Documente Academic

Documente Profesional

Documente Cultură

Elevators Types

Încărcat de

Waleed Mohammed Fekry0 evaluări0% au considerat acest document util (0 voturi)

7 vizualizări2 paginiElevators Types

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentElevators Types

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

7 vizualizări2 paginiElevators Types

Încărcat de

Waleed Mohammed FekryElevators Types

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

Machine-Roomless Elevators

This revolutionary elevator system is based on the first

major breakthrough in lifting technology in nearly 100

years. Designed for buildings between two and 30

stories, this system employs a smaller sheave than

conventional geared and gearless elevators. The

reduced sheave size, together with a redesigned

machine, allows the machine to be mounted within the

hoistway itselfeliminating the need for a bulky

machine room on the roof.

Just as unique are the flat polyurethane-coated steel

belts, an Otis invention for the Gen2 elevator system,

that replace the heavy, woven steel cables that have

been the industry standard since the 1800s. The belts

make the smaller sheave possible. They are only 0.1

inch (3 mm) thick, yet they are as strong as woven steel

cables and far more durable, flexible and space-saving.

Machine-roomless elevators are ideal for a variety of

applicationsand the most unusual, such as the Christ

the Redeemer monument in Rio de Janeiro.

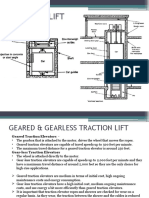

Gearless Traction Elevators

In 1903, Otis introduced the design that would become

the standard in the elevator industrythe gearless

traction elevator. These elevators typically operate at

speeds greater than 500 feet per minute (2.54 meters

per second).

In a gearless traction machine, woven steel cables

called hoisting ropes are attached to the top of the

elevator car and wrapped around the drive sheave in

special grooves. The other ends of the cables are

attached to a counterweight that moves up and down in

the hoistway on its own guiderails. The combined weight

of the elevator car and the counterweight presses the

cables into the drive sheave grooves, providing the

necessary traction as the sheave turns. Gearless

technology makes the tallest buildings in the world

possible, such as Malaysias Petronas Towers.

Geared Traction Elevators

As the name implies, the electric motor in this design

drives a gear-type reduction unit, which turns the

hoisting sheave. While slower than a typical gearless

elevator, the gear reduction offers the advantage of

requiring a less powerful motor to turn the sheave.

These elevators typically operate at speeds from 350 to

500 feet per minute (1.7 to 2.5 meters per second) and

carry loads of up to 30,000 pounds (13,600 kgs). An

electrically controlled brake between the motor and the

reduction unit stops the elevator, holding the car at the

desired floor level.

S-ar putea să vă placă și

- Elevators Type From OttisDocument2 paginiElevators Type From OttisWesame ShnodaÎncă nu există evaluări

- Elevators & Escalators: Compiled by Ar. B. K. PrabuDocument35 paginiElevators & Escalators: Compiled by Ar. B. K. PrabushobanaÎncă nu există evaluări

- ElevatorsDocument10 paginiElevatorsKavyaÎncă nu există evaluări

- Selection of Drives and Control Systems For LiftsDocument4 paginiSelection of Drives and Control Systems For LiftsSaikat ChakrabortyÎncă nu există evaluări

- Elevator TypesDocument4 paginiElevator TypesIranthaMuthuÎncă nu există evaluări

- Mechanical System ReportDocument9 paginiMechanical System ReportLea MaligsayÎncă nu există evaluări

- Basic Components of Elevator Elevator Types: Hydraulic ElevatorsDocument4 paginiBasic Components of Elevator Elevator Types: Hydraulic ElevatorsEstiven GierÎncă nu există evaluări

- Elevators and Shafts: Qurat-Ul-Ain 103 4th YrDocument5 paginiElevators and Shafts: Qurat-Ul-Ain 103 4th Yraini zahidÎncă nu există evaluări

- ElevatorsDocument11 paginiElevatorsDalia M-aÎncă nu există evaluări

- ElevatorsDocument27 paginiElevatorsshelmiÎncă nu există evaluări

- Elevator TypesDocument4 paginiElevator TypesAngelica SantosÎncă nu există evaluări

- Lift2 Escalator Travelators and Walkways9.1.16Document41 paginiLift2 Escalator Travelators and Walkways9.1.16Manoj JainÎncă nu există evaluări

- Elevators: 3 Century B.C.E 1743Document15 paginiElevators: 3 Century B.C.E 1743Mara Erna TagupaÎncă nu există evaluări

- LiftDocument22 paginiLiftAmit KumarÎncă nu există evaluări

- BMC - Escalator, ElevatorDocument23 paginiBMC - Escalator, ElevatorJisniÎncă nu există evaluări

