Documente Academic

Documente Profesional

Documente Cultură

Entp4360 tc4 Team4 Chemprinter

Încărcat de

api-273016097Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Entp4360 tc4 Team4 Chemprinter

Încărcat de

api-273016097Drepturi de autor:

Formate disponibile

1

The 3D Chemputer

Application of Technology from The Economists Printing a Bit of Me

Jeremy Bates

Alan Houth

Dominic Lakhotia

Ram Maramba

University of Texas at Dallas

Fall 2014

THE 3D CHEMPUTER

Abstract

The article we selected discusses the creation of human organ tissue by means of 3D printing.

The possibility of successful bioprinting has many implications in the medical field including

safe testing of drugs, repairing tissue and muscle, and the potential to synthesize a complete

organ, though current technology is not advanced enough to design complex vascular systems.

It is with this emphasis on health and 3D printing that guided our groups focus to the

concept of 3D printing pharmaceuticals. Our creative process began with the idea of printing

living tissue. From there we considered the idea of printing the fungi found in penicillin. We

elected to take a less myopic approach by expanding the constraints placed on our concept,

which led to including all pharmaceutical drugs. Included in our report are technical feasibility

analysis, economic & political impact analysis, and the implementation of our proposed

concept.

THE 3D CHEMPUTER

Overall Impact

The 3D printer revolution has democratized manufacturing, making high-fidelity production

accessible to individuals. While economies of scale will always exist, 3D printing allows for rapid

prototyping and soft manufacturing at reasonable operating costs aimed at consumers.

This intersection of technology and accessibility has produced two notable emergent

properties: portability and little to no penalty for prototyping. 3D printers, both turnkey and

custom built, are inherently small and movable. Retail products are designed to be deliverable

by freight and custom built products are normally based off of commercial off-the-shelf

products also delivered through consumer channels. Although highly software-dependent,

operating costs are kept low due to cheap consumables. These printers also use soft tooling,

requiring small or no fixturing to fabricate items.

These two traits make 3D printing an ideal solution to many long-standing issues with research

teams across all fields, but the value of these solutions is especially high in the medical arena.

The bioprinting company Organovo has taken advantage of these qualities, modifying small,

commercially available printers at its outset to rapidly produce and test synthesized human

tissue until finding a commercially viable and sound product to bring to market.

Before 3D printing, the techniques available to manufacture slivers of tissue were an intensive,

manual process. The volume of information gleaned from repeated prototyping and testing

provided by rapid prototyping would take years to accumulate. The cost of this expertise does

not come cheaply; costs would quickly become prohibitive to manufacture these prototypes by

THE 3D CHEMPUTER

hand. With 3D printing, prototypes can be produced in under an hour and the process is

scalable once a viable product is found.

Applying these same traits to pharmaceutical manufacturing yields the same staggering results

with one important difference: medication is not nearly as fragile and does not require the

same care as manufactured human tissue. This further democratizes the process, making

pharmaceutical manufacturing accessible further down the supply chain, right down to the

consumer. Feasibly, customers will get better suited drugs faster as needed. This will reduce

cycle times, waste, and an ongoing process of trial and error before finding the right dosage

from off-the-shelf items.

Accessibility will no longer be an issue, but regulation will. Removing professional

intermediaries like pharmacies will also remove much needed inspection points and general

expertise. New regulation must be framed around direct access by consumers to already highlyregulated products. These changes must take an integrative approach, covering issues ranging

from product quality to abuse and illicit use. Chemistry is chemistry and the potential for abuse

of raw ingredients is a sizable hurdle.

The overall impact of this new process will largely be composed of balancing this newfound

accessibility within the proper guidelines of both medicine and the law. Fortunately,

prescription medication already has a robust policy framework. Wholesale changes will be slow

and will need constant adjustment, but the expertise and infrastructure already exists to

develop and police new regulation.

THE 3D CHEMPUTER

The second emergent property of portability will have a significant, wide-reaching impact to

manufactured medicine. The constant need to stay on a drug regimen has implications to a

middle-income American family on vacation, poverty-stricken children in Metro Manila, or

researchers in the Amundsen-Scott South Pole Station in Antarctica. The ability to bring a

consistent, continuous source of medication anywhere will change the face of personal

healthcare worldwide.

Printed pharmaceuticals are an intersectional concept, but the parts of the sum continue to

develop at a rapid pace. Canon and LG make pocket-sized photo printers using similar

technology to the original consumer printers modified by Organovo. As these new directional

technologies develop, advancements can be ported into the printed pharmaceutical industry.

