Documente Academic

Documente Profesional

Documente Cultură

Design of A Bicycle Powered Rope Pump

Încărcat de

Ortega IanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Design of A Bicycle Powered Rope Pump

Încărcat de

Ortega IanDrepturi de autor:

Formate disponibile

1

ABSTRACT

In the lush villages of Buikwe District, women spend many hours and have to walk many miles

every day to get water for their families to cook and drink. Water is a very important resource, that people

in first world countries take for granted because it is as easy as turning the faucet handle on. Humans can

only survive three to five days without water and getting clean water in third world countries and in

particular Buikwe District is a difficult problem. Most communities in this District get water from

standing sources including rivers, lakes, and even puddles which are often full of dirt and other dangerous

water borne diseases. In an effort to tap into the potable water just below the surface, the Rope pump

Team has decided to take the widely known designs of one of the simplest and cheapest water pumps, the

rope pump, and improve upon them.

The team has enhanced designs for almost every component of the pump. Things such as the

frame of the pump which could be made from spare bike parts or just scrap metal. The rope and seals are

also an important area of study that we will be spending a majority of our time working on. Traditional

rope pumps utilize knots what create a seal within a pipe and bring up water as they are pulled to the

surface. A third and final area of study is the drive mechanism of which we are considering a bike and its

connecting mechanism.

After much research, calculations and experimental tests, we were able to find the best

combination of improvements to improve output nearly 200% over traditional rope pumps. With the

improvements stated in this report the team will be able to not only increase the water output to the

surface but also eliminate a lot of the danger associated with the construction of the guide box as well as

improving the durability of the pump by using proper rope and seal combinations.

The team hopes all of the work this semester will be diffused across many third world districts

and if it can improve just one life out there then we can deem all our hard work, sweat and tears a raging

success.

2

ACKNOWLEDGEMENT

With a sense of gratitude, we would like to thank every body who gave us his or her time and

inconsistent pieces of advice concerning the project and in learning the intricacies that were

related to it.

We would like to express our indebtedness to Mr. Ssempebwa Ronald, and Dr.Ssengonzi

Bagenda for their wordily advice, commendable guidance, constant inspiration and

encouragement that we got from them throughout the course of the project. Without them, this

project wouldnt have got off the ground.

3

DEDICATION

This work is dedicated to our parents and guardians who strived to see that our academics are a

success.

4

DECLARATION

We declare that this work is out of our hard work and has never been presented to any institution

of higher learning for the award of any academic qualification.

NAME REG.NO SIGNATURE

ORTEGA IAN 11/U/11049/EMD/PD

SSEBUNYA ISA 11/U/10740/EME/PE

OKELLO DANIEL 13/U/450/EMD/GV

AKELLO LILIAN 11/U/864/EMD/GV

SSEBUUFU HUSSEIN 11/U/209/EMD/GV

5

APPROVAL

I hereby approve that the work herein presented was done by the student under my supervision.

Signature Date

MR. SSEMPEBWA RONALD

6

ACRONYMS

Acronym Meaning

PVC Polyvinyl Chloride Pipe

Shs. Shillings

7

Table of Contents

ABSTRACT ................................................................................................................................................... 1

ACKNOWLEDGEMENT ................................................................................................................................... 2

DEDICATION .................................................................................................................................................. 3

DECLARATION ............................................................................................................................................... 4

APPROVAL ..................................................................................................................................................... 5

ACRONYMS ................................................................................................................................................... 6

CHAPTER ONE: INTRODUCTION .................................................................................................................... 9

1.1Background .............................................................................................................................................. 9

1.2 Problem Statement ............................................................................................................................... 10

1.3Objectives of the Study .......................................................................................................................... 10

1.3.1General Objective ............................................................................................................................... 10

1.3.2Specific Objectives .............................................................................................................................. 10

1.4Scope of the Study ................................................................................................................................. 10

1.5Significance of The study ....................................................................................................................... 10

1.6 Justification of the Study ....................................................................................................................... 11

1.7Research Questions ............................................................................................................................... 11

CHAPTER TWO: LITERATURE REVIEW ......................................................................................................... 12

2.1 Overview ............................................................................................................................................... 12

2.2 Structure of A Rope Pump And Operation ............................................................................................ 12

2.3 Bicycle Power (Pedal Power) ................................................................................................................ 13

2.4 Pumping Water Using A Bicycle ............................................................................................................ 19

2.5 Drive Design Specifications ................................................................................................................... 20

CHAPTER THREE: METHODOLOGY .............................................................................................................. 26

3.1Overview ................................................................................................................................................ 26

3.2 Research Design .................................................................................................................................... 26

3.3 Data Source ........................................................................................................................................... 26

3.3.1 Primary Sources ................................................................................................................................. 26

3.3.2 Secondary Sources ............................................................................................................................. 26

3.4 Data Collection Method ........................................................................................................................ 26

CHAPTER FOUR:PRESENTATION AND DISCUSSION OF FINDINGS .............................................................. 28

4.1 Overview ............................................................................................................................................... 28

8

4.2 Conceptual Design Concepts ................................................................................................................ 28

4.3 Drive Design Concept 1 ......................................................................................................................... 28

4.4 Drive Design Concept 2 ......................................................................................................................... 29

4.5 Drive Design Concept 3 ......................................................................................................................... 31

4.6 Drive Design Concept 4 ......................................................................................................................... 33

4.7 Drive Design Concept 5 ......................................................................................................................... 35

4.8 Drive Design Concept 6 ......................................................................................................................... 36

4.9 Drive Design Concept Weighting Factors .............................................................................................. 37

Drive Design Concept Ranking .................................................................................................................... 37

Structure Concept 1 .................................................................................................................................... 39

Our Problem Solving Approach ................................................................................................................... 40

Final Design Assembly (Sketch) ................................................................................................................... 41

Mathematical Model .................................................................................................................................. 41

Pedaling Rate .............................................................................................................................................. 42

Economic Evaluation of The Design ............................................................................................................ 42

Rope Pump ............................................................................................................................................... 42

Bike Mount ............................................................................................................................................... 42

Other Costs ............................................................................................................................................... 43

CHAPTER FIVE: CONCLUSION AND RECOMMENDATION............................................................................ 44

5.1 Overview ............................................................................................................................................... 44

5.2 Conclusion ............................................................................................................................................. 44

5.3 Recommendations ................................................................................................................................ 44

REFERENCES ................................................................................................................................................ 46

9

CHAPTER ONE: INTRODUCTION

1.1 Background

Imagine that bottled water does not exist, running taps are non-existent, and walking a mile or

more to fetch water with a bucket is a daily activity from scarce boreholes and open wells. On top of the

difficulties of retrieving water, that source of water is most often than not polluted and undrinkable. But

when there is no other source of water, the most essential ingredient to life, there is no choice but to

consume the polluted water. High quality H2O is only obtained from chemical treatment, filtering or from

a clean ground water well. In Buikwe District, filtration is often absent, chemical treatment is unheard of,

and groundwater wells are not properly built or maintained and also become polluted from run-off. These

conditions are those of the bottom 80 percent of the worlds population which live in low standards of

living and 48 percent make an average wage of $2.00 USD per day or less.

One simple solution for retrieving safe water is by carefully implementing an innovative,

human-powered water pump. The team takes the challenge of successfully designing and building an

innovative rope pump for use in third world districts. More important than the design itself is the method

of communicating how to build, and maintain such a device in the simplest manner possible. With the

teams main focus on the rural areas of Buikwe District, we intend to make the rope pump a highly

adaptable device for any country. In order to achieve this, the pump must be physically adaptable and also

detailed yet simple.

