Documente Academic

Documente Profesional

Documente Cultură

Piping Material Classes: Notes

Încărcat de

Vedran KosanovicDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Piping Material Classes: Notes

Încărcat de

Vedran KosanovicDrepturi de autor:

Formate disponibile

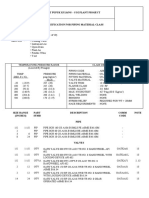

PIPING MATERIAL CLASSES

PRESSURE / TEMPERATURE

RATING

CS1-150-8

-20

50

100

150

Bar

19.6

19.3

17.8

17.7

SERVICE

CODE

RATING

CORR. ALLOWANCE

PIPING CLASS

MAT'L.

ASME B31.3

ANSI 150#

1/8"(3MM)

CS1-150-8

C.S (NACE)

SIZE (IN)

0.50

SCH

0.75

1.50

160

80

40

PIPE

A106 GR B SMLS BE (NACE)

FITTINGS

ASTM A 234 WPB BW(NACE)

FLANGES

ASTM A 105 (NACE) 150# WN RF SMOOTH FINISH

(125-250 AARH)

(BORE TO MATCH PIPE)

O'LETS

8

20

ASTM A105(NACE)

VALVES

BALL

BV-001

GATE

GV-001

BV-002

CHECK

GLOBE

NEEDLE

PLUG

BOLTS : ASTM A193 GR.B7M, CADMIUM PLATED.

BOLTING

NUTS : ASTM A194 GR 2HM HEAVY HEX. CADMIUM PLATED.

GASKETS

150#, RF, 4.5MM THK. SPIRAL WOUND ,316SS/FLEXIBLE GRAPHITE W/CS CADMIUM PLATED CAGE RING,FLEXITALIC CG OR

EQUIVALENT

NOTES:

1

D- DRAIN

2.

ALL ITEMS SHALL MEET REQUIREMENTS OF NACE-MR-01-75 AND QP-STD-R-001.

3. ONLY LONG RADIUS ELBOWS TO BE USED.

4. USE BUTT WELDED FITTINGS ONLY.SOCKET WELDING,THREADED FITTINGS SHALL NOT BE USED.

5. IN ADDITION TO THE HYDRO/PNEUMATIC TEST CARRIED OUT IN VENDORS PLACE, ALL VALVES TO BE TESTED AT SITE AS PER

BS6755 PART 1.

X:\022-00734 IA COMPRESSOR\PIPING\MANIFOLDS\PIPING MATL SPEC\REV 2\1654-1012 REV2.XLS

PAGE 1 OF 5

06/10/2015

PIPING MATERIAL CLASSES

PRESSURE / TEMPERATURE

RATING

CS1-300-4

-20

50

100

150

Bar

51.1

50.1

46.4

45.2

SERVICE

CODE

RATING

CORR. ALLOWANCE

PIPING CLASS

MAT'L.

ASME B31.3

ANSI 300#

1/8"(3MM)

CS1-300-4

C.S (NACE)

SIZE (IN)

0.50

SCH

0.75

1.50

160

80

PIPE

A106 GR B SMLS BE (NACE)

FITTINGS

ASTM A 234 WPB BW(NACE)

FLANGES

ASTM A 105 (NACE) 300# WN RF SMOOTH FINISH

(125-250 AARH)

(BORE TO MATCH PIPE)

O'LETS

40

ASTM A105(NACE)

VALVES

BALL

BV-003

GATE

GV-002

BV-004

CHECK

GLOBE

NEEDLE

PLUG

BOLTS : ASTM A193 GR.B7M, CADMIUM PLATED.

BOLTING

NUTS : ASTM A194 GR 2HM HEAVY HEX. CADMIUM PLATED.

GASKETS

300#, RF, 4.5MM THK. SPIRAL WOUND ,316SS/FLEXIBLE GRAPHITE W/CS CADMIUM PLATED CAGE RING,FLEXITALIC CG OR

EQUIVALENT

NOTES:

1

D- DRAIN

2.

ALL ITEMS SHALL MEET REQUIREMENTS OF NACE-MR-01-75 AND QP-STD-R-001.

3. ONLY LONG RADIUS ELBOWS TO BE USED.

4. USE BUTT WELDED FITTINGS ONLY.SOCKET WELDING,THREADED FITTINGS SHALL NOT BE USED.

5. IN ADDITION TO THE HYDRO/PNEUMATIC TEST CARRIED OUT IN VENDORS PLACE, ALL VALVES TO BE TESTED AT SITE AS PER

BS6755 PART 1.

X:\022-00734 IA COMPRESSSOR\PIPING\MANIFOLDS\PIPING MATL SPEC\REV 2\1654-1012 Rev 2.xls PAGE 1 OF 5

06/10/2015

PIPING MATERIAL SPECIFICATION

PRESSURE / TEMPERATURE

RATING

CS1-900-4

-20

50

100

150

Bar

153.1

153.1

150.1

138.8

135.8

SERVICE

CODE

RATING

CORR. ALLOWANCE

PIPING CLASS

MAT'L.

ASME B31.3

ANSI 900#

1/8"(3MM)

CS1-900-4

C.S (NACE)

SIZE (IN)

0.50

SCH

0.75

1.50

10

12

14

16

160

160

160

160

120

120

120

120

120

120

120

PIPE

A106 GR B SMLS BE (NACE)

FITTINGS

ASTM A 234 WPB BW(NACE)

18

20

24

A105(NACE),WN

FLANGES

RF1500#(BORE TO

A105(NACE),WN RF 900#

(BORE TO MATCH PIPE I.D)

MATCH PIPE I.D)

O'LETS

ASTM A105(NACE)

VALVES

BALL

BV-028

BV-027

GATE

GV-009

GV-010

GV-011

CHECK

CHV-009

GLOBE

GLV-009

NEEDLE

PLUG

BOLTS : ASTM A193 GR.B7M, CADMIUM PLATED

BOLTING

NUTS : ASTM A194 GR 2HM HEAVY HEX. CADMIUM PLATED.

