Documente Academic

Documente Profesional

Documente Cultură

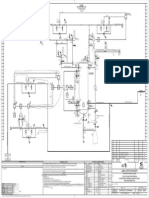

Ip060-45!20!02 Orifice Plate Assembly (Buyer's Scope)

Încărcat de

Rahul DevaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ip060-45!20!02 Orifice Plate Assembly (Buyer's Scope)

Încărcat de

Rahul DevaDrepturi de autor:

Formate disponibile

SPEC.NO.

: IP060-45-20-02

REV. 1

PROJECT NO.

: IP060

SH. 1 OF 5

DESCRIPTION

: ORIFICE PLATE ASSEMBLY

CHEMTEX

AREA : INSTRUMENTATION

IP060

FINE PROJECT

ORIFICE PLATE ASSEMBLY

(BUYER'S SCOPE)

PT. INDORAMA VENTURES INDONESIA

BANTEN, INDONESIA

REFERENCE SPEC. NO. EIT012-45-20-01, Rev.1

THIS DOCUMENT IS PROPRIETARY AND CONFIDENTIAL INFORMATION OF CHEMTEX AND ITS LICENSOR AND MAY BE USED ONLY WITH THEIR PRIOR WRITTEN CONSENT.

REV.

0

1

DESCRIPTION

ISSUED FOR ENQUIRY

REVISED AS MARKED & REISSUED FOR ENQUIRY

PREP'D.

CHK'D

APPR'D.

DATE

RKM

RKM

VIM

VIM

SSG

SSG

MAY 24 2013

AUG 27 2013

FILE NAME : IP060-45-20-02-1.XLS

SPEC. NO. IP060-45-20-02 REV. 1

CHEMTEX

SHEET 2 OF 5

ORIFICE PLATE ASSEMBLY

REV.

1

SCOPE:

THIS SPECIFICATION COVERS THE MINIMUM REQUIREMENTS FOR DESIGN, FABRICATION, TESTING AND

GUARANTEES FOR OPERATION AND PERFORMANCE OF THE INSTRUMENTS LISTED HEREIN.

VENDOR SHALL SUPPLY DOCUMENTATION PER "VENDOR DOCUMENT REQUIREMENT SCHEDULE" VD45-20.

REFERENCE STANDARDS/ DESIGN CODES :

a)

b)

c)

PIPE FLANGES AND FLANGED FITTINGS

ORIFICE FLANGES

ISO 5167 (ACCORDING TO FLOW MEASUREMENT ENGG. HANDBOOK

BY R.W. MILLER)

CODES AND STANDARDS SHALL BE THE LATEST ISSUE TO THE DATE OF INQUIRY INCLUDING ADDENDA,

REVISIONS OR SUPPLEMENTS.

3

ASME B16.5, 2009

ASME B16.36, 2009

SIZING CALCULATIONS

:

:

:

TECHNICAL REQUIREMENTS :

ANY DEVIATIONS FROM THE REQUIREMENTS OF THIS SPECIFICATION SHALL BE STATED AS EXCEPTIONS IN

VENDOR'S PROPOSAL. UNLESS SPECIFIC EXCEPTIONS ARE STATED, IT SHALL BE UNDERSTOOD THAT THE

INSTRUMENTS ARE IN COMPLETE ACCORDANCE WITH THE SPECIFICATION.

SIZING :

VENDOR TO CALCULATE ORIFICE BORE DIAMETER BASED ON PROCESS DATA GIVEN FOR EACH INSTRUMENT &

THE SAME SHALL BE SUBMITTED ALONG WITH THE OFFER.

NAMEPLATE :

EACH INSTRUMENT SHALL HAVE A CORROSION RESISTANT NAMEPLATE PERMANENTLY FASTENED TO IT

WITH DETAILS.

NOTES

VENDOR TO PROVIDE NUTS & BOLTS FOR EACH TAG NOS OF MATERIAL ASTM A193 GR. B7 & ASTM A194

GR. 2H RESPECTIVELY.

VENT / DRAIN HOLE SHALL BE PROVIDED FOR ORIFICE BORE DIAMETER GREATER THAN 1" (25.4 mm).

IF REYNOLDS NUMBER IS LESS THAN 10,000 USE QUADRANT-EDGED ORIFICE.

VENDOR SHALL QUOTE FOR SPARES FOR TWO YEARS OF OPERATION.

10

VENDOR SHALL PROVIDE PLUG FOR FLANGE TAPS.

