Documente Academic

Documente Profesional

Documente Cultură

Temperature-Rise Test Report Clipper INT 12260W KEMA

Încărcat de

Jorge BejaranoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Temperature-Rise Test Report Clipper INT 12260W KEMA

Încărcat de

Jorge BejaranoDrepturi de autor:

Formate disponibile

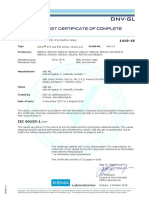

REPORT OF PERFORMANCE

OBJECT

Prefabricated substation

TYPE

Clipper C27

08-1284

SERIAL No.

37062003

1000 kVA, 20 kV / 410 V, 50 Hz

MANUFACTURER

Areva T&D

Saint Jean de Vdas, France

CLIENT

Areva T&D

Saint Jean de Vdas, France

TESTED BY

KEMA HIGH-VOLTAGE LABORATORY

Arnhem, the Netherlands

DATES OF TESTS

11 till 19 December 2007

TEST PROGRAMME

Temperature-rise test, in accordance with IEC 62271-202 (2006-06).

SUMMARY AND

CONCLUSION

The test is passed with satisfactory results in case the enclosure class is

designated as mentioned below:

1 With IP43 configuration for all compartments.

The minimum possible enclosure class is 10 K.

2 With IP43 configuration for the LV and HV switchgear compartments and

with IP23 configuration for the transformer compartment.

The minimum possible enclosure class is 5 K.

This Report of Performance applies only to the object tested. The responsibility for conformity of any

object having the same designations with that tested rests with the Manufacturer.

Version: 1

Order No: 70770177

This report consists of 24 pages in total.

Copyright: Only integral reproduction of this report is permitted without written

permission from KEMA. Electronic copies in e.g. PDF-format or scanned version of

this report may be available and have the status for information only.

The sealed and bound version of the report is the only valid version.

KEMA Nederland B.V.

P.G.A. Bus

KEMA T&D Testing Services

Managing Director

Arnhem, 22 May 2008

-2-

08-1284

TABLE OF CONTENTS

Version: 1

TABLE OF CONTENTS .......................................................................................................................... 2

1

Identification of the test object......................................................................................................3

1.1

1.2

Ratings assigned by the manufacturer ........................................................................................3

Description of the test object........................................................................................................3

1.3

List of drawings ............................................................................................................................5

2

2.1

General information......................................................................................................................6

The tests were witnessed by........................................................................................................6

2.2

The tests were carried out by.......................................................................................................6

2.3

2.4

Reference to other reports ...........................................................................................................6

Purpose of the test .......................................................................................................................6

2.5

2.6

Measurement uncertainty.............................................................................................................6

Applicable standards ....................................................................................................................6

3

3.1

Temperature-rise test ...................................................................................................................7

Temperature-rise test on the power transformer outside the enclosure ......................................7

3.1.1

3.1.2

Determination of the total losses in accordance with IEC 60076-1 .............................................7

Determination of the top oil temperature-rise of the power transformer (total losses).................7

3.2

3.2.1

Temperature-rise test on the complete assembly........................................................................8

Location of thermocouples ...........................................................................................................8

3.2.2

List of thermoucouples ...............................................................................................................10

3.2.3

3.2.4

Supplied power and supplied currents to the substation ...........................................................11

Temperature-rise test data.........................................................................................................12

APPENDIX A

MEASUREMENT UNCERTAINTIES......................................................................... 15

APPENDIX B

MANUFACTURERS DRAWINGS ............................................................................ 16

APPENDIX C

PHOTOGRAPH OF THE TEST SET-UP .................................................................. 24

-3-

08-1284

IDENTIFICATION OF THE TEST OBJECT

1.1

Ratings assigned by the manufacturer

Rated primary voltage (Umax)

24

kV

Rated secondary voltage

Rated frequency

410

50

V

Hz

Number of phases

Rated primary current

3

28,9

Rated secondary current

Rated maximum power of the substation

1406

1000

A

kVA

Rated power of transformer

1000

kVA

Total losses of transformer

12257 W

determined during tests

Rated temperature-rise class of enclosure

Rated IP class of enclosure

determined during tests

determined during tests

1.2

Description of the test object

Prefabricated substation

Manufacturer

Type

Areva T&D, Saint Jean de Vdas, France

Clipper C27

Serial no.

Drawings

37062003

see appendix B

Year of manufacture

2007

Version: 1

Transformer

Manufacturer

Type

GEC Alsthom, Le Petit Quevilly, France

UTHA

Serial no.