GASKETS

900#, RF, 4.5MM THK. SPIRAL WOUND ,316SS/FLEXIBLE GRAPHITE W/CS CADMIUM PLATED CAGE RING,FLEXITALIC CG OR

EQUIVALENT

NOTES:

1

P - PROCESS

2. ALL ITEMS SHALL MEET REQUIREMENTS OF NACE-MR-01-75 AND QP-STD-R-001.

3. ONLY LONG RADIUS ELBOWS TO BE USED.

4. USE BUTT WELDED FITTINGS ONLY.SOCKET WELDING,THREADED FITTINGS SHALL NOT BE USED.

5. IN ADDITION TO THE HYDRO/PNEUMATIC TEST CARRIED OUT IN VENDORS PLACE, ALL VALVES TO BE TESTED AT SITE AS PER

BS6755 PART 1.

6. GASKET CONTACT FACE OF FLANGES SHALL BE SMOOTH FINISHED TO 3.2-6.3 MICROMETER Ra AS PER ASME B46.1

X:\022-00734\IA COMPRESOOR\PIPING\MANIFOLDS\PIPING MATL SPEC\REV 2\1654-1012 Rev 2.xls

PAGE 1 OF 9

06/10/2015

36

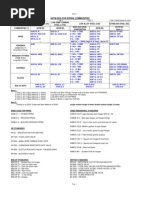

PIPING MATERIAL CLASSES

CS1-150-8

BALL VALVES

GENERAL:

TAG NO

BV-001

SIZE RANGE

1"- 11/2"

DESIGN SPECIFICATION

BS5351

DIMENSIONS

BS5351

PRESSURE DESIGN

ANSI CLASS 150

BODY,CONSTRUCTION

SPLIT

BALL,CONSTRUCTION

TRUNION

BORE

REDUCED

END CONNECTION

FLANGE 150#, RF TO ASME B16.5, SMOOTH FINISH TO 3.2 TO 6.3 MICROMETER Ra AS PER ASME B 46.1

OPERATION

LEVER OPERATED

FIRE SAFE

API 607 / API 6FA / BS6755 Part 2

SERVICE

SOUR GAS

TEMPERATURE LIMIT

-20 DEG C TO 121 DEG C

MATERIALS:

BODY

FORGED A105

TRIM

SS316 / SS316L

BALL

ASTM A182 GR F316/316L

STEM

ASTM A276 TYPE 316/316L

STEM AND GLAND PACKING

GRAPHITE,PTFE

SEAT RINGS

DEVLON OR EQUIVALENT

PRIMARY SEAL AND

BODY INSERT

VITON AED

SPIRAL WOUND GASKET

GRAPHITE WITH PTFE FILLER

STUD BOLTS AND NUTS

ASTM A193 GR B7M / A194 GR 2HM CADMIUM PLATED

OTHERS:

TESTING

BS 6755 PART 1

MARKING

MSS-SP-25

CERTIFICATION

EN 10204,TYPE 3.1B FOR PRESSURE PARTS.

ADDITIONAL REQUIREMENTS: 1.ALL WETTED PARTS SHALL MEET REQUIREMENTS OF NACE-MR-01-75

LATEST EDITION AND QP-STD-R-001.

2.ANTI STATIC DEVICE, ANTI BLOW OUT STEM , AUTO BODY CAVITY

PRESSURE RELIEF SEAT DESIGN SHALL BE PROVIDED

X:\022-00734 IA COMPRESSOR\PIPING\ MANIFOLDS\PIPING MATL SPEC\REV 2\1654-1012 Rev. 2 xls

PAGE 3 OF 5

06/10/2015

PIPING MATERIAL CLASSES

CS1-150-8

BALL VALVES

GENERAL:

TAG NO

BV-002

SIZE RANGE

2"- 3"

DESIGN SPECIFICATION

BS5351 / API6D

DIMENSIONS

BS5351 / ASME B16.10

PRESSURE DESIGN

ANSI CLASS 150

BODY,CONSTRUCTION

SPLIT

BALL,CONSTRUCTION

TRUNION

BORE

REDUCED

END CONNECTION

FLANGE 150#, RF TO ASME B16.5, SMOOTH FINISH TO 3.2 TO 6.3 MICROMETER Ra AS PER ASME B 46.1

OPERATION

LEVER OPERATED.

FIRE SAFE

API 607 / API 6FA / BS6755 Part 2

SERVICE

SOUR GAS

TEMPERATURE LIMIT

-20 DEG C TO 121 DEG C

MATERIALS:

BODY

FORGED A105 / ASTM A 216 GR WCB.

TRIM

SS316 / SS316L

BALL

ASTM A182 GR F316/316L

STEM

ASTM A276 TYPE 316/316L

STEM AND GLAND PACKING

GRAPHITE,PTFE

SEAT RINGS

DEVLON OR EQUIVALENT

PRIMARY SEAL AND

BODY INSERT

VITON AED

SPIRAL WOUND GASKET

GRAPHITE WITH PTFE FILLER

STUD BOLTS AND NUTS

ASTM A193 GR B7M / A194 GR 2HM CADMIUM PLATED

OTHERS:

TESTING

BS 6755 PART 1 / API 598

MARKING

MSS-SP-25

CERTIFICATION

EN 10204,TYPE 3.1B FOR PRESSURE PARTS.