11

VENDOR TO SUPPLY GASKETS AS PER THE FOLLOWING SPECIFCATION.

GASKET

CODE

G13S

SPECIFICATION

G50

WHITE VIRGIN PTFE , ASME B16.21 - 177 DEG C ( 350 DEG F)

G63G4

ASME CLASS 300, 0.175" THICK, 304 SS SPIRAL WOUND WITH FLEXIBLE GRAPHITE FILLER AND

CS OUTER CENTERING RING , ASME B16.20 - 398 DEG C ( 748.4 DEG F)

G81

NBR BONDED, NON ASBESTOS SYNTHETIC FIBER (RING TYPE), ASME B16.21 - 150 DEG. C (302 DEG. F).

FLEXIBLE GRAPHITE (WITH 316SS PERFORATED SHEET REINFORCEMENT INSERT), ASME B16.21 - 270 DEG C

(518 DEG F).

LIST OF DOCUMENTS ATTACHED :

DESCRIPTION

DRAWINGS

ORIFICE PLATE ASSEMBLY

STD52001.00X

SPEC. NO. / DWG. NO. /

FORM NO.

REV.

IP060-IP-052002 (SHT. 1 OF 12)

TO

IP060-IP-052002 (SHT.12 OF 12)

NO. OF

SHEETS

12

FILE NAME

IP060-IP-052002A

TO

IP060-IP-052002L

SPEC. NO. IP060-45-20-02 REV. 1

CHEMTEX

SHEET 3 OF 5

ORIFICE PLATE ASSEMBLY

--ORIFICE PLATES--

--ORIFICE FLANGES--

1 TYPE

CONCENTRIC

6 FLANGES

INCLUDED

2 STANDARD

ISA

7 TYPE

WELD NECK

3 BORE

MAXIMUM FLOW RATE

8 TAPS

FLANGE

4 MATERIAL

316 SS

9 SIZE

1/2" NPT

5 RING MAT'L & TYPE

GENERAL

9 TAG NO.

1350-FE-65103

1350-FE-65106

1350-FE-65109

10 SERVICE

INST AIR FOR WINDER

LP COMPRESSED AIR

HP AIR FOR SUCTION GUN

FLOW

FLOW

FLOW

11 LINE NO.

4" IA-65101 PS-1G

8" GA-5k-65103 PS-1

8" HA-65105 PS-1

4" SCH STD

8" SCH STD

8" SCH STD

INST AIR

LP COMPRESSED AIR

12 LINE SIZE & SCH.

13

14 FLUID

15 FLUID STATE

GAS

FLOW UNIT

kg/hr

kg/hr

473

16 FLOW NORMAL

17 FLOW

SERVICE CONDITIONS

GAS

MIN.

HP AIR

GAS

kg/hr

5602

703

MAX.

686

6866

8981

18 PRESSURE

kg/cm2 G

NOR. MAX.

7.5

4.5

4.5

9.5

10

19 TEMPERATURE

Deg C

NOR. MAX.

AMB

60

AMB

60

AMB

60

20 VISCOSITY

Cp

NOR. MAX.

0.0193

0.0193

0.0193

NOR. MAX.

/ 9.66

/ 6.26

/ 11.92

21 SP.GRAVITY / DENSITY

kg/m3

22 QUALITY % OR SUPERHEAT

23 MOLECULAR WEIGHT

CP/CV

29

25 REYNOLDS NO.

kg/cm2

29

BASE TEMP.

29 SPECIFIC GRAVITY AT BASE

1.408

29

1.408

-

0.1

0.1

0.1

27 PERMANENT PRESSURE LOSS

28 BASE PRESS.

1.408

-

24 SUPERCOMPRESSIBILITY FACTOR

26 MAX. ALLOW. PRESSURE DROP

*

-

*

-

30

METER

31 TYPE OF METER

D.P.TRANSMITTER (BY OTHERS)

D.P.TRANSMITTER (BY OTHERS)

D.P.TRANSMITTER (BY OTHERS)