Power

114130

1000 kVA

Type of cooling

Vector symbol

ONAN

Dyn11

Rated primary voltage

20 kV

Rated primary current

No. of primary tappings

28,9 A

3 (20,5 kV 20,0 kV 19,5 kV)

Rated secondary voltage

Rated secondary current

410 V

1406 A

Short-circuit impedance

Winding material

5%

Al

Standard

NF C 52 113

-4-

HV Switchgear

Manufacturer

Type

Areva T&D, Mcon, France

FBX-C/24-16/C-C-T1

Serial no.

Rated voltage

FBX - 0743069/AMT

24 kV

Rated current

630 A

Rated frequency

Standard

50 Hz

IEC 62271-200

HV fuses

Manufacturer

Type

Areva T&D, Montpellier, France

FDW7.2-50-4-6 (with medium type striker pin)

No. of fuses installed

Rated voltage

Rated current

7,2 kV

50 A

Year of manufacture

Standard

2007

IEC 60282 / DIN 43625

LV switch-disconnector

Manufacturer

Socomec Guerin, France

Type

Serial no.

SIRCO 1800A / HN 63-S-61

10107-160

No. of switch disconnectors installed

No. of phases

1

3

Rated voltage

Rated current

400 V

1800 A

Rated frequency

50/60 Hz

Standard

IEC 60947-3

Version: 1

LV fuse switch-disconnector

Manufacturer

Pronutec, Lemoa, Spain

Type

No. of fuse switch disconnectors installed

BTVC 400A DU

8

No. of phases per fuse switch disconnector

Rated voltage

Rated current

690 V / 500 V

315 A / 400 A

Rated frequency

Standard

50 Hz

IEC 60947-3 / VDE 0660-107

08-1284

-5-

08-1284

LV fuse

Manufacturer

Type

Siemens

3NA3 254 (NH2-gG)

Rated voltage

Rated current

500 V

355 A

No. of of fuses installed

12

1.3

List of drawings

The manufacturer has guaranteed that the object submitted for tests has been manufactured in

accordance with the following drawing.

KEMA has verified that this drawing adequately represents the object tested.

The following drawing is included in appendix B of this report:

- 104093 D (7 sheets)

1000 kVA package substations Clipper C27 (modifications)

-6-

GENERAL INFORMATION

2.1

The tests were witnessed by

Name

Company

Mr T. Cormenier

Areva T&D

08-1284

Saint Jean de Vdas, France

2.2

The tests were carried out by

Name

Company

Mr W.J.W.M. Sloot

Mr A.H. Minkhorst

Mr R.J. Kloppenburg

Mr G.J. Jansen

KEMA Nederland B.V.,

Arnhem, the Netherlands

2.3

Reference to other reports

Report no.

Tests described

08-1285

2112200.01-QUA/INC

Temperature-rise test with additional IR radiation

Verification of the degree of protection

2.4

Purpose of the test

Purpose of the test was to verify whether the material complies with the specified requirements.

2.5

Measurement uncertainty

A table with measurement uncertainties is enclosed in appendix A. Unless otherwise indicated in the

report, the measurement uncertainties of the results presented are as indicated in this table.

2.6

Applicable standards

When reference is made to a standard and the date of issue is not stated, this applies to the latest

Version: 1

issue, including amendments, which have been officially published prior to the date of the tests.

-7-

08-1284

TEMPERATURE-RISE TEST

Standard and date

Standard

Test dates

IEC 62271-202, clause 6.3

11 19 December 2007

In particular, the test shall demonstrate that the temperature-rise of the transformer inside the

enclosure, does not exceed that measured on the same transformer outside the enclosure, by more

than the value which defines the class of enclosure.

3.1

Temperature-rise test on the power transformer outside the enclosure

3.1.1

Determination of the total losses in accordance with IEC 60076-1

item

dc-resistance

at amb of 18 C

load losses

at ref of 75 C

no-load losses

tap position

2

2

HV winding

3,6889

LV winding

1,0817 m

losses

10266 W

1991 W

total losses

3.1.2

12257 W

Determination of the top oil temperature-rise of the power transformer (total losses)

100

90

absolute temperature [C]

80

70

stability reached

12-12-2007 at 09h25

top oil: 79,2 C

average am bient: 21,3 C

60

50

40

30

20

10

0

16:00

20:00

00:00

04:00

08:00

12:00

16:00

tim e

top oil

Figure 1

am bient

am bient

Heat-run on transformer with total losses of 12,26 kW.

item

top oil temperature

average ambient temperature

top oil temperature-rise of the transformer outside the enclosure

Version: 1

am bient

a)

top-oil

79,2 C

21,3 C

57,9 K

-8-

3.2

Temperature-rise test on the complete assembly

3.2.1

Location of thermocouples

08-1284

Figures 2 and 3 show the location of the thermocouples that were installed. Figure 4 is a photograph

of the total assembly without the roof of the substation.