ADDITIONAL REQUIREMENTS: 1.ALL WETTED PARTS SHALL MEET REQUIREMENTS OF NACE-MR-01-75

LATEST EDITION AND QP-STD-R-001

2.ANTI STATIC DEVICE, ANTI BLOW OUT STEM , AUTO BODY CAVITY

PRESSURE RELIEF SEAT DESIGN SHALL BE PROVIDED

X:\022-00734 IA COMPRESSOR\PIPING\MANIFOLDS\PIPING MATL SPEC\REV 2\1654-1012 Rev. 2 xls

PAGE 4 OF 5

06/10/2015

PIPING MATERIAL CLASSES

CS1-150-8

GATE VALVES

GENERAL:

TAG NO

GV-001

SIZE RANGE

1"-11/2"

DESIGN SPECIFICATION

BS5352

DIMENSIONS

BS2080

PRESSURE DESIGN

ANSI CLASS 150

WEDGE TYPE

SOLID

STEM

RISING, OUTSIDE SCREW AND YOKE

BONNET

BOLTED

END CONNECTION

FLANGE 150#, RF TO ASME B16.5, SMOOTH FINISH TO 3.2 TO 6.3 MICROMETER Ra AS PER ASME B 46.1

OPERATION

HAND WHEEL OPERATED

SERVICE

HYDROCARBON PROCESS, SOUR

TEMPERATURE LIMIT

-20 DEG C TO 121 DEG C

MATERIALS:

BODY

FORGED A105

WEDGE AND BODY SEATS

AISI 410 / AISI 316

STEM

ASTM A182 GR F316/316L

GLAND

AISI 410 / AISI 316 / AISI 316L

BODY SEAT FACING

STELLITE 6 FACINGS

WEDGE SEAL AREA

STELLITE 6 FACINGS

BACK SEAT

RENEWABLE, AISI 316 / AISI 316L WITH STELLITE 6 FACINGS

STEM PACKING

BRAIDED ASBESTOS FREE GRAPHITE / IMPREGNATED FLEXIBLE

GRAPHITE

GRAPHITE WITH PTFE FILLER

ASTM A193 GR B7M / A194 GR 2HM CADMIUM PLATED

SPIRAL WOUND GASKET

STUD BOLTS AND NUTS

OTHERS:

TESTING

BS 6755 PART 1

MARKING

MSS-SP-25

CERTIFICATION

EN 10204,TYPE 3.1B FOR PRESSURE PARTS.

ADDITIONAL REQUIREMENTS: 1.ALL WETTED PARTS SHALL MEET REQUIREMENTS OF NACE-MR-01-75

LATEST EDITION AND QP-STD-R-001

X:\022-00734 IA COMPRESSOR\PIPING\MANIFOLDS\PIPING MATL SPEC\REV 2/1654-1012 Rev. 2 xls PAGE 5 OF 5

06/10/2015

PIPING MATERIAL CLASSES

CS1-300-4

BALL VALVES

GENERAL:

TAG NO

BV-003

SIZE RANGE

1"- 11/2"

DESIGN SPECIFICATION

BS5351

DIMENSIONS

BS5351

PRESSURE DESIGN

ANSI CLASS 300

BODY,CONSTRUCTION

SPLIT

BALL,CONSTRUCTION

TRUNION

BORE

REDUCED

END CONNECTION

FLANGE 300#, RF TO ASME B16.5, SMOOTH FINISH TO 3.2 TO 6.3 MICROMETER Ra AS PER ASME B 46.1

OPERATION

LEVER OPERATED

FIRE SAFE

API 607 / API 6FA / BS6755 Part 2

SERVICE

SOUR GAS

TEMPERATURE LIMIT

-20 DEG C TO 121 DEG C

MATERIALS:

BODY

FORGED A105

TRIM

SS316 / SS316L

BALL

ASTM A182 GR F316/316L

STEM

ASTM A276 TYPE 316/316L

STEM AND GLAND PACKING

GRAPHITE,PTFE

SEAT RINGS

DEVLON OR EQUIVALENT

PRIMARY SEAL AND

BODY INSERT

VITON AED

SPIRAL WOUND GASKET

GRAPHITE WITH PTFE FILLER

STUD BOLTS AND NUTS

ASTM A193 GR B7M / A194 GR 2HM CADMIUM PLATED

OTHERS:

TESTING

BS 6755 PART 1

MARKING

MSS-SP-25

CERTIFICATION

EN 10204,TYPE 3.1B FOR PRESSURE PARTS.

ADDITIONAL REQUIREMENTS: 1.ALL WETTED PARTS SHALL MEET REQUIREMENTS OF NACE-MR-01-75

LATEST EDITION AND QP-STD-R-001.

2.ANTI STATIC DEVICE, ANTI BLOW OUT STEM , AUTO BODY CAVITY

PRESSURE RELIEF SEAT DESIGN SHALL BE PROVIDED

X:\022-00734 IA COMPRESSOR\PIPING\MANIFOLDSlls\PIPING MATL SPEC\REV 2/1654-1012 Rev. 2 xls PAGE 3 OF 5

06/10/2015

PIPING MATERIAL CLASSES

CS1-300-4

BALL VALVES

GENERAL:

TAG NO

BV-004

SIZE RANGE

2"- 3"

DESIGN SPECIFICATION

API6D

DIMENSIONS

API6D

PRESSURE DESIGN

ANSI CLASS 300

BODY,CONSTRUCTION

SPLIT

BALL,CONSTRUCTION

TRUNION

BORE

REDUCED

END CONNECTION

FLANGE 300#, RF TO ASME B16.5, SMOOTH FINISH TO 3.2 TO 6.3 MICROMETER Ra AS PER ASME B 46.1

OPERATION

LEVER OPERATED.