0 - 900 kg/hr

0 - 8500 kg/hr

0 - 11000 kg/hr

* 1000 mmWC

* 1250 mmWC

* 1250 mmWC

34 SEAL SP.GR. AT 15.5 C (60 F)

35 STATIC PRESSURE RANGE

32 FLOW RANGE

33 DIFF. RANGE - 'DRY'

36

37 ORIFICE BORE DIAMETER 'd'

PLATE / FLANGE

38 LINE ID 'D'

4.026

7.981

7.981

39 BETA RATIO - d/D

40 FLANGE RATING

300# RF AS PER ASME B16.36

300# RF AS PER ASME B16.36

300# RF AS PER ASME B16.36

ASTM A 105 N

ASTM A 105 N

ASTM A 105 N

NOTE 7

NOTE 7

NOTE 7

3 mm

6.1 mm

6.1 mm

44 GASKET/PLATE HOLDER MATERIAL

NOTE 11

NOTE 11

NOTE 11

45 STUDS & BOLTS MATERIAL

NOTE 6

NOTE 6

NOTE 6

*

*

*

*

*

*

503651-1350-060

503651-1350-060

503651-1350-060

41 FLANGE MATERIAL

42 VENT OR DRAIN HOLE

43 PLATE THICKNESS

46

47 MANUFACTURER

48 MODEL NO.

49 P & ID NO.

VENDOR TO SPECIFY / CONFIRM.

STD52002.00X

SPEC. NO. IP060-45-20-02 REV. 1

CHEMTEX

SHEET 4 OF 5

ORIFICE PLATE ASSEMBLY

--ORIFICE PLATES--

--ORIFICE FLANGES--

1 TYPE

CONCENTRIC

6 FLANGES

INCLUDED

2 STANDARD

ISA

7 TYPE

WELD NECK

3 BORE

MAXIMUM FLOW RATE

8 TAPS

FLANGE

4 MATERIAL

316 SS

9 SIZE

1/2" NPT

5 RING MAT'L & TYPE

GENERAL

9 TAG NO.

1350-FE-65114

1840-FE-65602

10 SERVICE

LLP COMPRESSED AIR

FLOW

INDUSTRIAL WATER SUPPLY

HEADER FLOW

8" GA-3k-65104 PS-1

6" IW(S)-65601 PS-1

8" SCH STD

6" SCH STD

11 LINE NO.

12 LINE SIZE & SCH.

13

14 FLUID

LLP COMPRESSED AIR

15 FLUID STATE

GAS

FLOW UNIT

INDUSTRIAL WATER

LIQUID

2945

16 FLOW NORMAL

17 FLOW

SERVICE CONDITIONS

kg/hr

MIN.

m3/hr

26.2

3240

MAX.

40.1

18 PRESSURE

kg/cm2 G

NOR. MAX.

3.5

19 TEMPERATURE

Deg C

NOR. MAX.

AMB

60

30

60

20 VISCOSITY

Cp

NOR. MAX.

0.0192

0.47

0.8

NOR. MAX.

/ 4.56

/ 993

21 SP.GRAVITY / DENSITY

kg/m3

22 QUALITY % OR SUPERHEAT

23 MOLECULAR WEIGHT

CP/CV

29

1.408

18

24 SUPERCOMPRESSIBILITY FACTOR

25 REYNOLDS NO.

26 MAX. ALLOW. PRESSURE DROP

kg/cm2

27 PERMANENT PRESSURE LOSS

28 BASE PRESS.

0.1

0.3

BASE TEMP.

29 SPECIFIC GRAVITY AT BASE

30

METER

31 TYPE OF METER

D.P.TRANSMITTER (BY OTHERS)

D.P.TRANSMITTER (BY OTHERS)

32 FLOW RANGE

0 - 4000 kg/hr

0 - 50 m3/hr

33 DIFF. RANGE - 'DRY'

* 1000 mmWC

* 2000 mmWC

34 SEAL SP.GR. AT 15.5 C (60 F)

35 STATIC PRESSURE RANGE

36

37 ORIFICE BORE DIAMETER 'd'

PLATE / FLANGE

38 LINE ID 'D'

7.981

6.065

39 BETA RATIO - d/D

40 FLANGE RATING

300# RF AS PER ASME B16.36

300# RF AS PER ASME B16.36

ASTM A 105 N

ASTM A 105 N

42 VENT OR DRAIN HOLE

NOTE 7

NOTE 7

43 PLATE THICKNESS

6.1 mm

3 mm

44 GASKET/PLATE HOLDER MATERIAL

NOTE 11

NOTE 11

45 STUDS & BOLTS MATERIAL

NOTE 6

NOTE 6

*

*

*

*

503651-1350-060

503656-1840-060

41 FLANGE MATERIAL

46

47 MANUFACTURER

48 MODEL NO.

49 P & ID NO.

VENDOR TO SPECIFY / CONFIRM.

