Documente Academic

Documente Profesional

Documente Cultură

Calculate The Relieving Temperature & Latent Heat of Vaporization For Fire Case PSV Sizing by Shell DEP Method

Încărcat de

rohitkushTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Calculate The Relieving Temperature & Latent Heat of Vaporization For Fire Case PSV Sizing by Shell DEP Method

Încărcat de

rohitkushDrepturi de autor:

Formate disponibile

6/27/2014

Process Design Engineer Tools: To calculate the Relieving temperature & Latent Heat of Vaporization for Fire case PSV sizing by Shell DEP method.

Process Design Engineer Tools

This blog is specially Design to provide design tools for Process Design Engineers. Hope tools avilable on this site

will prove benificial for you. I always welcome you to give your valuable feed back on : lokeshjacobs@gmail.com

How you feel after

visiting m y blog

Very good

0 (0%)

Good

0 (0%)

O.K

0 (0%)

Not good

0 (0%)

Votes so far: 0

Poll closed

Blog Archive

2012 (3)

Wednesday, March 21, 2012

To calculate the Relieving temperature & Latent

Heat of Vaporization for Fire case PSV sizing by

Shell DEP method.

1 4 9 7 9

About Me

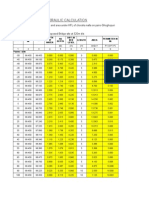

OBJECTIVE: To calculate the Relieving temperature & Latent

Heat of Vaporization for Fire case PSV sizing by Shell DEP

method.

(This method is based on mass flow it gives somewhat higher relieving temperature)

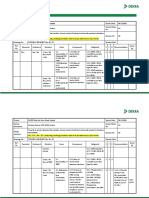

PFD: PFD developed in Aspen HYSYS

March (3)

Mar 26 (1)

Mar 21 (2)

More

accurate

Method to

calculate

the

relieving

te...

To calculate

the

Relieving

temperatur

e & Latent

He...

2009 (5)

Page view s w orld

w ide

1.

Methodology: Following are the steps to be followed for developing the

model in HYSYS.

a.

b.

c.

d.

e.

f.

g.

h.

i.

j.

Open HYSYS and define the stream component, Select fluid package then

go to simulation environment and pick a material stream from HYSYS utility

panel.

L.K. Singh

AMIChemE

Whatever I have

shared here on my

blog that experience

has come by working

with some good

companies like

IIP,JACOBS,IK-EPC

SAMSUNG,PETROFA

C. I have worked in

Refinery technology

development,PMC,EP

C,Petrochemical and

Refinery residual

basic and Detailed

Engineering,I have

also worked on

offshore and onshore

FEED,Conceptual

and Detailed

Engineering projects

for SHELL & Petronas

company.

View my complete

profile

Define the stream conditions Temperature as Operating temperature and

Pressure as Relieving Pressure give some mass flow rate let say 100 kg/hr.

Once stream (14) is conversed now put a heater (E-100) downstream of

material stream (14).

Now define the vapor fraction of stream (17) for 5% flashing by mole if

the composition basis is mole % and after that go to heater parameter and

define pressure drop across heater zero, now E-100 and stream 17 is

conversed.

Now put an Adjuster on stream 17 to adjust vapor fraction 5% by mole

basis to convert into 5% weight basis.

Now place a Flash drum (V-104) for flashing stream no 17.

Define two outlet streams 15 & 16 for V-104, 15 for vapor outlet and 16

for liquid outlet from the flash drum.

If the stream 16 vapor fraction is zero then automatically stream 16 is at

its bubble point, therefore got into the properties of stream 16 and note

down the mass enthalpy (-1969KJ/Kg).

Now place a heater E-102 downstream of stream16 to bring the stream

at its dew point.

Define a heater E-102 outlet stream 18, now define the pressure drop

across heater zero and stream vapor fraction 0.00001.

http://crazy-processdesignengineertools.blogspot.ae/2012/03/to-calculate-relieving-temperature.html

1/3

6/27/2014

Process Design Engineer Tools: To calculate the Relieving temperature & Latent Heat of Vaporization for Fire case PSV sizing by Shell DEP method.

k.