With these mountain high goals of simplicity, functionality, and a large target population, the team

expects to achieve a large impact in communities worldwide. Results of this design project were intended

to improve the quality of life for third world communities by providing easy access to safe drinking water.

Even helping one community or even one person within a community by providing clean and safe

drinking water by the implementation of this rope pump will be considered success.

10

1.2 Problem Statement

Women from Buikwe spend many hours and have to walk many miles every day to get water for their

families to cook and drink from not only distant boreholes but also wells contaminated by runoff.

This sanitation level and related water crisis can not be ignored since its leaving a mark of

an increasing toll on human life, health and livelihoods. One simple solution is to carefully

design a simple, innovative bicycle powered rope pump to address the issue.

1.3 Objectives of the Study

1.3.1 General Objective

The main objective was to design a simple, innovative bicycle powered rope pump for

Buikwe district where existing few bore holes are too distant yet the remaining

alternative wells are contaminated by runoff with related water born diseases.

1.3.2 Specific Objectives

This project was guided by the following specific objectives;

1. To devise a concept thats cheaper compared to other forms of water-pumping yet

very efficient.

2. To design a simple rope pump thats easy to fabricate, and very easy to maintain

3. To make a design where the bicycle is still reusable after the pumping purposes are

done.

1.4 Scope of the Study

The bicycle powered pump only considered utilization in the rural communities of Buikwe

District where access to boreholes is only after miles of walking yet available contaminated wells

have a scare of water borne diseases. The material of the rope pump had to be of waste materials,

very durable yet cheap at the same time.

1.5 Significance of The study

Once the design of the bicycle rope pump is adopted, it will solve the water-supply problem in

Buikwe District by using a cheap, efficient and innovative means. This means that more families

will have access to safe and clean drinking water in addition to other domestic purposes so as to

increase on health and living standards in the district.

The researched work is to be used as a basis of further research and compilation of study books,

journals which can be utilized by different groups of people.

11

1.6 Justification of the Study

If access to safe drinking water and corresponding long distances for the only contaminated

water is not addressed, it will cost Buikwe District a couple of ages to penetrate through a circle

of poor health and living standards. A simple design of a bicycle powered rope-pump could be

an immediate savior.

1.7 Research Questions

This study was guided by the following research questions;

1. What is the structure of the rope pump and how does a rope pump operate?

2. What are the various factors and parameters concerned with bicycle power?

3. How can water be pumped using a bicycle?

4. How could a suitable lay out of the designed system be developed in relation to the

already existing bicycle powered rope pump designs (our design specifications)?

12

CHAPTER TWO: LITERATURE REVIEW

2.1 Overview

This chapter contains the relevant information and facts about

the rope pumps design and operation, bicycle power and

design parameters to be considered while developing a bicycle

powered rope pump, major aspects considered in the design,

operation of these components and the well-depth

characteristics in Buikwe district versus the bicycle powered

rope pump, and water that can be delivered.

2.2 Structure of A Rope Pump And Operation

According to a briefing paper from Water Aid in Ghana, the

rope pump is a simple technology hand pump that has the

potential of reducing the cost of installing hand pumps by

about 75 to 80 percent. The Rope Pump features a unique

design in which small plastic pistons are lined up on a rope.

The distance between the pistons is approximately 1 m. The

drive wheel is crank operated and pulls the rope through a

plastic rising pipe. The drive wheel consists of cut old tires. A

concrete guide box with a glass bottle at the well ground leads

the rope with the pistons into the rising main pipe.

2.2.1 Mode and Operation

This pump type works with

a loop of rope, which is pulled through a plastic riser pipe. Regularly spaced washers are fixed

on the rope (approx. 1 m spacing), which are guided into the riser pipe at the bottom of the well

and are carrying water to the spout. At the pump stand, the rope is moved by a rubber lined

pulley, mostly made of cuttings from worn car tires. The pulley is operated with a crank handle

in a steady speed, so that sufficient water is flowing from the spout.

Because of the required clearance between the washers and the riser pipe, the movement of the

rope needs a certain speed, so that the velocity of the drawn water is continuous.

As soon as the operation stops, the water in the rising main will drain slowly.

This type of pump is usually placed on a dug-well and its mostly used as family pump.

However, there are different models existing that are suitable for larger communities and also to

be installed on boreholes.

Figure 1: Rural Water Supply Image

13

The rope and washer pump has the advantage of a simple design and fairly easy maintenance.

In the words of Wikipedia; A rope pump is a kind of pump where a loose hanging rope is

lowered down into a well and drawn up through a long pipe with the bottom immersed in water.

On the rope, round disks or knots matching the diameter of the pipe are attached which pull the

water to the surface. The original rope pumps used knots along the rope length but can be made

with flexible or rigid valves on the rope instead of knots. Alternatively they may use only rope,

simply relying on the water clinging to the rope as it is quickly pulled to the surface

2.3 Bicycle Power (Pedal Power)

In talking about bicycle power, we are concerning ourselves more with the aspect of pedal power

that is, the power generated from the act of a human being pedaling on a bicycle. A person can

generate four times more power (1/4 horsepower (hp)) by pedaling than by hand-cranking. At

the rate of 1/4hp, continuous pedaling can be done for only short periods, about 10 minutes.

However, pedaling at half this power (1/8 hp) can be sustained for around 60 minutes. Pedal

power enables a person to drive devices at the same rate as that achieved by hand-cranking, but

with far less effort and fatigue. Pedal power also lets one drive devices at a faster rate than

before (e.g. winnower), or operate devices that require too much power for hand-cranking (e.g.

thresher). This in reference with Darrow and Kens book on Pedal power.

POWER LEVELS

The power levels that a human being can produce through pedaling depend on how strong the

pedaler is and on how long he or she needs to pedal. If the task to be powered will continue for

hours at a time, 75 watts mechanical power is generally considered the limit for a larger, healthy

non-athlete. A healthy athletic person of the same build might produce up to twice this amount.

A person who is smaller and less well nourished, but not ill, would produce less; the estimate for

such a person should Probably be 50 watts for the same kind of power production over an

extended period. The graph in Figure 1 shows various record limits for pedaling under optimum

conditions. The meaning of these curves is that any point on a curve indicates the maximum

time that the appropriate class of person could maintain the given average power level.

14

Power levels are also directly related to the environment of the person doing the pedaling. To

be able to continue pedaling over an extended period, a person must be able to keep cool--

whether because the ambient temperature is low enough, or because there is adequate breeze.

There is a vital difference between pedaling a stationary device and pedaling a bicycle at the

same power output. On a bicycle, much of the pedaling energy goes into overcoming wind

resistance; this wind resistance, however, provides an important benefit: cooling. Because of the

wind, even in hot, humid climates, so long as the bicyclist drinks enough liquids, dehydration

and heat stroke are unlikely to occur.

On the other hand, when pedaling a stationary device on a hot or humid day at more than about

half the maximum possible power output, there is a considerable danger of the pedaler's

collapsing because of an excessive rise in body temperature.

15

Therefore, it is essential that an individual pedaling such a stationary device in hot or humid

conditions be provided with shade from the sun, plenty of water, and preferably some sort of fan.

A portion of the power that the pedaler is producing can be used to drive this fan; this is an

efficient use for the power, since it will help prevent damage to the pedaler's health.