Portable solutions with pre-measured materials will allow individuals to create customized

medications even in remote locations. Missionary doctors can synthesize specific compounds

for underserved children and adults in provincial areas. In isolated research facilities,

pharmacists can remotely manufacture medicine for minor ailments on a printer locally

accessible to researchers.

More importantly, as covered below, the economics of pharmaceutical medication will be

drastically altered, removing the cost and bureaucracy of middlemen between manufacturers

and consumers.

THE 3D CHEMPUTER

Technical Feasibility

In 2011 at a TED conference, Lee Cronin, leader of a world-class team of chemists at Glasgow

University, spoke about his teams efforts to create inorganic life. In 2012, he returned to the

same stage to reveal his most recent research endeavor -- a 3D Chemputer that combines 3D

printing and the fundamentals of mechanosynthesis to create medicine.

Mechanosynthesis, put simply, is the construction of molecules using incredibly sophisticated

machinery that works at the atomic level. Dr. Mohamed Alhnan, lecturer in pharmaceutics at

the University of Central Lancashire, has patented a special 3D printer prototype that assembles

at the molecular level -- this printer could be adapted to print pharmaceutical compounds (The

Fix).

The filaments of Dr. Alhnans printer, which usually produce polymers, would be modified to

produce pharmaceutical compounds. These medical filaments have special properties that

enable them to be combined with antibacterial, and in particular, chemotherapeutic drug

compounds (Inside3dp). Pharmacists can infuse the filament with the appropriate dosage

requirement of a certain drug, and then use the Chemputer to transform the drug-infused

biomaterial into capsules or pills.

If implemented on a global scale, healthcare systems around the world would save hundreds of

millions of dollars every year spent on bulk production of medicine -- by moving control from

Big Pharma into the hands of the consumer, the entire distribution model of medicine would

be, in essence, flattened (The Week).

THE 3D CHEMPUTER

This revolutionary device would put an end to the one size fits all dose, where patients have

historically been subjected to taking too much or too little of a prescribed drug. With some

medications, like those that treat liver disease, a fraction of a milligram of a drug makes a big

difference in the effects on an individual, and pharmaceutical laboratories have trouble

tailoring their drug production due to insurmountable costs (Telegraph).

With the Chemputer, chemicals and dosages could be tailored to meet each individuals specific

needs. Additionally, allergies and other health concerns can be edited out. Patients would

enter their prescription information at an online pharmacy and have access to chemical

blueprints and chemical ink. They could then print the drug in their own home with a 3D

molecular printer.

Political and Economic Feasibility

Whenever a truly disruptive innovation is born, one has to look at who will be affected by the

change. Inefficiency and redundancy breed both jobs and incomes. But, just because the

current framework provides jobs does not mean that it is appropriate to stick with the same

framework indefinitely. Just look at the U.S. agriculture industry; taxpayers effectively pay

American farmers wages through government subsidies. America could purchase its food from

other countries at a much more cost-effective rate than paying farmers in America for the same

goods. The reasons to subsidize local food sources: to reduce reliance on foreign sources and to

keep afloat an often, but not always, profitable industry.

It is counterintuitive for a nation to foot the bill for an obsolete industry. Logic would indicate

that it would be more advantageous for a country to focus its resources on the most advanced

THE 3D CHEMPUTER

industries, areas where none of a nations competitors can rival them. Nevertheless, farm

subsidies are a complex issue with many players involved. Where truly radical change is

introduced, all the players involved must be taken into account.

First we can look at the manufacturers of pharmaceuticals. If consumers are able to print

medication, how does this affect the profits of the manufacturer? Manufacturers will not

willingly sell fewer products or generate less profit through sales. Perhaps they are increasing

their margins by not being forced to physically distribute their products. And what would they

be selling exactly? Possibly the physical materials needed to synthesize medications or the

blueprint needed to print the drugs. The blueprint might be licensed out and paid for annually

or as a onetime fee. Measures must be ensured to prevent piracy of pharmaceutical blueprints.

If the manufacturers stand to lose profit in any area of their business, they have the ability to

use their deep pockets and clout in Washington to purchase favorable legislation.

Intermediaries such as pharmacies will also need to consider how their business will be

impacted by the advent of 3D pharmaceutical printing. Stores like Walgreens and CVS are

basing their business models on the health aspects of everyday life. Would they have a place in

this new framework? They might stock materials for printing as opposed to the actual drugs. If

so, is this framework any more efficient than the current one? After-all, if the only change is in

the distribution of printing materials instead of drugs themselves, we must consider if

significant amounts of money are being saved. Perhaps the printing materials are very dense,

and by virtue more cost-effective than physical drugs.