Version: 1

Figure 2

Location of thermocouples.

Version: 1

-9-

Figure 3

Location of thermocouples.

Figure 4

Photograph of assembled substation without roof.

08-1284

-10-

3.2.2

List of thermoucouples

The numbers indicated in figures 2 and 3 correspond with the numbers listed in the table.

TC no.

description

upper terminal main switch L1

upper terminal main switch L2

upper terminal main switch L3

lower terminal main switch L1

lower terminal main switch L2

lower terminal main switch L3

connection vertical to horizontal busbar L3

connection vertical to horizontal busbar L2

connection vertical to horizontal busbar L1

10

busbar connection fuse-switch disconnector L3

11

busbar connection fuse-switch disconnector L2

12

busbar connection fuse-switch disconnector L1

13

busbar connection strip of fuse-switch disconnector L3

14

busbar connection strip of fuse-switch disconnector L2

15

busbar connection strip of fuse-switch disconnector L1

16

top of fuse cover of fuse-switch disconnector L3

17

top of fuse cover of fuse-switch disconnector L2

18

top of fuse cover of fuse-switch disconnector L1

19

operating handle of fuse-switch disconnector L3

20

operating handle of fuse-switch disconnector L2

21

operating handle of fuse-switch disconnector L1

22

top-oil of power transformer

23

top of high-voltage switchgear

24

handle of low-voltage main switch

25

door low-voltage compartment (20 cm from top)

26

door high-voltage switchgear compartment (20 cm from top)

27

door transformer compartment (20 cm from top)

28

top louver ventilation grid transformer compartment

29

top louver ventilation grid transformer compartment

30

top louver ventilation grid transformer compartment

31

ambient

32

ambient

33

ambient

34

ambient

35

1)

cable terminal of fuse-switch disconnector L1

36

1)

cable terminal of fuse-switch disconnector L1

37

1)

cable terminal of fuse-switch disconnector L1

Version: 1

1) Temperatures measured with hand held equipment.

08-1284

-11-

08-1284

At four locations around the substation, at a distance of approximately 1m and at approximately the

average height of the current carrying parts in the substation, thermocouples were installed to

measure the ambient temperature during the test.

3.2.3

Supplied power and supplied currents to the substation

Transformer, HV and LV interconnections, and low-voltage equipment temperature-rise tests,

have been performed simultaneously. As outlined in clause 6.3.1 of IEC 62271-202, a temperaturerise test of the HV switchgear is not required. In order to be able to carry out the test on the

transformer, the LV terminals of the transformer were interconnected. The LV assembly has been

tested with a short-circuit connection on the feeding terminals of the LV switch-disconnector.

A diagram of the circuits is given in figure 5.

Figure 5

Diagram of the temperature-rise test.

Version: 1

In order to obtain the most severe conditions in respect to heat generation, the supply current of the

LV switchboard has been distributed over a minimum number of adjacent LV outgoing feeders. These

feeders were loaded with the maximum possible current and smallest possible size of the fuse rating.

-12-

08-1284

The following loading conditions were applicable during the temperature-rise test:

side

total-loss

injection in the

transformer

HV

LV

12,26 kW

rated LV

current of the

transformer

maximum

allowable

current per

1), 2)

LV-feeder

no. of adjacent

feeders

connected in

the circuit

installed fuse

size

352 A

350 A

1408 A

1) The manufacturer has declared the maximum allowable current for the LV switch-fuse disconnectors for this application.

2) The cables for the connection to the feeders of the fuse-switch disconnectors were selected In accordance with clause

8.2.1.3.1 and table 8 of IEC 60439-1. The size of the cables was 240 mm2. Adjustable impedances, installed in every LV

cable, were used to equalize the currents.

3.2.4

Temperature-rise test data

In total two tests have been carried out:

1 Test in a proved IP43 configuration for all compartments.

2 Test in a proved IP43 configuration for the LV and HV switchgear compartments and with a

proved IP23 configuration for the transformer compartment.

The absolute temperature data of both tests is shown in the graph, presented in figure 6.

