Documente Academic

Documente Profesional

Documente Cultură

Shuttering Techniques

Încărcat de

Madhavan100%(1)100% au considerat acest document util (1 vot)

272 vizualizări2 paginiShuttering

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentShuttering

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

272 vizualizări2 paginiShuttering Techniques

Încărcat de

MadhavanShuttering

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

QHSE

DEPARTMENT

TOOL BOX TALK - QUALITY

SHUTTERING

TECHNIQUES

TBT NO

PAGE

1 of 1

INTRODUCTION

Installation and Removal of Formworks

WHY?

Awareness of all Personnel involved in installation and deshuttering activities.

DOs

DONT

INSTALLATION

INSTALLATION

Dimension according to approved drawings.

Confirm/Verify Competent and train personnel.

Used Proper equipment/tools.

Overflowing of shutter oil, oil will trapped and

possible causes of blowholes and discoloration

of finished concrete

Checked Alignment and & Levelness

Cleaning of shutters

Over tighten of tie rods and bolts, possible

cause of bulging or irregular shape of concrete

structure

Proper sealing of joints to avoid leakage of

slurry concrete

Cast-in Items, fixtures, box-outs and

Embedments are in-placed. Allowance/space

should anticipate to avoid difficulty in

deshuttering.

Position support ,bracing and anchoring as per

drawing

Fix tie rods & bolts

Form oil/ release agents are applied as per

manufacturers recommendation.

Chamfers at perimeter corner shall installed

(as per drawing) to prevent chipped/broken

edges during deshuttering

Testing or mock-up units shall

performed before mass production of

shutters

DESHUTTERING

Obtain required concrete strength before

deshuttering. Secure test reports to avoid

damage of concrete units

Verify/confirm competent and train personnel.

Used Proper equipment/tools.

DESHUTTERING

Start the deshuttering without confirmation

of concrete cube results.

TOOL BOX TALK - QUALITY

SHUTTERING

TECHNIQUES

Checked any irregular shape, damage

occurred during concrete and removal

Cleaning immediately the shutter for next

activity.

Visual checking of finished concrete units, to

avoid reoccurrences of defects

QHSE

DEPARTMENT

TBT NO

PAGE

1 of 1

S-ar putea să vă placă și

- Painting Inspector Hand BookDocument5 paginiPainting Inspector Hand BookAmaan Khan100% (7)

- Method Statement For FormworkDocument4 paginiMethod Statement For FormworkSaiful Azri67% (3)

- Steel Fabrication Method StatementDocument12 paginiSteel Fabrication Method Statementvolcanox1288% (59)

- Deck Sheet Method StatementDocument7 paginiDeck Sheet Method StatementAKBAR ALIÎncă nu există evaluări

- Atox Mill Grouting Procedure For Foundation Parts: Approved Date: 21-Dec-2009 Created By: BGR Approved By: RHDocument5 paginiAtox Mill Grouting Procedure For Foundation Parts: Approved Date: 21-Dec-2009 Created By: BGR Approved By: RHmkpqÎncă nu există evaluări

- Procedure For Surface Preparation and Painting: Spectraa Technology Solutions LTDDocument4 paginiProcedure For Surface Preparation and Painting: Spectraa Technology Solutions LTDAshokkumar ThangarajÎncă nu există evaluări

- PaintingDocument31 paginiPaintingehsan hatamiÎncă nu există evaluări

- Fabrication ProcedureDocument17 paginiFabrication ProcedureThi Pham100% (9)

- Paint Inspection ServicesDocument27 paginiPaint Inspection ServicesJAVID TAJHIZ MAHAN100% (1)

- Ek 33 Çelik Konstrüksiyon Uygulama Planı (Steel Structure Method Statement) ÖrneğiDocument3 paginiEk 33 Çelik Konstrüksiyon Uygulama Planı (Steel Structure Method Statement) Örneğican akkaleÎncă nu există evaluări

- Paint Inspection Services - Specifications RXDocument28 paginiPaint Inspection Services - Specifications RXTony NellickenÎncă nu există evaluări

- Valve Inspection and Testing API - 598Document31 paginiValve Inspection and Testing API - 598Salem GarrabÎncă nu există evaluări

- Method Statement 2 - Spraytek PlasterDocument6 paginiMethod Statement 2 - Spraytek PlasterMohammad Arif RasheedÎncă nu există evaluări

- Method Statement Painting WorkDocument5 paginiMethod Statement Painting WorkTaqiuddinHarith78% (9)

- Erection Steel Structure ProcedureDocument15 paginiErection Steel Structure ProcedureOussama Sissaoui100% (1)

- Connection Clips: Method Statement GeneralDocument2 paginiConnection Clips: Method Statement GeneralSABEASNÎncă nu există evaluări

- Roadseal: Product SpecificationDocument2 paginiRoadseal: Product SpecificationSaran Kl100% (1)

- Erection Steel Structure Procedure - Method StatementDocument12 paginiErection Steel Structure Procedure - Method StatementBalakrishna ChowdaryÎncă nu există evaluări

