Documente Academic

Documente Profesional

Documente Cultură

Euro 2

Încărcat de

Gabriel Patilea0 evaluări0% au considerat acest document util (0 voturi)

182 vizualizări179 paginiNormative europene

Titlu original

EURO_2

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentNormative europene

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

182 vizualizări179 paginiEuro 2

Încărcat de

Gabriel PatileaNormative europene

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 179

Tempus Phare Complementary Measures Project 01198

plementing of Structural Eurocodes in Romaniar

Civil Engineering Standards

rdinator: D. Dubina Contractor: J. Rondal :

CALCULUL STRUCTURILOR DIN |

BETON, BETON ARMAT SI BETON

PRECOMPRIMAT

DESIGN OF CONCRETE, REINFORCED

CONCRETE AND PRESTRESSED

CONCRETE STRUCTURES

EUROCODE 2 —

Mie

CUVANT INAINTE

FOREWORD

Eurocodurile structurale

1. Scurt istoric”

Idea de 2 initia elaborarea unor

internationale pentru proiectarca structurilor s-a

nascut in 1974, si are la baza cooperarea dintre

citeva organizatii profesional- stiinfifice, cu

activitate bine cunoscut, in domeniul

constructiilor.

Activitatea acestor organizatii, in dorneniul

coordonirii principiilor, agrementirii tehnice gi

prestandardizarii a fost si este de o importanja

deosebiti pentru stendardizarea_intemationali.

Experti din multe ri, ce fac parte din aceste

organizatii, schimb& opinii in legatura cu munca

stiingific si experienta practic’.

Fari obligatia de a formula re;

elaboreazi rapoarte si, pe

recomandiri de calcul i proiectare.

Standardizarea intemationela nu este posibildi

fir o pregitire prealabili si rd conventii

mutuale intre asemenea orgenizatii

In sectorul constructiilor, unmitoarele organizatii

sunt implicate in elaborarea normelor de calcul si

de proiectare:

IABSE-Asociatia Intemational pentru Poduri si

Scructari Ingineresti

CIB-Consiliul Intern

Smdiu si

Constructiilor

RILEM-Asociatia International pentru Testarea

si Cercetarea in Laborator a Materialelor si

Constructiilor

CEB-Comitetul Euro-Intemational pentru Beton

FIP-Federatia Intemational pentru Beton

Precomprimat

ECCS-Conventia Europeani pentru Consirvetii

Metalice

JCSS-Comitetul pentru Siguranta Structurilor

ISSMFE-Societatea International pentru

Mecanica Pamancurilor si Ingineria Fundetiilor.

Regulile de baz pentru caleulul structurilor au

fost realizate printr-o strnsi cooperare in cadrul

JCSS. S-au formulat conditiile de siguranté si

exploatare pe baza conceptului de rise, in functie

de criteriile de fiabilitate ale structurilor. Aceste

conditii au asigurat baza comuna a normelor de

caloul

norme

li, acestea

cat posibil,

jonal pentru Cercetare,

in, domeniul

Documentare

The Structural Eurocodes

1. Short History”

The idea to develop models for an intemational

set of Codes for structural design was born in

1974 based on an agreement between several

technical-scientific organisations.

The activities of these organisations in the field

of co-ordination of principles, agreement on

technical matters and prestendardisation were

and are outstanding importance for intemational

standardisation. They comprise experts fom

mauy countries serving the exchange of scientific

findings and practical experiences.

Without the obligation for _ formulating

mandatory rules, state-of-the-art reports are

elaborated, and also-as far as possible and

necessary-recommendations for corresponding

fature rules (e.g. Model Codes).

There would be not international standardisation

without the preparatory work and without the

mutual agreement in these organisations.

In the construction sector, the following

associations involved in this preparatory work in

particular:

JABSE-Intemational Association for Bridge and

‘Structural Engineering

CiB-International Council for

Rescarch, Studies and Documeniation

Building

RILEM-International Association of the Testing

and Research Laboratories for Materials and

Constructions

CEB-Euro-Internstional Committee for Concrete

FiP-Intemational Federation for Prestressed

Concrete

ECCS-European Convention for Constructional

Steelworks

JCSS-Joint Committee on Structural Safety

ISSMFE-International Society for

Mechanics and Foundation Engineering.

Soil

In close co-operation the common basic rules for

siructural design were developed in the JCSS.

Requirements for safety and serviceability of

siructures based on the principle of risk in tems

of reliability conditions were formulated. It was

the aim to use these rules as 2 common basis for

the material-related design codes.

() G Breitschafi, L. Oestlund, M. Kersken-Bradly, The Structural Eurocodes-Conceptual

Approach, IABSE Conference on Structural Eurocodes, Davos 1992.

Pe aceasti baza, unele dintre orgenizatiile

implicate, respectiv CEB, CIB, ECSS si o parte

din ISSMEE, au realizat modcle sau recomandiri

pentru normele de calcul.

fn acest mod, s-au creat premizele necesare

intocmirii si elaborarii “Eurocodurilor

Structurale", urmarindu-se o armonizare a

principiilor cadru pe dou’ directii, respectiv:

-de-a lungul granitelor statelor participante la

actiuni si,

-intre diferite materiale de constructii, metode de

constructie, tipuri de clidiri si constructii

ingineresti.

Aceste criterii de armonizare eu favorizat

compatibilizarea normelor intre ele i obsinerea

unor nivele de fiabilitate comparable.

La sfarsitul deceniului_sapte, Comisia

Comunitijii Europene’a lust initiativa elaboririi

Eurocodurilor, folosind activitatea de pregitire

mentionati anterior.

Sub cenduceres Comitetului Conducitor din

cadrul Comisici CE (CEC), primul proiest

individual de tip Eurocode (pentru structuri

metalice) a fost pregitit de un grup tehnic de

lucru in concordangéi cu principiile de bazi ale

standardizirii, adicd cu 0 —_participarea

cuprinzitoare si reprezentativa a organizatiilor

expert si a specialistilor.

2. Baza legal?

Conditiile de infiinjare si principiile de

functionare a Comunitiii Economice Europene a

fost stabilita prin Tratatul de la Roma, in 1957.

Incepind din 1985, acest tratat a fost modificat si

completat, printr-o serie de decizii in vederea

credrii Pietei Europene Unice pana in 1992.

Prin Actul European Unic din 1987, s-au pus

bazele initierii procesului de armonizare la nivel

comunitar a regulilor si normelor tchnice ca

premizi a eliminirii barierelor existente, din

acest punct de vedere, in cadrul liberei circulatii

amérfurilor si a schimbului de servi

Pentru a realiza si impune asemenea misuri,

Comunitates European actioneazi in plan

juridic print-o Directiva a Consiliului. Prin

Directiva Consiliului se definesc cerintele

esentiale la nivelul produselor sau a instaletiilor,

urmand ca, ulterior si fie elaborate specificatii

tehnice si standarde de citre Organizatia

Enropean3 de Standardizare (CEN/CENELEC).

Dupi adoptarea acestor norme, in urma votului

0

Some of the organisations, such as CEB, CIB,

ECSS and parts of ISSMFE, developed then

models or recommendations for the material-

related design codes based on the agreed

common rules as mentioned above.

Thus the technical basis was prepared for a

formal establishment of the “Structural

Eurocodes” with the aim of a two-dimensional

harmonisation:

-across the borders of states,

-between differen construction materials,

construction methods, types of building and civil

engineering works,

to achieve full consistency and compatibility of

the various codes with each other and 10 obtain

comparable safety levels.

Already at the end of the seventies the

Commission of the European Communities took

the initiative for elaborating the Eurocodes by

using the above preparatory work:

Directed by a Steering Committee chaired by the

EC Commission (CEC) the first drafts of the

individual Eurocodes were prepared by technical

working groups in accordance with the basic

principles of standardisation, ie. with

comprehensive participation of expert

organisations and professions.

2. Legal Background”

The Roman Treaties of 1957 establishing the

European Ecoromic Community have been

modified and amended since 1985 by essential

decision iaken in order to create the conditions

for completing the Intemal Market uatil 1992.

On the basis of the European Single Act of 1987

it was intended to initiate 2 comprehensive

harmonisation of technical rules and regulations

in order to remove-among other things-technical

barriers to the free movement of goods and to the

exchange of services.

For realising measures of this kind, the European

Community disposes of the legal instrument of

the Council Directive. A Council Directive

Cefines the essential requirements for the range

of products or plants to be regulated and refers,

for the rest, to European technical specifications

consisting, in general, of European standards

established by the European Standard

Organisation CEN/CENELEC. After adoption

Ale:

exprimat in cadrul Consiliul de Ministrii, prinu-o

Directiva a Consiliul acestea se transpun in legi

nationale ale statelor membre.

in sectoral constructiilor, armonizarea le nivel

european se realizeazi prin urmatoarele

documente:

Directive Lucririlor Publice 89/44Q/EEC si

Direotiva referitoare la Servicii (Proiect)

Acestea stabilesc atit principiile de functionare

ale pietei in domeniul constrvetiilor, cat si

criteriile de elaborare a normelor tehnice.