100

IP43 configuration, stability reached 18-12-2007 at 10h55, top-oil: 82,9 C, average ambient: 18,0 C, top-oil temp.-rise: 64,9 K

90

Transformer compartment IP23

HV-switchgear compartment IP43

LV-switchgear compartment IP43

stability reached

18-12-2007 at 18h15

top-oil: 78,7 C

average ambient: 18,8 C

top-oil temp.-rise: 59,9 K

absolute temperature [C]

80

70

60

50

40

30

20

10

Transformer outside substation, top-oil temp.-rise: 57,9 K

0

17-12-2007

12:00

17-12-2007

16:00

17-12-2007

20:00

18-12-2007

00:00

18-12-2007

04:00

18-12-2007

08:00

18-12-2007

12:00

18-12-2007

16:00

18-12-2007

20:00

19-12-2007

00:00

19-12-2007

04:00

19-12-2007

08:00

19-12-2007

12:00

date / time

TC 1

TC 2

TC 3

TC 4

TC 5

TC 6

TC 7

TC 8

TC 9

TC 10

TC 11

TC 12

TC 13

TC 14

TC 15

TC 16

TC 17

TC 18

TC 19

TC 20

TC 21

top oil

TC 23

TC 24

TC 25

TC 26

TC 27

TC 28

TC 29

TC 30

TC 31

TC 32

TC 33

TC 34

Version: 1

Figure 6

Data of temperature-rise tests.

-13-

08-1284

The results and requirements are also listed in the following table.

TC no.

Version: 1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

1)

35

1)

36

1)

37

recorded absolute temperature

test 1

(C)

79,3

81,5

81,6

61,6

65,6

67,0

51,6

58,6

62,6

57,5

62,4

62,5

72,0

72,5

75,0

42,4

51,2

48,3

22,3

25,2

29,5

82,9

33,3

35,1

42,1

24,7

46,8

47,2

46,2

47,0

17,9

18,0

18,0

18,0

-

test 2

(C)

71,2

72,6

73,3

58,1

62,3

63,8

49,6

56,6

60,1

55,6

60,0

60,4

64,8

66,6

68,5

43,1

50,7

47,1

22,5

25,2

28,6

78,7

31,4

32,8

38,9

24,2

44,0

44,8

44,1

44,1

18,7

18,9

18,7

18,7

35,0

33,0

35,0

determined temperature-rise

test 1

(K)

61,3

63,5

63,6

43,6

47,6

49,0

33,7

40,7

44,7

39,8

44,4

44,6

54,1

54,5

57,0

24,4

33,2

30,3

4,3

7,2

11,6

64,9

15,3

17,1

24,1

6,7

28,8

29,2

28,2

29,0

-

test 2

(K)

52,4

53,8

54,6

39,4

43,5

45,0

30,8

37,8

41,4

36,8

41,2

41,7

46,0

47,9

49,8

24,3

31,9

28,3

3,8

6,4

9,9

59,9

12,7

14,1

20,2

5,5

25,3

26,1

25,3

25,4

17,0

15,0

17,0

maximum allowable

temperature-rise

(K)

65

65

65

65

65

65

65

65

65

65

65

65

40

40

40

25

25

25

1)

57,9 + class

30

25

30

30

30

40

40

40

65

65

65

-14-

08-1284

1) Top oil temperature-rise determined outside enclosure (see 3.1.2) + class of enclosure

Result

All individually determined temperature-rise values are in compliance with the requirements.

The following conclusions can be drawn from the determined top-oil temperature-rises in the two tests:

-

With IP43 configuration for all compartments, the minimum possible enclosure class is 10 K.

With IP43 configuration for the LV and HV switchgear compartments and with IP23 configuration

for the transformer compartment, the minimum possible enclosure class is 5 K.

Version: 1

Both tests are passed with satisfactory results when the enclosure class is designated as mentioned

above.