PEDALING RATE

How fast should a person pedal? Human beings are very adaptable and can produce power over a

wide range of pedaling speeds. However, people can produce more power--or the same amount

of power for a longer time--if they pedal at a certain rate. This rate varies from person to person

depending on their physical condition, but for each individual there is a pedaling speed

somewhere between straining and flailing that is the most comfortable, and the most efficient in

terms of power production. (For centuries, this fact was apparently not recognized.

The predominant method of human power production was to strain with maximum strength

against a slowly yielding resistance. This is neither comfortable nor efficient. Neither is the

opposite extreme of flailing at full speed against a very small resistance.

A simple rule is that most people engaged in delivering power continuously for an hour or more

will be most efficient when pedaling in the range of 50 to 70 revolutions per minute (rpm). See

Figure 2. For simplicity's sake, we will use 60 rpm, or one revolution of the pedal cranks per

seconds an easy reference value for estimates of the gear ratios required to drive a given load.

16

GEAR RATIOS

The relationship between the rotating speed of whatever is being driven and the pedaling rate

(both expressed in revolutions per minute) is called the gear ratio. Most practical applications of

Pedal power will use bicycle-chain drives, which on bicycles range from 1:1 (the rear wheel

turns at the same speed as the turns at five times the speed of the cranks) for high gears.

Very-Low-Power Applications

There are some very-low-power applications of pedal power, in which the required power

output is so far below that of which human beings are capable that maximum efficiency is not a

concern. For example, sewing machines are generally limited to a less than optimum value to

allow the sewing table to be placed at a convenient height. The pedaler provides a range of

sewing speeds without gear-change mechanisms. A large step-up ratio is usually given by a

round belt made of leather. It cannot transmit large torques; this inability serves a purpose,

because when the sewing needle jams, the belt slips, preventing the needle from breaking.

High-Power Applications

An example of an application at the higher-power end of the scale is a hypothetical maximum-

power drive for an irrigation pump. Let us suppose that the pump has the speed-versus-power

characteristics shown in Figure 3, and that the pedalers will be paid to produce as much power as

they comfortably can for periods of two hours at a time.

Choosing a conservative value from Figure 1, we estimate that a mechanical output of 100 watts

seems reasonable for this length of time. Furthermore, we estimate from Figure 2 that the

optimum pedaling speed to give this power output is 55 rpm.

17

We can then see from Figure 3 that when the pump absorbs 100 watts, its speed of revolution

should be 95 rpm. We need, therefore, a step-up gear of 95:55. We have available a set of

bicycle cranks and pedals with a chain wheel having 48 teeth. To achieve our ratio of 95:55, we

then need:

45 x 55/95 = 27.8 teeth on the cog (the smaller sprocket attached to the pump shaft).

Ideally then, we should use a sprocket of 28 teeth. However, sprockets of 27, 28, or 29 teeth

would be acceptable.

No allowance has been made in this calculation for energy losses in the chain

transmission. This is because a single chain going over two sprockets is very efficient--over 95

percent, even for unlubricated, worn, or dirty chains.

However, some applications require two stages of step-up transmission, and in these cases,

power losses are greater. For instance, suppose that a ventilation fan must be driven for a long

period at 900 rpm, and the optimum pedaling speed is estimated to be 60 rpm. The step-up ratio

is then 900:60 = 15:1. The smallest sprockets generally available for bicycles have 12 teeth. The

chain-wheel for a single step-up stage would need:

12 x 15 = 180 teeth.

Such a chain-wheel is not available, but even if one were specially made, it would have a

diameter far too large to pedal around. Moreover, using a very large-chainwheel with a very

small cog produces a small angle of contact (or wrap) around the cog; this causes high tooth

wear on the cog.

Therefore, a step-up ratio of 15:1 is better produced by a two-stage step-up gear. For example,

a standard high-gear arrangement from a bicycle could be used. It has a chainwheel of 48 teeth

driving a cog of 13 teeth, fixed to a second shaft on its own bearings(*) (for instance, another

bicycle crankset with another chainwheel of 48 teeth on the countershaft, driving a cog of 12

teeth on the shaft to be driven. The combination would then be:

(48/13) x (48/12) = 14.8.

This is close enough to 15:1 to be useful.

In this case, it would be best to assume that there would be a 10 percent loss of power. For

example, if the pedaler can produce an output of 50 watts for the desired period, the driven

device will receive 45 watts input.

18

PEDALING POSITIONS

There are three common pedaling positions:

* The first is the upright position used by the majority of cyclists around the world. In this

position, the seat, or saddle, is located slightly behind where it would be if it were a seat, or

vertically above the crank axis; the hand grips are placed so that the rider leans forward just

slightly when pedaling. Tests have shown that subjects using this position are able to produce

the most pedaling power when the top of the saddle is fixed at a distance 1.1 times the leg length

to the pedal spindle at the pedal's lowest point.

* The second position is the position used by riders of racing bicycles with dropped handlebars,

when they are holding the upper parts of the bars. Their back is then at a forward lean of about

40 degrees from the vertical. Their saddle height requirements are similar to those of cyclists in

the first position. (The position of the racing bicyclist who is trying to achieve maximum speed is

not suitable for power production on a stationary device. Even racing bicyclists sometimes

experience great pain after a long time in this position, and the position is unnecessary on a

stationary device because there is no wind resistance to overcome.

* The third position is the position used in modern semi-recumbent bicycles. The placement of

the center of the pedaling circle relative to the seat is shown in Figure 4.

19

In this seating position, the pedaling forces are countered by the lower back pushing into the seat

(which is similar in construction to a lawn chair made of tubes and canvas). The arms and hands

do not need to remain on the handlebars to perform this function, the way they usually do in the

first two positions.

They can remain relaxed, and free to guide the work that the pedaler is powering. The upper

body too can remain relaxed, and the chest is in a position that makes breathing easier than when

the pedaler bends forward. The major disadvantage of this position is that, since the pedaler's

legs move forward from the body, it may be hard to position large, deep equipment like a lathe or

saw so that it is in reach without being in the way.

In almost all other respects, the semi-recumbent position is highly desirable, though not essential.

2.4 Pumping Water Using A Bicycle

This is concerned with observing various means in which water can be pumped using a bicycle

thus the idea of a bicycle powered water pump. Attaching the pump to the bike is a critical part

of our design. We want to make it in such a way that the bike can still be used as a means of

transportation and the pump can be attached and detached easily, no matter what shape the frame

is. Below are a list of possible mounting solutions for each of the different pumps.

1. Piston Pump: This design requires changing the rotational motion into linear motion. This

can be done by attaching a wheel or crank arm of some sort with an offset pin to attach the piston

to.

-It is possible to mount the pistons to the pedals of the bike so that the pedals move up and down

and compress the piston. However, this is hard to prevent from interfering with normal pedaling

and requires a mounting point on the frame.

-Also, a second wheel could be attached to the back wheel so that the second wheel takes force

from the wheel and then converts it to linear motion. This is very easy to remove and since tires

are usually similarly sized, it can be adapted to different frames. However, this design relies on

friction and may lead to slipping or inefficiency.

-Redesigning the back wheel to be switched out for the pump would utilize many of the existing

components. However, designing this in such a way that the bike is still usable is difficult.

2,3,4. All these pumps accept rotary motion, which is abundant on a bicycle.

-Mounting a gear to attach to the chain would be a way to tap energy from the chain but it

requires a mounting point on a bicycle.