G

M

P

S

STD52002.00X

SPEC. NO. IP060-45-20-02 REV. 1

CHEMTEX

SHEET 5 OF 5

FLOW MEASUREMENT

REV.

CHEMTEX

VENDOR DOCUMENT REQUIREMENT & SCHEDULE

INSTRUMENTATION

ITEM : HEAD TYPE FLOW METERS (ORIFICE)

PROJECT : IP060

SPECNO.: IP060-45-20-02

DESCRIPTION OF DOCUMENTATION

PO NO.:

----QUOTE---

VALIDATION DATE:

Outline Dimensional Drawings & Connections

Specifications

Calculations

Bill of Materials

I. O. M.

Inspection and Test Report

Quality Certificate

Certificate of Conformance (CFC)

2

2

2

2

----------CERTIFIED----------

----------APPROVAL----------

QTY_P QTY_D QTY_P QTY_D

3

3

3

3

3

3

LEAD (wks)

QTY_R QTY_P QTY_D

5

5

5

5

5

5

5

5

1

1

1

1

1

1

1

1

LEAD (wks)

(4) ARO

(4) ARO

(4) ARO

(4) ARO

(4) ARO

(2) PTSR

(2) PTSR

(2) PTSR

INSTRUCTIONS :

1. Vendor shall be responsible for the correctness of all Drawings and Documents.

2. Vendor must obtain written approval from Chemtex for any deviation from Drawings / Documents specifications.

3. Vendor shall identify Drawings by printing the following information in the title box on each Drawing :

a.

Customer name.

b.

Chemtex Purchase Order Number and Vendor Order Number.

c.

Equipment Item Number and Name to which the print applies.

4. All final Documents are to be bound together with an index. This is to include all applicable items shown in the

table above.

5. Drawings will not be accepted unless the above information is incorporated on all Documents furnished by vendor.

NOTES :

APPROVAL:

CERTIFIED :

ADA

ARO

PTSR

Qty_P

Qty_R

Qty_D

QUOTE

:

:

:

:

:

:

:

Drawings/Documents require Chemtexs approval prior to fabrication.

Vendor shall certify that the Drawings/Documents being furnished accurately describe the

equipment/items covered by this purchase order.

After Drawing/Document Approval

After Receipt of Order

Drawings/Documents required Prior To Shipment Release

Quantity of Prints or Copies

Quantity of Reproducibles

Quantity of Digital Documentation

Prints or copies of Drawings / Documents required With Quotation.

SCHEDULE : VD45-20

REVISION : 10/01/99 REV. 0

S-ar putea să vă placă și

- Pocket Guide to Flanges, Fittings, and Piping DataDe la EverandPocket Guide to Flanges, Fittings, and Piping DataEvaluare: 3.5 din 5 stele3.5/5 (22)

- Volume3A MechDocument321 paginiVolume3A MechAdeel JamilÎncă nu există evaluări

- Anubar SpecDocument8 paginiAnubar SpecSHIVAJI CHOUDHURYÎncă nu există evaluări

- BE-WI-248-01-F07 Datasheet Turbine FlowmeterDocument3 paginiBE-WI-248-01-F07 Datasheet Turbine Flowmetermika cabelloÎncă nu există evaluări

- BE-WI-248-01-F12 Datasheet Level Instrument Displacer or FloatDocument3 paginiBE-WI-248-01-F12 Datasheet Level Instrument Displacer or Floatmika cabelloÎncă nu există evaluări

- Positioner SpecsDocument1 paginăPositioner Specsbiswasdipankar05Încă nu există evaluări

- Tata Consulting Engineers Limited Dew Point Analyzer: GeneralDocument2 paginiTata Consulting Engineers Limited Dew Point Analyzer: GeneralcvkgrpdÎncă nu există evaluări

- Datasheet PSV PDPDEDocument8 paginiDatasheet PSV PDPDERicardo NapitupuluÎncă nu există evaluări

- Datasheet Pressure Indicating Controller PDFDocument5 paginiDatasheet Pressure Indicating Controller PDFHimawan Sigit NugrohoÎncă nu există evaluări

- Datasheet For Flow ComputerDocument2 paginiDatasheet For Flow ComputerAngela BarberÎncă nu există evaluări

- Control ValveDocument22 paginiControl Valvesantoshsapan25Încă nu există evaluări