Directiva Consiliul ~—referitoare. la

interpretarea/corelarea legilor, normelor si

decretelor din farile membre ale uniunii, in

Jegitura cu industria de constructii este de primi

importanyi.

Ea se aplica intregului “sectorul de constructii””

si, defineste de la inceput principalele ceringe in

urmatoarele domenii:

= rezistenfi si stabilitate

- sigurante la foc

- igiend, snatate si mediu inconjurdtor

-sigurang in exploztare

- protectia impotriva zgomotului

~economia energiei si retinerea cildurii

Directiva Consiliului cu privire la industria de

constructii obliga statcle membre si ia masuti

pentru ca specificatiile tehnice europene, si

devin’ valabile in aceste tari, urmind ca

standardele si normativele nationale

corespunzitoare si fie retrase din folosinta dupa

© perioada stabilita.

Mandatele date de CEC cite CEN pentru

amonizarea standardelor se bazeazi pe asa

numitele Documente Interpretative.

Directiva Consiliului defineste prin aceste

documente interpretative specificatiile tehnice

europene in felul urmitor:

-ca standarde armonizate, elaborate de CEN sau

CENELEC, pe baza unor mandate date de cZtre

Comisia Comunititii Europene (CEC) sau;

-ca aprobari tehnice curopene, rezultate in urma

avizului statelor membre, in cazul in care

standardele armonizate nu exist

In corelare cu “Nova metodologie pentru

armonizere tehnica si standardizare“ adoptata

prin Rezolutia Consiliului in mai 1985, actiune

within the Council of Ministers by weighted

voting, a Council Directive has 10 be transposed

into national law of the Member States.

Jn the construction sector,

-the Public Works Directive 89/440/EEC and

-the Service Directive (Draft)

are thus important for the harmonisation of

technical rules, as in the request for tenders and

placing of orders on public construction works

and engineering services the harmonised

European technical specifications have to be

used 2s 2 technical basis,

The Council Directive on the approximation of

Jaws, regulations and administrative provisions

of the Member States relating to constructions

products (CPD 89/106/EEC) is of central

Importance,

Jt applies to the whole “construction sector” and

defines right at the beginning the essential

requirements in the following elds:

-mechanical resistance and stability

~salety in case of fire

-hygiene, health and the environment

-safety in use

protection against noise

-energy economy and heat retention.

The Council Directive on Building Products

obliges the Member Stetes to take care that these

European technical specifications become valid

in their relevant countries and to withdraw their

corresponding national standards or rules after a

certain period of transition.

The mandates given by the CEC 10 CEN for the

establishment of a harmonised standard are based

on the relevant “Interpretative Documents”.

The Council Directive on Building Products

defines in these interpretative documents the

European technical specifications

-a5 harmonised standards established by CEN or

CENELEG, respectively, on behalf of @ mandate

given by the Commission of the European

Communities (CEC) or;

-as European technical approvals issued by the

relevant approval bodies nominated by the

Member States in cases where harmonised

standards do not or not yet exist.

With reference to the so-called “New Approach

to technical harmonisation and standards”

adopted by a Council Resolution of May 1985

m

de realizare a Eurocodurilor a fost trecuta la

sfarsitul anului 1989 in responsabilitatea

Comitetului European de Standardizare. In mai

1990 CEN se creaza un nou Comitet Tehnic,

CEN/TC 250-“Eurocodurile _Structurale“.

Acestui comitet, ia fost dat mandatul pentru

claborarea Standardelor Europene pentru

Constructii, avind ca obicct de activitate:

“Standardizarea regulilor si metodelor de

proiectare a structurilor pentru cladiri si

constructii ingineresti tinand seama de legatura

dintre normele de calcul, comportarea materiale

si tehnologia de executie si control.

Programului TC 250 se bazeazi in principal pe

‘unmitoarcle date initiale:

-pregitirea activitatilor preparatorii re

nivelul _organizatiilor _profesional-stiintifice

internationale in sectorul constructiilor;

-nommelc de referinta ale Organiza

Internationale pentru Standardizare (ISO);

-deciziilor uate de citre Comunitatea Europeana

in legitura cu crearea Pietei Europene Unice, la

care au aderat si tarile membre din Asociatia

Europeana a Liberului Schimb (EFTA).

3, Programul EUROCODE in eadrul

CEN/TC 250

Programul de lueru al CEN/TC250 se desfasoara

conform Documentelui Interpretativ IDI,

mentionat anterior si in cadral cooperarii dintre

CEC si CEN. Printre altele, in Documental

Interpretativ IDI se stipuleazé:

“Burocodurile vor servi ca norme de referinta,

find supuse recunoasterii autoritatilor din stetele

membre, si are ca scop:

4) furnizarea criteriilor esentiale de verificare a

structurilor pentru clidiri si lucréri inginerestis

b) asigura baza tehnico-legala contractelor

specifice de executie a luotirilor de constructii si

serviciilor ingineresti

c) asigura cadrul redactirii specificatiilor tehnice

pentru materiale si produse utilizate in

constructii...*

“Programul EUROCODE fumizeazi in cadrul

unui sistem coerent si cuprinzitor de norme,

metode de proiectare variate si alte elemente

specifice de proiectare importante in practica,

‘acoperind toate tipurile de cladiri si lucriri

ingineresti, realizate din materiale de constructii

diverse...“

Programul BUROCODE prevede, in total noua

Iv

the further development of the Eurocodes was

transferred, at the end of 1989, to the European

Committee for Standardisation (CEN). In May

1990 CEN created a new Technical Committee,

CEN/TC 250-"Siractural Eurocodes”. This

Committee was given the mandate to elaborate

Codes of Practice within the following scope:

“Standardisation of structural design rales for

building and civil engineering works taking into

account the relationship between design rules

‘and the assumption to be made for materials,

execution and control.”

The creation of TC 250 was mainly initiated by

and based on, respectively

“the preparatory work done by intemational

technicel-scientifie organisations in the

construction seclor;

-the relevant standards of the Intemational

Organisation for Standardisation (ISO):

-decisions taken in the European Community

with respect to the creation of the European

Internal Market, which was joined by the

‘Member States of the European Free Trade

‘Association (EFTA).

3. The EUROCODE programme in

CEN/TC 250

The working programme complies with the given

conditions of the above-mentioned Imerpretetive

document ID 1 and is based on a special;

agreement between CEC and CEN. Among other

things, the following is specified:

“The EUROCODES are intended 10 serve as

reference documents to be recognised by the

authorities of the Member States for the

following purposes:

2) as a means fo prove compliance of building

and civil engineering works with the essential

requirements;

b) as a basis for specifying contacts for the

execution of construction works and related

engineering services;

¢) as a framework for drawing up harmonised

technical specifications for construction

products...”

“The EUROCODE programme provides for a

consistent and comprehensive system of

structural design standards covering all types of

building and civil engineering works in the

different construction materials, the various

construction methods and other aspects of design

which are of general practical importance. ...”

The EUROCODE programme provides for a

normative, cu urmatoarele destinatii:

EUROCODE 1

pentru actiuni in constructii

EUROCODE 2

pentru structuri din beton, beton armat si beton

precomprimat

EUROCODE 3

pentm structuri metalice

EUROCODE 4

pentru structuri mixte

EUROCODE 5

pentru structuri din lemn

EUROCODE 6.

peatru structuri din zidirie

EUROCODE 7

pentru fundatii si inginerie geotehnica

EUROCODE8

pentru structuri amplasate in zone seismice

EUROCODE9

pentru structuri din aluminiu.

In textual Eurocodurilor se face distinctie intre

principiile de baza si regulile de aplicare.

Aplicarea unui EUROCODE necesita

intotdeauna respectarea principiilor, in timp ce

regulile de aplicere pot fi inlocuite, in cazuri

patticulare, prin reguli sau metode echivalente

daca se arata ca acestea respecta principiile. In

acest fel se asigura o mai mare flexibilitate in

aplicare, permitandu-se alternative in cadrul

nommei.

Intr-o prima etapa, normativele si pertile lor

importante se publica ca Norme Europene

Provizorii sau Prestandarde (ENV). In 1992,

Partea 1 a EC2, EC3, EC4 si BCS a fost pusa

deja in circulatie, in aceasta forma. Prima parte a

EUROCODE 1 s-a publicar in versinea ENV

din octombrie 1994. Dupi o perioada de tesiare,

se va organize conversia prestandardelor in

norme europene (EN).

4, Planul de conversie din ENV in EN

Schema de conversie din ENV in EN este

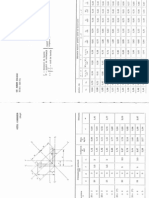

prezentata in figura 1.

In scopal realizarii conversiei, _ diferitele

Eurocoduri au fost organizate in patru grupe, de

la A la D. Timpul de conversie pentru fiecare

grup este dat mai jos.

total set of nine volumes according to the

following classification:

EUROCODE 1

for actions on structures (design loads)

EUROCODE 2

for concrete, reinforced concrete and prestressed

concrete structures

EUROCODE 3

for steel structures

EUROCODE 4

for composite steel and concrete structures

EUROCODE 5

for timber structures

EUROCODE 6

‘for masonry structures

EUROCODE 7

for foundations and geotechnical engineering

EUROCODE 8 ii

for structures in seismic zones

EUROCODE 9

for aluminium structures.