-15-

APPENDIX A

08-1284

MEASUREMENT UNCERTAINTIES

The measurement uncertainties in the results presented are as specified below unless otherwise

indicated.

measurement

measurement uncertainty

dielectric tests

and impulse current tests

peak value: 3%

capacitance measurement

0,3%

tan measurement

0,5% 5x10

time parameters: 10%

-5

partial discharge measurement

measurement of impedance

<

10 pC

2 pC

10 -

100 pC

5 pC

> 100 pC

20 %

1%

ac-resistance measurement

measurement of losses

1%

measurement of insulation resistance

10%

measurement of dc resistance

1 - 5

: 1%

5 - 10 : 0,5%

10 - 200 : 0,2%

radio interference test

2 dB

calibration of current transformers

2,2 x 10 Ii/Iu and 290 rad

calibration of voltage transformers

1,6 x 10 Ui/Uu en 510 rad

measurement of conductivity

5%

-4

-4

measurement of temperature

-50 C

-40 C : 3 K

Version: 1

-40 C 125 C : 2 K

125 C 150 C : 3 K

tensile test

1%

sound level measurement

type 1 meter as per IEC 651 and

ANSI S1.4.1971

measurement of voltage ratio

0,1%

-16-

APPENDIX B

08-1284

MANUFACTURERS DRAWINGS

Version: 1

7 pages

drawing no.

description/title

date

rev.

104093 D 1/7

1000 kVA package substations clipper C27 (modifications)

12-11-07

104093 D 2/7

104093 D 3/7

Front face

Rear face

104093 D 4/7

104093 D 5/7

Right side and left side

Top view

104093 D 6/7

Cross section A-A

104093 D 7/7

Cross section B-B

Version: 1

-17-

08-1284

Version: 1

-18-

08-1284

Version: 1

-19-

08-1284

Version: 1

-20-

08-1284

Version: 1

-21-

08-1284

Version: 1

-22-

08-1284

Version: 1

-23-

08-1284

-24-

Version: 1

APPENDIX C

PHOTOGRAPH OF THE TEST SET-UP

08-1284

S-ar putea să vă placă și

- Type Test Verification SafePlus 12 24 KVDocument8 paginiType Test Verification SafePlus 12 24 KVGary FortuinÎncă nu există evaluări

- 1MRG033422 A en KEMA Type Test Certificate of Complete Type Tests 670 and 650 Series Version 2.2Document22 pagini1MRG033422 A en KEMA Type Test Certificate of Complete Type Tests 670 and 650 Series Version 2.2Boudam BoudjemaÎncă nu există evaluări

- Technical Report - Internal Arc - OrmazabalDocument10 paginiTechnical Report - Internal Arc - OrmazabalAshish RanjanÎncă nu există evaluări

- Inspection and Test Procedures For CableDocument6 paginiInspection and Test Procedures For Cablemajid8080Încă nu există evaluări

- Type-Test Certificate of Dry-Type TransformerDocument3 paginiType-Test Certificate of Dry-Type TransformerrobievÎncă nu există evaluări

- As 60146.1.1-2002 Semiconductor Converters General Requirements and Line Commutated Converters - SpecificatioDocument10 paginiAs 60146.1.1-2002 Semiconductor Converters General Requirements and Line Commutated Converters - SpecificatioSAI Global - APACÎncă nu există evaluări

- 01 - Siemens VCB 3AHDocument40 pagini01 - Siemens VCB 3AHKrishna PardeshiÎncă nu există evaluări

- Is 1652 BatteryDocument11 paginiIs 1652 BatteryNikunj KumarÎncă nu există evaluări

- HI-POT Setup and TestingDocument10 paginiHI-POT Setup and Testingsaghaee.rezaÎncă nu există evaluări

- Cable TerminationDocument2 paginiCable Terminationapandey070273Încă nu există evaluări

- Auxiliary Transformer Test ProcedureDocument3 paginiAuxiliary Transformer Test ProcedureArun Kumar100% (1)

- Cable GlandsDocument20 paginiCable GlandsBalaji VenkatesanÎncă nu există evaluări

- Iec 62271-200 - 2011Document3 paginiIec 62271-200 - 2011Laurence Michael0% (1)

- Scsasacj0 - Distribution Technology Home - EskomDocument11 paginiScsasacj0 - Distribution Technology Home - EskomRichman MakwiramitiÎncă nu există evaluări

- Interleaved Bus Bar Explanation PDFDocument4 paginiInterleaved Bus Bar Explanation PDFVikram Singh100% (2)

- Iec-61439 Se6461Document32 paginiIec-61439 Se6461carlosmandopintoÎncă nu există evaluări

- Selection of Cables/ConductorsDocument37 paginiSelection of Cables/ConductorsshuwingÎncă nu există evaluări

- 5-CESI-CENELEC-outdoor-cold Shrink Termination-Full TestDocument31 pagini5-CESI-CENELEC-outdoor-cold Shrink Termination-Full TestlatifÎncă nu există evaluări