- Orifice Plate DatasheetDocument29 paginiOrifice Plate DatasheetshayabajÎncă nu există evaluări

- Actuator Selection Guide For Flow-Tek Ball ValvesDocument16 paginiActuator Selection Guide For Flow-Tek Ball ValvesArt G. EnziÎncă nu există evaluări

- Appendix 5 - Control and Alarm SetpointsDocument20 paginiAppendix 5 - Control and Alarm SetpointsCù Xuân HuyÎncă nu există evaluări

- FS 3210 - FS-Gas Flow ComputerDocument6 paginiFS 3210 - FS-Gas Flow ComputerBinu ManiÎncă nu există evaluări

- FN400 H# Series Long Radius Flow Nozzles - Holding Ring TypeDocument1 paginăFN400 H# Series Long Radius Flow Nozzles - Holding Ring TypeAjay ChodankarÎncă nu există evaluări

- ORIFICEDocument1 paginăORIFICEhardavÎncă nu există evaluări

- Fuel Oil Unloading, Storage and Transfer System Storage Volume Calculation of Dyke AreaDocument2 paginiFuel Oil Unloading, Storage and Transfer System Storage Volume Calculation of Dyke Areaananyo_senguptaÎncă nu există evaluări

- PB TW10 GBDocument6 paginiPB TW10 GBfebri_bontangÎncă nu există evaluări

- PCAM-200-HD-K-002 (Rev. L.T.M.)Document5 paginiPCAM-200-HD-K-002 (Rev. L.T.M.)Augusto CamposÎncă nu există evaluări

- INDEX AND GENERAL NOTES FOR CONTROL VALVE DATASHEETDocument5 paginiINDEX AND GENERAL NOTES FOR CONTROL VALVE DATASHEETveenaÎncă nu există evaluări

- Orifice Plate Flow Meter Data SheetDocument4 paginiOrifice Plate Flow Meter Data SheetTaimoor KhanÎncă nu există evaluări

- Actuated Ball Valve 357 D - BDKDocument4 paginiActuated Ball Valve 357 D - BDKfarhanakhtar ansariÎncă nu există evaluări

- Revision Index Description and / or Revised Sheets: Technical Specification Un - Rio / Atp - Ro 1 of 73 75Document255 paginiRevision Index Description and / or Revised Sheets: Technical Specification Un - Rio / Atp - Ro 1 of 73 75neivaprojetosÎncă nu există evaluări

- Instrument Index Platform: Domain: Finalproject Plant: AreaDocument3 paginiInstrument Index Platform: Domain: Finalproject Plant: AreaJasJusÎncă nu există evaluări

- TORQUES Actuator For Ball Valve PDFDocument12 paginiTORQUES Actuator For Ball Valve PDFChaerul AnwarÎncă nu există evaluări

- Coriolis Mass Flow MeterDocument2 paginiCoriolis Mass Flow MeterSreejesh SundaresanÎncă nu există evaluări

- 123939-60A3 R1 Instrumentation Symbols and IdentificationDocument31 pagini123939-60A3 R1 Instrumentation Symbols and IdentificationSaid SalemÎncă nu există evaluări

- Writeup On Safety Valve Erv PDFDocument28 paginiWriteup On Safety Valve Erv PDFSravan DasariÎncă nu există evaluări

- Jubail Export Refinery: Wash Water Break Tank 101-D-0004Document1 paginăJubail Export Refinery: Wash Water Break Tank 101-D-0004ahm3d16nÎncă nu există evaluări

- Hook Ups PDFDocument8 paginiHook Ups PDFAnonymous d7Jde8Încă nu există evaluări

- Sov - 1Document1 paginăSov - 1biswasdipankar05Încă nu există evaluări

- r2b p3 206 02 P HD 00200 - Datasheets For Control Valve, Globe, U 21000 - Rev.1Document377 paginir2b p3 206 02 P HD 00200 - Datasheets For Control Valve, Globe, U 21000 - Rev.1Diana Paula Echartea MolinaÎncă nu există evaluări

- 00000-Jds-003 (Level Trans DS) Rev 0Document4 pagini00000-Jds-003 (Level Trans DS) Rev 0sithulibraÎncă nu există evaluări

- 00000-JDS-014 (Pressure Safety Valve) Rev 0Document4 pagini00000-JDS-014 (Pressure Safety Valve) Rev 0sithulibra100% (1)