Now stream heater E-102 and stream 18 is conversed and stream 18 is at

Dew point.

l.

m.

n.

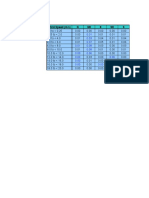

Note down the temperature of stream 18, which your relieving

temperature (194.8 deg C) at relieving pressure.

Now got to the stream 18 properties note the value of mass enthalpy (-1610

KJ/Kg).

Subtract the liquid mass enthalpy (-1969 KJ/kg) from vapor mass

enthalpy (-1610KJ/Kg), you will get the latent heat of vaporization 358.6

KJ/Kg.

Result:

1.

The Relieving Temperature at relieving Pressure is

194.6 deg C.

2. Latent Heat of Vaporization is 358.6 KJ/Kg.

Posted by L.K. Singh AMIChemE at 3:59 AM

(funny (0

Reactions:

(interesting (0

(cool (0

Recommend this on Google

2 comments:

Duy Hai December 8, 2013 at 7:59 PM

Dear Mr L.K. Singh,

your sharing is very useful. Could you explain for me the following, please:

- why define the vapor fraction of stream (17) for 5% flashing by mole? why not

3% or 10%, or any other values?

- why we should convert the vapor fraction by mole basis to vapor fraction by

weight basis?

- My mass enthalpy of streams 16 and 18 doesn't different, due to very small of

stream vapor fraction 0.00001.

Thank you in advanced,

Hai.

Reply

Replies

L.K. Singh April 7, 2014 at 9:38 PM

5% flashing is based on Shell DEP.

If we use wt percent, it gives more accuracy because mole basis is a

major unit.

Reply

Enter your comment...

Comment as:

Publish

Google Account

Preview

http://crazy-processdesignengineertools.blogspot.ae/2012/03/to-calculate-relieving-temperature.html

2/3

6/27/2014

Process Design Engineer Tools: To calculate the Relieving temperature & Latent Heat of Vaporization for Fire case PSV sizing by Shell DEP method.

Links to this post

Create a Link

Newer Post

Home

Older Post

Subscribe to: Post Comments (Atom)

Simple template. Powered by Blogger.

http://crazy-processdesignengineertools.blogspot.ae/2012/03/to-calculate-relieving-temperature.html

3/3

S-ar putea să vă placă și

- Rigorously Size Relief Valves For Critical FluidsDocument10 paginiRigorously Size Relief Valves For Critical Fluidsashirwad shetty100% (2)

- Safety/Heat Transfer Tower Pressure Relief CalculationDocument6 paginiSafety/Heat Transfer Tower Pressure Relief Calculationsriman1234Încă nu există evaluări

- Heat Exchanger Tube RuptureDocument3 paginiHeat Exchanger Tube RuptureKarthik Sakthivel100% (1)

- Relief Valve Sizing for ColumnsDocument10 paginiRelief Valve Sizing for ColumnsbalajikrishnanÎncă nu există evaluări

- Calculate The Relieving Temperature Latent Heat of Vaporization For Fire Case PSV Sizing by Shell DEP Method PDFDocument3 paginiCalculate The Relieving Temperature Latent Heat of Vaporization For Fire Case PSV Sizing by Shell DEP Method PDFDjamel Ait MohamedÎncă nu există evaluări

- Accurate Prediction of Tower ReliefDocument5 paginiAccurate Prediction of Tower ReliefSheetal Solanki100% (1)

- Chemeng - 201001 Aa2bc0b481 PPDocument6 paginiChemeng - 201001 Aa2bc0b481 PPponnusjÎncă nu există evaluări

- Using The Dynamic Depressuring Utility To Simulate High Pressure Blowdown ScenariosDocument4 paginiUsing The Dynamic Depressuring Utility To Simulate High Pressure Blowdown Scenariosebby1Încă nu există evaluări

