Documente Academic

Documente Profesional

Documente Cultură

Index For Aws

Încărcat de

Vijay Chander Reddy KeesaraDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Index For Aws

Încărcat de

Vijay Chander Reddy KeesaraDrepturi de autor:

Formate disponibile

INDEX FOR AWS

1) Recommended practices for welding of austenitic chromium nickel steel tube and

piping

2) Recommended practices for welding of chromium molybdenum steel tube and

piping

3) Recommended practices for local heating of of welds in pipes and tubes

4) Recommended practices for root pass welding of pipes with out backing

WELDING TECHNOLOGY

1. Survey of joining and cutting process

2. Physics of welding

3. Heat flow in welding

4. Welding Metallurgy

5. Design for welding

6. Symbols for welding and inspection

7. Residual Stresses and distortion

8. Welding and cutting costs Estimation and control

9. Fixtures and Positioners

10. Automation and control

11. Welding Quality

12. Testing for evaluation of welding

13. Codes and other standards

14. Qualification and certification

15. Inspection

16. Safe practices

17. Terms and definitions

18. S I Units

WELDING PROCESS

1. Arc Welding power sources

2. Shielded Metal Arc Welding

3. Gas Tungsten Arc Welding

4. Gas Metal Arc Welding

5. Flux Cored Arc Welding

6. Submerged Arc Welding

7. Electrogas Welding

8. Electro Slag Welding

9. Stud Welding

10. Plasma Arc Welding

11. Oxyfuel Gas Welding

12. Brazing

13. Soldering

14. Oxygen Cutting

15. Arc Cutting and Gouging

16. Laser Beam Welding

17. Spot, Seam and Projection Welding

18. Flash, Upset and Percussion welding

19. Resistance welding equipment

20. High frequency welding

21. Electron Beam welding

22. Laser beam welding

23. Friction welding

24. Explosion welding

25. Ultrasonic welding

26. Diffusion welding

27. Adhesive bonding of metals

28. Thermal spraying

29. Other welding process

30. Welding hand book index

MATERIALS AND APPLICATIONS

1. Aluminum and Aluminum Alloys

2. Magnesium and Magnesium Alloys

3. Copper and Copper alloys

4. Nickel and Cobalt alloys

5. Lead and Zinc

6. Plastics

7. Composites

8. Ceramics

9. Maintenance of repair welding

10. Underwater welding and cutting

11. Welding hand book index.

MATERIALS AND THEIR WELDABILITY

1. Carbon and low alloy steels

2. Stainless Steels

3. Tool and Die Sheets

4. High alloy steels

5. Cast Iron

6. Nickel and cobalt alloys

7. Copper Alloys

8. Aluminum Alloys

9. Magnesium Alloys

10. Titanium, Zirconium, Hafnium, Tantalum and Columbium

11. Other metals

12. Dissimilar metals

13. ndex

ENGINEERING COST QUALITY AND SAFETY

1. Design for welding

2. Symbols for welding and brazing And NDT

3. Economics ad cost estimating

4. Fixtures and Positioners

5. Automation and control

6. Codes and standards

7. Qualification and certification

8. Weld quality

9. Inspection

10. Safe practices

S-ar putea să vă placă și

- The Practical Metal-Workers' AssistantDocument716 paginiThe Practical Metal-Workers' Assistantfer75333% (3)

- Fundamentals of Joining ProcessesDocument21 paginiFundamentals of Joining ProcessesNosta Silva100% (1)

- 3 Unit 2 - Arc, Gas, Plastic Welding, LBW, EBW and Thermit WeldingDocument96 pagini3 Unit 2 - Arc, Gas, Plastic Welding, LBW, EBW and Thermit WeldingAditya KumarÎncă nu există evaluări

- Applied Welding Engineering: Processes, Codes, and StandardsDe la EverandApplied Welding Engineering: Processes, Codes, and StandardsÎncă nu există evaluări

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesDe la EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesÎncă nu există evaluări

- Welding and Cutting ProcessDocument60 paginiWelding and Cutting Processquiron2010100% (1)

- Module 6 PDFDocument180 paginiModule 6 PDFyoustruelyÎncă nu există evaluări

- Unit - IIDocument143 paginiUnit - IIjyothiÎncă nu există evaluări

- VC Constructions Business PlanDocument15 paginiVC Constructions Business PlanVijay Chander Reddy KeesaraÎncă nu există evaluări