- PMS Rev 0Document36 paginiPMS Rev 0rami ghorbelÎncă nu există evaluări

- Blowdown Calculation Inventory - Subsea FlowlineDocument13 paginiBlowdown Calculation Inventory - Subsea FlowlineNK0% (1)

- Differential Pressure Transmitter (Smart)Document6 paginiDifferential Pressure Transmitter (Smart)JKKÎncă nu există evaluări

- Technical Specification for Flow Orifice AssemblyDocument14 paginiTechnical Specification for Flow Orifice Assemblyvishal.nithamÎncă nu există evaluări

- ULTIMATE Pipe Calculation v1.0Document3 paginiULTIMATE Pipe Calculation v1.0psn_kylmÎncă nu există evaluări

- 7-12-0017 Rev 5Document2 pagini7-12-0017 Rev 5cynideÎncă nu există evaluări

- STG Instrument Hook-Up Material ListDocument4 paginiSTG Instrument Hook-Up Material Listraobabar21Încă nu există evaluări

- Prosertec Srl. 4to Anillo #3880 y Av. Roca y Coronado: Fluid PropertiesDocument1 paginăProsertec Srl. 4to Anillo #3880 y Av. Roca y Coronado: Fluid PropertiesAlba Duaneth Rocabado MendietaÎncă nu există evaluări

- Venturi Flowmeter Specification Sheet: Venturi Meter GAH Downstream Design Data DimensionsDocument1 paginăVenturi Flowmeter Specification Sheet: Venturi Meter GAH Downstream Design Data Dimensionshardik033Încă nu există evaluări

- Valve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016Document4 paginiValve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016JOSE MARTIN MORA RIVEROSÎncă nu există evaluări

- PID ChecklistDocument1 paginăPID Checklistsahil gohadÎncă nu există evaluări

- TK02 Rev01Document7 paginiTK02 Rev01mggz_15Încă nu există evaluări

- 377 Series Trip Valves: Product BulletinDocument3 pagini377 Series Trip Valves: Product BulletinIsmail AhmadÎncă nu există evaluări

- Control Valve Specification SheetDocument1 paginăControl Valve Specification SheetJuan Krloz CastañedaÎncă nu există evaluări

- Va1-Lici-00eg-I-m4d-Das-0009 RTD & ThermowellDocument17 paginiVa1-Lici-00eg-I-m4d-Das-0009 RTD & ThermowellKhang TrangÎncă nu există evaluări

- Flow Meter Data SheetDocument2 paginiFlow Meter Data SheetAnonymous S0Dyd1FsXÎncă nu există evaluări

- Flow Meter Sizing MOSDocument11 paginiFlow Meter Sizing MOSra9622Încă nu există evaluări

- Gear Pump Datasheets 1Document12 paginiGear Pump Datasheets 1MauliÎncă nu există evaluări

- FS 3201 - FS-Flow TotalizerDocument4 paginiFS 3201 - FS-Flow TotalizerBinu ManiÎncă nu există evaluări

- NaturalConvectionHeatTransferCoefficients SI Units Final ProtectedDocument44 paginiNaturalConvectionHeatTransferCoefficients SI Units Final ProtectedFabio MiguelÎncă nu există evaluări

- 2.3 Control Valve ScheduleDocument13 pagini2.3 Control Valve Scheduleapi-19500842Încă nu există evaluări

- Temperature Instrument SpecificationDocument14 paginiTemperature Instrument Specificationamini_mohiÎncă nu există evaluări

- TDS For Y-StrainerDocument2 paginiTDS For Y-StrainerRAGHVENDRA PRATAP SINGHÎncă nu există evaluări

- Valve SheetDocument23 paginiValve SheetAris KancilÎncă nu există evaluări

- GCI Storage Tank Data SheetDocument4 paginiGCI Storage Tank Data SheetAlvin Smith60% (5)

- Fire Suppression Detecion PrincipleDocument1 paginăFire Suppression Detecion PrincipleRahul DevaÎncă nu există evaluări

- Control Valve Specification SheetDocument5 paginiControl Valve Specification SheetRahul DevaÎncă nu există evaluări

- Ip060-45!43!01 Pressure Transmitter (Electronic) (Buyer's Scope)Document7 paginiIp060-45!43!01 Pressure Transmitter (Electronic) (Buyer's Scope)Rahul DevaÎncă nu există evaluări

- Efficient Placement of SensorsDocument2 paginiEfficient Placement of SensorsRahul DevaÎncă nu există evaluări