20

-Tapping into the rear wheel is a nice way of mounting the pump and the speed and resistance

can be controlled by using the gear shifters. It's more controllable than mounting to the chain as

it can be controlled by both the front and rear derailleurs.

-The back wheel could be redesigned, which is probably the most durable option but again has

problems with using the bike as a bike.

-It would be possible to attach a friction wheel to the back wheel but there is no advantage of this

system over attaching it to the chain.

2.5 Drive Design Specifications

Each of the following subsections describes each design specification that must be taken into

consideration when developing a rope pump design. Each design specification will then be

weighted based on importance in the subsequent section.

Function/Performance

Performance of the pump must be able to function in wells up to 20 meters in depth and pump

water at a rate at least 5 gallons per minute. With this performance in mind, we wish to build a

pump that can pump at least 5 gallons per minute at an angle (from 0 to 80 degrees, 0 being

straight down).

Product Cost

In the end the cost of the pump must be no more than $100 USD. The Gross National Income

(GNI) Per Capita for Uganda is $2,740 and for the Lower Middle class the average annual

income is $1,619 in US dollars. In the end the pump needs to be below $100 in order to be

implemented. Current rope pumps in place range from $35 to $150 depending on model, location

of production, and cost of materials and labor.

Delivery Date

Delivery date for the working model*, mini-model**, and a training manual to create the pump

to be created is no later than May 26, 2014. *=6.096 meter or 20 feet depth, **= 0.6096 meters

or 2 feet depth

Quantity

A minimum for this project was 1 full* scaled model, 1 mini** model, and a training manual to

create the pump to be completed by the delivery date (May 26, 2014). *=6.096 meter or 20 feet

depth, **= 0.6096 meters or 2 feet depth

21

Environmental Issues

Product must be created with the aim to create zero environmental issues. The parts for the

pump are to be used from reusable waste or recycled materials.

Safety

Operation of the pump must not harm the operator in any way and thus will have a guard

protecting the crank mechanism, the rope, the piping from the well, as well as over the well.

There will be zero sharp edges to be cut on.

Quality

Commonly the rope on the rope pump is most likely to fail. The rope is to be made from a

material with a high UV resistance, low water absorption rate (less than 20% water absorbed of

its weight in water if full emersion of rope in water for one hour), little to no elasticity, and be

able to withstand a water PH level of at least 7.5. The pipe is to be made from a low pressure

material that does not break down by UV rays and constant water usage (must last 10 years

before breaking).

Energy Consumption

Energy that the pump must consume in order to operate is a critical design specification to meet.

The majority of people who use the pump on a daily basis are women and children. The women

and weaker children must be able to crank the handle with little difficulty. This means that the

force exerted on the handle by the user must be below a specified value. This value is currently

unknown but will be determined through experimentation. This experiment will involve a crank

that is to be turned by several willing volunteers. These volunteers will be of varying gender,

age, strength, and height. This large sample size will allow for the most accurate results. Each

volunteer will turn the crank several times each having varying resistance. From this, the

maximum force that any given person is able to exert on the crank can be determined. Using

these results, that maximum force can be applied to the rope pump design and in turn meet this

design specification of 75 watt input, at 5 m head or about 4.5 m/hour.

Reliability

Since the pump is used on a regular basis, reliability is an essential factor. All components must

be able to withstand daily utilization without breaking for at least 1 year. This includes the rope,

piping, rubber stoppers, crank mechanism, handle, and support structure. The rope must be able

to withstand the exerted forces and constant rubbing/friction against the piping without stretching

beyond functionality or breaking. The piping must not wear down beyond functionality or crack

at any location along the 20m span. The rubber stoppers must keep a strong seal in the piping

and not wear from the friction along the piping. The crank mechanism and handle cannot fatigue

or fail due to repeated use. The support structure must be strong enough to take the repeated

22

loading and not fatigue or fail. Since the pump will produce a consistent flow rate of 5 gpm

throughout its expected lifespan of 20 years, reliability is essential.

Maintenance

Bases upon reliability, the pump needs to be able to go untouched/maintenance free for a 1-2

year period. This entails that no components will break or fatigue beyond functionality for at

least one year (see reliability). Beyond that, simple lubrication or rope replacement may be

needed. After 1 year of use, and every one year thereafter, the pump should be inspected for any

wear and determine if components are in need of repair or replacement. Potential crank

mechanism repairs/replacement may be needed after 5 years due to climate. This includes the

wheel and handle of the crank. All routine maintenance must be able to be completed with the

limited tool supply of the locals and require no power machinery. The piping material should be

able to last at least 10 years before breaking

Mechanical Loading

All moving components of the pump must be able with withstand at least 5 years of repeated

loading without major fatigue or failure, averaging about 10,000 cycles. These moving

components of the pump include the internals of the crank mechanism. Aside from routine yearly

maintenance of lubrication, the mechanism must be able to withstand regular use for 5 years

without having to be replaced. This means that material choice has a large impact on the lifespan

of the crank mechanism components. Therefore, this material selection will be researched and

chosen carefully.

Size

Overall height must be no more than 6 feet tall so that all repair/maintenance can be accessed

easily without help from equipment. This will ensure more efficient maintenance and all

components are within arms-reach if a situation arises. The crank handle is to be no more than 4

feet from the ground as children must be able to operate the pump without assistance. When

disassembled, all components must be small enough to be transported easily (see transportation

and packaging).

Weight

Total weight of the product must be no more than 50 pounds but may vary due to well depth.

Rope pumps must be heavy enough that it does not move around or tip will in use. On the other

hand, components must be light enough that transportation by hand is possible. The given 50

pound constraint is for a pump capable of reaching a depth of 20m. Pumps beyond 20m may

weigh upward of 50 pounds due to the additional piping and rope needed.

23

Spatial Constraints

There are zero spatial constraints as the pump will be utilized in an open outdoor environment.

Aside from any size design specifications (see size).

Aesthetics

All metal components are to be coated in a single color of durable/anti-rust paint that is not

offensive to the culture of Ugandan people. Part of aesthetics includes the touch and feel of the

product. All edges will be rounded smooth with at least a 0.020 radius. The product will appear

clean, smooth and simple. There will be a maximum of 60-65 decibels, the equivalent of a

normal conversation, generated from operation, no decibels generated when stationary, and no

noise pollution created. The product will appeal to the lower class (bottom 30% of the population

in terms of income) and for all age groups.

Transportation and Packaging

All components of the pump must be small enough to be transported easily in an available

vehicle (approx. 2m x 2m x 2m). The piping must be assembled from short 3-5m sections as

transportation of 20m length piping is not possible. All parts will be packaged separately except

for any fasteners and pipe fittings which will be bagged together. All other components will be

wrapped in 1 layer of bubble wrap and in one cardboard box.

Personnel

People using this pump are men, women, and children of all ages, sizes, strength, and nutrition.

The design is to specialize in ease of use for women and children in order to meet the previous

criteria. The product will utilize only one person for operation.

Service Life

Under normal service conditions the pump must be able to continue to function properly with

minimal repair and maintenance for a 5 year period. All components of the pump must be able

with withstand at least 1 year of repeated loading without major fatigue or failure. The required

repairs during the service life will be rope replacement annually, paint after 3 years and new

crank bearings after 3 years.

Noise Radiation

Noise pollution must be less than 60 dB as the operator must stand directly next to the pump for

operation. To reduce noise all moving joints will be greased with wheel bearing grease, including

the crank mechanism bearings.