- SAEP-351 Bolted Flange Joint AssemblyDocument12 paginiSAEP-351 Bolted Flange Joint AssemblyBebin Mathew75% (8)

- BVTC - Install Guide - Bag Louv - Final SCREENDocument12 paginiBVTC - Install Guide - Bag Louv - Final SCREENkmÎncă nu există evaluări

- Paint Inspection BasicDocument6 paginiPaint Inspection BasicmaddyÎncă nu există evaluări

- Fabrication and Erection ProcedureDocument13 paginiFabrication and Erection ProcedureshivanshsovÎncă nu există evaluări

- Method Statement of Pipe RackDocument8 paginiMethod Statement of Pipe RackLEIXIAO ZHANGÎncă nu există evaluări

- Specification Soil NailingDocument7 paginiSpecification Soil NailingAmir JiggyÎncă nu există evaluări

- Wavistrong Supplemental Installation InstructionsDocument13 paginiWavistrong Supplemental Installation Instructionsmg4myÎncă nu există evaluări

- How To Inspect Gear BoxDocument11 paginiHow To Inspect Gear BoxSubbarayan SaravanakumarÎncă nu există evaluări

- Method Statement For Cement Board Dry Wall PartitionsDocument10 paginiMethod Statement For Cement Board Dry Wall PartitionsComet GroupÎncă nu există evaluări

- Method Statement For Cement Board Dry Wall PartitionsDocument10 paginiMethod Statement For Cement Board Dry Wall PartitionsComet GroupÎncă nu există evaluări

- Method Statement For Cement Board Dry Wall PartitionsDocument10 paginiMethod Statement For Cement Board Dry Wall PartitionsComet GroupÎncă nu există evaluări

- PRES-M-07 Rotating EquipmentDocument2 paginiPRES-M-07 Rotating EquipmentsalamlinÎncă nu există evaluări

- TB-Air Cooler Plug Guidelines Rev 1Document2 paginiTB-Air Cooler Plug Guidelines Rev 1ABBGrain/gsharÎncă nu există evaluări

- Seal Install HandbookDocument12 paginiSeal Install HandbookEdgar CanelasÎncă nu există evaluări

- Plastering Works Method StatementDocument7 paginiPlastering Works Method StatementYan Belarmino33% (6)

- Glass Mosaic Tile To Swimming Pool Specification 240717Document8 paginiGlass Mosaic Tile To Swimming Pool Specification 240717aries llagasÎncă nu există evaluări

- Fire Protection Pipes Method StatementDocument11 paginiFire Protection Pipes Method StatementEdmund YoongÎncă nu există evaluări

- BF2D Parts - 3-26-09Document38 paginiBF2D Parts - 3-26-09petethefrenchÎncă nu există evaluări

- Painting ProcedureDocument62 paginiPainting Procedureasikur100% (3)

- Fabrication ProcedureDocument17 paginiFabrication Procedureanang Wahjudi100% (2)

- Work Method ProceduresDocument37 paginiWork Method ProceduresAnonymous K0fqIO100% (2)

- 03410Document5 pagini03410Jeffrey Carlo Viduya AgliamÎncă nu există evaluări

- Method Statement For PaintDocument5 paginiMethod Statement For PaintEngr Muhammad Sohail67% (3)

- Tank Repair - Shell InsertDocument2 paginiTank Repair - Shell InsertAzmin BorkhanÎncă nu există evaluări

- False Form WKDocument12 paginiFalse Form WKRonald Cario SeguinÎncă nu există evaluări

- General Specifications For The Proposed Gasoline StationDocument8 paginiGeneral Specifications For The Proposed Gasoline StationMark Anthony Capito Años100% (1)

- SECTION 031100 Concrete FormingDocument5 paginiSECTION 031100 Concrete FormingAlexander MasongsongÎncă nu există evaluări

- 022 Painting Spec (A)Document8 pagini022 Painting Spec (A)sravan_kits929Încă nu există evaluări

- Con-011 Instruction For Painting Work Rev.0Document11 paginiCon-011 Instruction For Painting Work Rev.0monchai_626Încă nu există evaluări

- Blasting Coating ProcedureDocument61 paginiBlasting Coating ProcedureZohair Aftab100% (1)

- Quality Control Procedure Strcture-SSDocument16 paginiQuality Control Procedure Strcture-SSKamran AliÎncă nu există evaluări

- SLC Hotel QC Checklist DRAFTDocument2 paginiSLC Hotel QC Checklist DRAFTErwin RosalesÎncă nu există evaluări

- PRES-M-09 Rotating Equipment - Gas TurbinesDocument2 paginiPRES-M-09 Rotating Equipment - Gas Turbinessalamlin100% (1)

- Spec VCL PDFDocument4 paginiSpec VCL PDFValiÎncă nu există evaluări

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreDe la EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreEvaluare: 4.5 din 5 stele4.5/5 (11)

- CNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingDe la EverandCNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingÎncă nu există evaluări

