenoid valve for radiator water recirculation

Pin Function

Cablecolour

code

1 Positivefor solenoidvalveradiator water recirculation 7550

2 Negativefor solenoidvalvefor radiator water recirculation 9552

ST23junction connector - immobilizer antenna

Pin Function

Cablecolour

code

1 Immobilizer antennasignal (VCMpin- X1/1) -

2 Immobilizer antennasignal (VCMpin- X1/3) -

3 - -

Aquila Trucks Centres

Figure55

KEY SIDECONNECTORVIEW

101531

Figure56

KEY SIDECONNECTORVIEW

101542

46 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST24junction connector (black) - CAN line for air conditioning system

Pin Function

Cablecolour

code

1 CAN Lline(BCB) Green

2 CAN Hline(BCB) White

ST25junction connector (black) - Intarder

Pin Function

Cablecolour

code

1 CAN VDBLine(L) Green

2 CAN VDBLine(H) White

3 Speedsignal for Intarder 5541

4 EOL dataentrylinefor Intarder control unit 3393

5 Kline 2293

Aquila Trucks Centres

101536

Figure57

KEY SIDECONNECTORVIEW

107183

Figure58

KEY SIDECONNECTORVIEW

ELECTRIC/ELECTRONICSYSTEM 47 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

ST26A - ST26B junction connector

ST26A (black) - Ecas (CAN)

Pin Function

Cablecolour

code

1 CAN VDBLine(L) Green

2 CAN VDBLine(H) White

3 Kline 2294

ST26B (black) - ABS/EBS (CAN)

Pin Function

Cablecolour

code

1 CAN VDBLine(L) Green

2 CAN VDBLine(H) White

3 Kline 2299

ST28junction connector- rotatingheadlights

Pin Function

Cablecolour

code

1 Groundfor left handsiderotatingheadlight 0000

2 Positivefor left handsiderotatingheadlight 1108

3 Free -

4 Positivefor right handsiderotatingheadlight 1115

5 Groundfor right handsiderotatingheadlight 0000

Aquila Trucks Centres

107188

Figure59

KEY SIDECONNECTORVIEW

48 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST30- ST31junction connector

ST30(blue) - provision for ADR(tachograph)

Pin Function

Cablecolour

code

1 Positive(+Batt) tachograph 7768

2 - -

3 Positive(+Batt) fromIBC3 7768

4 Positive(+Batt) Cluster / Central locking 7768

5 Batterydirect positive(+Batt) after fuse70058(20A) 7972

6 Positive(+Batt) 7972

ST31(green) - connection for ECAS (remote control)

Pin Function

Cablecolour

code

1 Power supplyto equalizationadjustment system(+15) 8810

2 Ground 0000

3 ClocklineonECASsuspensionscontrol keyboard 6402

4 ClocklineonECASsuspensionscontrol keyboard 6403

5 - -

6 - -

Aquila Trucks Centres

107538

Figure60

KEY SIDECONNECTORVIEW

107188

Figure61

KEY SIDECONNECTORVIEW

ELECTRIC/ELECTRONICSYSTEM 49 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

ST31A junction connector (green) - Cab rear

Pin Function

Cablecolour

code

1 Positivefor tool compartment lightingswitch 4448

2 Positivefor readingover headlight 4412

3 Ground 0000

4 Groundfor refrigerator 0000

5 Positivefor refrigerator (24V) 7735

6 Positivepower supplyfor BedModule 7906

7 Ground 0000

8 CAN (H) LineBCB White

9 CAN Line(L) BCB Green

10 Positivefor telephoneplug(12V) 7712

11 Telephoneplugground 0000

12 Positivefor lamp 7772

ST31B junction connector (blue) - auxiliary air heating

Pin Function

Cablecolour

code

1 Auxiliaryair heater warninglight 6655

2 Positive+30 7708

3 Ground 0000

4 Power supplyto auxiliaryfuel pumpfor air heater 7783

5 Auxiliaryheater Kline 2295

6 Power supplyto ambient temperaturesensor for auxiliarysensor 7512

Aquila Trucks Centres

101525

Figure62

KEY SIDECONNECTORVIEW

101529

Figure63

KEY SIDECONNECTORVIEW

50 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST31C junction connector (white) - water heatingtemperature sensor

Pin Function

Cablecolour

code

1 Positivefor internal temperaturedetectionprobe 7520

2 Negativefor internal temperaturedetectionprobe 0000

ST31L - ST31R junction connector

ST31L - connection for pneumatic heated seat

Pin Function

Cablecolour

code

1 Ground 0000

2 Positivefor driver sideheatedpneumaticseat 8031

ST31R - connection for pneumatic heated seat

Pin Function

Cablecolour

code

1 Ground 0000

2 Positivefor passenger sideheatedpneumaticseat 8031

Aquila Trucks Centres

107531

Figure64

KEY SIDECONNECTORVIEW

ELECTRIC/ELECTRONICSYSTEM 51 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