- PRV Sizing For Exchanger Tube RuptureDocument5 paginiPRV Sizing For Exchanger Tube RuptureNavid Sajedi80% (5)

- Advanced Hysys Course PSVDocument40 paginiAdvanced Hysys Course PSVEbby Onyekwe100% (2)

- Storage Tank Protection - Jump StartDocument18 paginiStorage Tank Protection - Jump StartSushant SharmaÎncă nu există evaluări

- Flare Header Sizing Design GuideDocument3 paginiFlare Header Sizing Design Guidec_nghia100% (1)

- Special Report: Design A Staggered Depressurization Sequence For Flare SystemsDocument4 paginiSpecial Report: Design A Staggered Depressurization Sequence For Flare Systemsdigeca100% (1)

- Supercritical Fluids PSV SizingDocument5 paginiSupercritical Fluids PSV SizingVikram Singh100% (5)

- 4 Simulation of Flare SystemsDocument14 pagini4 Simulation of Flare SystemsJeEJyZa0% (1)

- A New Approach For Finger Storage Slug CatcherDocument8 paginiA New Approach For Finger Storage Slug CatcherfanziskusÎncă nu există evaluări

- Distillation Column Relief Loads-Part 2Document7 paginiDistillation Column Relief Loads-Part 2Behnam HosseinzadehÎncă nu există evaluări

- Using DIERS Two-Phase Equations To Estimate Tube Rupture FlowratesDocument8 paginiUsing DIERS Two-Phase Equations To Estimate Tube Rupture FlowratesAugusto Jorge Lozada100% (1)

- Distillation Column Relief Loads - Part 1Document8 paginiDistillation Column Relief Loads - Part 1Behnam Hosseinzadeh50% (2)

- ASPEN Fire Relief Load Determination - Jump StartDocument27 paginiASPEN Fire Relief Load Determination - Jump StartDWNLD USRML100% (2)

- PSV Sizing CalculationsDocument53 paginiPSV Sizing CalculationsAMITH OK93% (28)

- Flare Ko Drum SizingDocument5 paginiFlare Ko Drum SizingSujith Sekar100% (2)

- Applying Relief Load Calculation MethodsDocument9 paginiApplying Relief Load Calculation MethodsKamil Marszałek100% (1)

- Understanding API and ASME Standards Can Help Prevent Oversizing PSVsDocument8 paginiUnderstanding API and ASME Standards Can Help Prevent Oversizing PSVs3110143Încă nu există evaluări

- Blowdown Calc FormulaeDocument1 paginăBlowdown Calc FormulaeWayne MonneryÎncă nu există evaluări

- Relief Valves Sizing MethodsDocument10 paginiRelief Valves Sizing MethodsRicardo BecÎncă nu există evaluări

- Refrigerated gas plant LTS temperatureDocument6 paginiRefrigerated gas plant LTS temperatureOsas UwoghirenÎncă nu există evaluări

- Estimating relief loads using conventional, steady-state and dynamic simulation techniquesDocument9 paginiEstimating relief loads using conventional, steady-state and dynamic simulation techniquessgrsth100% (5)

- Aspen FLARENET Getting StartedDocument62 paginiAspen FLARENET Getting StartedAde Nurisman100% (7)

- Relief Valve Calculation For Distillation TowersDocument5 paginiRelief Valve Calculation For Distillation TowersAbhinav Jain100% (1)

- FLARENETDocument19 paginiFLARENETrohmanÎncă nu există evaluări

- PSV Sizing (Two Phase - HEM)Document1 paginăPSV Sizing (Two Phase - HEM)Saeid Rahimi MofradÎncă nu există evaluări

- Tutorial Aspen DynamicsDocument20 paginiTutorial Aspen DynamicsRobbie_LOCO100% (2)

- New Approach To Relief Valve Load Calculations PDFDocument3 paginiNew Approach To Relief Valve Load Calculations PDFchemengseliem100% (1)

