Documente Academic

Documente Profesional

Documente Cultură

01EJ3060.PDF Prueba en Banco

Încărcat de

Alex PakitoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

01EJ3060.PDF Prueba en Banco

Încărcat de

Alex PakitoDrepturi de autor:

Formate disponibile

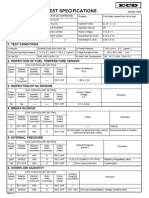

FOR EPS - 815

INJECTION PUMP TEST SPECIFICATIONS

INJECTION PUMP

096500-3060 (VE4/10E2300RND306)

MANUFACTURER

MAZDA

ENGINE TYPE

R2

VEHICLE MODEL

E SERIES

GOVERNOR TYPE

TIMER

096500-3060

Rotation

Clockwise viewed from drive side

Injection Order

A-B-C-D

Injection Interval

90

Electronic control

Rated Voltage

14 0.1 V

Electronic control

Dimension KF (mm)

5.30 0.10

Dimension K (mm)

3.30 0.10

Pump Select Switch No. (ECD Controller)

1. TEST CONDITIONS

1) Nozzle

4) Feed Pressure

093400-3230 (DN12SD12A)

2) Nozzle Opening Pressure

3) Test Oil

14.7 0.2 MPa ( 150 2 kg/cm2)

5) High Pressure Pipe

6) Inlet Fuel Temperature

SAE J967 (ISO4113)

19.6 kPa ( 0.2

2 6 840

kg/cm2)

mm

40 - 43 C (104 - 109.4 F)

2. INSPECTION OF FUEL TEMPERATURE SENSOR

ECD CONTROLLER SETTING

Pump

Speed

(rpm)

Display

Selector

Fuel

Temperat

Injection

Quantity

Command

Duty

Ratio

Command

Pump

Select

Switch

Sensor Resistance

(k )

REC OFF

1.85 1.50

Remarks

3. INSPECTION OF Ne SENSOR

ECD CONTROLLER SETTING

Pump

Speed

(rpm)

Display

Selector

Injection

Quantity

Command

Duty

Ratio

Command

Pump

Select

Switch

50

Np

REC OFF

Sensor Output

Voltage

(V)

Remarks

0.1 or more

4. BREAK-IN DRIVE

ECD CONTROLLER SETTING

Pump

Speed

(rpm)

Display

Selector

Injection

Quantity

Command

Duty

Ratio

Command

Pump

Select

Switch

Check

SPV OFF

446

REC OFF

1275

SPEED

446

REC OFF

Remarks

Setting

No fuel leaks, no abnormal noise, and no Drive more than 5 minutes.

abnormal temperature rising.

5. INTERNAL PRESSURE

ECD CONTROLLER SETTING

Pump

Speed

(rpm)

Display

Selector

Injection

Quantity

Command

Duty

Ratio

Command

Pump

Select

Switch

Internal Pressure

(kg/cm2)

SPV OFF

3D0

REC OFF

2125

SPEED

3D0

REC OFF

8.75 0.15 (857.9 14.7 kPa)

100

SPV OFF

539

REC OFF

2.00 or more (196 kPa)

Remarks

Adjust by Regulating Valve

Confirmation

6. OVERFLOW QUANTITY

ECD CONTROLLER SETTING

Pump

Speed

(rpm)

Display

Selector

Injection

Quantity

Command

Duty

Ratio

Command

Pump

Select

Switch

SPV OFF

3D0

REC OFF

2125

SPEED

3D0

REC OFF

157 - 251

2005.03.21

Overflow

Quantity

(cc/1000st)

Remarks

If its out of specification, change overflow valve.

FOR EPS - 815

096500-3060

7. ADJUSTMENT OF TIMER

(Always stop pump when changing the first digit of injection quantity command.)