- IridiumDocument11 paginiIridiumVijay Chander Reddy Keesara100% (1)

- Handbook On Electroplating With Manufacture of ElectrochemicalsDocument13 paginiHandbook On Electroplating With Manufacture of ElectrochemicalsAbeerÎncă nu există evaluări

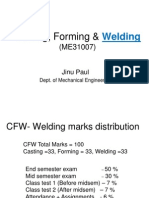

- Casting, Forming & WeldingDocument90 paginiCasting, Forming & WeldingmahdiÎncă nu există evaluări

- Welding Technology Two MarksDocument20 paginiWelding Technology Two Markssai100% (1)

- Capitive Power Plant For Rice MillDocument152 paginiCapitive Power Plant For Rice MillVijay Chander Reddy Keesara100% (1)

- Welding MidsemDocument100 paginiWelding Midsemamit kumarÎncă nu există evaluări

- CuniDocument32 paginiCunikampit100% (1)

- Weldingdefects 150915053459 Lva1 App6892 PDFDocument22 paginiWeldingdefects 150915053459 Lva1 App6892 PDFpaolaÎncă nu există evaluări

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDe la EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonÎncă nu există evaluări

- ASM HandbookDocument1 paginăASM HandbookSiyu ChenÎncă nu există evaluări

- Fundamentals of WeldingDocument79 paginiFundamentals of WeldingdselvakuuÎncă nu există evaluări

- List of Welding Codes PDFDocument3 paginiList of Welding Codes PDFAlienshow100% (2)

- Introduction to Welding and Brazing: The Commonwealth and International Library: Welding DivisionDe la EverandIntroduction to Welding and Brazing: The Commonwealth and International Library: Welding DivisionÎncă nu există evaluări

- Materials Workshop For The Refining & Petrochemical IndustryDocument281 paginiMaterials Workshop For The Refining & Petrochemical IndustrysantiagoÎncă nu există evaluări

- DPR For Par Boiled Rice IndustryDocument134 paginiDPR For Par Boiled Rice IndustryVijay Chander Reddy Keesara100% (1)

- Welding Consumables Ppt. 16 17Document128 paginiWelding Consumables Ppt. 16 17Senake50% (2)

- Documents - Pub - Advanced Welding TechnologyDocument60 paginiDocuments - Pub - Advanced Welding TechnologybalamuruganÎncă nu există evaluări

- ChromiteDocument29 paginiChromiteVijay Chander Reddy Keesara100% (3)

- Stainless SteelDocument34 paginiStainless SteelMohammed HilalÎncă nu există evaluări

- Die Casting Metallurgy: Butterworths Monographs in MaterialsDe la EverandDie Casting Metallurgy: Butterworths Monographs in MaterialsEvaluare: 3.5 din 5 stele3.5/5 (2)

- Microstructures of Copper AlloysDocument71 paginiMicrostructures of Copper Alloysmauriciodom100% (7)

- Iron OreDocument27 paginiIron OreVijay Chander Reddy Keesara0% (1)

- Unit V: Design of Weld Joints, Weldability and Testing of WeldmentsDocument24 paginiUnit V: Design of Weld Joints, Weldability and Testing of WeldmentsparthibankÎncă nu există evaluări

- Welding Technology SyllabusDocument1 paginăWelding Technology SyllabusShankaranarayanan100% (1)

- Welding DefectsDocument22 paginiWelding DefectsVijay Krishna KanthÎncă nu există evaluări

- Course Name: NAME 301 Shipbuilding Technology-I: Md. Omar FarukDocument56 paginiCourse Name: NAME 301 Shipbuilding Technology-I: Md. Omar FarukMd. Omar FarukÎncă nu există evaluări

- Weldingdefects 150915053459 Lva1 App6892Document22 paginiWeldingdefects 150915053459 Lva1 App6892Star GlacierÎncă nu există evaluări

- Mf5103 Advances in Casting and Welding: For Syllabus, Question Papers, Notes & Many MoreDocument2 paginiMf5103 Advances in Casting and Welding: For Syllabus, Question Papers, Notes & Many MoreNandha Gopal SenthilnathanÎncă nu există evaluări

- 01 Mechanical Engineering PDFDocument8 pagini01 Mechanical Engineering PDFAlvin Smith33% (3)

- 1a Arc Weld ProcessesDocument45 pagini1a Arc Weld ProcessesskgcÎncă nu există evaluări