FIRE SAFE

API 607 / API 6FA / BS6755 Part 2

SERVICE

SOUR GAS

TEMPERATURE LIMIT

-20 DEG C TO 121 DEG C

MATERIALS:

BODY

FORGED A105 / ASTM A 216 GR WCB.

TRIM

SS316 / SS316L

BALL

ASTM A182 GR F316/316L

STEM

ASTM A276 TYPE 316/316L

STEM AND GLAND PACKING

GRAPHITE,PTFE

SEAT RINGS

DEVLON OR EQUIVALENT

PRIMARY SEAL AND

BODY INSERT

VITON AED

SPIRAL WOUND GASKET

GRAPHITE WITH PTFE FILLER

STUD BOLTS AND NUTS

ASTM A193 GR B7M / A194 GR 2HM CADMIUM PLATED

OTHERS:

TESTING

BS 6755 PART 1 / API 598

MARKING

MSS-SP-25

CERTIFICATION

EN 10204,TYPE 3.1B FOR PRESSURE PARTS.

ADDITIONAL REQUIREMENTS: 1.ALL WETTED PARTS SHALL MEET REQUIREMENTS OF NACE-MR-01-75

LATEST EDITION AND QP-STD-R-001

2.ANTI STATIC DEVICE, ANTI BLOW OUT STEM , AUTO BODY CAVITY

PRESSURE RELIEF SEAT DESIGN SHALL BE PROVIDED

X:\022-00734 IA COMPRESSOR\PIPING\MANIFOLDS\PIPING MATL SPEC\REV 2\1654-1012 Rev. 2 xls PAGE 4 OF 5

06/10/2015

PIPING MATERIAL CLASSES

CS1-300-4

GATE VALVES

GENERAL:

TAG NO

GV-002

SIZE RANGE

1"-11/2"

DESIGN SPECIFICATION

BS5352

DIMENSIONS

BS2080

PRESSURE DESIGN

ANSI CLASS 300

WEDGE TYPE

SOLID

STEM

RISING, OUTSIDE SCREW AND YOKE

BONNET

BOLTED

END CONNECTION

FLANGE 300#, RF TO ASME B16.5, SMOOTH FINISH TO 3.2 TO 6.3 MICROMETER Ra AS PER ASME B 46.1

OPERATION

HAND WHEEL OPERATED

SERVICE

HYDROCARBON PROCESS, SOUR

TEMPERATURE LIMIT

-20 DEG C TO 121 DEG C

MATERIALS:

BODY

FORGED A105

WEDGE AND BODY SEATS

AISI 410 / AISI 316

STEM

ASTM A182 GR F316/316L

GLAND

AISI 410 / AISI 316 / AISI 316L

BODY SEAT FACING

STELLITE 6 FACINGS

WEDGE SEAL AREA

STELLITE 6 FACINGS

BACK SEAT

RENEWABLE, AISI 316 / AISI 316L WITH STELLITE 6 FACINGS

STEM PACKING

BRAIDED ASBESTOS FREE GRAPHITE / IMPREGNATED FLEXIBLE

GRAPHITE

GRAPHITE WITH PTFE FILLER

ASTM A193 GR B7M / A194 GR 2HM CADMIUM PLATED

SPIRAL WOUND GASKET

STUD BOLTS AND NUTS

OTHERS:

TESTING

BS 6755 PART 1

MARKING

MSS-SP-25

CERTIFICATION

EN 10204,TYPE 3.1B FOR PRESSURE PARTS.

ADDITIONAL REQUIREMENTS: 1.ALL WETTED PARTS SHALL MEET REQUIREMENTS OF NACE-MR-01-75

LATEST EDITION AND QP-STD-R-001

X:\022-00734 IA COMPRESSOR\PIPING\MANIFOLDS\PIPING MATL SPEC\REV 2\1654-1012 Rev. 2 xls PAGE 5 OF 5

06/10/2015

PIPING MATERIAL CLASSES

CS1-900-4

BALL VALVES

GENERAL:

TAG NO

BV-027

SIZE RANGE

1/2"- 11/2"

DESIGN SPECIFICATION

ASME B 16.34

DIMENSIONS

ASME B 16.10

PRESSURE DESIGN

ANSI CLASS 900

BODY,CONSTRUCTION

SPLIT

BALL,CONSTRUCTION

TRUNION

BORE

REDUCED

END CONNECTION

FLANGE 1500#, RF TO ASME B16.5, SMOOTH FINISH TO 3.2 TO 6.3 MICROMETER Ra AS PER ASME B 46.1

OPERATION

LEVER OPERATED

FIRE SAFE

API 607 / API 6FA / BS6755 Part 2

SERVICE

SOUR GAS

TEMPERATURE LIMIT

-20 DEG C TO 121 DEG C

MATERIALS:

BODY

FORGED A105

TRIM

SS316 / SS316L

BALL

ASTM A182 GR F316/316L

STEM

ASTM A276 TYPE 316/316L

STEM AND GLAND PACKING

GRAPHITE,PTFE

SEAT RINGS

DEVLON OR EQUIVALENT

PRIMARY SEAL AND

BODY INSERT

VITON AED

SPIRAL WOUND GASKET

GRAPHITE WITH PTFE FILLER

STUD BOLTS AND NUTS

ASTM A193 GR B7M / A194 GR 2HM CADMIUM PLATED

OTHERS:

TESTING

BS 6755 PART 1

MARKING

MSS-SP-25

CERTIFICATION

EN 10204,TYPE 3.1B FOR PRESSURE PARTS.