ECD CONTROLLER SETTING

Pump

Speed

(rpm)

Display

Selector

2125

1275

1275

1275

200

100

Timer Adjust

Timer Adjust

Timer Adjust

Timer Adjust

Timer Adjust

Timer Adjust

Pump

Select

Switch

Timer Stroke

(mm)

REC OFF

REC OFF

REC OFF

REC OFF

REC OFF

REC OFF

10.30 0.24

10.30 0.24

5.00 2.50

0

3.60 or more

0.40 or more

Duty

Injection

Ratio

Quantity

Command Command

000

100

200

300

400

500

0

0

50

100

0

0

Remarks

Internal Pressure : 2.0 kgf/cm2 or more (196.0 kPa)

NOTE : Adjustment should be done by Timer Adjust Shim.

8. PRESETTING FOR CAM ANGLE ADJUSTMENT

ECD CONTROLLER SETTING

Pump

Speed

(rpm)

Display

Selector

SPV OFF

360

SPL

Duty

Ratio

Command

Pump

Select

Switch

DENSO

Standard

[ND - CPS]

(cc/200stcyl.)

Bench Standard

(mm3/stcyl.)

100

REC OFF

100

REC OFF

3.4 0.1

17.0 0.1

Injection Quantity

Command

First Second Third

digit digit

digit

360

SPV OFF

100

REC OFF

360

SPL

100

REC OFF

3.4 0.1

17.0 0.1

Remarks

If Q is out of Target

Quantity with 4, 5, 3, adjust

2nd. and 3rd. digits to get

"Target Quantity".

Re-measurement

When the correction value is raised by 1 level,

the injection quantity is increased approx. 0.2 - 0.3 mm3/st (0.04 - 0.06 cc/200st).

9. ADJUSTMENT OF CAM ANGLE

ECD CONTROLLER SETTING

Pump

Speed

(rpm)

Display

Selector

Injection Quantity

Command

First Second Third

digit digit

digit

0

to

360

Cam

Angle

360

Cam

Angle

Duty

Ratio

Command

Pump

Select

Switch

Target Angle

(CA)

[Data on Display]

100

REC OFF

14.05 0.50

100

REC OFF

14.05 0.50

NOTE : Select "REC ON" position after "Target Angle" is gotten.

: Never forget removing pressure sensor from piping.

Remarks

Adjust 2nd. and 3rd. digits to get "Target

Angle".

FOR EPS - 815

096500-3060

the correction value is raised by 1 level, the injection quantity

( When

)

is increased approx. 0.2 - 0.3 mm /stcyl (0.04 - 0.06 cc/200stcyl).

10. ADJUSTMENT OF FUEL DELIVERY

ECD CONTROLLER SETTING

Pump

Speed

(rpm)

Display

Selector

Injection

Quantity

Command

Duty

Ratio

Command

Pump

Select

Switch

100

100

340

340

850

850

1275

1275

2125

2125

Q Adjust

Q Adjust

Q Adjust

Q Adjust

Q Adjust

Q Adjust

Q Adjust

Q Adjust

Q Adjust

Q Adjust

000

100

200

300

400

500

600

700

800

900

0

0

0

0

0

0

0

0

0

0

REC OFF

REC OFF

REC OFF

REC OFF

REC OFF

REC OFF

REC OFF

REC OFF

REC OFF

REC OFF

Target Quantity

[DENSO Standard]

(cc/200stcyl.)

Bench Standard

(mm3/stcyl.)

Max.

Spread In

Delivery

(mm3/st)

Outlet Fuel

Temperature

(C)

3.8 0.3

10.2 0.5

1.6 0.2

6.8 0.3

2.8 0.3

8.3 0.3

2.8 0.3

9.1 0.3

3.4 0.4

8.8 0.3

17.6 1.7

49.1 2.5

6.9 1.0

31.7 1.5

13.2 1.5

40.7 1.5

13.3 1.5

44.3 1.5

16.9 1.8

40.4 1.5

6.0

2.0

2.5

2.5

2.5

41.0 1.5

41.0 1.5

41.0 1.5

41.0 1.5

42.0 1.5

42.0 1.5

44.0 1.5

44.0 1.5

50.0 1.5

50.0 1.5

NOTE : Adjust 2nd. and 3rd. degits of "Injection Volume Command Value" switch to get target quantity.