ST34 (blue) junction connector- provision for ACC / simple gearbox control H

Pin Function

Cablecolour

code

1 VCMcontrol unit pinX3/7 0179

2

Power supplytowarninglight for ACC(AdaptiveCruiseControl) distancerulesignalling/ Power

supplyto splitter control solenoidvalve(gear reducer) mechanical gearbox

6179/9973

3 Positive5Vfor distancecontrol withACC(AdaptiveCruiseControl) great distance 8179

4 VCMcontrol unit pinX2/9 0139

5 Returnfromdistanceselector withACC (AdaptiveCruiseControl) 6178

6

Power supply to distancealarmbuzzer withACC(AdaptiveCruiseControl) / Power supplyto

splitter control solenoidvalve(mechanical gearbox)

1166/9974

7 Positive+15 8871

8 Positivefor instrumentslighting 4442

9 - -

Aquila Trucks Centres

107545

Figure65

KEY SIDECONNECTORVIEW

107188

Figure66

KEY SIDECONNECTORVIEW

52 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST35/1junction connector (yellow) - manual control air conditioning system

Pin Function

Cablecolour

code

1 - -

2 - -

3 - -

4 Positive+30 7550

5 - -

6 - -

7 - -

8 Ambient thermostat signal 9993

9 Negativeremotecontrol switchesair conditioningenablingcommand 0555

10 Positivesymbolslighting 4442

11 Positivefromremotecontrol switchinternal heatingenablingconsent 8004

12 Positiveremotecontrol switchair conditioner enablingcommand 8097

13 Contact of theremotecontrol switch(87) for auxiliaryheater 1st speedenabling 8884

14 Positivefor Topflapcommandingremoteswitchcontrol 8801

15 - -

ST35/2junction connector (yellow) - manual control air conditioning system

Pin Function

Cablecolour

code

1 Positivefor windshieldelectric defroster commandunit 8884

2 - -

3 Kline 2296

4 Positive+30fromBodyComputer 7786

5 - -

6 - -

Aquila Trucks Centres

Figure67

Figure68

KEY SIDECONNECTORVIEW

107538

107188

KEY SIDECONNECTORVIEW

ELECTRIC/ELECTRONICSYSTEM 53 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

ST36junction connector (grey) - T.G.C. / I.G.C.

Pin Function

Cablecolour

code

1 Alternator power supplyterminal 15 8876

2 Alternator power supplyterminal 15 8876

3 Signal for TGC closing 8035

4 Signal for TGC closing 8035

5 Batterypositive(+Batt) 7972

6 Batterypositive(+Batt) for tachographandIC 7768

7 Batterypositive(+Batt) for B.C. / B.M. / diagnosis/refrigerator connector 7972

8 CAN (H) line(BCB)

9 CAN (L) line(BCB)

10 Telephonesocket positive(12V) 7712

11 Groundfor telephone 0000

12 Positivefor bulb 7772

SST37C junction connector (yellow) - Toll Collect

Pin Function

Cablecolour

code

1 Positive+30after TGC 7772

2 Positivesymbolslighting 4442

3 Positive+15 8871

4 Speedsignal (tachograph) 5541

5 Ground 0000

6 - -

Aquila Trucks Centres

Figure69

107188

KEY SIDECONNECTORVIEW

54 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST39junction connector (yellow) - differential lock

Pin Function

Cablecolour

code

1 Positivesymbolslighting 4442

2 Signal fromfront transversedifferential lockcontrol switch 0902

3 Signal fromlongitudinal differential lockcontrol switch 0903

4 Signal fromrear transversedifferential lockcontrol switch 0904

5 Ground 0000

6 - -

Aquila Trucks Centres

Figure70

KEY SIDECONNECTORVIEW

101529

107531

KEY SIDECONNECTORVIEW

Figure71

ELECTRIC/ELECTRONICSYSTEM 55 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

ST40junction connector - navigation and it tools

Pin Function

Cablecolour

code

1 Positive+30after TGC 7772

2 Positive+15 8871

3 Speedsignal for navigator 5541

4 Positive12V 7712

5 CAN Lline(ICB) Green

6 CAN Hline(ICB) Bianco

7 Positivefor instrumentslighting 4442

8 Reversegear signal 2268

9 Ground 0000

Jointingconnector ST42- DDM/PDM supplies

Pin Function

Cablecolour

code

1 Positive+30 7777

2 Positive+15 8887

Aquila Trucks Centres

Figure72

KEY SIDECONNECTORVIEW

Figure73

KEY SIDECONNECTORVIEW

113250

105243

56 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST44junction connector - centralized locking with remote control