ADDITIONAL REQUIREMENTS: 1.ALL WETTED PARTS SHALL MEET REQUIREMENTS OF NACE-MR-01-75

LATEST EDITION AND QP-STD-R-001.

2.ANTI STATIC DEVICE, ANTI BLOW OUT STEM , AUTO BODY CAVITY

PRESSURE RELIEF SEAT DESIGN SHALL BE PROVIDED

X:\022-00734 IA COMPRESSOR\PIPING\MANIFOLDS\PIPING MATL SPEC\REV 2/1654-1012 Rev. 2 xls PAGE 3 OF 9

06/10/2015

PIPING MATERIAL CLASSES

CS1-900-4

BALL VALVES

GENERAL:

TAG NO

BV-028

SIZE RANGE

2"- 16"

DESIGN SPECIFICATION

API 6D

DIMENSIONS

API 6D

PRESSURE DESIGN

ANSI CLASS 900

BODY,CONSTRUCTION

SPLIT

BALL,CONSTRUCTION

TRUNION

BORE

REDUCED

END CONNECTION

FLANGE 900#, RF TO ASME B16.5, SMOOTH FINISH TO 3.2 TO 6.3 MICROMETER Ra AS PER ASME B 46.1

OPERATION

LEVER OPERATED UP TO 4"; GEAR OPERATED FOR 6'' AND ABOVE.

FIRE SAFE

API 607 / API 6FA / BS6755 Part 2

SERVICE

SOUR GAS

TEMPERATURE LIMIT

-20 DEG C TO 121 DEG C

MATERIALS:

BODY

FORGED A105 / ASTM A216 GR WCB.

TRIM

SS316 / SS316L

BALL

ASTM A182 GR F316/316L

STEM

ASTM A276 TYPE 316/316L

STEM AND GLAND PACKING

GRAPHITE,PTFE

SEAT RINGS

DEVLON OR EQUIVALENT

PRIMARY SEAL AND

BODY INSERT

VITON AED

SPIRAL WOUND GASKET

GRAPHITE WITH PTFE FILLER

STUD BOLTS AND NUTS

ASTM A193 GR B7M / A194 GR 2HM CADMIUM PLATED

OTHERS:

TESTING

BS 6755 PART 1

MARKING

MSS-SP-25

CERTIFICATION

EN 10204,TYPE 3.1B FOR PRESSURE PARTS.

ADDITIONAL REQUIREMENTS: 1.ALL WETTED PARTS SHALL MEET REQUIREMENTS OF NACE-MR-01-75

LATEST EDITION AND QP-STD-R-001.

2.ANTI STATIC DEVICE, ANTI BLOW OUT STEM , AUTO BODY CAVITY

PRESSURE RELIEF SEAT DESIGN SHALL BE PROVIDED

X:\022-00734 IA COMPRESSOR\PIPING\MANIFOLDS\PIPING MATL SPEC\REV 2/1654-1012 Rev. 2 xls PAGE 4 OF 9

06/10/2015

PIPING MATERIAL CLASSES

CS1-900-4

GATE VALVES

GENERAL:

TAG NO

GV-009

SIZE RANGE

1"-11/2"

DESIGN SPECIFICATION

BS5352 / ASME B16.10

DIMENSIONS

BS2080

PRESSURE DESIGN

ANSI CLASS 1500

WEDGE TYPE

SOLID

STEM

RISING, OUTSIDE SCREW AND YOKE

BONNET

BOLTED

END CONNECTION

FLANGE 1500#, RF TO ASME B16.5, SMOOTH FINISH TO 3.2 TO 6.3 MICROMETER Ra AS PER ASME B 46.1

OPERATION

HAND WHEEL OPERATED

SERVICE

HYDROCARBON PROCESS, SOUR

TEMPERATURE LIMIT

-20 DEG C TO 121 DEG C

MATERIALS:

BODY

FORGED A105

WEDGE AND BODY SEATS

AISI 410 / AISI 316

STEM

ASTM A182 GR F316/316L

GLAND

AISI 410 / AISI 316 / AISI 316L

BODY SEAT FACING

STELLITE 6 FACINGS

WEDGE SEAL AREA

STELLITE 6 FACINGS

BACK SEAT

RENEWABLE, AISI 316 / AISI 316L WITH STELLITE 6 FACINGS

STEM PACKING

BRAIDED ASBESTOS FREE GRAPHITE / IMPREGNATED FLEXIBLE

GRAPHITE

GRAPHITE WITH PTFE FILLER

ASTM A193 GR B7M / A194 GR 2HM CADMIUM PLATED

SPIRAL WOUND GASKET

STUD BOLTS AND NUTS

OTHERS:

TESTING

BS 6755 PART 1

MARKING

MSS-SP-25

CERTIFICATION

EN 10204,TYPE 3.1B FOR PRESSURE PARTS.