- Elevators: Sahar Khan Jadoon FA11-BAR-017Document5 paginiElevators: Sahar Khan Jadoon FA11-BAR-017saharkj67Încă nu există evaluări

- Fundamentals of Elevators and Escalators in The WorkplaceDocument10 paginiFundamentals of Elevators and Escalators in The WorkplaceTin VillalbaÎncă nu există evaluări

- BU 2 Study Guide 6 1Document19 paginiBU 2 Study Guide 6 1Bautista JunÎncă nu există evaluări

- Types of ElevatorsDocument6 paginiTypes of Elevatorsnirvaang100% (1)

- Special Type of ElevatorDocument24 paginiSpecial Type of Elevatordeepankumar jeganathanÎncă nu există evaluări

- Building ServicesDocument57 paginiBuilding Servicessofiya0% (1)

- Functional Requirements of 8 Transportation Systems in A Building.Document40 paginiFunctional Requirements of 8 Transportation Systems in A Building.Umar Faruq AfokeÎncă nu există evaluări

- What Is Elevator / Lift?: How Does A Lift Work?Document8 paginiWhat Is Elevator / Lift?: How Does A Lift Work?ankitaÎncă nu există evaluări

- Lifts & EscalatorsDocument37 paginiLifts & EscalatorsNikita SalunkheÎncă nu există evaluări

- Term Paper 2 MENGR 3100Document5 paginiTerm Paper 2 MENGR 3100caytonericazoeÎncă nu există evaluări

- Lifts and SkyscrapersDocument9 paginiLifts and SkyscrapersSa ReddiÎncă nu există evaluări

- Design ELEVDocument30 paginiDesign ELEVShiella Barroga LorenzoÎncă nu există evaluări

- Lifting and Handling EquipmentsDocument54 paginiLifting and Handling Equipmentsalvin100% (1)

- Verticalcirculationandservices 170429050933 PDFDocument105 paginiVerticalcirculationandservices 170429050933 PDFFaisal NasimÎncă nu există evaluări

- Mech AssignmentDocument3 paginiMech AssignmentJuvy May Dedicatoria SabangÎncă nu există evaluări

- VerticalDocument26 paginiVerticalArt IjbÎncă nu există evaluări

- 10 Week NotesDocument39 pagini10 Week Notescharusri74Încă nu există evaluări

- Elevators: Types of ElevatorDocument17 paginiElevators: Types of ElevatorAngelica Marie LopezÎncă nu există evaluări

- Tugas Bahasa Inggris: New Designs Going Up-Working Knowledge On ElevatorsDocument4 paginiTugas Bahasa Inggris: New Designs Going Up-Working Knowledge On ElevatorsDodiÎncă nu există evaluări

- Vertical Circulation: Team 1Document41 paginiVertical Circulation: Team 1hanya HaythamÎncă nu există evaluări

- MRL ElevatorsDocument85 paginiMRL ElevatorsAkshay PaiÎncă nu există evaluări

- Vertical Transportation in BuildingsDocument104 paginiVertical Transportation in Buildingsiqbal s.jeelaniÎncă nu există evaluări

- ECM 216 BUILDING SERVICES Bab 2.5 Lift and ElevatorDocument5 paginiECM 216 BUILDING SERVICES Bab 2.5 Lift and ElevatorAZUAN BIN AHMAD FAUZIÎncă nu există evaluări

- Tumanon - Research No. 1 - SKYSCRAPERDocument15 paginiTumanon - Research No. 1 - SKYSCRAPERZiggy TumanonÎncă nu există evaluări

- So How Do Elevators or Lifts WorkDocument12 paginiSo How Do Elevators or Lifts WorkAyesha MAhmoodÎncă nu există evaluări

- Tugas Terjemahan B.Inggris (Jordi Arif Gultom) 5203321007Document3 paginiTugas Terjemahan B.Inggris (Jordi Arif Gultom) 5203321007DodiÎncă nu există evaluări

- Carunungan, Marie Util-313Document38 paginiCarunungan, Marie Util-313Marie Holgado CarununganÎncă nu există evaluări

- EscalatorDocument18 paginiEscalatorbhargav_eedeÎncă nu există evaluări

- Addis Ababa Bole Internationa Airport InterpriseDocument21 paginiAddis Ababa Bole Internationa Airport Interprisegari100% (1)

- Lenchico RSW2Document22 paginiLenchico RSW2Chanty LenchicoÎncă nu există evaluări

- Unit 1Document30 paginiUnit 1Navya chowdaryÎncă nu există evaluări

- Lift 1Document27 paginiLift 1shelmi100% (1)