Jn the texts of the EUROCODES distinction is

made between basic principles and rules for

application. Compliance with 2 EUROCODE

always necessitates the observance of the

principles, whereas the rules for application can

be replaced in the individual case by equivalent

alternatives if it is shown that they satisfy the

principles. It is thus intended to provide a more

flexible use by allowing deviations within the

scope of the EUROCODE.

dn a first step, the individual Codes and their

relevant parts are published as European

Prestandards (ENV). In 1992 EUROCODE 2,

EUROCODE 3, EUROCODE 4 and probably

EUROCODE 5-Part I one of cach-was already

available. The first parts of EUROCODE J was

published in ENV version on October 1994.

‘After a test period, their transposition into EN

standards is planned.

4. Planning for conversion from ENVs to ENs

The flowchart of conversion scheme from ENVs

to ENs is shown in Figure 1.

The different EUROCODES were organised into

four groups, from A to D, in order to manage the

conversion activity. The time planning, for each

group, is given below.

Asocierea normelor in vederea conversiei Groups of related parts for parallel

paralele conversion

Grupa _A-Norme generale _de_proiectarea_a Group A-Basio buildings desien and seismic

clidirilor si proiectarea antiseism

‘Acest grup cuprinde normele referitoare la bazele

proiectirii, ectiunile de calcul, prevederi generale

This group comprises the parts dealing with the

Basis of Design, essential loading (actions)

v

considerations, the general and building rules for |

si specifice pentru constructiile din beton si otel,

precum si prevederi suplimentare pentru calculul conerete and steel construction — and’

la seism a constructiilor (vezi tabelul 1). supplementary rules for earthquake resistance of 5 E

buildings (see Table 1). | E ele

6

Tabelal -Gropa A-Norme generale de proiectarea a clidirilor si proiectarea antiseism | E 3 6 abe

(Group A-Basic buildings design and seismic) i a2 28

Nr. EN Titlul prescurtat Sinteza observatillor | *Perioada de conversie (luni) i : & 3 388

ENNo. Brief Title dupa ancheta(2 ani) | *Conversion Period (months)) | shod 5 25888

Result of 2 yr. Enguiry. | é Shaky ee

EN 1991-1 |Bazele provectarii ‘AUG 96 2 gs A 28772] [s

Basis of design eee 8

EN 1991-2-1 | Densitati, ete. JUNE 97 24 a é es a

Densities etc. a z

EN 1991-2-3 | Incarcari din zipada JUNE 97 24 a 8 3 =

‘Snow loeds | eS 2aa8 @ye828 “

EN 1991-2-4 |Incrciri din vant JUNE 97 24 t a Soohe eS ec ie =

__ | Wind loads | 2 ERS 5353 “48 8 5

EN 1992-1-1 | Structuri beton-Generalitati OCT 95 40 ; & 3822825 a8 3 [3

Conerete-General z BenSTk2 z aL JESS 21 (82

EN 1993-1-1 | Structuri otel-Generalitati OCT 95 40 S Sn] |EESSS B38

Steel-General 3 325! || [see 2] (gs 3

EN 1994-1-1 | Structuri mixte-Generalitati OCT 95 41 ane S5 yess £5

Composite-General ge 2 a 3 a

EN 1998-1-1 | Seism-Generalitati MAY 97 28 { Qs £35

Seismic-General I Oe

EN 1998-1-2 |Seism-Cladiri MAY 97 28 | Og zee

Seismic-Buildings | o8 al |ERee »

EN 1998-1-3 i MAY 97 28 | Bz : 3528528

° RO; s 5 6 j gs z o

EN 1998-5 MAY 97 28 a | ESE<8 &

2 7

| 9 ag

Tabelul 2-Grupa B-Alte parti generale si parti cu privire la preductia de beton pentru ‘constructii | z = 8

(Group B-Other geacral parts and parts related to concrete products for buildings) i zt e zg =

Nr. EN Titlul prescurtat ‘Sinteza observatillor | *Perioada de conversie(Iuni)] | a 2a =

ENNo. Brief Title dupa ancheta (2 ani) | “Conversion Period (months) | a :

Result of 2 yr Enquiry j 2

EN 1992-1-3 [Beton precomprimat 18 4 é .

Precast concrete MAY 97 Saal | g

EN 1992-1-4 |Beton ugor 18 Be 5 3

4 Lightweight concrete MAY 97 2 a8 i

EN 1992-1-5 | Toroane in constructii 18 a 2 2

Tendons in buildings MAY 97 2 By z i

EN 1992-1-6 |Betonul simplu 18 SoHE SZ

Plain concrete MAY 97 588

EN 1995-1-1 |Lemn-Generalitati 36 3863

Timber-General AUG 96 8g 5 z 2 a

EN 1996-1-1 |Zidirie -Generalitati 35 aga A ©

Masoary-General SEPT 97 85 - 3 z

EN 1997-1 |Geotehnica-Generalitati 31 “8 is

Geotechnics-General MAY 97

Figura 1-Planul de conversie din ENV in EN

(Planning for conversion from ENVs to ENs)

vu

Tabelul 3-Grupa C-Calculul Rezistentei la foo a siructurilor

(Group C-Design for structural resistance to fire)

Table 5-Alte proiecte (Others)

NEEN Titlul prescurtat Sinteza observatillor _ | *Perioada de conversie (uni)

EN No. Brief Title dupa ancheta (2 ani) *Conversion Period

Result of 2 yr. Enquiry. (months)

EN 1991-2-2 |Actiunea focului OCT 97 22

Fire actions

EN 1992-1-2 |Beton-Proiectarea la foc oct 97 2

Concrete-Fire part

EN 1993-1-2 | Otel -Proiectarea la foc oct 97 2

Steel-Fire part

EN 1994-1-2 |Mixte-Proiectarea la foc oct 97 2

Composite-Fire part

EN 1995-1-2 |Lemn-Proiectares la foc ocr 97 22

Timber-Fire part

EN 1996-1-2 |Zidarie -Proiectarea la foc ocT 97 2

Mosoncy-Fire

Tabelal 4-Grupa D-Poduri

(Group D-Bridges)

Reziltatele _] *Perioada de conversie

EN Titlu prescurtat_ | Publicarea ENV] anchetei (luni)

Brief Title ENV Published| Resultof | *Conversion Period

Enquiry (EST) (Months)

EN 1991-2-5 |Actiuni termice FEB 97 SEPT 99 4

Thermal actions

EN 1991-2-6 |Incarcari din constructie | FEB 97 SEPT 99 24

Construction loads

EN 1991-2-7 | Incareari accidentale FEB 97 SEPT 99 4

Accidental loads

EN 1991-3. | Incarcari din trafic MAR 95 oct 97 24

Traffic loads

EN 1992-2 |Poduri din beton AUG 96 MAR 99 36

Conorete bridges

EN 1993-2 |Poduri din otel SEPT 97 APR OD 36

Steel bridges

EN 1994-2. |Poduri mixte oct 97 MAY 00 36

Composite bridges

EN 1995-2. |Poduri din lemn AUG 97 MAR 00 30

: Timber bridges

EN 1998-2. | Actiunca seismului DEC 94 JULY 97 34

Bridges (Seismic)

Alte proiecte Others

Unmatoarele parti ale_prestandardelor The following EUROCODE prestandard parts are

EUROCODE ru sunt incluse in grupele de mai not included in the above groups and generally

sus si se ccupa in general de structuri speciale; deal with specialist structures and/or have ENV

acestea vor parcurge sau nu pericada ENV. development period.

Proiecte Tidul Rezultatele anchetei

Prestandard Title Results of Enquiry

ENV 1991-4 | Actiuni asupra silozurilor si rezervoarelor DEC 97

Actions on silos and tanks

ENV 1993-4 | Silozuri si rezervoere din otel APR 99

Steel silos and tanks

ENV 1998-4 | Silozuri, rezervoare si conducte (Seism) Nov 99

Silos, tanks and pipelines (Seismic)

ENV 1991-5 | Actiuni-Macarale si masini SEPT 99

Actions-cranes and machinery

ENV 1993-6 | Structuri suport din ote] pentru macarale AUG 00

Steel crane supporting structures

ENV 1992-3 | Fundatii din beton SEPT 99

Concrete foundations

ENV 1993-5 [Pile din otel SEPT 99

Steel piling _

ENY 1997-2 | Geotehnica- incercari experimentale JULY 99

Geotechnics-Laboratory tests

ENV 1997-3 |Geotchnica- Incerciri pe teren JULY 99

Geotechnics-Field tests

ENV 1993-3 |Tumuri, stilpi inalti si cosuni de fum din otel APR 00

‘Steel towers, masts and chimneys

ENV 1998-3 | Tumuri, stdlpi inalti si coguri de fum (Seism) APR 99

Towers-masis and chimneys (Seismic)

ENV 1992-4 | Beton-Rezervoare MAR 00

Concrete-Water containment structures

ENV 1993-1-3 | Elemente din otel cu pereti subtiri formate la rece NOV 98

Cold formed steel in structures

ENV 1993-1-4 | Structuri din otel inoxidabil APR 99

| Stainless steel in structures

ENY 1996-1-3 | Incarcari laterale pe zidarii | AUG 00

Lateral lozding on masonry

ENV 1996-2 | Tipuri de zidanii AUG 00

| Selection of masonry units

ENV 1996-3 | Reguli simplificatoare pentru zidarii AUG 00

Simplified rules for masonry

ENV 1998-1-4 | Consolidares si intretinerea constructiilor (Seism) MAR 98

‘Strengthening and repair of buildings (Seismic)

ENV 1999-1-1 | Calculul structurilor din aluminiu-Generalitati MAY 00

Design of aluminium alloy stractures-General

ENV 1999-1-2 |Calculu! structurilor din aluminiu-Proiectarea la foc MAY 00

Design of aluminium alloy stractures-Fire design

ENV 1999-2 | Aluminiu-Probleme speciale si oboseala MAY 00

f Aluminium alloy-Special and fatigue

*Perioada de conversie variazi_datorita

volumului si complexitatii ¢iferite

documentatiilor ENV; se asteapta volumele cu

comentarii nationale dupa o ancheta de doi ani si

este necesara o perioada de traducere si editare.