ADDITIONAL REQUIREMENTS: 1.ALL WETTED PARTS SHALL MEET REQUIREMENTS OF NACE-MR-01-75

LATEST EDITION AND QP-STD-R-001

X:\022-00734 IA COMPRESSOR\PIPING\MANIFOLDS\PIPING MATL SPEC\REV 2/1654-1012 Rev. 2 xls PAGE 5 OF 9

06/10/2015

PIPING MATERIAL CLASSES

CS1-900-4

GATE VALVES

GENERAL:

TAG NO

GV-010

SIZE RANGE

2"

DESIGN SPECIFICATION

BS1414 /API 6D

DIMENSIONS

BS1414 / API 6D

PRESSURE DESIGN

ANSI CLASS 900

WEDGE TYPE

SOLID

STEM

RISING, OUTSIDE SCREW AND YOKE

BONNET

BOLTED

END CONNECTION

FLANGE 1500#, RF TO ASME B16.5, SMOOTH FINISH TO 3.2 TO 6.3 MICROMETER Ra AS PER ASME B 46.1

OPERATION

HAND WHEEL OPERATED

SERVICE

HYDROCARBON PROCESS, SOUR

TEMPERATURE LIMIT

-20 DEG C TO 121 DEG C

MATERIALS:

BODY

FORGED A105

WEDGE AND BODY SEATS

AISI 410 / AISI 316

STEM

ASTM A182 GR F316/316L

GLAND

AISI 410 / AISI 316 / AISI 316L

BODY SEAT FACING

STELLITE 6 FACINGS

WEDGE SEAL AREA

STELLITE 6 FACINGS

BACK SEAT

RENEWABLE, AISI 316 / AISI 316L WITH STELLITE 6 FACINGS

STEM PACKING

BRAIDED ASBESTOS FREE GRAPHITE / IMPREGNATED FLEXIBLE

GRAPHITE

GRAPHITE WITH PTFE FILLER

ASTM A193 GR B7M / A194 GR 2HM CADMIUM PLATED

SPIRAL WOUND GASKET

STUD BOLTS AND NUTS

OTHERS:

TESTING

BS 6755 PART 1 / API 6D.

MARKING

MSS-SP-25

CERTIFICATION

EN 10204,TYPE 3.1B FOR PRESSURE PARTS.

ADDITIONAL REQUIREMENTS: 1.ALL WETTED PARTS SHALL MEET REQUIREMENTS OF NACE-MR-01-75

LATEST EDITION AND QP-STD-R-001

X:\022-00734 IA COMPRESSOR\PIPING\MANUFOLD\PIPING MATL SPEC\REV 2\1654-1012 Rev. 2 xls PAGE 6 OF 9

06/10/2015

PIPING MATERIAL CLASSES

CS1-900-4

GATE VALVES

GENERAL:

TAG NO

GV-011

SIZE RANGE

3"-6"

DESIGN SPECIFICATION

BS1414 /API 6D

DIMENSIONS

BS1414 / API 6D

PRESSURE DESIGN

ANSI CLASS 900

WEDGE TYPE

SOLID

STEM

RISING, OUTSIDE SCREW AND YOKE

BONNET

BOLTED

END CONNECTION

FLANGE 900#, RF TO ASME B16.5, SMOOTH FINISH TO 3.2 TO 6.3 MICROMETER Ra AS PER ASME B 46.1

OPERATION

HAND WHEEL OPERATED UP TO 4'', GEAR OPERATED FOR 6''.

SERVICE

HYDROCARBON PROCESS, SOUR

TEMPERATURE LIMIT

-20 DEG C TO 121 DEG C

MATERIALS:

BODY

ASTM A 216 GR WCB

WEDGE AND BODY SEATS

AISI 410 / AISI 316

STEM

ASTM A182 GR F316/316L

GLAND

AISI 410 / AISI 316 / AISI 316L

BODY SEAT FACING

STELLITE 6 FACINGS

WEDGE SEAL AREA

STELLITE 6 FACINGS

BACK SEAT

RENEWABLE, AISI 316 / AISI 316L WITH STELLITE 6 FACINGS

STEM PACKING

BRAIDED ASBESTOS FREE GRAPHITE / IMPREGNATED FLEXIBLE

GRAPHITE

GRAPHITE WITH PTFE FILLER

ASTM A193 GR B7M / A194 GR 2HM CADMIUM PLATED

SPIRAL WOUND GASKET

STUD BOLTS AND NUTS

OTHERS:

TESTING

BS 6755 PART 1 / API 6D.

MARKING

MSS-SP-25

CERTIFICATION

EN 10204,TYPE 3.1B FOR PRESSURE PARTS.

ADDITIONAL REQUIREMENTS: 1.ALL WETTED PARTS SHALL MEET REQUIREMENTS OF NACE-MR-01-75

LATEST EDITION AND QP-STD-R-001

X:\022-00734 IA COMPRESSOR\PIPING\MANIFOLD\PIPING MATL SPEC\REV 2\1654-1012 Rev. 2 xls PAGE 7 OF 9

06/10/2015

PIPING MATERIAL CLASSES

CS1-900-4

GLOBE VALVES

GENERAL:

TAG NO

GLV-009

SIZE RANGE

1/2"- 1 1/2"

DESIGN SPECIFICATION

BS5352

DIMENSIONS

BS2080

PRESSURE DESIGN

ANSI CLASS 1500

WEDGE TYPE

SOLID

STEM

RISING, OUTSIDE SCREW AND YOKE

BONNET

BOLTED

END CONNECTION

FLANGE 1500#, RF TO ASME B16.5, SMOOTH FINISH TO 3.2 TO 6.3 MICROMETER Ra AS PER ASME B 46.1

OPERATION

HAND WHEEL OPERATED.

SERVICE

HYDROCARBON PROCESS, SOUR

TEMPERATURE LIMIT

-20 DEG C TO 121 DEG C

MATERIALS:

BODY

FORGED A105

WEDGE AND BODY SEATS

AISI 410 / AISI 316

STEM

ASTM A182 GR F316/316L

GLAND

AISI 410 / AISI 316 / AISI 316L

BODY SEAT FACING

STELLITE 6 FACINGS

WEDGE SEAL AREA

STELLITE 6 FACINGS

BACK SEAT

RENEWABLE, AISI 316 / AISI 316L WITH STELLITE 6 FACINGS

STEM PACKING

BRAIDED ASBESTOS FREE GRAPHITE / IMPREGNATED FLEXIBLE

GRAPHITE

GRAPHITE WITH PTFE FILLER

ASTM A193 GR B7M / A194 GR 2HM CADMIUM PLATED

SPIRAL WOUND GASKET

STUD BOLTS AND NUTS

OTHERS:

TESTING

BS 6755 PART 1 / API 6D.