- Ip060-45!23!05 Turbine FlowmeterDocument4 paginiIp060-45!23!05 Turbine FlowmeterRahul DevaÎncă nu există evaluări

- COO-CIS PertaminaDocument1 paginăCOO-CIS PertaminaRahul DevaÎncă nu există evaluări

- FAT Procedure Rev.1Document9 paginiFAT Procedure Rev.1Rahul Deva100% (1)

- Distributorship 2012 LoDocument1 paginăDistributorship 2012 LoRahul DevaÎncă nu există evaluări

- Hydraulic Calculation Tutorial #1Document9 paginiHydraulic Calculation Tutorial #1Rahul Deva100% (1)

- Cable and Connection ProductsDocument26 paginiCable and Connection ProductsRahul DevaÎncă nu există evaluări

- Loudspeaker BuilderDocument85 paginiLoudspeaker BuilderRahul Deva100% (3)

- PH1 Pull Handle Call Point Weatherproof Exd FeaturesDocument2 paginiPH1 Pull Handle Call Point Weatherproof Exd FeaturesRahul DevaÎncă nu există evaluări

- Belawan BuildingDocument1 paginăBelawan BuildingRahul DevaÎncă nu există evaluări

- Arun BuildingDocument1 paginăArun BuildingRahul DevaÎncă nu există evaluări

- Experience List Pt. Arya Semesta: NO. Tahun Name of Project Description RemarkDocument1 paginăExperience List Pt. Arya Semesta: NO. Tahun Name of Project Description RemarkRahul DevaÎncă nu există evaluări

- 1 AsDocument6 pagini1 AsRahul DevaÎncă nu există evaluări

- SystemConfigurationReport CNGDocument10 paginiSystemConfigurationReport CNGRahul DevaÎncă nu există evaluări

- Lion Air Eticket Itinerary / Receipt: Condition For More InformationDocument1 paginăLion Air Eticket Itinerary / Receipt: Condition For More InformationRahul DevaÎncă nu există evaluări

- 00 - Gas Detection BasicDocument28 pagini00 - Gas Detection BasicRahul DevaÎncă nu există evaluări

- ASTERIX Rack System CatalogueDocument7 paginiASTERIX Rack System CatalogueRahul DevaÎncă nu există evaluări

- CCF06032013 00000Document1 paginăCCF06032013 00000Rahul DevaÎncă nu există evaluări

- CCF06032013 00003Document1 paginăCCF06032013 00003Rahul DevaÎncă nu există evaluări

- Lion Air Eticket Itinerary / Receipt: Condition For More InformationDocument1 paginăLion Air Eticket Itinerary / Receipt: Condition For More InformationRahul DevaÎncă nu există evaluări

- Ultima X Series Data Sheet - Pak KhunDocument6 paginiUltima X Series Data Sheet - Pak KhunRahul DevaÎncă nu există evaluări

- MSDS - GcaDocument3 paginiMSDS - Gcapassword2013Încă nu există evaluări

- Eticket KMLFHX (1) 1Document2 paginiEticket KMLFHX (1) 1Rahul DevaÎncă nu există evaluări

- Audio Line High-End Preamplifier With ICsDocument3 paginiAudio Line High-End Preamplifier With ICsRahul DevaÎncă nu există evaluări

- Formulir IM2Document2 paginiFormulir IM2Rahul DevaÎncă nu există evaluări

- Emergency Lighting System Design GuideDocument10 paginiEmergency Lighting System Design GuideRahul DevaÎncă nu există evaluări

- Ieee Standard For Power Systems-Insulation CoordinationDocument21 paginiIeee Standard For Power Systems-Insulation Coordinationcarlos_alfaro_herreraÎncă nu există evaluări

- Dropsa YoensaDocument73 paginiDropsa YoensaCAGERIGOÎncă nu există evaluări

- Mmpapmg 88Document32 paginiMmpapmg 88Pier Paolo LilliuÎncă nu există evaluări

- CSEC Physics P2 2012 JuneDocument14 paginiCSEC Physics P2 2012 JuneBill BobÎncă nu există evaluări

- Solution To Problems in Quantum Field Theory: 1 Photons and The Electromagnetic FieldDocument34 paginiSolution To Problems in Quantum Field Theory: 1 Photons and The Electromagnetic FieldAlvaro Rafael Martínez100% (2)