11. RECONFIRMATION OF FUEL DELIVERY

ECD CONTROLLER SETTING

Pump

Speed

(rpm)

Display

Selector

Injection

Quantity

Command

Duty

Ratio

Command

Pump

Select

Switch

100

100

340

340

850

850

1275

1275

2125

2125

Confirm

Confirm

Confirm

Confirm

Confirm

Confirm

Confirm

Confirm

Confirm

Confirm

000

100

200

300

400

500

600

700

800

900

0

0

0

0

0

0

0

0

0

0

REC OFF

REC OFF

REC OFF

REC OFF

REC OFF

REC OFF

REC OFF

REC OFF

REC OFF

REC OFF

Target Quantity

[DENSO Standard]

(cc/200stcyl.)

Bench Standard

(mm3/stcyl.)

Max.

Spread In

Delivery

(mm3/st)

Outlet Fuel

Temperature

(C)

3.8 0.3

10.2 0.5

1.6 0.2

6.8 0.3

2.8 0.3

8.3 0.3

2.8 0.3

9.1 0.3

3.4 0.4

8.8 0.3

17.6 1.7

49.1 2.5

6.9 1.0

31.7 1.5

13.2 1.5

40.7 1.5

13.3 1.5

44.3 1.5

16.9 1.8

40.4 1.5

6.0

2.0

2.5

2.5

2.5

41.0 1.5

41.0 1.5

41.0 1.5

41.0 1.5

42.0 1.5

42.0 1.5

44.0 1.5

44.0 1.5

50.0 1.5

50.0 1.5

12. CHECK POINT

ECD CONTROLLER SETTING

Pump

Speed

(rpm)

Display

Selector

Injection

Quantity

Command

Duty

Ratio

Command

Pump

Select

Switch

2550

2600

Confirm

Confirm

A00

B00

0

0

REC OFF

REC OFF

Target Quantity

[DENSO Standard]

(cc/200stcyl.)

Bench Standard

(mm3/stcyl.)

Outlet Fuel

Temperature

(C)

3.6 0.6

2.0 or less

18.3 3.0

9.9 or less

52.0 4.0

53.0 4.0

13. NOTE

Timing mark re-marking position : Based on cylinder A, cam lift distance (plunger) should be 1.25 mm

S-ar putea să vă placă și

- (Oto-Hui - Com) Edc Hino s05Document2 pagini(Oto-Hui - Com) Edc Hino s05ahmed_eng_1500Încă nu există evaluări

- 8520A060A TestplanDocument2 pagini8520A060A TestplanBaytolga can100% (1)

- Diesel Injection Pump Test BenchDocument15 paginiDiesel Injection Pump Test BenchedgarjayaÎncă nu există evaluări

- PQ1000 Operetion Manual-New PDFDocument4 paginiPQ1000 Operetion Manual-New PDFtong SaetungÎncă nu există evaluări

- All Passenger Car Dealers/TascsDocument9 paginiAll Passenger Car Dealers/TascssouravÎncă nu există evaluări

- Common Rail Injectors Repairing Table: MM Bar M M M NM NM NM NMDocument1 paginăCommon Rail Injectors Repairing Table: MM Bar M M M NM NM NM NMakhmedÎncă nu există evaluări

- Ref. No.: EG 4010 Date: Page: Jul., 2004Document80 paginiRef. No.: EG 4010 Date: Page: Jul., 2004mpecha67% (3)

- Control Elec Ecd-V3Document21 paginiControl Elec Ecd-V3Fabian Henao Calle100% (1)

- Daewoo Matiz 2000-2013 Wheel AlignmentDocument6 paginiDaewoo Matiz 2000-2013 Wheel AlignmentOMARÎncă nu există evaluări

- Bk2q-9k546-Ag 20190701 143833Document2 paginiBk2q-9k546-Ag 20190701 143833คุณชายธวัชชัย เจริญสุขÎncă nu există evaluări