MARKING

MSS-SP-25

CERTIFICATION

EN 10204,TYPE 3.1B FOR PRESSURE PARTS.

ADDITIONAL REQUIREMENTS: 1.ALL WETTED PARTS SHALL MEET REQUIREMENTS OF NACE-MR-01-75

LATEST EDITION AND QP-STD-R-001

X:\022-00734 IA COMPRESSOR\PIPING\MANIFOLD\PIPING MATL SPEC\REV 2/1654-1012 Rev. 2 xls PAGE 8 OF 9

06/10/2015

PIPING MATERIAL CLASSES

CS1-900-4

CHECK VALVES

GENERAL:

TAG NO

CHV-009

SIZE RANGE

6"- 16"

DESIGN SPECIFICATION

API STD 594

DIMENSIONS

API STD 594 / ASME B 16.10

PRESSURE DESIGN

ANSI CLASS 900

BODY CONSTRUCTION

WAFER LUG TYPE.

DISC

DUAL PLATE

SERVICE

WET SOUR PROCESS

TEMPERATURE LIMIT

-20 DEG C TO 121 DEG C

MATERIALS:

BODY

FORGED A105 / ASTM A216 GR WCB.

TRIM

316 SS HARD FACED

SEAT FACING

STELLITE 6 FACING

DISC CONTACT AREA

STELLITE 6 FACINGS

PLATES AND PIN RETAINERS

ASTM A105 N / ASTM A216 GR WCB.

SPRINGS

INCONEL X750

RETAINER GASKET

FLEXIBLE GRAPHITE

STEM PACKING

BRAIDED ASBESTOS FREE GRAPHITE / IMPREGNATED FLEXIBLE

GRAPHITE

STUD BOLTS AND NUTS

ASTM A193 GR B7M / A194 GR 2HM CADMIUM PLATED

OTHERS:

TESTING

API 594

MARKING

API 594

CERTIFICATION

EN 10204,TYPE 3.1B FOR PRESSURE PARTS.

ADDITIONAL REQUIREMENTS: 1.ALL WETTED PARTS SHALL MEET REQUIREMENTS OF NACE-MR-01-75

LATEST EDITION AND QP-STD-R-001

X:\022-00734 IA COMPRESSOR\PIPING\MANIFOLD\PIPING MATL SPEC\REV 2\1654-1012 Rev. 2 xls PAGE 9 OF 9.

06/10/2015

S-ar putea să vă placă și

- All-in-One Manual of Industrial Piping Practice and MaintenanceDe la EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceEvaluare: 5 din 5 stele5/5 (1)

- 7a. Steel Pipeline FittingDocument37 pagini7a. Steel Pipeline Fittingamaliabdulkader100% (1)

- Pipe Class Data Sheet - Rev.1Document4 paginiPipe Class Data Sheet - Rev.1bonnicoÎncă nu există evaluări

- rc61180 b09Document9 paginirc61180 b09eww08Încă nu există evaluări

- Documents Plc150Document7 paginiDocuments Plc150Anonymous cuOIjrLIÎncă nu există evaluări

- Piping Class: REV Description Size Rating END Tag/Sche Material Trim Code ComplemenDocument10 paginiPiping Class: REV Description Size Rating END Tag/Sche Material Trim Code ComplemenamevaluacionesÎncă nu există evaluări

- PCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Document6 paginiPCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Moises Alvarez LeandroÎncă nu există evaluări

- Table BrenchDocument11 paginiTable BrenchLuis GonzalezÎncă nu există evaluări

- 6877-SM-LM-99-00-09014-A1A7 Document Number: Merlin Version 2.2 11-JAN-05 15:46:38 Detailed ReportDocument12 pagini6877-SM-LM-99-00-09014-A1A7 Document Number: Merlin Version 2.2 11-JAN-05 15:46:38 Detailed ReportSalimÎncă nu există evaluări

- Process Industry Practices PipingDocument5 paginiProcess Industry Practices Pipingalberto rodriguezÎncă nu există evaluări

- Volime II of II Mechanical Piping-GAILDocument245 paginiVolime II of II Mechanical Piping-GAILBathi Hari PrasadÎncă nu există evaluări

- 1CB2S40 Piping Material Class Specification: 000-SP-PI02-0191Document5 pagini1CB2S40 Piping Material Class Specification: 000-SP-PI02-0191faber_tru2869Încă nu există evaluări

- Asme B31.3 Process Piping Course Supplement: BechtDocument2 paginiAsme B31.3 Process Piping Course Supplement: BechtNurSarahÎncă nu există evaluări

- PN09CS1S01Document5 paginiPN09CS1S01joana ramirezÎncă nu există evaluări

- Piping Material ClassesDocument42 paginiPiping Material Classest_i_f_anoÎncă nu există evaluări

- PN01CS1B02Document5 paginiPN01CS1B02ger80100% (1)

- 102001-Crn-Pip-Pms-001 04202021Document3 pagini102001-Crn-Pip-Pms-001 04202021Karl CaudalÎncă nu există evaluări

- HidraulicaDocument4 paginiHidraulicaAntonio Anatoly Viamont PintoÎncă nu există evaluări

- Ejemplo Piping Class PDFDocument5 paginiEjemplo Piping Class PDFDagoberto CerrudÎncă nu există evaluări