“The conversion periods appear disparate due to

the need to reflect the varying size and

complexity of the ENV — documents-the

anticipated volume/gravity of National

comments at 2 year Enquiry Sage and the extent

of editing and translation work necessary.

x

5. Proiectul TEMPUS-Phare CME 01198,

5. TEMPUS-Phare CME 01198 Project

Principalut obiectiv al acestui proiect a fost dea The main outcome of this project was to propose,

publica si de a raspéndi la institutiile importante

ia cinci volume cu exemple si institution of five

entru cinci Eurocoduri Structural.

Tabelul 6 arata Eurocodurile selectate pentru

aceasta activitate, institutiile care au

implicate si editorii volumelor.

publish and disseminate in Romanian relevant

volumes with worked

examples on several Structural EUROCODES.

Table 6 shows the selected EUROCODES for

fost this activity, the invited institution and the

volume editors.

FTabelul 6 EUROCODURILE selectate si institutiile partenere implicate

(Selected EUROCODES and involvement of partner institution)

EUROCODE Institutii implicate (Involved institutions) Editorii volumelor

UE. ROU) (Volume editors)

[Bob UPT)

EC2 UL, NTUA, UN UPT, UTC-N, UTI |A. Ghersi (UN)

A. Plumiere (UL)

IC. Trezos (NTUA)

D. Dubina (UPT)

EC3 UL, NTUA, UN uPT I. Rondal (UL)

I. Vayas (NTUA)

EC4 INSA UPT, UTCN, UTI |V. Pacurar UTC-N)

J.M. Aribert (INSA)

ECT LCPC, CUL, TUB uTcB I. Manoliu (UTCB)

A. Marcu (UTCB)

D. Lungu UTCB)

ECB UL, UN, NTUA, TUB UTCB,UPT —_|F. Mazzolani (UN)

S. Savidis (UTB)

‘Legend: UL-University of Liege; NTUA-

University of asi

Coordonatorul si contractantul

Naples; INSA-Rennes; CUL-City University London; LCPC-Laboratoire Central des Ponts et|

Cheusses; TUB-TU Berlin; UPT-“Politchnica University of Timisoara; UTC-N-Technical

‘University of Cluj-Napoca; UTCB-Technical University of Construction Bucharest; UTI-Technical

proiectului The

adreseazi sincere mulfumiri tuturor autorilor address

tional Technical University of Athens; UN-University of|

Co-ordination and Contractor

Project

sincere thanks to all the

their

implicati in aceasta activitate dificila, care are ca contributions involved in a such heavy work,

rezultat final publicarea a mai mult de 1600 de

utile si pages

(presupunem noi) privitoare la EUROCODE applications and commentaries.

EUROCODE, Evidentiem in mod They are especially grateful to the volume editors

pagini cu aplicatii si comentarii

interesante

normele

deosebit activitatea depusa de citre cditorii de

coordonarea scientific co-ordination of the related working

Volume, pentru organizarea si

stiintifica a echipelor de lucru. De asemenea, groups

dorim sa mulfumim pe aceasta cele Comisiei

Europene pentru asigurares suportului financiar

which provides es a final results, more then 1500

with very interesting and useful

for the specific management and for their

We also wish to acknowledge the

support of European Commission for publishing

this volume of great interest for structural

sia cadrului necesar in vederea publicarii acestor engineering activity in Romania.

volume de mare interes pentru activitatea de

constructii din Romania,

Prof. Dan Dubina

The ,Politehnica* University of Timisoara

x

Prof, Jacques Rondal

‘The University of Liege

21

22

23

CUPRINS

PREFATA

BAZELE PROIECTARI IN

NORMELE EUROPENE

Eurocodurile. Concepte de baza

Conceptul general de proiectare

Bazele proiectarii in EC2 si STAS

10107/0-90

Calculul structurilor in EC2

PRINCIPIE PRIVIND STABILI-

TATEA INCARCARILOR

Stari limita ultime

Stari limita de exploatare

Exemple de calcul

INCOVOIERE CU FORTA

AXIALA

Ipoteze simplificatoare

Discutie asupra diggramei_ de

deformatii specifice

Sectiuni dreptunghiulare

Sectiuni T

Sectiuni circulare si inelare

Exemple de calcul

STAREA LIMITA ULTIMA

DATORITA DEFORMATIULOR

STRUCTURALE

Introducere

Clasificarea structurilor si elementelor

structurale

Date specifice pentru diferite tipuri de

structuri

Stalpi izolati

Exemple de calcul

CALCULUL PLACILOR DE

BETON ARMAT

Domeniu

‘Metode de calcul acceptabile

Calculul liniar cu sau fara redistribuire

Metode de calcul plastic

Metode numerice de calcul neliniar

Metode practice de calcul

Exemple de calcul

CONTENTS

PREFACE

BASIS OF DESIGN IN EUROPEAN

NORMS

Eurocodes. Conceptual approach

Basis of design. General concept

Basis of design in EC2 and Romanian

Norm

Structural analysis in EC2

BASIS OF ACTION CALCULATION

Ultimate limit states

Serviceability limit states

Design examples

BENDING AND

FORCE

Basic assumption

Discussion on strain diagram

LONGITUDINAL

Rectangular sections

Flanged sections

Cireular and ring-shaped sections

Design examples

ULTIMATE LIMIT STATE

INFLUENCED BY STRUCTURAL

DEFORMATIONS

Introduction

Classification of structures and structural

elements

Specific data for different

structures

Isolated columns

Design examples

types of

ANALYSIS OF SLAB SYSTEM

Area

Acceptable methods of analysis

Linear analysis with or

redistribution

Plastic methods of analysis

Numerical methods of non-linear analysis

Practical methods of analysis

Design examples

without

Pag.

52

67

69

1

89

96

108

108

109

109

10

i

ul

118

Cap 2

Cap. 3

Cap. 4

Cop. 5

Cap. 6

Cep.7

Cep. 8

Cap. 9

Cap.10

Cap.

Cap.12

Cap.13

Cap.14

Cap.15

AUTORII VOLUMULUI - AUTHORS

Prof. Corneliu BOB - Timisoara

Prof. Ovidiu MIRSU, Ing. Liane BOB - Tirnisoara

Prof. Tudor CLIPII - Timisoara,

Prof. Constantin TREZOS - Athens

Prof. loan CADAR - Timisoara,

Prof. Doina NOUR - Iasi

Prof. Anton IONESCU, Ing, Calin MIRCEA - Cluj-Napoca

Prof. Valeriu STOIAN, Ing. Luminita FEKETE - Timisoara

Dr. ing. Agneta TUDOR - Timisoara,

Prof. André PLUMIER - Liége

Ing. Aurora FLOREA - Timisoara,

Prof. Ildiko BUCUR, Ing. Calin MIRCEA-Cluj-Napoca

Prof. Corneliu BOB - Timisoara

Prof. Cornel FURDU! - Timisoara

Prof. Nicolae FLOREA - Iasi

Dr. ing. Stefan IOSIP-MOT, Dr. ing. Cornel JIVA - Timisoara

Prof. Traian ONET, Prof. Cornelia MAGUREANU - Cluj-Napoca

Dr. ing. Aurel IRHASIU-Timisoara

Editare computerizata

Computer processing Ing. Emilian JORGOVAN

Fjolosit la edificarca constructillor. Aceast

> ealitate ridica importante intrebari despre cum pot

proiectate, realizate si pastrate in viitor

© Gonstructiile de beton armat la costuri acceptabile

pentra diferite perioade de utilizare si, in avelasi

timp, avand un aspect estetic multumitor. Pe de

‘alta parte sunt necesare eforturi pentru incurajarea

jitoarelor dezvoltari in domeniu.

Un posibil raspuns la aceste probleme cat si la

altele care mai pot sa apara in viitor il reprezinta

sistemul european de normative pentru structurile

de beion.