- Back Leak TestDocument13 paginiBack Leak Testcartronix20100% (1)

- 1458718041Document24 pagini1458718041Jose Camacho HernandezÎncă nu există evaluări

- Fit For The Future:: Everything For Diesel ServiceDocument68 paginiFit For The Future:: Everything For Diesel Servicemihai37100% (2)

- ECD-V4 OutlineDocument4 paginiECD-V4 OutlineВячеслав ГлушакÎncă nu există evaluări

- CRS (ECD-U2P) For Land CruiserDocument45 paginiCRS (ECD-U2P) For Land CruiserВячеслав ГлушакÎncă nu există evaluări

- Seven Nozzles - Catalogue - 2012-12+updatesDocument94 paginiSeven Nozzles - Catalogue - 2012-12+updatesPier GattiÎncă nu există evaluări

- 096500-0101 ToyotaDocument9 pagini096500-0101 Toyotan95kÎncă nu există evaluări

- 2.8 Zexel Pump1Document2 pagini2.8 Zexel Pump1cork_ieÎncă nu există evaluări

- Ford Ranger BrochureDocument8 paginiFord Ranger BrochureGabriel Andrew EstrellaÎncă nu există evaluări

- Vp44 Injection Pump Repair ManualDocument2 paginiVp44 Injection Pump Repair Manualmarran almarranyÎncă nu există evaluări

- GME TX4200 Owner's ManualDocument33 paginiGME TX4200 Owner's ManualHelen HelenopoulosÎncă nu există evaluări

- Bomba de Alta Predion Denso Hp4Document4 paginiBomba de Alta Predion Denso Hp4pepeladazoÎncă nu există evaluări

- Nozzles and Spare Parts For: Denso Common Rail InjectorsDocument6 paginiNozzles and Spare Parts For: Denso Common Rail InjectorsBalariniRetífica100% (1)

- Test Plan: 9320A070 MODY02: Pump SpecificationDocument7 paginiTest Plan: 9320A070 MODY02: Pump SpecificationUserfabian215Încă nu există evaluări

- 08 Engine MechanicalDocument80 pagini08 Engine MechanicalmadcostaÎncă nu există evaluări

- Oem Components For VRZ Type Injection PumpsDocument3 paginiOem Components For VRZ Type Injection PumpsMoaed KanbarÎncă nu există evaluări

- Nantai Products 2014Document40 paginiNantai Products 2014Alex Pakito100% (1)

- Hino Parts Torque Summer 2012 PDFDocument8 paginiHino Parts Torque Summer 2012 PDFWahyu Bayu Aji100% (2)

- TCM InjectorSID05 7Document7 paginiTCM InjectorSID05 7leather_nunÎncă nu există evaluări

- Dokumen - Tips - Bomba Ve VRZ Ee14e 11162 VRZ Service ManualDocument117 paginiDokumen - Tips - Bomba Ve VRZ Ee14e 11162 VRZ Service ManualAntonio GasparÎncă nu există evaluări

- Denso CodeDocument5 paginiDenso CodeTamer MoustafaÎncă nu există evaluări

- Mhi Turbo Applications MelettDocument5 paginiMhi Turbo Applications MelettSteven BraganÎncă nu există evaluări

- Differential CaseDocument5 paginiDifferential CaseOmar Jayson Siao VallejeraÎncă nu există evaluări

- TICS Pump Electrical Part Resistance For HINODocument35 paginiTICS Pump Electrical Part Resistance For HINOBala Equal BalanceÎncă nu există evaluări

- 0 400 866 208 TestPlanDocument2 pagini0 400 866 208 TestPlanคุณชายธวัชชัย เจริญสุข100% (2)

- Common Rail Injector Tester CR-C +S60H Multifunction Test MachineDocument3 paginiCommon Rail Injector Tester CR-C +S60H Multifunction Test MachineAlen HuangÎncă nu există evaluări