Pin Function

Cablecolour

code

1 Clinker control 1113

2 - -

3 Batterypositive(+Batt) 7772

4 Ground 0000

5 Control for centralizedlockingto BodyComputer (door opening) 0064

6 Control for centralizedlockingto BodyComputer (door closing) 0065

7 Power supply+15 8871

8 - -

ST45junction connector- 24V connection for radio

Pin Function

Cablecolour

code

1 Positive+30for preamplifier 7772

2 Positive+15for radio receiver 8871

3 Ground 0000

4 Positivesymbolslighting 4442

5 CAN lineL (IDB) Green

6 CAN lineH (IDB) White

7 Positive+30for radio receiver 7770

8 - -

Aquila Trucks Centres

Figure74

KEY SIDECONNECTORVIEW

Figure75

KEY SIDECONNECTORVIEW

101523

107545

ELECTRIC/ELECTRONICSYSTEM 57 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

ST48junction connector (yellow) - EM control unit (PTO)

Pin Function

Cablecolour

code

1 CAN Lline(ICB) Green

2 CAN Hline(ICB) White

3 Kline Green

4 Positive+30after TGC 7772

5 Positive+30 7166

6 Positive+15 8166

7 Ground 0000

8 Wiringfor CAN Lline(SB) Green

9 Wiringfor CAN Hline(SB) White

10 P.T.O. control signal 1 0131

11 P.T.O. control signal 1 0132

12 P.T.O. control signal 1 0123

13 Positive+30for bodybuildersconnector (72072C) 7795

14 Positive+30for bodybuildersconnector (72072D) 7796

15 - -

Jointingconnector ST 49 - Allison transmission setup

Pin Function

Cablecolour

code

1 Starter motor remotecontrol switchground 0008

Aquila Trucks Centres

101542

Figure76

KEY SIDECONNECTORVIEW

105251

Figure77

KEY SIDECONNECTORVIEW

58 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST54junction connector- provision for ACC

Pin Function

Cablecolour

code

1 CAN lineL (VDB) Green

2 CAN lineH (VDB) White

3 CAN lineL (VDB) Green

4 CAN lineH (VDB) White

5 Positive+15 8176

ST55A junction connector- SCR system(urea)

Pin Function

Cablecolour

code

1 CAN lineL (ECB) Green

2 CAN lineH (ECB) White

3 CAN lineL (ECB) Green

4 CAN lineH (ECB) White

5 Kline 2257

6 Positive+15 8540

7 Power supplyto combustionair relativehumidityandtemperaturesensor 8173

8 Signal for combustionair relativehumiditysensor 5173

9 Combustionair relativehumidityandtemperaturesensor ground 0173

10 Combustionair temperaturesensor signal 5174

11 Power supplyto enginebrakesolenoidvalve 9966

12 Enginebrakesolenoidvalveground 0043

Aquila Trucks Centres

Figure78

101523

KEY SIDECONNECTORVIEW

Figure79

KEY SIDECONNECTORVIEW

101531

ELECTRIC/ELECTRONICSYSTEM 59 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

ST55B - ST56junction connector

ST55B - SCR system power supply(urea)

Pin Function

Cablecolour

code

1 Batterypositive(+Batt) SCRSystem 7540

ST56(black) - Connection for ADR cut generator

Pin Function

Cablecolour

code

1 Alternator power supplyterminal 15 8876

ST59junction connector - 2

nd

front axle ECAS fault / longitudinal lock (8x8)

Pin Function

Cablecolour

code

1 ECASfault signal / front longitudinal differential locksengagedsignal (8x8) 6401/ 6643

2 ECASfault signal switchearth 0000

Aquila Trucks Centres

101525

Figure80

KEY SIDECONNECTORVIEW

101542

Figure81

KEY SIDECONNECTORVIEW

60 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST63junction connector- auxiliary water heater CAN

Pin Function

Cablecolour

code

1 CAN Line(L) BCB Green

2 CAN (H) LineBCB White

ST64junction connector (black) - 15-poles current outlet free pins

Pin Function

Cablecolour

code

1 Power supplyto current outlet 8021

2 Power supplyto current outlet 7021

3 Transversedifferential blockingsignal 6621

4 Power supplyto positivetrailer interlocking+15 8075

5 Power supplyto positivetrailer interlocking+15 8075

Aquila Trucks Centres

101531

Figure82

KEY SIDECONNECTORVIEW

101536

Figure83

KEY SIDECONNECTORVIEW

ELECTRIC/ELECTRONICSYSTEM 61 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

ST65- ST67junction connector

ST65- CAN for trailer (PTO with EM)