- Gtu 11Document31 paginiGtu 11Suchitra dhrubcharan hotaÎncă nu există evaluări

- Mechanism of Passenger LiftsDocument11 paginiMechanism of Passenger LiftsrutujaÎncă nu există evaluări

- Dodi Sevent Situmorang - TR B.inggrisDocument5 paginiDodi Sevent Situmorang - TR B.inggrisLasro Banjar nahorÎncă nu există evaluări

- Elevators and Escalators Case StudyDocument14 paginiElevators and Escalators Case Studyakshay salvi0% (1)

- Transportation in Buildings: 1. Vertical 2. Inclined 3. HorizontalDocument104 paginiTransportation in Buildings: 1. Vertical 2. Inclined 3. HorizontalManoj JainÎncă nu există evaluări

- Types of Elevators - Home Elevators - Residential Elevators - 1626693900854Document9 paginiTypes of Elevators - Home Elevators - Residential Elevators - 1626693900854Aluko Damilare MosesÎncă nu există evaluări

- Bu 1Document120 paginiBu 1Chi De LeonÎncă nu există evaluări

- Pedal Operated ForkliftDocument56 paginiPedal Operated Forkliftfahamith ahamed100% (1)

- Escalators: Vivek Kamlesh KareliaDocument25 paginiEscalators: Vivek Kamlesh KareliaShubhamSachdevaÎncă nu există evaluări

- 3 Wheel Forklift For Industrial PurposesDocument33 pagini3 Wheel Forklift For Industrial PurposesRamakrishna KatkamÎncă nu există evaluări

- Lecture 7 - Mechanical Transportation - Module 3 - ElevatorsDocument21 paginiLecture 7 - Mechanical Transportation - Module 3 - ElevatorsShubhaÎncă nu există evaluări

- 4 - Unit 4Document99 pagini4 - Unit 4Saran T SÎncă nu există evaluări

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsDe la EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsÎncă nu există evaluări

- Line Items: Optimistic Averagepessimistic WebsiteDocument8 paginiLine Items: Optimistic Averagepessimistic Websiteeng_waleed2008Încă nu există evaluări

- Elkana Job Offer Letter Online Work at Your Home: Last Date Is: 07 December 2016Document2 paginiElkana Job Offer Letter Online Work at Your Home: Last Date Is: 07 December 2016eng_waleed2008Încă nu există evaluări

- Spacial SM Nsysm12830Document2 paginiSpacial SM Nsysm12830eng_waleed2008Încă nu există evaluări

- Section 3 Flange Out Ladder 2015Document8 paginiSection 3 Flange Out Ladder 2015eng_waleed2008Încă nu există evaluări

- Project CharterDocument2 paginiProject Chartereng_waleed2008Încă nu există evaluări

- Building Management System PDFDocument24 paginiBuilding Management System PDFeng_waleed2008100% (3)

- ClimaSys CV NSYCVF850M115PF PDFDocument1 paginăClimaSys CV NSYCVF850M115PF PDFeng_waleed2008Încă nu există evaluări

- JKR Road Layout Design Blueprint For IskandarDocument36 paginiJKR Road Layout Design Blueprint For Iskandarchernl2004Încă nu există evaluări

- 02 - Non-Dir Over CurrentDocument58 pagini02 - Non-Dir Over Currenteng_waleed2008Încă nu există evaluări

- ClimaSys CV NSYCVF300M230PF PDFDocument1 paginăClimaSys CV NSYCVF300M230PF PDFeng_waleed2008Încă nu există evaluări

- Hse Company ProfileDocument4 paginiHse Company Profileeng_waleed200850% (2)

- Ipcamera TutorialDocument5 paginiIpcamera Tutorialeng_waleed2008Încă nu există evaluări

- Cma - Tower Capital Market Authority Kafd - Riyadh: Delivery Inspection RequestDocument3 paginiCma - Tower Capital Market Authority Kafd - Riyadh: Delivery Inspection Requesteng_waleed2008Încă nu există evaluări

- Advance Work Request of Scheduled Activity CommencementDocument1 paginăAdvance Work Request of Scheduled Activity Commencementeng_waleed2008Încă nu există evaluări

- Leds Application To The Photovoltaic Street Lighting: M. Fathi and A. ChikoucheDocument4 paginiLeds Application To The Photovoltaic Street Lighting: M. Fathi and A. Chikoucheeng_waleed2008Încă nu există evaluări

- Request For ClarificationDocument1 paginăRequest For Clarificationeng_waleed2008Încă nu există evaluări

- Cma - Tower Capital Market Authority Kafd - Riyadh: Drawing SubmittalDocument1 paginăCma - Tower Capital Market Authority Kafd - Riyadh: Drawing Submittaleng_waleed2008Încă nu există evaluări