- CET Power - Agil Modular UPS - User Manual - v7.4Document66 paginiCET Power - Agil Modular UPS - User Manual - v7.4Renzo Velarde100% (1)

- 1960000-5272 2Document5 pagini1960000-5272 2Edinson Ariel Chavarro QuinteroÎncă nu există evaluări

- Ford Kuga 2.5L 2008 Timing BeltDocument5 paginiFord Kuga 2.5L 2008 Timing BeltSenaMecánicaElectrónicaÎncă nu există evaluări

- Launch x431 Heavy Duty For Trucks Vehicle ListDocument85 paginiLaunch x431 Heavy Duty For Trucks Vehicle ListARYÎncă nu există evaluări

- Common Rail System (CRS) SERVICE MANUAL: Operation: YD2K3 EngineDocument44 paginiCommon Rail System (CRS) SERVICE MANUAL: Operation: YD2K3 EngineAntony ColonnaÎncă nu există evaluări

- Plunger Element 090150-5681Document1 paginăPlunger Element 090150-5681dieselinjectionÎncă nu există evaluări

- Daedong Marine Tec Inc. 2012 CATALOGUEDocument8 paginiDaedong Marine Tec Inc. 2012 CATALOGUEhaphong30000% (1)

- F 002 A0z 755 Spare PartsDocument17 paginiF 002 A0z 755 Spare PartsGowtham100% (1)

- Service Manual: Common Rail System (CRS) For Isuzu 6de1 EngineDocument33 paginiService Manual: Common Rail System (CRS) For Isuzu 6de1 EngineDagar GRÎncă nu există evaluări

- 2003 CodesDocument6 pagini2003 Codesonyx_lucianoÎncă nu există evaluări

- How To Diagnose Vp44 Fuel System IssuesDocument17 paginiHow To Diagnose Vp44 Fuel System Issuesมนต์ชัย บุญธนลาภÎncă nu există evaluări

- x431 Isuzu Thailanda - Progra. Injector DieselDocument2 paginix431 Isuzu Thailanda - Progra. Injector Dieselwilliam_senati20057051Încă nu există evaluări

- 9161Document5 pagini9161BaytolgaÎncă nu există evaluări

- 01EJ3051Document3 pagini01EJ3051ForteLubÎncă nu există evaluări

- Injection Pump Test SpecificationsDocument3 paginiInjection Pump Test Specificationsaddiesel100% (1)

- 01EJ0081Document3 pagini01EJ0081ForteLub100% (1)

- Inj. Pump Calibration Data: 1. Test ConditionsDocument6 paginiInj. Pump Calibration Data: 1. Test ConditionsMiguel RojasÎncă nu există evaluări

- 01EK1410Document2 pagini01EK1410Ventas DamÎncă nu există evaluări

- 01EJ2010Document3 pagini01EJ2010ForteLubÎncă nu există evaluări

- Inj - Pump C Alibratio N Data: 1.test ConditionsDocument2 paginiInj - Pump C Alibratio N Data: 1.test ConditionsDavid Carlos Dady0% (1)

- Hino FuelPump Calibrate 098000-1150Document2 paginiHino FuelPump Calibrate 098000-1150คุณชายธวัชชัย เจริญสุข100% (2)

- 01EK1310Document2 pagini01EK1310ficoschaÎncă nu există evaluări

- Inj. Pump Calibration Data: 1. Test ConditionsDocument4 paginiInj. Pump Calibration Data: 1. Test ConditionsEdinson Ariel Chavarro Quintero100% (2)

- Inj. Pump Calibration Data: 1. Test ConditionsDocument6 paginiInj. Pump Calibration Data: 1. Test ConditionsMiguel RojasÎncă nu există evaluări

- Delphi Electronic Unit Injectors Catalog PDFDocument20 paginiDelphi Electronic Unit Injectors Catalog PDFAlex Pakito100% (2)

- Delphi E3 Unit Injector PDFDocument2 paginiDelphi E3 Unit Injector PDFAlex Pakito100% (1)