24

Operation Instructions

One manual is to be provided displaying how the mechanism works, how to assemble and install,

how to operate, and tables showing the ideal diameters of pipe/rope for various well depths. The

manual will be written so that anyone over the age of 14 in a third world country can understand,

install, maintain and operate the rope pump.

Human Factors

Rope Pumps must be designed in such a way that human interaction is ergonomically feasible.

Design of the pump will incorporate ease of maintenance, operation and installation. The overall

installed height of the pump shall not exceed 4 feet. A mechanical advantage of at least 2 will

allow anyone to operate the crank mechanism and pump water. Use of the pump will be

desirable with noise pollution under 60 dB, mechanical advantage, ergonomic grip, and

satisfactory water outputs.

Health Issues

Rope pumps will not cause any adverse health effects. In fact with the clean filter option it can

actually eliminate 99.9% of water-borne disease through the use of a bio-sand filter. Any pinch

points will be covered or addressed to eliminate any accidental injuries. An auto locking feature

will also be included to prevent the wheel from reversing in direction while there is water in the

pipe causing it to spin rapidly and cause possible injury. All materials will be non-toxic

according to US regulations to prevent any toxins from entering the water stream.

Government Regulations

There are zero government regulations regarding types of pumps used. No government

regulations currently exist that prevents any of the materials needed to construct the rope pump

from being imported if needed.

Shelf-Life Storage

Replacement parts for the rope pump should be available in local shops or junkyards. At these

shops the parts would have a limited life span of 10 years before degradation will occur in the

polyester rope and rubber stoppers. Metal components (wheel, cover, handles) as long as they are

kept out of the weather have a very long life span of nearly 100 years.

Operating Costs

There is to be zero operating costs outside of routine maintenance and replacement parts. Human

input is used to power the machine unless it is wind driving getting rid of the fuel operating cost.

Once the rest of the parts are purchased and assembled on a already dug well there are no further

costs to the user besides the use of human power.

25

Environmental Conditions

Access to safe drinking water is a widespread problem throughout most of Uganda. This leads to

many illnesses including intestinal parasites and amoebic dysentery, among others. Industrial and

agricultural runoff and intentional pollution is dumped into the rivers and lakes by commercial

farms. Products will be made of materials used to withstand UV light that is greater than 3 eV

with exposure lasting an average of 16 hours a day year round.

26

CHAPTER THREE: METHODOLOGY

3.1 Overview

This chapter contains how the research was conducted and the major description of

the methods which were used to obtain data, tools and instruments used in the design

of the bicycle powered rope pump.

3.2 Research Design

The research of this project was designed basing largely on the study of the pedal-

powered rope-pump, as regards, the structure of the rope pump, bicycle power and

pedal power, pumping water using a bicycle and the drive design specifications.

3.3 Data Source

In this design, research was based on both the primary and secondary sources of

information.

3.3.1 Primary Sources

This was directly obtained from different pump dealers online including among

others and various domestic water pumping systems already in use in Uganda in

different homesteads.

3.3.2 Secondary Sources

This data type was obtained from mechanical engineering text books like

mechanical engineering design, rated design. Other sources included the previous

reports done already by colleagues in the same field of engineering.

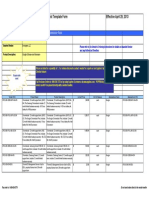

3.4 Data Collection Method

This was our major tool in arriving at our final design consideration. Each design

specification was rated based upon weighting factors. Rating was done on a scale of 1

to 5, where 5 is the most important. The results are tabulated in Table 1 below.

27

From the Weighting Factor table shown above, it is evident that some design specifications

heavily outweigh and hold more importance than others. The design specifications that had a

weighting factor of five, therefore being of utmost important, are function/performance, product

cost, safety, quality, noise radiation, operating instructions, human factors, health issues, and

environmental conditions. As a result, those design specification were be always considered

when choosing a final design.

28

CHAPTER FOUR: PRESENTATION AND DISCUSSION OF FINDINGS

4.1 Overview

This chapter presents the findings on the different studies made, the various components

considered in the design of the bicycle powered rope pump and the intended design

under study.

4.2 Conceptual Design Concepts

Conceptual ideas below were the result of hours of research and contemplation, which

were most certainly subject to change, as well as included additional ideas as the project

progressed and experimental results proved an idea worthy of use or not.

4.3 Drive Design Concept 1

Drive design concept 1 is through the use of an indoor bicycle trainer device (see Figure

1). Drive design concept 1 is a simple, yet effective, structure that suspends the rear

wheel of the bicycle off of the ground allowing the user to pedal in place. There is also a

small wheel that the rear wheel of the bicycle rests on. Normally, this is used to create

resistance to the user; however, we have no use for the resistance mechanism. Instead,

that small wheel will be linked to the top rotating wheel of the rope pump. Therefore, as

the bicycle is pedaled it will turn the small wheel, thus rotating the top wheel of the rope

pump. Two wheels will be linked using a bicycle chain or of the same rope used in the

pump itself. Drive design concept 1 will allow the user to pedal their bicycle in place and

simultaneously pump water with minimal effort.

Figure 1: Example of Stationary Bike Trainer

There exists several pros and cons of this design concept. The first pro is that the bicycle

is easily removable. The user can use their personal bicycle, attach it to their rope pump,

29

and then disconnect and ride away when finished. It will require no modification to the

bicycle and is also very easy to use. Simply clamp in the rear axle of the bicycle between

the pins, and it is ready to use. So another pro is ease of use. Since the device is of

simplistic design and has minimal moving parts, it is less likely to break. This will be

beneficial as it creates less maintenance for the user. Another pro is the compact size,

allowing for easy transportation to storage or to another rope pump.

Design Concept 1 also has several cons. First being that is may be difficult to build with

available materials. Since it must support the weight of the rider, the device must be

made of high strength steel. It also requires very accurate and reliable bearings and

requires the rider to need more stability to use. Since the bicycle is only supported by the

rear wheels axle, the rider must keep high balance or else they may fall over. Design

Concept 1 may prove difficult if children utilize the device. Another con is it may be

easily susceptible to theft due to its small and lightweight size. There is the potential for

slip between the bike tire and the small wheel on the device. If a large force is needed to

turn the pump wheel, slip may occur if not enough force is being applied to the wheel

and may cause a loss of efficiency in the pump.

4.4 Drive Design Concept 2

Drive Concept 2 also utilizes a stationary bicycle trainer device. Design of this device is

much different than the previous. This device utilizes a set of long rollers placed parallel

to each other (see Figure 2). The rear wheel of the bicycle sits in the gap between the two

rollers (see Figure 3). So the rider can pedal in place and turn the rollers that are in

contact with the rear wheel. Transferring the power between the device and the pump is

the same as Design Concept 1. One of the rollers will be linked to the top wheel of the

rope pump. Therefore, as the bicycle is pedaled it will turn the rollers, thus rotating the

top wheel of the rope pump. The roller and pump wheel will be linked using a bicycle

chain or of the same rope used in the pump itself and will allow the user to pedal their

bicycle in place and simultaneously pump water with minimal effort.