- Advance Welding PDFDocument2 paginiAdvance Welding PDFRajeevÎncă nu există evaluări

- Metal Joining Processes and Manufacturing Practices 18ME331Document30 paginiMetal Joining Processes and Manufacturing Practices 18ME33120G062 NALVETHA BÎncă nu există evaluări

- RM01 - Arc Weld ProcessesDocument53 paginiRM01 - Arc Weld ProcessesAnonymous cgcKzFtXÎncă nu există evaluări

- Welding Syllabi R2013Document1 paginăWelding Syllabi R2013Sajailslhuti JilluÎncă nu există evaluări

- Mett.7th SemDocument9 paginiMett.7th SemLokesh DahiyaÎncă nu există evaluări

- Extra QuestionDocument5 paginiExtra QuestionIslam MohammedÎncă nu există evaluări

- Lecture NoteDocument93 paginiLecture Noteamit kumarÎncă nu există evaluări

- Nptel: Steel Making - Web CourseDocument2 paginiNptel: Steel Making - Web CourseSahil JhambÎncă nu există evaluări

- Asm Handbook File 1Document3 paginiAsm Handbook File 1Jeffrey Ho0% (2)

- Special Metals Joining (WeldingWorld) PDFDocument52 paginiSpecial Metals Joining (WeldingWorld) PDFاکبر کرمیÎncă nu există evaluări

- Materials For High Temperature High Pressure Applications andDocument28 paginiMaterials For High Temperature High Pressure Applications andDrVRKÎncă nu există evaluări

- Arcwelding 170804063548Document72 paginiArcwelding 170804063548Izzat TammamÎncă nu există evaluări

- Weld AbilityDocument34 paginiWeld AbilityMuzaffarÎncă nu există evaluări

- B-5 IRC-Final (22-03-21) - CompressedDocument136 paginiB-5 IRC-Final (22-03-21) - CompressedGobinder Singh VirdeeÎncă nu există evaluări

- Welding Vs BrazingDocument7 paginiWelding Vs Brazingكنوزخطاب100% (1)

- Steel Designation0Document13 paginiSteel Designation0Palak NaikÎncă nu există evaluări

- 4 SmawDocument39 pagini4 SmawEngineerSajidAlamÎncă nu există evaluări

- 1.define Briefly About The Effect of Alloying On Steels?Document7 pagini1.define Briefly About The Effect of Alloying On Steels?rp0212Încă nu există evaluări

- Welding: DefinitionDocument23 paginiWelding: DefinitionPRATIK PODDARÎncă nu există evaluări

- Copper Alloys - AbhayDocument8 paginiCopper Alloys - AbhayAbhay GuptaÎncă nu există evaluări

- Dumas - Jumille - Welding MetallurgyDocument22 paginiDumas - Jumille - Welding MetallurgyChris John TecsonÎncă nu există evaluări

- Beab05 Metals StudentDocument46 paginiBeab05 Metals StudentRuby Lyn Alcaide LazaÎncă nu există evaluări

- WeldingDocument80 paginiWeldingssukhmeet551Încă nu există evaluări

- Welding and Corrosion Performance of INCO-WELD 686CPT Filler Metal in Waste-To-Energy Power PlantsDocument6 paginiWelding and Corrosion Performance of INCO-WELD 686CPT Filler Metal in Waste-To-Energy Power Plantsmohamed AdelÎncă nu există evaluări

- AKANDE Heritage ProjectDocument28 paginiAKANDE Heritage ProjectAkande HeritageÎncă nu există evaluări

- Investigatory ProjectDocument18 paginiInvestigatory Projecthitesshkumar12Încă nu există evaluări

- IV. Question and Answers: WersDocument1 paginăIV. Question and Answers: WersVijay Chander Reddy KeesaraÎncă nu există evaluări

- QAP For MS Pipes-RevisedDocument3 paginiQAP For MS Pipes-RevisedVijay Chander Reddy Keesara25% (4)

- Costing Per SQ - MtrsDocument2 paginiCosting Per SQ - MtrsVijay Chander Reddy KeesaraÎncă nu există evaluări

- Tyre PyrolysisDocument12 paginiTyre PyrolysisVijay Chander Reddy KeesaraÎncă nu există evaluări

- Wind Power Sector in IndiaDocument139 paginiWind Power Sector in IndiaVijay Chander Reddy KeesaraÎncă nu există evaluări