- 200LC Technical Manual Operation and Tests TM1663 PDFDocument696 pagini200LC Technical Manual Operation and Tests TM1663 PDFAlex Pakito100% (1)

- NuevoDocumento 2017-05-23 PDFDocument55 paginiNuevoDocumento 2017-05-23 PDFAlex PakitoÎncă nu există evaluări

- Testeo y Ajuste Motor D7GDocument140 paginiTesteo y Ajuste Motor D7GAlex PakitoÎncă nu există evaluări

- Overviewpartno PDFDocument48 paginiOverviewpartno PDFAbomazen Galal100% (1)

- Ddec VI Troubleshooting PDFDocument122 paginiDdec VI Troubleshooting PDFAlex PakitoÎncă nu există evaluări

- Injection Pump Cat 3406Document115 paginiInjection Pump Cat 3406Vicente Ortiz Delgado94% (34)

- Nantai Catalog 2015Document41 paginiNantai Catalog 2015Alex PakitoÎncă nu există evaluări

- Common Rail SparesDocument20 paginiCommon Rail SparesMilan Blagojevic100% (4)

- Bomba Zexel PFDocument1 paginăBomba Zexel PFCarlos RomeroÎncă nu există evaluări

- Fuel D13Document12 paginiFuel D13Eduardo Pai Tocarlo90% (40)

- The Proforma Invqwqoice For Your CRS300 Common Rail Test Bench 2015.6.11Document1 paginăThe Proforma Invqwqoice For Your CRS300 Common Rail Test Bench 2015.6.11Alex PakitoÎncă nu există evaluări

- Slides.D13A. Presentation. enDocument10 paginiSlides.D13A. Presentation. enAlex PakitoÎncă nu există evaluări

- Product Matrix: The Chart Below Defines The Necessary Components To Test Target Eui/EupsDocument1 paginăProduct Matrix: The Chart Below Defines The Necessary Components To Test Target Eui/EupsAlex PakitoÎncă nu există evaluări

- Nantai Products 2015Document46 paginiNantai Products 2015Alex PakitoÎncă nu există evaluări

- ADocument6 paginiASamir Ami100% (2)

- Dpico: Inj. Pump Calibration DataDocument5 paginiDpico: Inj. Pump Calibration DataAlex PakitoÎncă nu există evaluări

- Nantai Products 2014Document40 paginiNantai Products 2014Alex Pakito100% (1)

- ADocument6 paginiASamir Ami100% (2)

- 606 9460Document2 pagini606 9460Alex PakitoÎncă nu există evaluări

- APEX408 QuotationDocument1 paginăAPEX408 QuotationAlex PakitoÎncă nu există evaluări

- 01EJ2000Document3 pagini01EJ2000ForteLubÎncă nu există evaluări

- Injection Pump Test Specifications: CPS CPS21 AVM2PC-10hp AVM2PC-20hpDocument2 paginiInjection Pump Test Specifications: CPS CPS21 AVM2PC-10hp AVM2PC-20hpAlex PakitoÎncă nu există evaluări

- l200 Diagrama 7Document4 paginil200 Diagrama 7Alex PakitoÎncă nu există evaluări

- Specifications SENR6411-08-01-ALLDocument112 paginiSpecifications SENR6411-08-01-ALLИгорь СамоукинÎncă nu există evaluări

- Specs VC82ASEDocument1 paginăSpecs VC82ASEyudi handokoÎncă nu există evaluări

- CAT - C7 (Prefix C7S) .C7S300-UpDocument12 paginiCAT - C7 (Prefix C7S) .C7S300-UpPhil B.Încă nu există evaluări

- Spare Part XSRDocument3 paginiSpare Part XSRAziz RahmatullahÎncă nu există evaluări

- 04rx8-Service Highlights PDFDocument540 pagini04rx8-Service Highlights PDFAnonymous wpUyixsjÎncă nu există evaluări