30

Figure 2: A second example of a Stationary Bike Trainer

Figure 3: Example of a Roller Bike Trainer

31

One pro of this design concept is that there is no attachment of the bicycle to the device

needed. Since the bicycle simply rests on top of the rollers, no modification to the bicycle

is necessary. One can use their personal bicycle and ride away when finished pumping

water. Similar to the first design concept, the device has minimal moving parts and is

very simplistic, creating less maintenance for the user. Another pro is that it could be

built easily with available materials and can be made of wood, PVC piping, and basic

hardware (see Figure 3), resulting in lower costs. Design Concept 2 is that there will be

minimal slip between the roller and the bicycle tire. Unlike design concept 1, 100% of

the rider weight will be directly on the rollers. Create a larger force and more friction

between the tire and roller will result in minimal slip. Therefore, pump efficiency will be

high.

Cons of this design concept include high stability of rider, high chance of theft, and a

heavier rider is required. Since the bicycle is not supported in any way, the rider must

keep perfect balance otherwise they may fall over and may prove difficult for children to

accomplish. Theft is a big con as the device is lightweight and small. Therefore, the

device must be secured to avoid theft. Lastly, Drive Design Concept 2 will have it so that

a light rider will not be as efficient as heavy riders. Since, the amount of friction between

the roller and tire depends on the weight of the user; lighter riders will not create as much

friction. In turn, when being used by a lighter rider, slip may occur between the rollers

and tire, causing a decrease in pump efficiency.

4.5 Drive Design Concept 3

Design Concept 3 involves joining the bicycle axle with the top rope pump wheel axle.

The rear of the bicycle will be supported off of the ground at the same vertical height as

the top wheel of the rope pump and will have the bicycles rear axle be lengthened and

supported by a frame (see Figure 4). The top pump wheels axle will also be lengthened

in such a way that the two axles (bike and pump) can be joined together. Axles will be

connected using simple hardware that can be easily undone for removal. Since the

bicycle wheel and pump wheel now share an axel, pedaling the bike will turn the pump

wheel simultaneously pumping water with little effort.

32

Figure 4: Example of a Mounted Stationary Bike Trainer Pumping Water

33

One major pro of this design concept is that 100% of the power is transferred from the

bicycle to the pump, resulting in a high efficiency. Since both wheels share an axle, there

is no possibility for any type of slip. There is also no extra stability required of the rider.

This is due to the rear axle being completely supported by a frame. The rider has no fear

of falling over. Another pro is that any size or age of person can utilize it. Weight is not a

factor of efficiency like the previously discussed design concepts and can also be easily

constructed from available materials and is of simplistic design. Lastly, since the frame is

large and heavy, chances of theft decrease significantly.

Major cons of this design concept are that the rear bicycle wheel must be at the same

vertical height as the top pump wheel. Therefore, if the rope pump was built with a high

wheel, the bicycle will have to be supported very high as well. Another major con is that

this design will require some modification to the bicycle. The rear axle must be extended

and makes removal of the bicycle much more difficult. The bicycle will still be rideable,

but with some slight modifications. Connection of the two axles may also prove fairly

difficult and connections must be secure, but also not permanent in order to remove the

bicycle after use.

4.6 Drive Design Concept 4

Design Concept 4 uses friction between the rear bicycle wheel and the top rope pump

wheel. The rear wheel of the bicycle is supported just off of the ground by the axle,

similar to Design Concept 1. It is placed in such a way that the tire butts up against the

top wheel of the pump (see Figure 5). Therefore as the bicycle wheel is turned, it will

turn the pump wheel by friction between the tire and pump wheel. Pedaling the bicycle

will pump water with minimal little.

34

Figure 5: Example of a Mounted Bike Being Used to Pump Water

Pros of this design concept include similar ones to those of the previously discussed

design concepts. One being that there is no extra stability needed to utilize the pump.

User will have no fear of falling over because the rear wheel is supported by a frame.

Any size or age person can operate this device and weight has no effect of pump

efficiency. Design Concept 4 is very simplistic and can be easily built from available

materials. Since the structure is secured to the ground, theft is less likely to occur.

Another pro of this design concept is that no modification is done on the bicycle.

Securing the wheel is similar to design concept 1, therefore removal is simple and fast.

The bicycle can be ridden normally after the user is done pumping water.

One con of the design concept is that the rear wheel of the bicycle must be supported off

of the ground. Another major con of the design is that slip may occur between the tire

35

and pump wheel. If there is not enough force between the two wheels, friction will be

lowered and slip will occur. Thus, the efficiency of the pump will go down.

4.7 Drive Design Concept 5

Design Concept 5 involves some modification to the bicycle. A small third wheel is

mounted to the front of the bicycle (see Figure 6) and the wheel is linked to the main

sprocket of the bicycle using a chain. The rear wheel of the bicycle must be supported

just off the ground so it can rotate freely and is then connected to the top pump wheel by

chain or the same rope used in the pump itself. As the bicycle is pedaled, the attached

third wheel will rotate, and in turn rotate the top pump wheel. Thus, pedaling the bicycle

will pump water with minimal effort.

Figure 6: Mounted Bike Being Used for Mechanical Power

A major pro of this design concept is that 100% of the power is transferred to the pump.

Since there is no friction necessary, no slip will cause a lowered efficiency and also

requires no extra stability to ride. There is no fear of the rider falling over because the

rear wheel of the bicycle if fully supported. Another pro is that any age or size person

can utilize the device with ease. Another bonus is that the entire concept can be built

from available materials and extra bicycle parts. Lastly, since the drive connection device

is attached to the bicycle, theft will not be a factor.

An obvious con of this design concept is that major modification must be done to the

bicycle. A third wheel must be attached and extra chain run to that wheel. Bicycles will

36

not be rideable with the chain attached to the third wheel. In turn, removal of the bicycle

from the pump is difficult and requires the removal of a chain. This concept is also more

difficult to construct. Bicycle modification must be precise and accurate in order for it to

operate properly. Materials are readily available, but skill level of the worker must be

high.

4.8 Drive Design Concept 6

In the final design concept, a few major modifications were added to the bicycle and are

permanently attached. These modifications include the rear tire of the bicycle is removed

from the rim, the rear end of the bicycle is mounted to a support frame near the top wheel

of the pump, and finally the rear bicycle wheel and top pump wheel is connected via

rope, just at the rope runs around the rim of the pump wheel (see Figure 7). There will be

tension in the rope and friction will cause the wheels to turn in unison. Pedaling the

bicycle will turn the pump wheel, thus pumping water with minimal effort.

Figure 7: Another Example of a Mounted Bike Being Used for Power

37

Pros of this design concept includes: extra stability, accept a wide range of users, and is

easily constructed. There is no extra stability required to utilize this device because the

entire bicycle is supported by a frame. This means that the rider will have no need to fear

of falling over. This concept also accepts a wide range of users. Any age, size, or gender

person can operate the pump with ease. Weight has no effect on pump efficiency. Lastly,

the device is easily constructed from readily available materials. Design of the structure

is simplistic and easy to build.

This design concept has numerous cons, first being that heavy modification of the

bicycle is needed. Due to the modification, bicycle will no longer be rideable and will not

be removable like in the previous design concepts. Since the bicycle must be left at the

location of the pump, theft is a large factor. Parts and main components may be stolen

and it will no longer be usable. The last con is that slip may occur. There must be high

tension in the rope running from the rear bicycle wheel to the top pump wheel.

Otherwise, slip will occur and pump efficiency will decrease significantly.