THE 3D CHEMPUTER

Finally we have to consider the end-consumers themselves. Would printing drugs be a cheaper

or otherwise more desirable alternative to the current framework? It is easy to believe that

purchasing the raw materials in mass would be more economical than buying synthesized

medications, but questions remain about the complexity of the process of actually printing the

drugs. Would it be worthwhile to average consumers, is the pressing question. One advantage

is the potential to print drugs that are not currently produced because there is not currently a

market large enough to justify manufacturing them. Chemistry professor Lee Chronin

elaborates, This model changes that economy of scale; it could makes any drug cost effective

(The Guardian). It is reasonable to presume that facilities such as retirement homes and

hospitals would benefit more from such technology rather than the end-consumers. It would be

advantageous for a retirement home to possess the capability of printing drugs as opposed to

relying on deliveries or dedicating employee time to retrieving them. In that sort of high

consumer-to-3D printer environment the marginal cost is decreased.

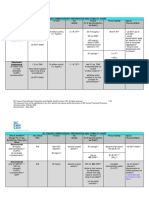

Implementation: Time and Cost

The disruptive innovation of products, services, experiences, and technology requires large

amounts of time to implement -- sometimes taking a lifetime for the founder or even passing

the task on to the next generation to ensure that it is implemented correctly and made a reality

as the perfect final product to the end users.

Likewise, the cost that comes along with disruptive innovation depends on the scale of the

business, resources, and how effectively those innovations can be managed in regards to cost

THE 3D CHEMPUTER

10

leadership. As outlined in the article Printing a Bit of Me, a set of tissues used to reproduce

human organs can cost over $2000 for laboratory testing.

The nature of creativity and innovation of new ideas always come with a high price, with the

strategy of marketing towards less price-sensitive customers, with the eventual target of pricesensitive consumers as time goes by. Our research showed that the average implementation

time for 3d biotech printers can take up to 10 years to arrive in hospitals and pharmacies. It is

projected to take an extra five years for the technology to be disseminated among the general

public.

Today, these bioprinters can cost between $150,000 and $250,000. Six-figure products have a

hard time penetrating the average consumer market. In 2014, hospitals and pharmaceutical

firms are the only viable customers. Like most high-end technology appliances, these

insurmountable costs are projected to decrease exponentially over time (Medical News Today).

Conclusion

The advent of user-manufacturable pharmaceuticals will be an enormous undertaking, but the

benefits will far outweigh the consequences. The implications are far-reaching and making this

technology accessible will take extensive testing and development. However, the technology is

sound and an infrastructure is already in place to regulate the unprecedented access to

personalized pharmaceuticals brought about by the 3D Chemprinter.

THE 3D CHEMPUTER

11

Works Cited

Adams, Tim. The Chemputer That Could Print Out Any Drug. The Guardian. Guardian

News, 21 July 2012. Web. 25 Nov. 2014.

<http://www.theguardian.com/science/2012/jul/21/chemputer-that-prints-out-drugs>.

3D Printer Custom-Made Drugs: The Future of Medicine. Inside3dp. N.p., n.d. Web. 26 Nov.

2014. <http://www.inside3dp.com/3d-printed-custom-made-drugs-future-medicine>.

3D Printed Drugs Could Revolutionise Prescriptions. The Telegraph. Telegraph Media

Group, 28 Apr. 0031. Web. 26 Nov. 2014.

<http://www.telegraph.co.uk/health/11202016/3D-printed-drugs-could-revolutioniseprescriptions.html>.

3D Printing Could Revolutionize Drugs. The Fix. N.p., n.d. Web. 26 Nov. 2014.

<http://www.thefix.com/content/we-could-soon-3d-print-drugs-home91839>.

3D Printing May Make Individualized Medicine More Affordable. Medical News Today.

MediLexicon International, 25 Oct. 2014. Web. 01 Dec. 2014.

<http://www.medicalnewstoday.com/articles/284381.php>.

Can You 3d Print Drugs? The Week. N.p., n.d. 26 Nov. 2014.

<http://theweek.com/article/index/246091/can-you-3d-print-drugs>.