- 2019 ERIKC Diesel Injector Spare Parts & Tool Catalog PDFDocument33 pagini2019 ERIKC Diesel Injector Spare Parts & Tool Catalog PDFHerbert SanchezÎncă nu există evaluări

- 203 SenDocument4 pagini203 SenSiding BarroÎncă nu există evaluări

- Soul 2010 1.6LDocument71 paginiSoul 2010 1.6LIsmael RodriguezÎncă nu există evaluări

- Evo 4-5-6 Conversion To Evo7-8 ECU Pinout DiagramsDocument10 paginiEvo 4-5-6 Conversion To Evo7-8 ECU Pinout Diagramsrjlaforteza100% (3)

- (TM) Suzuki Manual de Taller Suzuki Samurai 2000Document266 pagini(TM) Suzuki Manual de Taller Suzuki Samurai 2000Antonio Jose Delgado RodriguezÎncă nu există evaluări

- ECM Daewoo MatizDocument5 paginiECM Daewoo Matizwnsd88% (8)

- February 9, 2009 S-B-18.00/40a S-B-18.00/40 Dated October 28, 2008 18Document9 paginiFebruary 9, 2009 S-B-18.00/40a S-B-18.00/40 Dated October 28, 2008 18kevin gradinÎncă nu există evaluări

- Manoj ReportDocument119 paginiManoj ReportPratikmundraÎncă nu există evaluări

- 757 PW2 CH 75 2004 SingleDocument23 pagini757 PW2 CH 75 2004 SingleDiego Ruddy Arcaine ZegarrundoÎncă nu există evaluări

- Fiat 128 MotoriDocument13 paginiFiat 128 MotoriZastava 101 KlubÎncă nu există evaluări

- How Stuff Works Industrial RevolutionDocument3 paginiHow Stuff Works Industrial RevolutionHarry PettsÎncă nu există evaluări

- Almera n16 Europa Em-K9kDocument98 paginiAlmera n16 Europa Em-K9kMARK llÎncă nu există evaluări

- 8FD30Document11 pagini8FD30El Castillo Del Diablo0% (1)

- Isuzu Rodeo X22SE PDFDocument576 paginiIsuzu Rodeo X22SE PDFOrlando ZaldivarÎncă nu există evaluări

- N2kmQ5 - 0521644895 - 0521642779engines PDFDocument268 paginiN2kmQ5 - 0521644895 - 0521642779engines PDFvalles_1168100% (2)

- AfterSales Training - Air Cooled Engine RepairDocument72 paginiAfterSales Training - Air Cooled Engine RepairPaul Williams100% (2)

- D51ex-22-Catalogo Atualizado Kepb023313Document555 paginiD51ex-22-Catalogo Atualizado Kepb023313Josiel Grunhauser100% (2)

- M0064186 New Cylinder Pack Components Are Now Available For Certain 793 Motores Reman 793 CuffedDocument8 paginiM0064186 New Cylinder Pack Components Are Now Available For Certain 793 Motores Reman 793 CuffedEstevaoÎncă nu există evaluări

- Esécificaciones Alfa Romeo 145 Twin Spark Engine AR 38501 PDFDocument2 paginiEsécificaciones Alfa Romeo 145 Twin Spark Engine AR 38501 PDFJhon VillamizarÎncă nu există evaluări

- Exhaust Gas Recirculation SystemDocument6 paginiExhaust Gas Recirculation SystemgustavoÎncă nu există evaluări

- HCCI SeminarDocument20 paginiHCCI SeminarSandeep Pathak100% (1)

- Reciprocating EnginesDocument3 paginiReciprocating EnginesHarish Reddy Singamala100% (1)

- Johnson 6HP 1965-68Document8 paginiJohnson 6HP 1965-68Brtnik1100% (1)

- Wacker RT820Document204 paginiWacker RT820Luiggii BanyaiÎncă nu există evaluări

- HMMWV Test-Diagnostics PDFDocument168 paginiHMMWV Test-Diagnostics PDFAnonymous 6dNlD7n0Încă nu există evaluări