Prezentul volum contine un apreciabil numar

"de exemple de calcul si teoria specifica fiecarui

capitol, ambele in concordenta cu prevederile din

ii care au conceput cepitolele prezentei

“cari apartin de corpurile profesorale de la

urmatoarele scoli de constructi

-Universitatea “Politehnica” Timisoara

-Universitatea Tehnica din Cluj-Napoca

-Universitatea Tehnica “Gheorghe Asachi” din

hasi

Universitatea Tehnica Nationala din Atena,

Grecia

Universitatea Tehnica din Liege, Belgia

Prin acest volum se intentioneaza sa se faca

cunoscute principalele prevederi ale Eurocodului 2

unui larg cere de ingineri din Romania si nu

numai; din acest considerent Iucrarea este scrisa in

limbile romans si engleze. Capitolele din carte se

<< refera, in principal la cele existeme in EC 2

= Prezentarea cuprinde, de asemenea, referiri la

prevederile esentiale din normele romanesti si cele

din alte tari europene privind structurile din beton

armat. O atentie speciala s-a acordat si_unor

subjecte cum ar fi: Bazele pentru calculul

actiunilor; Metoda sistemelor de bare; Rezistenta

la foc. Aceste capitole, abordate succint in EC 2,

ajuta cititorul la o mai buna receptare @ intregului

material prezentat,

Autori au utilizat, atat cat a fost posibil,

simbolurile, notatiile si unitatile de masura din

Eurocodul 2. Formulele, tabelele, figurile si lista

bibliografica au fost numerotate pentru fiecare

cepitol in parte. Referirile Ja numerotarea

cepitolelor, formulelor, figurilor si tabelelor din

1. PREFACE

Concrete is ubiquitous and unique; it is the

most used building and construction material. This

raises important questions of how concrete should

be designed, constructed and kept with all

requirements for cost effective use in the short and

Jong term. Equally, it must also be aesthetic

presentation in structures and yet encourage

further radical development.

A possible answer at these questions and, other

future aspects could be obtained from the

European Regulation System for concrete

structures.

The present volume contains both numerical

Examples and corresponding theory in accordance

with Eurocode 2 -EC2 -"Design of concrete

Structures”.

The chapters of the book were prepared by

authors which are staff members of:

Politehnice” University of Timisoara,

Romania

Technical University of — Cluj-Napoca,

Romania

"Gheorghe Asachi” Technical University of

lassy, Romania

-National Technical University of Athens,

Greece

-University of Liege, Belgium

This volume intends to make Eurocode 2

familiar to a wider circle of engineers from

Romania and not only. For this reason the book

wes written in Romanian and English. The book

briefly follows the corresponding chapters of

Eurocode 2. The presentation referred not only to

the provisions of EC2, but also to the relevant

provisions of the existing Romanian Code and

other European National Norms on concrete

structures. Special attention was paid to some

subjects like: Basis of Actions Calculation; Strut

and Tie Method; Fire Resistance. Such chapters,

only scantily treated in EC2, will help the readers

in understanding the other subjects of the book.

The authors used, as it was possible, the

symbols, notations and units from the Eurocode 2.

‘The Formulas, Tables, Figures and References

have been numbered, separately, to each chapter.

The numbers of the chapters, formulas, figures

and tables from EC2 and other references are

‘written in “italics”.

The editors wish to thank all that contributed to

EC? si alte surse bibliografice sunt scrise in

“italic”.

Editor

dorese sa multumeasca tuturor celor

care au contribuit la reusita realizarii acestei cart:

antori, participanti la Seminarul de a Timisoara

din Iulie 1996, sponsor, colectivul de tiparize si

prof, 0. MIRSU pentra sprijinul acordat la

verificarea manuscrisului_lucrarii. Totodata isi

exprima speranta unei primiri corespunzatoare a

yolumului din partea cititorilor.

Timisoara,

November 1996

the success of the Book, the authors, the

participants to the Timisoara Seminar in July

1996, the sponsors, the publishers. Particular

thanks must be given to prof. O. MIRSU for his

final check of the manuscript. Finally, they hope

that the present volume will find a corresponding

approval by the readers.

Prof. Corneliu BOB

2.BAZELE PROIECTARII IN NORMELE EUROPENE

2.1 EUROCODURILE. CONCEPTE DE BAZA

Ideea realizarii unor modele pentru un set de “Coduri

Internationale”, in vederea proiectarii tuturor tipurilor de

structuri pentru constructii a aparut in 1974 si s-a bazat pe 0

intelegere inte mai multe organizatii tehnico-stiintifice. La

activitatile initiale de realizare a codurilor internationale au fost

implicate urmatoarele organizatii stiintifice[2.7):

CEB-Comitetul Euro-Intemational pentru beton

FIP-Federatia Internationala pentru Beton Precomprimat

TABSE-Asociatia Internationala pentru Poduri si Structuri

Ingineresti

CIB-Consiliul International pentru Documentare, Studiu si

Cercetari in Constructii

RILEM-Asociatia Internationala a Laboratoarclor de

Incercari si Cercetari pentru Materiale si Constructii

ECCS-Conventia Europeana pentru Constructii de Otel

ICSS-Comitetul Unit pentru Siguranta Structurilor

ISSMFE-Societatea Internationala pentru Geotehnica si

Fundatii

Scopal realizarii eurocodurilor pentru structuri a avut, inca

din faza initiala, un caracter bidimensional (geografic si

tchnic): atat pentru diverse tari europene cat si pentru diferite

materiale de constructii, metode de executie si tipuri de

constructii, In acelasi timp sa urmarit obtinerea unei

compatibiliteti a ciferitelor coduri de proiectare in vederea

realizarii unor niveluri de siguranta comparabile [2.5].

Principalele etape ale elaborarii Eurocodurilor pentru

structuri, cat si organizatiile care participa la aceste activitati,

sunt prezentate in tabelul 2.1.

2. BASIS OF DESIGN IN

EUROPEAN NORMS

2.1 EUROCODES. CONCEPTUAL

APPROACH

In the construction sector, the

following associations are

involved in the preparatory work

for international standardisation:

CEB-Euro-International

Committee for Concrete

FiP-International Federation

for Prestressed Concrete

IABSE-Intemational

Association for Bridge and

Structural Engineering

CIB-International Council for

Building Research, Studies and

Documentation

RILEM-International Assoc,

of the Testing and Research Lab,

for Materials and Constructions

ECCS-European Convention

for Constructional Steelworks

ICSS-Joint Committee and

Structural Safety

ISSMFE-International

Society for Soil Mechanics and

Foundation Engineering.

The technical basis was

prepared for a formal

establishment of the "Structural

Eurocodes" with a two-

dimensional harmonisation:

across the border of states,

between different construction

materials, construction methods

and types of buildings and civil

engineering works [2.5].

Evrocodul 2, parte a sistemului de reglementari europene,| The political and legal

‘object cerintele esentiale privind rezistenta, | background «for Structural

lurabilitatea constructiilor de beton armat si| Furocodes are presented in

Table. 2.1 ; more attention is

are drept

exploatarea si dl

eton precomprimat. Unele dintre secventele mai importante

ale elaborarii eurocodurilor in general si Eurocodului 2(EC2) paid to Eurocode 2

in special sunt prezentate in tabelul 2.1 The objectiv of the future 2s

European Regulation System 25

Etape ale elaborarii Eurocodului EC 2 Tabel 2.1. | was bom in 1976. BE se

The work on EC2 started in ae EESE

‘Anu! Organizatii si obiective 1979 and was originally based on a er tl

the CEB/FIP Model Code 1978 2S ee

Europene (CEC) initiaza|| A CEC Comission established

in 1981 the programme for a total

lset of cight volumes (EC9 was

1976 |Comisia Comunitat

lobiectivul armonizarii normelor tehnice

later decided) of Eurocedes: = gs =

1979 |[ncepe elaborarea Eurocodului EC2 avand la bazal = ee ea i €

|Codul Model CEB/FIP 1978 ECI: for actions on structures 2 Bo 2 cand 8

7981 [0 comisie a CEC stabileste programul pentru opt|| EC2: for concrete,reiforced 2 ae ee § 2

Eurocoduri (ECO a fost propus pentru elaborare maiconcrete and prestressed concrete fo) |~28 oe s

harziu): |structures eS Se ars ci

IECI: Bazele proiectarii si actiunii in constructii EC3: for steel structures e [Gee] jess mze8

IEC2; Structuri de beton, beton armat si betonl] EC4: for composite steel and eee ase we S8ae Ps

lprecomprimat lconerete structures 3 wee 2eeb2 S

C3: Structuri de otel ECS for timber structures we | [Ses Roeee

5C4: Structuri compuse otel-beton EC6: for masonry structures Be Sa ae

ECS: Structuri de lemn EC7: for foundations and es 5 wes

C6: Structuri de zidarie geotechnical structures S es

EC7: Fundetii si inginerie geotehnica ECS: for structures in seismic uw

3

2

IEC8: Structuri in zone seismice zones eB

IEC9: Structuri de aluminiu ECS: for aluminium structures =,

{984 _|[Flaborarea primului “Raport tehnic” al EC2 A first draft for EC2 was es a

lpublished in 1984. we

1987 |-CEC “da mandat™ Comisici Europene dein 1985 partly very detailed ae se

IStandardizare CEN pentru stabilirea unor standarde||comments have been elaborated go he

larmonizate land were assessed in 1986 and as g S28

|-Blaborarea primelor comentarii ale EC2 1987 by the Editorial Group for = a5 aes

1989__|Elaborarea si aprobarea raportului final ptr. EC2 IEC2. 3 2) £

s é Es]

1990 |CEN creeaza “Comitetul tehnic CEN/TC 250] A revised final Draft was

IEurocoduri pentru structuri cu 9 subcomitete SC|lapproved in 1989. In 1990 Sub-.

imandatate a definitiva Eurocodurile Commitee 2(SC2) of TC250 of

|CEN was formed.