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Updated Antibiotic Chart - 2016 PDFDocument2 paginiUpdated Antibiotic Chart - 2016 PDFmugenzi eric100% (1)

- Medicinal and Aromatic Crops PDFDocument194 paginiMedicinal and Aromatic Crops PDFAshutosh LandeÎncă nu există evaluări

- Best Medication for Excess Stomach AcidDocument7 paginiBest Medication for Excess Stomach AcidRiley HaneyÎncă nu există evaluări

- Emergency Crash Cart ContentsDocument15 paginiEmergency Crash Cart ContentsCLaui SagibalÎncă nu există evaluări

- MRTZ Bestel GB PDFDocument8 paginiMRTZ Bestel GB PDFmilanmcaÎncă nu există evaluări

- Clinical Trials of Drug SubstancesDocument9 paginiClinical Trials of Drug SubstancesMahum SohailÎncă nu există evaluări

- India Pharma 2020 - Executive Summary - McKinseyDocument34 paginiIndia Pharma 2020 - Executive Summary - McKinseymaheshvtajaneÎncă nu există evaluări

- Pravastatin SodiumDocument3 paginiPravastatin Sodiumapi-3797941Încă nu există evaluări

- 03 120610e Kolliphor GradesDocument6 pagini03 120610e Kolliphor GradesPanggih SaputroÎncă nu există evaluări

- Absorption of Drugs From Extravascular RoutesDocument11 paginiAbsorption of Drugs From Extravascular RoutesraviÎncă nu există evaluări

- Mdma by HPLCDocument5 paginiMdma by HPLCCarolmariaÎncă nu există evaluări

- Dermovate™ 0.05% W/W Ointment: Package Leaflet: Information For The UserDocument6 paginiDermovate™ 0.05% W/W Ointment: Package Leaflet: Information For The UsermahardiantooÎncă nu există evaluări

- BEXIMCODocument115 paginiBEXIMCONoor Ibne SalehinÎncă nu există evaluări

- Casey Malys: ExperienceDocument2 paginiCasey Malys: Experienceapi-519492883Încă nu există evaluări

- Fixed Dose CombinationsDocument1 paginăFixed Dose CombinationsSatyarth RaiÎncă nu există evaluări

- Drug Shop Dec. 202021Document88 paginiDrug Shop Dec. 202021Endre Shitaye KulkiÎncă nu există evaluări

- Chemo Stability Chart - AtoKDocument59 paginiChemo Stability Chart - AtoKAfifah Nur Diana PutriÎncă nu există evaluări

- Production Scheduling in Pharmaceutical IndustryDocument83 paginiProduction Scheduling in Pharmaceutical IndustrySubhodeep SenguptaÎncă nu există evaluări

- Senior Director Bioprocess Development in Northern California Resume Venkatesh SrinivasanDocument4 paginiSenior Director Bioprocess Development in Northern California Resume Venkatesh SrinivasanVenkateshSrinivasan1Încă nu există evaluări

- Amlodipine - C20H25ClN2O5 - PubChem PDFDocument72 paginiAmlodipine - C20H25ClN2O5 - PubChem PDFDavid HCÎncă nu există evaluări

- Avantor Services Overview BrochureDocument11 paginiAvantor Services Overview BrochureXochitemiqui YoacihualtÎncă nu există evaluări

- Aspects of 3D Printed Drugs: Journal of Medical Engineering & TechnologyDocument10 paginiAspects of 3D Printed Drugs: Journal of Medical Engineering & TechnologyRanjeet SinghÎncă nu există evaluări

- Gastric Emptying PresentationDocument8 paginiGastric Emptying Presentationrahul2kÎncă nu există evaluări

- Sulphite SensitivityDocument3 paginiSulphite SensitivityKrishan BhanotÎncă nu există evaluări

- Pharma GDPI PrepDocument1 paginăPharma GDPI PrepPRAJWAL RASTOGIÎncă nu există evaluări

- DroperidolDocument1 paginăDroperidolIvanne HisolerÎncă nu există evaluări

- CinnamonDocument4 paginiCinnamonapi-334673900Încă nu există evaluări

- Microtrac Application Notes Pigment Particle Size MeasurementDocument7 paginiMicrotrac Application Notes Pigment Particle Size MeasurementMaddyÎncă nu există evaluări

- 8435 Leche en PolvoDocument12 pagini8435 Leche en PolvomaveloÎncă nu există evaluări

- Introduction To Science and Risk Based Cleaning Validation Using ASTM E3106 E3219Document9 paginiIntroduction To Science and Risk Based Cleaning Validation Using ASTM E3106 E3219nsk79inÎncă nu există evaluări