- Ensure Plant Safety with Thermal Relief Valve Decision FlowchartDocument3 paginiEnsure Plant Safety with Thermal Relief Valve Decision FlowchartBacelis100% (3)

- Fire Case and Hydraulic Thermal Expansion Acc To API 521 and ISO 23251 PDFDocument8 paginiFire Case and Hydraulic Thermal Expansion Acc To API 521 and ISO 23251 PDFAnggya AnggyÎncă nu există evaluări

- Accurate Wetted Areas For Partially Filled VesselsDocument2 paginiAccurate Wetted Areas For Partially Filled Vesselsraghu.cecri805867% (3)

- Doc. No.: PDG-MUM-XXX Rev. 0 Relief Valve Sizing Philosophy Page 1 of 10Document10 paginiDoc. No.: PDG-MUM-XXX Rev. 0 Relief Valve Sizing Philosophy Page 1 of 10kishna009Încă nu există evaluări

- Gas-Liquid And Liquid-Liquid SeparatorsDe la EverandGas-Liquid And Liquid-Liquid SeparatorsEvaluare: 3.5 din 5 stele3.5/5 (3)

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsDe la EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsEvaluare: 3.5 din 5 stele3.5/5 (14)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentDe la EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentÎncă nu există evaluări

- Surface Production Operations: Volume IV: Pumps and CompressorsDe la EverandSurface Production Operations: Volume IV: Pumps and CompressorsEvaluare: 5 din 5 stele5/5 (4)

- Flow Analysis for Hydrocarbon Pipeline EngineeringDe la EverandFlow Analysis for Hydrocarbon Pipeline EngineeringÎncă nu există evaluări

- Process Simulation Cases Flash SeparationDocument23 paginiProcess Simulation Cases Flash Separationahmed atwaÎncă nu există evaluări

- Hysys WorkbookDocument23 paginiHysys WorkbookDaniloÎncă nu există evaluări

- Boiler Feed Water Treatment & BlowdownDocument6 paginiBoiler Feed Water Treatment & BlowdownnurulÎncă nu există evaluări

- Two-Stage Compression and Separation of Natural Gas StreamDocument23 paginiTwo-Stage Compression and Separation of Natural Gas StreamAli AlengineerÎncă nu există evaluări

- Phthalic2 B PDFDocument11 paginiPhthalic2 B PDFIzzati AhmadÎncă nu există evaluări

- Acetone ProductionDocument8 paginiAcetone ProductionZahraa GhanemÎncă nu există evaluări

- CL405 2021 End Term ExaminationDocument4 paginiCL405 2021 End Term ExaminationArpit GuptaÎncă nu există evaluări

- Latent Heat of Vaporization Via Hysys Flash Calculations - LinkedInDocument5 paginiLatent Heat of Vaporization Via Hysys Flash Calculations - LinkedIngopinath87Încă nu există evaluări

- NATURAL GAS BOILER CALCULATIONS INSTRUCTIONSDocument20 paginiNATURAL GAS BOILER CALCULATIONS INSTRUCTIONS@sss100% (1)

- Calculation of Relief Load On ColumnDocument5 paginiCalculation of Relief Load On Columnnghiemta18Încă nu există evaluări

- VaporizerDocument13 paginiVaporizerSurya Budi Widagdo100% (1)

- How ToDocument45 paginiHow ToDHAVALESH AMÎncă nu există evaluări

- Heat Pump Lab SheetDocument5 paginiHeat Pump Lab SheetLegendaryNÎncă nu există evaluări

- Cumene BDocument6 paginiCumene BimanchenÎncă nu există evaluări

- Aspen Example Test - EO v2018Document2 paginiAspen Example Test - EO v2018marij233Încă nu există evaluări

- Separations and Reactors Design Project Production of Allyl ChlorideDocument8 paginiSeparations and Reactors Design Project Production of Allyl ChlorideAdelina SimionÎncă nu există evaluări

- Project 2 CumeneDocument9 paginiProject 2 CumeneUmar Alijandro50% (2)