- Combined Instrument Transformers Ivokt TMCDocument8 paginiCombined Instrument Transformers Ivokt TMCRamzan100% (1)

- Product Quality Plan: Customer Manufacturer Conductor Type SizesDocument7 paginiProduct Quality Plan: Customer Manufacturer Conductor Type SizesAvinash LalÎncă nu există evaluări

- Cable Testing ProcedureDocument1 paginăCable Testing ProcedureSerkam PED100% (2)

- TRAX Manual enDocument58 paginiTRAX Manual enJack Duff100% (3)

- Manual Rmo TD M Rxx0td 304 enDocument30 paginiManual Rmo TD M Rxx0td 304 enHamilton Velandia GalloÎncă nu există evaluări

- CESI Short Circuit Withstand Test Dry Type Transformer Imefy 1500 11Document21 paginiCESI Short Circuit Withstand Test Dry Type Transformer Imefy 1500 11Bash MatÎncă nu există evaluări

- Certificate of Calibration and Conformance: OmicronDocument1 paginăCertificate of Calibration and Conformance: OmicronNadiaÎncă nu există evaluări

- CSC 326 Transformer Protection Ied Technical Application ManualDocument445 paginiCSC 326 Transformer Protection Ied Technical Application ManualAssistant executive engineerÎncă nu există evaluări

- Tech Specification For LT Power CableDocument23 paginiTech Specification For LT Power CablePramod B.Wankhade0% (1)

- IS 2026 Part 5Document10 paginiIS 2026 Part 5Narendra SinhaÎncă nu există evaluări

- Is 8623Document19 paginiIs 8623Gaurav AgarwalÎncă nu există evaluări

- SPG 32-1750 / 32-3500 / Surgeflex 32: Operating ManualDocument39 paginiSPG 32-1750 / 32-3500 / Surgeflex 32: Operating ManualHadi TÎncă nu există evaluări

- E VD4Document36 paginiE VD4NayanÎncă nu există evaluări

- Collar Test For BushingDocument21 paginiCollar Test For Bushingfajar9nugraha-2100% (1)

- Testing Procedure For Potential Transormer: Prepared byDocument1 paginăTesting Procedure For Potential Transormer: Prepared byGuru MishraÎncă nu există evaluări

- TDS, CSD - Iec 60502-2Document4 paginiTDS, CSD - Iec 60502-2Ghiles AOUICHEÎncă nu există evaluări

- Filling Up Hermetically Sealed TransformerDocument7 paginiFilling Up Hermetically Sealed TransformerDist Tx100% (3)

- Elect 03 Method Statement For Testing of MV Cables For CSE at SS1Document8 paginiElect 03 Method Statement For Testing of MV Cables For CSE at SS1Qwe7 Al-Al50% (2)

- International Standard: High-Voltage Test Techniques - General Definitions and Test RequirementsDocument8 paginiInternational Standard: High-Voltage Test Techniques - General Definitions and Test RequirementssknÎncă nu există evaluări

- Low Voltage and High Voltage Cable Testin1Document3 paginiLow Voltage and High Voltage Cable Testin1Himdad TahirÎncă nu există evaluări

- 1030365248421-Mvap en 0899Document4 pagini1030365248421-Mvap en 0899Stone123456789Încă nu există evaluări

- Routine Test Vs Type Test Report PDFDocument3 paginiRoutine Test Vs Type Test Report PDFMuhammad SyarifÎncă nu există evaluări

- 1 - Hi Pot Test Procedure For SwitchyardDocument6 pagini1 - Hi Pot Test Procedure For Switchyardbayu dewanto100% (1)

- Synergy Elektrik (PVT.) LTD PDFDocument3 paginiSynergy Elektrik (PVT.) LTD PDFMuhammad KashifÎncă nu există evaluări

- Test Procedure For Cable BoxDocument7 paginiTest Procedure For Cable BoxmridgreatÎncă nu există evaluări

- ZN1 ManualDocument40 paginiZN1 Manualpkgoyal1983Încă nu există evaluări

- Cable Testing Rev 0Document8 paginiCable Testing Rev 0johnyquest_007Încă nu există evaluări

- ELK145-En R58 20150701 Only For Erection ProdmanDocument432 paginiELK145-En R58 20150701 Only For Erection ProdmanAbdul Baset100% (1)

- Iph 1374.2101477.0910Document40 paginiIph 1374.2101477.0910Yudhika CibroÎncă nu există evaluări

- 2000KVA Transformer Data SheetDocument2 pagini2000KVA Transformer Data SheetCoral bhai50% (2)