1991 Ec2 este claborat in forma unui “Prestandard|| EC2 was insued in form of an

[European ENV”, aprobat de SC2 [European Pre-Standard ENV at

the end of 1991 and EC2-Partl

Ihave been elaborated in 1992.

1992 |EC2-Pariea 1 “Reglementari generale si reguli pentrul) In Figure 2.1 future regulation

{constructii: este definitiva |system for concrete structures is

Tn figura 2.1 este prezentata schema de alcatuire privind|presented. It is concemed with the

reglementarile tehnice europene pentru beton. Acestea se referalessential requirements for

Ia cerintele esentiale privind rezistenta, exploctarea siresistance, serviceability and

Gurabilitatea structurilor de beton. Idurability of concrete structure.

Tig. 2.1 Reglementari tehnice curopene pentru beton

European Regulation system for concreie

cr

10

2.2 CONCEPTUL GENERAL DE PROIECTARE

in concordanta. cu BCI, Cap.2.,

eurocodurilor, proiectarea, constructia si

asigura:

comun tuturor

inuetinerea, vor

-pesfommante adecvate sub toate cctiunile posibiley =

-durabilitate adecvata in corelatie cu costurile de mentinert

sub influenta tuturor actiunilor;

in cazul unor actiuni except!

aiba un caracter disproportionat

solicitari.

jonale, avarile care rezulta sana

fata de cele care apar din alte

In functic de consecintele economice si sociale ce apar la

rupere exista trei clase de rise:

Clasa,J;: Rise seazut cu consecinte economice si sociale mici

sau neglijabile

Clasa 2: Risc mediu cu consecinte economice si sociale

considerabile

Clasa 3: Risc ridicat cu consecinte economice sl sociale

foarte mari

2.2.1. Principiile de proiectare la starile limita

Starile limita sunt imaginate a fi marginile unui domeniu in

jmterioal caruia structura satisface criteriul de proiectare.

Startle limita sunt definite a fi:

Starile limita ultime, care sunt asociate cu colapsul sau alte

forme ale ruperii structurii.

Starile limita de exploatare, corespunzand stadivlui dincolo

de care cerintele privind 0 exploatare normala nu mai sunt

satisfecute:

Pentra starile limita ultime si pentru cele de exploatare, la

care depasirea uneia cauzeaza 0 degradare permanenta, cerintele

de proiectare, pentru un caz simplu, sunt:

Bp SRG 1)

valoarea de proicctare a efectului actiunii fiind:

Sy = S(Fy,gofa) 22)

in care:

Fyeste valoarea de proiectare a unei actiuni,

ag-valoarea de proiectare a unei marimi geometice,

fyevaloarea de proiectare a unei proprictati a matecialuluis

22 BASIS OF DESIGN. GENERAL

CONCEPT(2.5]

‘According to EC 1, Chap.2.1.

structures shall be designed,

constructed and maintained to

achieve:

-perform adequately under all

expected actions;

“to have adequate durability

in relation to maintenance costs;

-not be subsequently damaged

disproportionately to the original

cause in the case of exceptional

hazards.

In function of economic and

social consequences of failure

there are:

Class 1: Low risk

Class 2: Medium risk

Class 3: High risk

2.2.1. Principles of limit state

design

Limit staies are __the

boundaries of a domain within

which the structure is assumed

to satisfy the design criteria and

are classified into:

Ultimate limit states which

are those associated with

collapse or with other forms of

structural failure.

Serviceability limit state are

those associated with specified

service criteria for normal use.

For the ultimate limit state

and those serviceability limit

states where the passage of @

limit state causes a permanent

damage, the design requirements

may be written by equation (2.1)

and (2.2) for the simplest case,

where:

Fy is the design value of an

action,

ay is the design value of 2

geometrical quantity,

fj is the design value of a

12

material property;

iar valoarea de proiectare a rezistentei este:

Re =R@.,f.) (23)

Pentru celelalte cazuri ale starilor limita de exploatare,

conditia de proiectare poate fi scrisa:

Sy =S(F,.a4.f,) factor de conversie, prin care valoarea determinata prin

incercari de laborator este c

convertita la una care apare i

structura studiata, a“

2.2.4. Combinatiile actiunilor

peecale nt astfel combinate incat sa produca efectul cel

fefavorabil asupra structurilor in cazul starilor limit

considerate. ere

Pentru starile limita ultime, combinatiile considerate sunt:

combinatii fundamentale si combinatii accidentale.

La combinatiile fundam

¢ entale, valoarea de ject

efectului actiunii Sz este: ia

8, =D reGe + 1Qit Lovo +1 28)

in care valorile coeficientilor sunt date in tabelul 2.3

dimensiunilor geometrice ale

le valorile

caracieristice, notate a, care corespund, in general, celor

-the overell shape and size of

the structural system

-the shape of the components

-the shape and size of cross

sections, support —_areas,

connections etc.

The geometrical data are

represented by their

characteristic values, a, which

usually correspond to these

specified by the designer.

2.2.3. Design values

7 The basic variables are

introduced into the calculation

model with their design values.

Fy foractions

fj for material properties

ay for geometrical data ;

Sce equations (2.5), (2.6) and

(2.7) where:

F,.f,.a, are characteristic

values of actions, material

properties and geometric data

Yom 8 Specific factors for

actions and material properties;

Aa-additive geometrical data

7 ae conversion factors

from laboratory data to those

which are used in a structure

design.

2.2.4,

actions

Actions shall be combined so

that they produce the most

unfavourable effect on the

structure for the limit state

considered.

For the ultimate limit state

there are: fundamental

combinations and accidental

combinations.

For fundamental

combinations, the design value

Sd is evaluated by the loads

given in equation (2.8)

Combination of the

(Table 2.3).

|

15

Valorile coeficientilor de siguranta pentru combinatii fu

Numerical values of specified factors for fundamental

ndamentale

combinations Tabel 2.3

Cociienti de Sieuranta Sajesy | Etec cefavorabil Unfavourable | Efect favorabil Favourable

coefficients effect effect

‘Actiuni permanente, Gy yor1.35 o=1.0

Permanent action

‘Actiuni variabile, Qe yor1.50 yo=10

Variable actions:

Forta de precomprimare, Py yp=1.2 sau (or) 1.0 ‘ye=0.9 sau (or)1.0

Prestressing force

In cazul combinatiilor accidentale, valoarea de proiectare a

efectului actiunii Sq este:

= Dye tvQut DV +Ar 29)

in care:

‘yoa=1 sau este dat in normative nationale;

Gy-valoarea caracteristica a actiunilor permanente;

Qey-valoarea caracteristica a uneia (cea mai importanta)

actiune variabila;

Qk -valori caracteristice ale altor actiuni variabile;

‘A-valoarea de proiectare, dependenta de timp, ectiunilor

indirecte (actiunea seismica);

o.wuiyia-factori de combinare a actiunilor (vezi Cap. 3)

Pentru starile limita de exploatare exista tei tipuri de

combinati

-Combinatii rere, folosite in cazurile in care la depasirea unei

stari limita sc cauzeaze 0 degradare locala permanenta sau 0

deformatie neacceptabila;

-Combinatii frecvente, folosite in cazurile in care la

depasirea unei stari limita se cauzeaza degradari locale,

deformatii mari sau vibratii care sunt temporare

-Combinatii cvasi-permanente folosite pentru efecte de lunga

durata importante.

16

For accidental combinations,

the design value Sq is evaluated

by the loads given in cquation

(2.9) where:

yoas1 or from National

Norms;

Gg-characteristic value of

permanent actions;

Qui-characteristic value of

one( the main) variable action;

Qui-characteristie values of

the other variable actions;

Ajtime dependent

value of indirect

(seismic action);

WoWia.Wi2 combination.

factors of actions (see Chap. 3).

For the serviceability limit

states there are three types of

combinations:

-The rare combinations are

used mainly in those cases when

excedance of a limit state causes

a permanent local damage or a

permanent unacceptable

deformation.

f, pe cilindri la 28 delR, Ry, pe cuburi 141 mm|

ile Ha 28 de zile

|Rezisténtele caracteristice:

Ry = (087 - 0.002Ry)Riv

|Rezistentele caracteristice:

if

fs

fi, = 0.30-£4.7° peaaaiee

Rezistentele de calcul: |Rezistentele de calcul:

fa

Ye

15- combinatii funda -

mentale de actiuni

combinatii acciden -

tale de actiuni

(fara cutremure)

2.3. BASIS OF DESIGN IN EC2

AND ROMANIAN NORM

The issue of EC? is a first

important step to harmonise

Romanian regulations for design

and construction of concrete

structure. Some comparisons

between EC2 and Romanian

Norm STAS 10107/0-92 are

presented concerning: material

properties, design stress-strain

curves, strain and stress

distribution at the ultimate limit

state ete.