- Ölflex® Classic 110 Sy: Product InformationDocument5 paginiÖlflex® Classic 110 Sy: Product InformationShashank SaxenaÎncă nu există evaluări

- Copper-Based Alloys For Structural High-Heat-Flux Applications: A Review of Development, Properties, and Performance of Cu-Rich Cu-Cr-Nb AlloysDocument33 paginiCopper-Based Alloys For Structural High-Heat-Flux Applications: A Review of Development, Properties, and Performance of Cu-Rich Cu-Cr-Nb Alloysgerardo saucedoÎncă nu există evaluări

- Brochure Cary 3500 Uv 5994 0335en Us AgilentDocument8 paginiBrochure Cary 3500 Uv 5994 0335en Us Agilentarfan.irinbestindoÎncă nu există evaluări

- Master Thesis in Civil EngineeringDocument8 paginiMaster Thesis in Civil Engineeringafkneafpz100% (2)

- Bayan College For Science & Technology: Instrumentation and MeasurementDocument16 paginiBayan College For Science & Technology: Instrumentation and MeasurementOmur NoorÎncă nu există evaluări

- Clocks:: Cheat Sheets - Clocks and CalendarsDocument8 paginiClocks:: Cheat Sheets - Clocks and CalendarsMeghna ChoudharyÎncă nu există evaluări

- B253 PDFDocument8 paginiB253 PDFSky LeeÎncă nu există evaluări

- Heterogeneous NucleationDocument4 paginiHeterogeneous NucleationDimpy KhatriÎncă nu există evaluări

- Yls-2000 PL1520542Document183 paginiYls-2000 PL1520542DavidÎncă nu există evaluări

- CENGR 3260 Introduction to HydraulicsDocument14 paginiCENGR 3260 Introduction to HydraulicsBry RamosÎncă nu există evaluări

- Tugas Fisika - 2Document4 paginiTugas Fisika - 2bellina yunitasariÎncă nu există evaluări

- Etag004 Fg004 Etics Fin2Document87 paginiEtag004 Fg004 Etics Fin2Serban RaduÎncă nu există evaluări

- Towards An Ontology of Scientific Models: # Springer Science + Business Media B.V. 2008Document9 paginiTowards An Ontology of Scientific Models: # Springer Science + Business Media B.V. 2008Isaac RacinesÎncă nu există evaluări

- DEC PRODUCTION 150K CUBIC METERS 31% NRWDocument1 paginăDEC PRODUCTION 150K CUBIC METERS 31% NRWGubat WDÎncă nu există evaluări

- TO-247AD Triac Dimensions and SpecificationsDocument4 paginiTO-247AD Triac Dimensions and Specificationsalex jordanÎncă nu există evaluări

- Compare marbles' stopping distances and momentumsDocument29 paginiCompare marbles' stopping distances and momentumsMelerose Dela SernaÎncă nu există evaluări

- Study On Scattering Characteristics of Chaff For RadarDocument4 paginiStudy On Scattering Characteristics of Chaff For RadarAshwani SinghÎncă nu există evaluări

- CollisionDocument17 paginiCollisionJamelleÎncă nu există evaluări

- Mechanical Engineering Lab ReportsDocument11 paginiMechanical Engineering Lab ReportsParikshit UjoodhaÎncă nu există evaluări

- CBSE Class 9 Science Chapter 8 Motion Revision NotesDocument24 paginiCBSE Class 9 Science Chapter 8 Motion Revision NotesBriti DubeyÎncă nu există evaluări

- 1.3.5 PreHeat TrainDocument20 pagini1.3.5 PreHeat TrainflowealthÎncă nu există evaluări

- CIBSE Guide C PRT 1Document76 paginiCIBSE Guide C PRT 1nubaz100% (1)

- Math formula cheat sheetDocument16 paginiMath formula cheat sheetNathan HurwitzÎncă nu există evaluări

- Neurophys 7 MetaneuronsDocument18 paginiNeurophys 7 Metaneurons王榮椿Încă nu există evaluări

- Maths em Iii Revision 2Document3 paginiMaths em Iii Revision 2Malathi RajaÎncă nu există evaluări

- University of Chicago Press Fall 2009 CatalogueDe la EverandUniversity of Chicago Press Fall 2009 CatalogueEvaluare: 5 din 5 stele5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesDe la EverandUniversity of Chicago Press Fall 2009 Distributed TitlesEvaluare: 1 din 5 stele1/5 (1)