- Insulation Resistance Testing of Cables in The Field-Rev-01Document22 paginiInsulation Resistance Testing of Cables in The Field-Rev-01Jalal AlbadriÎncă nu există evaluări

- EN - Tapcon 230 Expert Manual Instruþ Es de OperaþÒoDocument186 paginiEN - Tapcon 230 Expert Manual Instruþ Es de OperaþÒojoan75Încă nu există evaluări

- Cenelec: Harmonization Document Document D'Harmonisation HarmonisierungsdokumentDocument660 paginiCenelec: Harmonization Document Document D'Harmonisation HarmonisierungsdokumentMuhammad Shahrul IzwanÎncă nu există evaluări

- Itp Obp 60mva 150 - 11kvDocument8 paginiItp Obp 60mva 150 - 11kvKrisnandha RahardianÎncă nu există evaluări

- Energy Meter Testing ReportsDocument3 paginiEnergy Meter Testing ReportsViswanathan NarayananÎncă nu există evaluări

- Test Report SI-0672IPCDocument45 paginiTest Report SI-0672IPCjackyt09Încă nu există evaluări

- S7-200 Technical SpecificationsDocument78 paginiS7-200 Technical SpecificationsThuy Nguyen Xuan0% (1)

- ADu M3190Document16 paginiADu M3190Varun ThakurÎncă nu există evaluări

- D D D D D D D: SN54HC574, SN74HC574 Octal Edge-Triggered D-Type Flip-Flops With 3-State OutputsDocument16 paginiD D D D D D D: SN54HC574, SN74HC574 Octal Edge-Triggered D-Type Flip-Flops With 3-State OutputsJADERSONÎncă nu există evaluări

- Framit3 Ieee PaperDocument29 paginiFramit3 Ieee PaperFernandoMartínIranzoÎncă nu există evaluări

- Ansi Icea T 27-581-2008Document43 paginiAnsi Icea T 27-581-2008AnamulKabir67% (3)

- Frequency Response Analysis Using The Impulse Frequency Response Analysis (IFRA) MethodDocument22 paginiFrequency Response Analysis Using The Impulse Frequency Response Analysis (IFRA) MethodJorge BejaranoÎncă nu există evaluări

- Basic HiPotDocument27 paginiBasic HiPotZlatian RaduÎncă nu există evaluări

- What Means and Tools Would Be Necessary To Maintain Aged Transformer Population PDFDocument5 paginiWhat Means and Tools Would Be Necessary To Maintain Aged Transformer Population PDFJorge BejaranoÎncă nu există evaluări

- Cigre Guidelines For Life Management Techniques For Power Transformers PDFDocument125 paginiCigre Guidelines For Life Management Techniques For Power Transformers PDFJorge Bejarano100% (2)

- Final Report Concentrating Solar Thermal Power PlantsDocument95 paginiFinal Report Concentrating Solar Thermal Power PlantsEuis HafsahÎncă nu există evaluări

- Эрчим хүчний аудит гарын авлагаDocument58 paginiЭрчим хүчний аудит гарын авлагаDanaa BayantsetsegÎncă nu există evaluări

- Energy Audit Manual and ToolDocument283 paginiEnergy Audit Manual and ToolJorge BejaranoÎncă nu există evaluări

- A Manual For The Economic Evaluation of Energy Efficiency and Renewable Energy TechnologiesDocument120 paginiA Manual For The Economic Evaluation of Energy Efficiency and Renewable Energy TechnologiesJorge BejaranoÎncă nu există evaluări

- DOCWinDocument103 paginiDOCWinmujo_1Încă nu există evaluări

- Basic Electrical Characteristics and Application Designs of Low-I PhotocouplersDocument31 paginiBasic Electrical Characteristics and Application Designs of Low-I PhotocouplersWagner MirandaÎncă nu există evaluări

- Digital Image and Video Processing Nov 2022Document5 paginiDigital Image and Video Processing Nov 2022khushiduppalaÎncă nu există evaluări

- Canon 7161 Service ManuelDocument346 paginiCanon 7161 Service ManuelkopisanÎncă nu există evaluări

- Specification For Motor Actuators For ValvesDocument13 paginiSpecification For Motor Actuators For ValvesDanish MohammedÎncă nu există evaluări

- 26MF605W - LCD TV MonitorDocument108 pagini26MF605W - LCD TV MonitorJesus SilvaÎncă nu există evaluări

- Ee321 ObjectivesDocument3 paginiEe321 ObjectivesJomar DadorÎncă nu există evaluări