23.1. Material properties

23.1.1. Concrete

The definition of the

characteristic and design value

of concrete strength are

presented in Table 2.4 (EC2: 3.7

and 4.2.1).

fy(R,) is average value of

lconcreie compressive strength

fy (Ry,) is the charact. 28 days

compressive strength measured on

lcylinders fay or on cubes Rix;

Ry is the characteristic

compressive strength calculated

fas cylinders strength from cube

strength;

faim is the mean tensile strength

lin uniaxial tension;

fu(Re) is the design value of

lconcrete compressive strength;

yelYic) is partial safety

icoefficient for concrete.

In Figure 2.2 the definition of

the characteristic strength is

lshown.

nis number of samples;

s is standard deviation;

finos and frogs are fractiles for

Iminimum (5%) and maximum

(95%) values.

17

In figura 2.2 este prezentat modul de definire a rezistentelor

caracteristice (minime) in care:

neste numarul de epruvete;

s este deviatia standard;

fags si feoos sunt fractilii pentru valorile minime (5%) si

maxime (95%)

Se observa valorile diferite ale factorilor specifici cat si

necesitatea introducerii factorului de conversie pentru valoarea

deteminata pe cuburi a rezistentei la compresiune a betonului;

in normele romanesti rezistenta la compresiune a betonului se

determina pe cuburi, in timp ce in structura compresiunea este

de tipul rezistentet prismatice (cilindrice). Corelatia dintre

rezistenta cubica si rezistenta cilindrica cu punerea in

evidenta a claselor de beton dupa cele doua standarde, este

redata in in fig 2.3.

Yn conformitate cu tabelul 4.8 din EC2 rezistenta la forte

taietoare (efortul unitar tangential de calcul) pentru elemente

fara armare la forte taietoare este:

25 fey

oo (2.10)

Yalorile de proiectare pentru efortul uniter de lunecare, in

cazul unor conditii bune de aderenta sunt:

036fF.

; bare netede Qily

; bare profilate (2.12)

Valorile de calcul ale rezistentelor se deduc din valorile

caracteristice prin aplicarea unui coeficient partial de siguranta

‘ypentcu beton conform relatici (2.6).

Yalorile rezistentelor (conform tab. 3.1 din EC2 si tab 3 din

STAS 10107/0-90) sunt redate in tabelul 2.5 si figura oe

“Deosebirea esentiala dintre cele douz norme este evidentiata de

modalitatea diferita de stabilire 2 modulului de elasticitate 2

betonului: in normele romanesti se determina modulul de

clasticitate tangent la diagrara efort unitar-deformatie

specifica; in EC2 se stabileste o valoare secanta a modulului de

elasticitate, in conformitate cu formula data in tab. 2.5.

In acest fel se explica valorile mai mici ale modulului de

clasticitate dupa EC2 fata de STAS 10107/0-90 pentru valori

mai ridicate ale claselor de betoane.

18

From Table 2.4 it can be seen

the necessity of a transformation

factor for cube strength to

characteristic compressive

strength.

In Fig. 23 is shown the

relationship between cube and

cylinder strength of concrete: the

correspondence between EC2

and Romanian Norm concerning

concrete class C as well as Bc is

also illustrated.

The basic design shear

strength of members without

shear reinforcement (Table 48

of EC2) are given by formula

(2.10)

The design values for the

ultimate bond stress for good

bond conditions are:

formula (2.11) for plain bars

formula (2.12) for high bond

bars

Design value of strength are

derived from the characteristic

values oy applying the

appropriate partial Safety factor y

for concrete (see equation 2.6)

The values of strength and

modulus of elasticity are given

in Table 2.5 (from Table 3.1 of

EC2 and Table 3 of STAS

10107/0-90) and Fig. 2.4.

The difference between the

two norms concerning the

modulus of elasticity is:

Romanian Norm define the

modulus by the tangent of the

stress-strain diagram; in EC2 the

modulus is defined by formula

from Table 2.5 as a secant to the

stress-strain diagram.

ength

Cylinder s

s

ol

2 7

2 a

2 Feags(fes)= fom 1655

fom LESS

Sinaia er

fe 0.05 (fer) fem fc095 fe

Fig 2.2 Definirea rezistentelor caracteristice

Definition of the characteristic strenght

A

C 50/60

35/45

| 6 30/37

C 25/30

20 ¢ 20/25

C 16/20

C 12/15

10 20 30 40 50 60

Rezistenta cubica N/mm?

Cube strenght

Fig. 2.3 Corelatia rezistenta cubica-rezistenta cilindrica

Relationship belween cube und cylinder sirength

19

0

50)

58

33.3

41

29

5.3

0.41

Tabel 2.5.

c35/4 | C40/5 | C45/5 | C50/6

70

5

4S

53

30

38

an

4.9

0.41

B700

45

31,5

278

1.85)

Bc50 | Bc60

60

0

40

48

26.7

35

2.5

4.6

O41

38.5

26.5

251

1.65

38000 | 40000

100 | B600

5

50)

1.45)

5

35

B

233

32

22

4.2

037

Bed0

B

31.6

22,

2.20

7

38

20

2.9

3.8

0.34

Be35

B4sO

28

45

20.5

2.03

2.94

1.35

, for concrete class

€25/3 | 30/3

0

25

33

16.7

26

18

33

0.30.

30500 | 32000 | 33500 | 35000 | 36000 | 37000

Be30

B400

24.3

ig

1.86

271

1.25

20

28

i723

22

15

2.9

0.26

26000 | 27500 | 29000

Be25

B300.

20.5

15

1.65

224

1.10

16

10.7

19

1.3

25

Bc20

B250

16.6

12.5

1.43

1.98

0.95

14000 | 21000 | 24000 | 27000 | 30000 | 32500 | 34000 | 36000

is of elasticity, in Nin’

24

C16R | C2072

C12/

12

20

1.6

a

Bols

B200

12.5

20

1.19

171

0.80

Bld

BI1SO0

8.5

15

6.5

0.92

141

0.60

10

a7

0.76

1.08

0.50

(Pa) Strength and modul

6A

Be7.5

B100

la

rezistentei

fom

la

fo 95=1.3 fem

Rezistenta la forte taietoare (/.=1.5)

BC2

fox

fea

‘Valoarea medie a rezistentei la intindere a

0.7m

Tre

Refer)

Ry (Em)

Re (fed)

intindere

Ra Ciew.05).

Ry

Compresiune

dri,

fey=0.30f 2?

Limita inferioara (fractilul 5%) pt. rezist.

Ia intindere a betonului

Limita

foo 05

rezistenta

la

rezistentel

a

Eu, = 9a +8

STAS 10107/0-90

pl.

Strength class of concrete

la

a

Rezistenta caracteristica la compresiune pe

calcul

caracteristica

medie

lacompr. pe ci

determinata pe cuburi

medic

de

ice.

superioara

compresiune

caracterist

5

3

zl

§|

3|

s

2

3

3

Clasele de rezistenta pentru beton in N/mm?

Modulul de elasticitate al betonului la

Tipul rezistentei

Valoarea medie a modului de elasticitate

(secant) al betonului

Rezistenta caracteristica la compresiune pe

cilindri

Rez. de calcul la compresiune

Rezistenta

Rezistenta de calcul la intindere

Strength class of concrete

Tipul rezist. -Notatic

Rezistenta medie la intindere

3

5

z

g

Valoarea

Valoarea

betonului

Rezistenta

(Fractilul 5%)

cuburi

KN

Fox Canz)} & Gr)

50

40

30

20

LEGENDA:

— STAS 10107/0

EG,

10 —

57510 6 20 25 30 35 40 45 50 55 60 Be

REUSE MS OW OB),

20 25 30 37 45 50 BI

Forma generala a diagramei efort unitar deformatie specifica

pentru cazul solicitarii la compresiune este prezentata in fig.

2.5. (fig. 4.2 dupa EC2): diagrama idealizeta cat si diagrama

pentru proicctare a structurilor de beton armat sunt date printr~

un model matematic exprimand o diagrama rectangular

parabolica (Functia 4.2 a EC2). Conform standardului STAS

10107/0-90 se foloseste acecasi. diagrama —reciangular

parabolica. Ecuatiile care reprezinta partea curba a diagramelor

sunt diferite ca forma de scriere, dar continutul esie acelasi

Diferentele care apar se refera la valorile difetite ale factorilor

specifici.

In conformitate cu EC2, este posibila si utilizarea unei curbe

caractetistice de forma celei din fig, 2.6, care este mai apropiata

de realitate.

4 Valorile rezistentelor si modulilor de elasticitate

Values of strength and modulus of elasticity

The general form of the

stress-strain diagram for uniaxial

compression is shown

schematically in Figure 2.5 (Fig.

4.2 of EC2): ideslised diagram

as well as design diagram for

structural analysis are given by

a mathematical model expressed

by a parabolic rectangular

diagram (Function 4.2 of EC2),

From Romanian STAS.