Pin Function

Cablecolour

code

1 CAN SBline(L) (connectionfor trailer - PTO withEM)

2 CAN SBline(H) (connectionfor trailer - PTO withEM)

ST67- UREA dosingmodule solenoid

Pin Function

Cablecolour

code

1 Power supplyto dosingmodulesolenoidvalvewithSCR 7541

2 Ureaelectricdosingunit (-) control 9541

ST68junction connector- UREA temperature sensor

Pin Function

Cablecolour

code

1 Signal cableto ureatanklevel sensor withSCR 6543

2 UreatankwithCSRlevel andtemperaturesensor ground 0543

3 Signal cableto ureatanktemperaturesensor withSCR 6542

Aquila Trucks Centres

Figure84

KEY SIDECONNECTORVIEW

105334

101531

Figure85

KEY SIDECONNECTORVIEW

62 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST69junction connector- Intarder

Pin Function

Cablecolour

code

1 Solenoidvalvefor retarder oil accumulator 0311

2 Solenoidvalvefor retarder oil accumulator 9311

3 Water temperaturetransmitter for retarder 5309

4 Water temperaturetransmitter for retarder 0309

5 Solenoidvalvefor retarder enabling 0310

6 Solenoidvalvefor retarder enabling 9310

ST70junction connector (black) - ASR solenoid valve

Pin Function

Cablecolour

code

1 ASRsolenoidvalve(-) control 0260

2 ASRsolenoidvalvepower supply 9260

Aquila Trucks Centres

Figure86

KEY SIDECONNECTORVIEW

101542

ELECTRIC/ELECTRONICSYSTEM 63 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

ST72junction connector (black) - rear block wear / transverse differential lock

Pin Function

Cablecolour

code

1 To thedeviator for signallingof transversedifferential lockof Rockwell rear axlesfor thethirdaxle 0041

2 To thedeviator for signallingof transversedifferential lockof Rockwell rear axlesfor thethirdaxle 0000

3 To thedeviator for signallingof transversedifferential lockof Rockwell rear axlesfor thethirdaxle 0040

4 To thesensor for circuit signallingof rear wheel shoeswear 6667

5 To thesensor for circuit signallingof rear wheel shoeswear 6664

Aquila Trucks Centres

Figure87

101531

KEY SIDECONNECTORVIEW

64 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

Junction connector ST73/1- ST73/2- ST73/3- ST73/4

ST73/1(black) - 1

st

front axle block wear (right)

Pin Function

Cablecolour

code

1 To thesensor for circuit signallingof front wheel shoeswear 6664

2 To thesensor for circuit signallingof front wheel shoeswear 6664

ST73/2(black) - 1

st

front axle block wear (left)

Pin Function

Cablecolour

code

1 To thesensor for circuit signallingof front wheel shoeswear 6664

2 To thesensor for circuit signallingof front wheel shoeswear 0000

ST73/3(black) - 2

nd

front axle block wear (right)

Pin Function

Cablecolour

code

1 To thesensor for circuit signallingof front wheel shoeswear 6664

2 To thesensor for circuit signallingof front wheel shoeswear 6664

ST73/4(black) - 2

nd

front axle block wear (left)

Pin Function

Cablecolour

code

1 To thesensor for circuit signallingof front wheel shoeswear 6664

2 To thesensor for circuit signallingof front wheel shoeswear 0000

Aquila Trucks Centres

101531

Figure88

KEY SIDECONNECTORVIEW

101536

Figure89

KEY SIDECONNECTORVIEW

ELECTRIC/ELECTRONICSYSTEM 65 TRAKKER EURO 4/5

Print 603.93.641 Base- November 2006

ST75A junction connector - 1st front axle differential lock

Pin Function

Cablecolour

code

1 1

st

front axledifferential locksignal 6659

2 Ground 0000

ST75B junction connector - 2nd front axle differential lock

Pin Function

Cablecolour

code

1 2

nd

front axledifferential locksignal 6659

2 Ground 0000

3 Front longitudinal differential lockengagedsignal (8x8) 6643

Aquila Trucks Centres

101538

Figure90

KEY SIDECONNECTORVIEW

66 ELECTRIC/ELECTRONICSYSTEM TRAKKEREURO 4/5

Base- November2006 Print 603.93.641

ST77- ST78JUNCTION CONNECTOR BODYBUILDERS (CHASSIS - TRUCK)

ST77(black) - Right hand side SML indicator light (Side Marker Lamp)

Pin Function

Cablecolour

code

1 Signal for sidelamps 3330

2 Groundfor sidelamps 0000

3 Signal for sidelamps 3330

4 Groundfor sidelamps 0000

ST78(black) - Left hand side SML indicator lamp(Side Marker Lamp)

Pin Function

Cablecolour

code

1 Signal for sidelamps 3339

2 Groundfor sidelamps 0000

3 Signal for sidelamps 3339

4 Groundfor sidelamps 0000

Aquila Trucks Centres