- Small Block Chevrolet: Stock and High-Performance RebuildsDe la EverandSmall Block Chevrolet: Stock and High-Performance RebuildsEvaluare: 4 din 5 stele4/5 (6)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successDe la EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successEvaluare: 4.5 din 5 stele4.5/5 (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- SolidWorks 2017 Black Book: SolidWorks Black BookDe la EverandSolidWorks 2017 Black Book: SolidWorks Black BookEvaluare: 3.5 din 5 stele3.5/5 (3)

- Zinc Oxide Pigments: Standard Specification ForDocument2 paginiZinc Oxide Pigments: Standard Specification ForMadhavanÎncă nu există evaluări

- Bore Pile Procedure - Training Presentation - Rev.01Document23 paginiBore Pile Procedure - Training Presentation - Rev.01MadhavanÎncă nu există evaluări

- SHEETPILE INSTALLATION-TrainingDocument17 paginiSHEETPILE INSTALLATION-TrainingMadhavanÎncă nu există evaluări

- SHEETPILE INSTALLATION-TrainingDocument17 paginiSHEETPILE INSTALLATION-TrainingMadhavanÎncă nu există evaluări

- AMCRPS Piling Handbook 9th Web-3Document455 paginiAMCRPS Piling Handbook 9th Web-3loketeloko100% (1)

- What Effect Does Waterjet Cleaning Have On The Surface? Thirty Years Perspective Lydia Frenzel Advisory Council San Marcos TXDocument70 paginiWhat Effect Does Waterjet Cleaning Have On The Surface? Thirty Years Perspective Lydia Frenzel Advisory Council San Marcos TXRauf AliyevÎncă nu există evaluări

- Chemical Analysis of Cuprous Oxide and Copper Pigments: Standard Test Methods ForDocument5 paginiChemical Analysis of Cuprous Oxide and Copper Pigments: Standard Test Methods ForMadhavanÎncă nu există evaluări

- Concrete Crack PresentationDocument32 paginiConcrete Crack PresentationMadhavanÎncă nu există evaluări

- Instruction Manual For Safety and Comfort PDFDocument24 paginiInstruction Manual For Safety and Comfort PDFmjrobust05Încă nu există evaluări

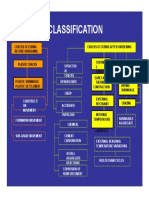

- Concrete Crack ClassificationDocument1 paginăConcrete Crack ClassificationMadhavanÎncă nu există evaluări

- Concrete Crack PresentationDocument32 paginiConcrete Crack PresentationMadhavanÎncă nu există evaluări

- Concrete Crack ClassificationDocument1 paginăConcrete Crack ClassificationMadhavanÎncă nu există evaluări

- Bs 1387 PDFDocument26 paginiBs 1387 PDFMadhavanÎncă nu există evaluări

- Concrete Crack PresentationDocument32 paginiConcrete Crack PresentationMadhavanÎncă nu există evaluări

- Understanding The Basic Commissioning (CX) ProcessDocument3 paginiUnderstanding The Basic Commissioning (CX) ProcessMadhavanÎncă nu există evaluări

- Concrete Crack ClassificationDocument1 paginăConcrete Crack ClassificationMadhavanÎncă nu există evaluări

- Understanding The Basic Commissioning (CX) ProcessDocument3 paginiUnderstanding The Basic Commissioning (CX) ProcessMadhavanÎncă nu există evaluări

- Understanding The Basic Commissioning (CX) ProcessDocument3 paginiUnderstanding The Basic Commissioning (CX) ProcessMadhavanÎncă nu există evaluări

- Project Quality ManagementDocument33 paginiProject Quality ManagementMadhavanÎncă nu există evaluări

- The First Core-Loc BreakwaterDocument13 paginiThe First Core-Loc BreakwaterFelipe FernandesÎncă nu există evaluări

- Understanding The Basic Commissioning (CX) ProcessDocument3 paginiUnderstanding The Basic Commissioning (CX) ProcessMadhavanÎncă nu există evaluări

- Understanding The Basic Commissioning (CX) ProcessDocument3 paginiUnderstanding The Basic Commissioning (CX) ProcessMadhavanÎncă nu există evaluări

- Buildings Comissioning PresentDocument3 paginiBuildings Comissioning PresentMadhavanÎncă nu există evaluări

- Understanding The Basic Commissioning (CX) ProcessDocument3 paginiUnderstanding The Basic Commissioning (CX) ProcessMadhavanÎncă nu există evaluări

- 1b6 Project CostsDocument25 pagini1b6 Project CostsHoangÎncă nu există evaluări

- 1b6 Project CostsDocument25 pagini1b6 Project CostsHoangÎncă nu există evaluări

- Holiday DetectionDocument4 paginiHoliday DetectionAnsar Ali100% (1)

- Nominal Pipe Size Conversion To Metric SizeDocument2 paginiNominal Pipe Size Conversion To Metric SizetowiwaÎncă nu există evaluări

- Capping Beam Installation - Training Presentation - Rev.01-ChinmoyDocument15 paginiCapping Beam Installation - Training Presentation - Rev.01-ChinmoyMadhavanÎncă nu există evaluări

- Rockland Manual REV BDocument42 paginiRockland Manual REV BMadhavan100% (1)