4.9 Drive Design Concept Weighting Factors

When choosing the top design concept, several weighting factors come into play. All of

which are a factor in the design concept. They may either be a benefit or a downfall of

the design. This brings to question of what factors are most important and why. It is

critical to specify what factors have the biggest impact on the possible success or failure

of the design. Weighting factors that were examined and rated for our six design

concepts are:

1 Bicycle is easily removable from pump

2 Bicycle requires no modifications

3 Bicycle is still ride able after use

4 Simple to construct

5 Can be made of readily available materials

6 Device is not susceptible to theft

7 Requires no extra or special ability to operate

8 High power transfer efficiency

9 Device is easily maintained

10 Wide range of people can operate the device with ease

Drive Design Concept Ranking

All weighting factors were evaluated for each conceptual design concept. If the design

concept satisfied the condition, it was given a 1. If the design concept did not satisfy

the condition, it was given a 0. Each design concept was then totaled. Each of the

design concept(s) with the highest score were the top concepts rated by the weighing

factors. Results from the tabulated analysis are shown below:

38

Table 2: Drive Design Concept Ranking

Co

nc

ep

t 1

Co

nce

pt 2

C

o

n

ce

pt

3

Co

nc

ep

t 4

C

o

n

ce

pt

5

C

o

n

c

e

p

t

6

Easily Removable 1 1 0 1 0

0

No Modifications 1 1 0 1 0

0

Bike Still Rideable 1 1 1 1 1

0

Easy Construction 1 1 0 1 0

1

Available Materials 0 1 1 1 1

1

Low Chance of

Theft

0 1 0 0 1

1

Low Ability

Required

1 0 1 1 1

1

High Efficiency 0 0 1 0 1

1

Easily Maintained 1 1 1 1 0

1

Usable by All

People

0 0 1 1 1

1

TOTAL: 6 7 6 8 6

7

39

According to the ranking system, conceptual design concept 4 is the best choice based

upon the chosen weighting factors. Design concepts 2 and 3 are close behind with one

less point than the top choice.

Structure Concept 1

Structure Concept 1 will be a basic A-Frame design with steel plates to reinforce critical

joints (see Figure 8). A- Frames are known to be very durable. Size and simplicity of

design means fairly easy construction. This design limits the amount of space

underneath and can not fit as many well sizes.

Figure 8: Drawing of A-Frame Pump Design

Structural Concept 2

Structure Concept 2 (see Figure 9) will consist of a square base with a A-Frame riser.

This design allows for a wider base and is simple to construct. This concept is better for

fitting more well types and is less spatially constrained. This design requires slightly

more material than concept one as it has 4 additional legs.

40

Figure 9: Drawing of Trapezoid Based Pump

Our Problem Solving Approach

We chose to join the bicycle axle with the top rope pump wheel axle. This was done

using a detachable chain (a removable link) to ease work for connecting and

disconnecting the bicycle drive from the rope pump.

The rear of the bicycle is supported off of the ground to some suitable vertical height

using a simple frame to enable the behind wheel rotate and transfer drive. The wheel

axle for the rope pump is an old bicycle wheel. One major pro of our design concept is

that 100% of the power is transferred from the bicycle to the pump resulting in a high

efficiency.

Another pro of our design is that any size or age of person can utilize it. Weight is not a

factor of efficiency compared to previous designs. The other pro is that the bicycle is still

rideable after use.

41

Final Design Assembly (Sketch)

We used a quick release chain link to transfer the drive from the rear end of the bicycle to

the rope pump wheel axle.

Mathematical Model

A person can generate four times more power (1/4 horsepower (hp)) by pedaling than

by hand-cranking. At the rate of 1/4hp, continuous pedaling can be done for only short

periods, about 10 minutes. However, pedaling at half this power (1/8 hp) can be

sustained for around 60 minutes. Pedal power enables a person to drive devices at the

same rate as that achieved by hand-cranking, but with far less effort and fatigue. Pedal

power also lets one drive devices at a faster rate than before.

The power levels that a human being can produce through pedaling depend on how

strong the pedaler is and on how long he or she needs to pedal. If the task to be powered

will continue for hours at a time, 75 watts mechanical power is generally considered the

limit for a larger, healthy non-athlete. A healthy athletic person of the same build might

produce up to twice this amount.

A person who is smaller and less well nourished, but not ill, would produce less; the

estimate for such a person should Probably be 50 watts for the same kind of power

production over an extended period.

42

Pedaling Rate

How fast should a person pedal? A simple rule is that most people engaged in delivering

power continuously for an hour or more will be most efficient when Pedaling in the

range of 50 to 70 revolutions per minute (rpm). For simplicity's sake, we used 60 rpm, or

one revolution of the pedal cranks per second, as an easy reference value for estimates of

the gear ratios required to drive a given load.

Economic Evaluation of The Design

Rope Pump

For the total cost of the rope pump, all of the necessary materials and the quantity needed

are listed in the table below along with their corresponding prices.

Table 6: Cost Breakdown for Rope Pump

20m (65.6168ft.): PVC Pipe

Shs.18750

(7) Couplers Shs.7000

(1) 1/2 Bushing Shs.3000

(2)1/2 Ts Shs.2300

40m (131.264ft.)5/32 Polypropylene

Rope

Shs.25000

(2) cans of spray Paint Shs.20000

Rubber Sheet Shs.12000

Glue and Primer for PVC Shs.31000

#10 Washers Shs. 20000

3/16 Mild Plate Steel Shs. 10000

9ft.1 OD Mild Steel Tubing Shs.45000

TOTAL Shs.194050

Bike Mount

For the cost of the optional bike mount, all of the necessary materials and the quantity

needed are listed in the table below along with their corresponding prices.

43

Table 7: Cost Breakdown for Bike Mount

9ft. 1 OD Mild steel

Tubing

Shs.44000

(2) Pins for Risers Shs.5000

8ft. Bike Chain Shs.25000

(2) Casters Shs.40000

9ft.1 OD Mild Steel

Tubing

Shs.45000

(1)Can of Spray paint Shs.7500

TOTAL Shs.166500

Other Costs

Old Bicycle Cost Shs.150000

2 Sprockets Shs.70000

Hacksaw Shs.30000

4 Pins Shs.15000

Miscellaneous Shs.100000

Inflation estimates Shs.90000

TOTAL Shs.450000

The Overall cost estimate for our design comes to Shs.815550 which is less than one million

Ugandan shillings.

44

CHAPTER FIVE: CONCLUSION AND RECOMMENDATION

5.1 Overview

This chapter includes the conclusions on the intended design, the consequences and the

challenges encountered during the processes of developing the system. Furthermore in this

chapter there has been a number of recommendations drawn for purposes of adoption and also

aid for further related research.

5.2 Conclusion

This project focused on designing a bicycle powered rope pump for rural communities where

there exists no piped water and other means of extracting water egg boreholes are distant to

access for an average family. Basing on the findings of the study, the following conclusions have

been drawn;

There is need to tap into multi-function designs that can be applied to agriculture as far as

mechanical (pedal) power is concerned.

Our developed design means that the bicycle is still reusable for transport purposes after

its been engaged in pumping purposes, this means that an average family that already

has a bicycle doesnt incur an extra cost when it comes to getting pedal power, the only

costs incurred are those involved in the design of the rope pump and the bike mount plus

the drive connections.

Theres limited data when it comes to well-depths in Uganda and the depth of the water

tables, this in one way or another limited our study and may have contributed to a certain

degree of error.

Apart from using pedal power for pumping, it can further be applied to powering other

machines. These include; bicycle mills, bicycle blenders and bicycle nut shellers among

others, thus our design should simply be the tip of the ice burg as far as pedal power is

concerned in Uganda.