- Irwin, Engineering Circuit Analysis, 11e ISV Chapter 13Document92 paginiIrwin, Engineering Circuit Analysis, 11e ISV Chapter 13이잉Încă nu există evaluări

- Drayvery PMSM Servodvigateley Seriya Kbs MG User Guide EngDocument315 paginiDrayvery PMSM Servodvigateley Seriya Kbs MG User Guide EngAxel MurellerÎncă nu există evaluări

- FPGA On SOM Example 469 EuroDocument30 paginiFPGA On SOM Example 469 Euroyahia elshakhsÎncă nu există evaluări

- CDM-625A-EN Advanced Satellite ModemDocument5 paginiCDM-625A-EN Advanced Satellite ModemEsapa EyongesiÎncă nu există evaluări

- B.E. (Instrumentation & Control) Subject: Building Automation-Ii Experiment Number: 2 Title: To Study Fas Loops and ClassificationsDocument11 paginiB.E. (Instrumentation & Control) Subject: Building Automation-Ii Experiment Number: 2 Title: To Study Fas Loops and ClassificationsNɩĸʜɩɭ AɱɓʀɘÎncă nu există evaluări

- Multiple Choice Questions and Answers On Transistor Biasing - Electronics PostDocument8 paginiMultiple Choice Questions and Answers On Transistor Biasing - Electronics PostDurga DeviÎncă nu există evaluări

- Approval Sheet: Customer ManufacturerDocument7 paginiApproval Sheet: Customer ManufacturerypadillaÎncă nu există evaluări

- Modi Con 512Document60 paginiModi Con 512Time To Use BrainÎncă nu există evaluări

- PowerFlex 70 - 700 Drive - Parameters To Configure Dynamic Braking ResistorDocument2 paginiPowerFlex 70 - 700 Drive - Parameters To Configure Dynamic Braking ResistorHenrique MartinatoÎncă nu există evaluări

- Home Automation Using Arduino and IOTDocument4 paginiHome Automation Using Arduino and IOTInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- FSP Dagger PRO User ManualDocument47 paginiFSP Dagger PRO User ManualHarith FitryÎncă nu există evaluări

- This Product Is Also Available As A Modular Mechanical System Electric Cylinder EPCCDocument40 paginiThis Product Is Also Available As A Modular Mechanical System Electric Cylinder EPCCSysviewÎncă nu există evaluări

- Awg Cable IntroductionDocument2 paginiAwg Cable IntroductionFrancis LeeÎncă nu există evaluări

- Datasheet IC CARGA ZTE L2 PLUSDocument40 paginiDatasheet IC CARGA ZTE L2 PLUSsamÎncă nu există evaluări

- Boschrexroth Re29993Document4 paginiBoschrexroth Re29993Service - Anda Hydraulics Asia Pte LtdÎncă nu există evaluări

- Design and Implementation of A Gas Leakage Detector Using Wireless Data Acquisition System For Real Time Applications Using The Concept of IoTDocument3 paginiDesign and Implementation of A Gas Leakage Detector Using Wireless Data Acquisition System For Real Time Applications Using The Concept of IoTEditor IJRITCCÎncă nu există evaluări

- Frequency MeterDocument5 paginiFrequency MeterNh Chuminda YapaÎncă nu există evaluări

- Gear Tooth Speed Sensor GS1001 GS1002 Datasheet 1075695Document3 paginiGear Tooth Speed Sensor GS1001 GS1002 Datasheet 1075695Sigit RomadhonÎncă nu există evaluări

- Is - Iec.60793.1.42.2007 - OPGW Chromatic DisperssionDocument31 paginiIs - Iec.60793.1.42.2007 - OPGW Chromatic DisperssionKumara SubramanianÎncă nu există evaluări

- It8000 Indicator: Industrial Programmable Analog / Digital Controller, IP65Document6 paginiIt8000 Indicator: Industrial Programmable Analog / Digital Controller, IP65Leandro CamargoÎncă nu există evaluări

- Electrical Resistance of Semi-ConductorDocument11 paginiElectrical Resistance of Semi-ConductorZeyad EssamÎncă nu există evaluări

- Assignment 10: Unit 13 - Week 10Document4 paginiAssignment 10: Unit 13 - Week 10Anjali YadavÎncă nu există evaluări

- Ierg3820 Lab Report1 Teamc03Document8 paginiIerg3820 Lab Report1 Teamc03Iii猫一Încă nu există evaluări