10107/0-00 the same parabolic

reclangular diagram is used

| Fig26,

21

At first appearance there is a

difference between mathematical

formulations of the parabolic

rectangular diagram in the two

norms, but the formulas give

the same values

An actual stress-strain diagram

lis also used from EC2 (Figure

[2.6a). Such diagram can be used

order

O astfel de diagrama se poate folosi la calculul dupa teoria

rdinul IL. i

" Valorle pentru deformatia specifica limita a betonului ea,

sunt date in tabelul 2.6 pentru clasele de beton.

Valorile e pentru sectiuni dreptunghiulare

The values Gy for rectangular cross sections

Clasa betonului | C12/15]C1620]C20/25]C

Tabel 2.6,

30] C30/37

Pints 3s | 34 [33 [32 _| othe second analysis of

‘betorulul C4095 |C45155|Cs0/60[ = concrete structures.

Chss Beton si 3.0 2.9 28 ‘The ultimate limit strain

as values for concrete class

A given in Table 2.6

6./ Rel fea) ;

| 7 | (dealised diagram | a

AK M00 (2508 “MN |

1 7 | DiagramG@ pentru he

Pe oe

Ve |, proiectare oe

7 Design diagram

|

|

| |

| EC 2-92

i,” OOD &,{ ZS0EF | teal

0.001 0.002 0.003 0.0035

here,

6 £b Yoo oy

R --| 7] + Ey Ze)

1

[Diagram proiectare

[Design diagram

10107/0-90

|

0002

STAS

|

|

|

|

|

|

o.007 0.003 0.0035

( 2 6.35 < B35)

Fig. 2.5 Diagrame caracteristice efort unitar-deformatie specifica pentru solicitare la

conapisiuns

Stress-sirain diagrams Jor uniaxial compression

G, simplificare

fe XSinpiification & _ __kn=nt

tc Z > 1#k=2)n

nF /E,

O4fe

2.6 Diagrama curbilinie efort-unitar deformatie specifica

Actual stress-strain diagram

Coeficientul lui Poisson pentru ceformatii in domeniul| Poison’s ratio for clastic

elastic se ia egal cu 0.2 iar daca se edmite fisurarea betonului | strain is 0.2, if cracking is

imins atunci coeficientul se poate presupune zero. peinitted for concrete in tension

it may he zero.

The coefficient of thermal

expansion may be taken equal to

1ox10“'C,

Deformatiile dependente de timp, curgerea lenta si] Time dependent

deformatia de contractie sunt prezentate in tabelul 2.7 si tabelul | deformations, creep and

28. shrinkage strains, are given in

Tables 2.7 and2.8.

Coeficientul de dilatare liniara la temperatura se ia egal cu

10x10°/°C.

- Coeficietul final de curgere lenta (c0,t,)

© Final creep coefficient Tabel 2.7

Varsta la incarcare to ile] Atmosfera uscata —- RH=30% | Atmosfera umeda _ RI=80%

Age ct leading tp days | Drv conditions conditions

Raport specific (

50 150 600 |__ 600

1 35 46 37 ay

7 3.9. 3.1 2.6 aD

28 3.0 25 2.0 5

90 24 2.0 16

365 18 15 12

Deformatia finala de contractie,

Final shrinkage strains

coo i %o

Tabel 2.8

Situarea elementului | Umiditate relativa Raport specific: 2A Ju, mm

~ Location of the Relative humidity (National size)

member %

£150

Interior! Jaside 50 -0.60

Exterior/ Outside 80. 0.33

Acaria sectiunii transversale a betonului/ cross secilon area of concrete

_Luperimetrul ariei Ac / perimeter of concrete area

2.3.1.2. Armatura pentru beton armat

Tn conformitate cu sectiunea 3.2 a EC2 produsele sunt

clasifieate dupa: rezistenta (notata fj), clasa (indicand

caracteristicile de ductilitare), diametru, _caracteristicile

suprafetei si sudabilitete.

Rezistenta reprezinta veloarea nominala a efortului

caracteristic de curgere (fy) data in N/ mm’.

Doua clase de ductilitate se definese:

Gnalta (H): eu25.0% cu (filf,)>1.08 (2.13)

“normala (N): 5u>2.5% cu (fife 1.05

Pentra analiza postelastica a structurilor la starile limita

ultime se admite calculul plastic penta structuri cu elemente

ductile la care se foloseste un otel de inalta ductilitate. Pentru

analiza liniara cu admiterea redistributiilor, conditia care se

pune otelului folosit (se neglijeaza verificarea capacitatilor de

rotire a zonelor critice) este:

8207 pentru clasa H si

52085 pentru clasa N, unde 14)

8 este raportul dintre momentul incoveietor redistribuit la

momentul incovoietor dinaintea redistributiei

Caracteristicile suprafetei sunt definite de:

-bare profilate cu aderenta sporita;

-bare netede cu aderenta redusa.

Diagrama caracteristica efort unitar-deformatie specifica

este prezentata in fig. 2.7 atat dupa EC2 cat si dupa STAS

10107/0-90. Sc constata diferente numei in ceea ce priveste

valorile diferite ale factorilor specifici cat si ale defurmatiilor

specifice limita.

In tabelul 2.9a sunt prezentate proprietatile armaturilor

SSOOH si SSOON in conformitate cu ENV10080.

* Pentru comparatie propriciatile otelului $420H dupa DIN

488, notat Bst 420S si ale otelului PC60 sunt prezentate in

tabell 2.9b.

2.3.1.2. Reinforcing steel

Section 3.2 of EC2 classify

the products according to: grade

(fi), class (ductility), size,

surface characteristics and

weldability.

Grade denote the value of the

specified characteristic yield

stress (fx) in Nimm’.

Two classes of ductility are

defined:

-High (H)

-Normal (N)

For structural analysis in

ultimate limit state, the plastic

approach may be used for very

ductile structural elements with

high ductility steel. Using linear

analysis with redistribution, the

condition related to the steel,

allowing the omission of an

explicit check on the rational

capacity of critical zones is

(2.14) where 8 is the ratio of the

redistribution moment to the

initial moment

Surface characterstics are

defined as:

-tibbed bars with high bond

action

-plain smooth bars with low

bond action

Stress-strain diagram is

shown in Fig, 2.7 from EC2 and

Romanian Norm. Some

differences there are between the

specific factors and ultimate

limit strains.

Properties of reinforcing steel

grade SS00H and S500N of

various product from ENV

10080 are presented in Table

29a

In Table 2.9b the properties

of steel S420H after DIN 488-

Bst 420S and PC6O after

Romanian Norms are presented.

b).

Ag EE2— 1992

A

1.15: peniru combinatii

Eyy> 90"oo pentru mare

Sau

ductilitate cu Ha >108 fundamentate

a X@- 1.00; pentru combinatii

Ey> 25%eo pentru duciilitate 4 accidentale

normalé cu ‘ey > 1.05 [find cutremur)

ake

} 2

E, = 200 kN /mm Gan iCae)

STAS 10107/0 -90

10°%eo grupari de incor dri

obisnuite

Eau = 50%o Qrupdri de incdrcdri ma=1: pentru velori de baza

cu actiuni seismice

Equ= 15% STNB

an

Fig. 2.7 Diagrame caracteristice fort unitar-deformatie specifica ale armaturilor pentru beton

armat

Stress-strain diagrams for reinforcing steel

Proprictatile armaturilor de rezistenta s

j clase S500H si SSOON

conform ENV 10080 \ tee oe

Properties ofits et Bare Spire, lite Plase sudate | p'

nas eee Bars Coils Welded Fabric

te Eau S500H | SSOON | S500H | SSOON | SSO0H | S500N

Z| Rezi

Sieleat 6la 40| 6la 16| 61a16 | 4 lal6 | 6lal6 | 41a 16 -

$ reat de) CORRE ||) S00 | 500% |) 500) [pe 5005/5800 :

(N/m?) 1

ea 3 1.03 or | 1.08 | 1.03 or | 0.95

1.08 1.03 or 1.08

: ee Ce 1.05 1.05 5 oa os

Fr fAlungte wala la foal 5 | 2or | 5 2or a8

* | maxima (%) 25

Total elongation at max.

Ose 3 | Table3 | Table 3 | Table 3

i 3| Table 3 | Table 3 | Tal

‘Aptitudinea la incovoiere | Table r able 5 Tae

4 ncercareladesdoire) | ENV | ENV | ENV | ENT

Suitable for bending

‘Rebend test) =

3 resets la oboseala} 2007 | 200 | 200 | 200 | 100

(N/mm?)

Fatigue strength - ; ar pyar 053

9 Rezistenta sudurilor (N) =- e

Strength of welded joints __| ts

0 |Deviatia permisibila a +45 44.5 445 H4.5 $4.5 +45

maselor (%) 0

Permissible deviation

‘from nominal mass

1) Valoti pentru probebilitatea p; ¥=1-0=0.95 sau 0.90

Values for probability

2) 150 Nine penca diametra for diameter >20mm

A-Aria sectiunil transversale a firelor mai groase

Nominal cross sectional area of thicker wire

Proprictatile ammaturlor de rezistenta si clasa $420H si PC60 on

Properties of reinforcing steel S420H and ae SS en