5.3 Recommendations

With regard to the process undertaken in the compilation of this document, the observations

made and the system developed, the following recommendations have been drawn;

The design should be adopted by government, especially for areas that are similar to

Buikwe district. This will enhance agricultural production, improve health through access

to safe water and also solve the energy problem.

Further research should be done on other ways of making a bicycle reusable after

pumping moments, in a way that aims at optimization and efficiency. Research should

also be done on other pumps other than rope pumps that could be used for the same

purpose at a cheaper cost.

45

Finally, we propose that further research is carried out as far as pedal powered machines

are concerned as this could solve many problems for this agricultural nation, with the

majority of areas lacking access to electricity.

46

REFERENCES

1. Piloting the Rope Pump in Ghana, A WaterAid Briefing Paper-2004-No.1

2. http://en.wikipedia.org/wiki/Rope_pump

3. Darrow, Ken, and Pam, Rick. "Energy: Pedal Power," from Appropriate Technology

Sourcebook pp.189-196. Stanford, California: Volunteers in Asia, Inc., 1977.

4. "Pedal Power," a supplement to Energy for Rural Development. Washington, D.C.:

National Academy Press, 1981, pp. 137-148.

5. Whitt, Frank Rowland, and Wison, David Gordon. Bicycling Science. 2nd ed.

Cambridge, Massachusetts: The MIT Press, 1983.

6. http://appropriatetechnology.wikispaces.com/Bicycle+Water+Pump

7. Sustainable Water Demonstration Final Report by Bryan Dripps, Heather Reinhart and

Michael Henderson

S-ar putea să vă placă și

- Solar Powered Seed Sprayer: A Report on the Design of a Solar Powered Seed Spraying MachineDocument15 paginiSolar Powered Seed Sprayer: A Report on the Design of a Solar Powered Seed Spraying MachineSiddharth KumarÎncă nu există evaluări

- Paddle Powered Water PumpDocument35 paginiPaddle Powered Water PumpJahanzaib Khan100% (1)

- Final Thesis - 2Document48 paginiFinal Thesis - 2pratik giradkarÎncă nu există evaluări

- Design Plastic Bottle CrusherDocument4 paginiDesign Plastic Bottle CrusheragungÎncă nu există evaluări

- Compressed Air VehicleDocument21 paginiCompressed Air VehicleHarshit Dhawan100% (1)

- And Analysis of Pedal Power Water Pumping System 1 2 PDFDocument11 paginiAnd Analysis of Pedal Power Water Pumping System 1 2 PDFAnonymous 5OwMUDOIYÎncă nu există evaluări

- Rice Transplanter DesignDocument74 paginiRice Transplanter Designhoney mae100% (1)

- Pedal Powered Centrifugal Water Pump DesignDocument14 paginiPedal Powered Centrifugal Water Pump Designshareena tajÎncă nu există evaluări

- Electrical Power Generation Using Shock AbsorberDocument4 paginiElectrical Power Generation Using Shock AbsorberPushpa Mohan RajÎncă nu există evaluări

- Coconut Dehusking MachineDocument16 paginiCoconut Dehusking MachineArjuncv100% (4)

- Automatic Brake Failure Detection and Emergency Braking SystemDocument66 paginiAutomatic Brake Failure Detection and Emergency Braking Systemrohith kuruvaÎncă nu există evaluări

- Design and Fabrication of Motorized Hydraulic Jack SystemDocument8 paginiDesign and Fabrication of Motorized Hydraulic Jack SystemIJRASETPublicationsÎncă nu există evaluări

- Design & Fabrication of Portable Organic Waste Chopping Machine To Obtain CompostDocument8 paginiDesign & Fabrication of Portable Organic Waste Chopping Machine To Obtain CompostIJIRSTÎncă nu există evaluări

- ProjectDocument31 paginiProjectMR. CØØLÎncă nu există evaluări

- Design and Construction of A Plastic Shredder Machine For Recycling and Management of Plastic WastesDocument7 paginiDesign and Construction of A Plastic Shredder Machine For Recycling and Management of Plastic Wastesmd asifÎncă nu există evaluări

- Fabrication of Pedal Powered Water Purifier: V.Sridhar, G.Vinay, K.Sai Ram, B.Ajay RamDocument9 paginiFabrication of Pedal Powered Water Purifier: V.Sridhar, G.Vinay, K.Sai Ram, B.Ajay Ramvidu rathodÎncă nu există evaluări

- Design of Solar Steam Pump For Irrigation ProposalDocument13 paginiDesign of Solar Steam Pump For Irrigation ProposalAbebaw AyeleÎncă nu există evaluări

- Adigrat University: Pedal Operated Water Pump (Concrete Pedal Pump)Document50 paginiAdigrat University: Pedal Operated Water Pump (Concrete Pedal Pump)Melese HaileÎncă nu există evaluări

- Pedal Operated Multi-Operational Machine 1Document9 paginiPedal Operated Multi-Operational Machine 1John P0% (1)

- Design and Development of Road Power GenerationDocument11 paginiDesign and Development of Road Power GenerationRyan Joseph ManigbasÎncă nu există evaluări

- Introduction Edited On 09-05Document77 paginiIntroduction Edited On 09-05maleka anjum100% (1)

- Design and Fabrication of Pedal Operated Water PumpDocument14 paginiDesign and Fabrication of Pedal Operated Water PumpNagesh Sunny67% (3)

- Final Project Report Foot Step (With Out Footer)Document47 paginiFinal Project Report Foot Step (With Out Footer)Deepak Raj R100% (3)

- Design and Fabrication of Motorized Screw Jackdocx Final ReportDocument32 paginiDesign and Fabrication of Motorized Screw Jackdocx Final Reportsmartxdigital marketÎncă nu există evaluări

- Regenerative Shock Absorber Converts Vehicle Vibration into ElectricityDocument24 paginiRegenerative Shock Absorber Converts Vehicle Vibration into Electricityvineeth100% (1)

- Project Submitted in Partial Fulfillment of The Requirement For The Award of Degree ofDocument42 paginiProject Submitted in Partial Fulfillment of The Requirement For The Award of Degree ofDinesh WasalwarÎncă nu există evaluări

- Automatic Head Lamp Alignment SystemDocument48 paginiAutomatic Head Lamp Alignment SystemAakash Dindigul100% (1)

- Sand Slinger MC Pneumatic 2016 VeltechDocument47 paginiSand Slinger MC Pneumatic 2016 VeltechChockalingam AthilingamÎncă nu există evaluări

- Construction of 4-Lane Flyover at Amberpet Mini Project PresentationDocument9 paginiConstruction of 4-Lane Flyover at Amberpet Mini Project PresentationVujjini RaghuÎncă nu există evaluări

- 586-Automatic Transformer Heat Reduction SystemDocument4 pagini586-Automatic Transformer Heat Reduction SystemAmit Mohapatra100% (1)

- Design and Fabrication of Power Generation Shock AbsorberDocument1 paginăDesign and Fabrication of Power Generation Shock AbsorberVijay GanapathyÎncă nu există evaluări

- Design and Fabrication of Pendulum Based Water PumpDocument6 paginiDesign and Fabrication of Pendulum Based Water PumpVeljko MilkovicÎncă nu există evaluări

- Design and Fabrication of Mechanical Footstep Power GeneratorDocument19 paginiDesign and Fabrication of Mechanical Footstep Power GeneratorMonika kakadeÎncă nu există evaluări