- IELTS Reading Answer SheetDocument1 paginăIELTS Reading Answer Sheetskuppal50% (2)

- RelaibilityDocument10 paginiRelaibilityrohitkushÎncă nu există evaluări

- Academic Word List PDFDocument28 paginiAcademic Word List PDFukchaudharyÎncă nu există evaluări

- Static Charge RemoverDocument4 paginiStatic Charge RemoverrohitkushÎncă nu există evaluări

- LPG QuestionaireDocument1 paginăLPG QuestionairerohitkushÎncă nu există evaluări

- Supercritical Velocity GraphDocument1 paginăSupercritical Velocity GraphrohitkushÎncă nu există evaluări

- J1237 Asian Paints HAZOP WSDocument98 paginiJ1237 Asian Paints HAZOP WSrohitkushÎncă nu există evaluări

- Wind RoseDocument1 paginăWind RoserohitkushÎncă nu există evaluări

- Fire and Risk AssessmentDocument4 paginiFire and Risk AssessmentrohitkushÎncă nu există evaluări

- Flare Temp Vs Time CurveDocument1 paginăFlare Temp Vs Time CurverohitkushÎncă nu există evaluări

- Fault Tree PDFDocument1 paginăFault Tree PDFrohitkushÎncă nu există evaluări

- Essay Task-1 SampleDocument1 paginăEssay Task-1 SamplerohitkushÎncă nu există evaluări

- Explosion ResultsDocument9 paginiExplosion ResultsrohitkushÎncă nu există evaluări

- Flare Grid ResultsDocument1 paginăFlare Grid ResultsrohitkushÎncă nu există evaluări

- Radiation of FlareDocument1 paginăRadiation of FlarerohitkushÎncă nu există evaluări

- When Two Phase Flow Before Control Valve is Acceptable or NotDocument1 paginăWhen Two Phase Flow Before Control Valve is Acceptable or NotrohitkushÎncă nu există evaluări

- Risk MatrixDocument1 paginăRisk MatrixrohitkushÎncă nu există evaluări

- Radiation ContourDocument1 paginăRadiation ContourrohitkushÎncă nu există evaluări

- Exceedance CurveDocument1 paginăExceedance CurverohitkushÎncă nu există evaluări

- Pool Burn RateDocument1 paginăPool Burn RaterohitkushÎncă nu există evaluări

- Expectations For The Mi ProgramDocument3 paginiExpectations For The Mi ProgramrohitkushÎncă nu există evaluări

- HAZID WorksheetDocument1 paginăHAZID WorksheetrohitkushÎncă nu există evaluări

- Results For Vent SizingDocument3 paginiResults For Vent SizingrohitkushÎncă nu există evaluări

- Wind Speed (M/S) N NE E SE SDocument3 paginiWind Speed (M/S) N NE E SE SrohitkushÎncă nu există evaluări

- Criterion for hazard ranking procedureDocument1 paginăCriterion for hazard ranking procedurerohitkushÎncă nu există evaluări

- Data Requisition For HAZOPDocument1 paginăData Requisition For HAZOProhitkushÎncă nu există evaluări

- Hazard RiskDocument1 paginăHazard RiskrohitkushÎncă nu există evaluări

- Risk RankingDocument1 paginăRisk RankingrohitkushÎncă nu există evaluări

- PSM Goal PDFDocument2 paginiPSM Goal PDFrohitkushÎncă nu există evaluări

- PSM GoalDocument2 paginiPSM GoalrohitkushÎncă nu există evaluări

- CASR PART 43 Amdt. 1 PDFDocument21 paginiCASR PART 43 Amdt. 1 PDFarbypratamax66100% (1)

- Indonesian RecipeDocument2 paginiIndonesian RecipeJeremiah NayosanÎncă nu există evaluări

- Reciprocating - Pump - Lab Manual Ms WordDocument10 paginiReciprocating - Pump - Lab Manual Ms WordSandeep SainiÎncă nu există evaluări

- Process Control Lecture 9 (M2)Document53 paginiProcess Control Lecture 9 (M2)lalusebanÎncă nu există evaluări

- Car Parking - Rules and Regulations For Patients and Visitors - SOP0084Document2 paginiCar Parking - Rules and Regulations For Patients and Visitors - SOP0084in123Încă nu există evaluări

- In c1 20 Ex CteDocument7 paginiIn c1 20 Ex CteAlejandro HernándezÎncă nu există evaluări

- Benefits of Group Discussion as a Teaching MethodDocument40 paginiBenefits of Group Discussion as a Teaching MethodSweety YadavÎncă nu există evaluări

- BMM Cements LTD., Bharat Mines & Minerals, Gudipadu Cement Plant, GudipaduDocument2 paginiBMM Cements LTD., Bharat Mines & Minerals, Gudipadu Cement Plant, GudipaduDeepak Kumar PalÎncă nu există evaluări

- American Revolution NotesDocument50 paginiAmerican Revolution Notesmattmoore83100% (1)

- Possessive Pronouns and Adjectives ExplainedDocument5 paginiPossessive Pronouns and Adjectives ExplainedwilfredoÎncă nu există evaluări

- Sorted CatalogueDocument14 paginiSorted CatalogueHipocrates FCÎncă nu există evaluări

- Opa An AssDocument8 paginiOpa An Assgvkreddyg100% (1)

- Hydraulic CaculationDocument66 paginiHydraulic CaculationgagajainÎncă nu există evaluări

- M S Ramaiah Institute of Technology Department of CIVIL ENGINEERINGDocument10 paginiM S Ramaiah Institute of Technology Department of CIVIL ENGINEERINGPrashant SunagarÎncă nu există evaluări

- Example of A Chronological CVDocument2 paginiExample of A Chronological CVThe University of Sussex Careers and Employability CentreÎncă nu există evaluări

- CNS Cellular Reactions and Classical Disease PatternsDocument184 paginiCNS Cellular Reactions and Classical Disease Patternsdray2bigÎncă nu există evaluări

- Glenn GreenbergDocument3 paginiGlenn Greenbergannsusan21Încă nu există evaluări

- Karl Marx Power PointDocument28 paginiKarl Marx Power PointMUWULIZE EDWIN ENOCKÎncă nu există evaluări

- Socio-Economic and Government Impact On Business: Lesson 4.4Document18 paginiSocio-Economic and Government Impact On Business: Lesson 4.4racelÎncă nu există evaluări

- Check Lists Hospitals High RiseDocument7 paginiCheck Lists Hospitals High RiseRaghu RamÎncă nu există evaluări

- Debpriyo Roy Lab 1Document7 paginiDebpriyo Roy Lab 1udaikiranÎncă nu există evaluări

- M-3311 DNP ProtocolDocument32 paginiM-3311 DNP ProtocolmaheshÎncă nu există evaluări

- 5 Tower HardwareDocument37 pagini5 Tower HardwareAhmed ElShoraÎncă nu există evaluări

- Non-Ferrous Metal SmeltingDocument47 paginiNon-Ferrous Metal SmeltinggtdomboÎncă nu există evaluări

- Liquid Dosage Forms: Classification, Manufacturing and Quality Control TestsDocument43 paginiLiquid Dosage Forms: Classification, Manufacturing and Quality Control Testsbee859550% (4)

- ARNU15GL2G4Document2 paginiARNU15GL2G4julioÎncă nu există evaluări

- Clean Air Council Announces Diesel Pollution Retrofit With Local Port OperatorsDocument4 paginiClean Air Council Announces Diesel Pollution Retrofit With Local Port OperatorscleanaircouncilÎncă nu există evaluări

- ICICI Securities ReportDocument4 paginiICICI Securities ReportSaketh DahagamÎncă nu există evaluări

- Academic Reference Form - RCSI PDFDocument2 paginiAcademic Reference Form - RCSI PDFibexamsÎncă nu există evaluări