- 150# Cs Ball Valve Datasheet: GeneralDocument3 pagini150# Cs Ball Valve Datasheet: GeneralVijay GaikwadÎncă nu există evaluări

- 1CB1S50 Piping Material Class Specification: 000-SP-PI02-0189Document4 pagini1CB1S50 Piping Material Class Specification: 000-SP-PI02-0189faber_tru2869Încă nu există evaluări

- Class: CS: Description Material Sch. Rating Dim. Code EndsDocument4 paginiClass: CS: Description Material Sch. Rating Dim. Code EndsJorge Santos RomeroÎncă nu există evaluări

- 6oilccopdngglobal2152008 Voll III 20piping 20 20 MechanicalDocument643 pagini6oilccopdngglobal2152008 Voll III 20piping 20 20 Mechanicaldinesh2u85Încă nu există evaluări

- Issued For Construction: Pipe Class Ms-11Document4 paginiIssued For Construction: Pipe Class Ms-11Yapo Freddy50% (2)

- ESLCS150-01 Pipe ScheduleDocument3 paginiESLCS150-01 Pipe Schedulethomas.jaggerÎncă nu există evaluări

- 094135-PI-MTO-001 - BOM For Piping & Valve - Rev.1Document80 pagini094135-PI-MTO-001 - BOM For Piping & Valve - Rev.1thongÎncă nu există evaluări

- PN15CS1S01Document4 paginiPN15CS1S01joadÎncă nu există evaluări

- PN01CB1S01Document5 paginiPN01CB1S01joana ramirezÎncă nu există evaluări

- DOC-NA-ME-500 - Piping Class PDFDocument12 paginiDOC-NA-ME-500 - Piping Class PDFedscesc10Încă nu există evaluări

- Stainless Steel Pipe and Fittings SpecificationDocument10 paginiStainless Steel Pipe and Fittings SpecificationCassy AbulenciaÎncă nu există evaluări

- Valve Trim Temperatur e Range °F Design Code Rev. #Corr. Allow. (In) Service Pressure Rating Material Piping Mat'l ClassDocument42 paginiValve Trim Temperatur e Range °F Design Code Rev. #Corr. Allow. (In) Service Pressure Rating Material Piping Mat'l ClassJuan Carlos ValderramaÎncă nu există evaluări

- Piping Material SpecificationDocument36 paginiPiping Material Specificationravirawat15100% (2)

- Specification of StrainerDocument3 paginiSpecification of StrainermishtinilÎncă nu există evaluări

- ACS11Document3 paginiACS11Ebby OnyekweÎncă nu există evaluări

- Volime II of II Mechanical Piping PDFDocument245 paginiVolime II of II Mechanical Piping PDFkamleshyadavmoneyÎncă nu există evaluări

- Piping Material Class c13b Bs 171 ProjectDocument7 paginiPiping Material Class c13b Bs 171 ProjectemanÎncă nu există evaluări

- Astm Nos For PipingDocument6 paginiAstm Nos For PipingJessica HerringÎncă nu există evaluări

- A2 1 16junDocument2 paginiA2 1 16junamitrai86Încă nu există evaluări

- PipeClass NG 11.08.09 PDFDocument138 paginiPipeClass NG 11.08.09 PDFbadelitamariusÎncă nu există evaluări

- Sample Pipe IsometricsDocument2 paginiSample Pipe Isometricslinkinpark11129116Încă nu există evaluări

- Ansi Flange HandbookDocument76 paginiAnsi Flange HandbookSuperstarVirgo100% (1)

- VAAS C47 Series Cryo Ball Valve CatalogueDocument8 paginiVAAS C47 Series Cryo Ball Valve CatalogueDanielle JohnsonÎncă nu există evaluări

- 20072-07 2701-01.097-H-221 B1WRDocument5 pagini20072-07 2701-01.097-H-221 B1WREmmanuelle David MoraÎncă nu există evaluări

- Class A6A3Document14 paginiClass A6A3SalimÎncă nu există evaluări

- Piping: Material SpecificationDocument2 paginiPiping: Material SpecificationGABRIELA310Încă nu există evaluări

- Class A6A9Document13 paginiClass A6A9SalimÎncă nu există evaluări

- Process Industry Practices PipingDocument5 paginiProcess Industry Practices Pipingalberto rodriguezÎncă nu există evaluări

- Email Clarifications From KingsDocument16 paginiEmail Clarifications From KingsAJAY PatilÎncă nu există evaluări

- Piping Class K2a1Document9 paginiPiping Class K2a1jast111Încă nu există evaluări

- Retqw3 2 PDFDocument6 paginiRetqw3 2 PDFalberto rodriguezÎncă nu există evaluări

- Xcpipe PDFDocument6 paginiXcpipe PDFalberto rodriguezÎncă nu există evaluări

- Water SystemDocument9 paginiWater SystemArun GuptaÎncă nu există evaluări

- Class A1A9Document14 paginiClass A1A9SalimÎncă nu există evaluări

- Valve Data Sheet - Gate Valve: Colves Fluid Control S.R.LDocument1 paginăValve Data Sheet - Gate Valve: Colves Fluid Control S.R.LMohamed gaballa SaidÎncă nu există evaluări

- United Insulation DocumentsDocument168 paginiUnited Insulation Documentsjsherrer1Încă nu există evaluări

- Gas Pipeline SpecDocument4 paginiGas Pipeline SpecA_bener100% (1)

- PN01CS1S013 PDFDocument6 paginiPN01CS1S013 PDFalberto rodriguezÎncă nu există evaluări

- S-0000-1360-0005 - TECHNICAL SPECIFICATION FOR PipesDocument22 paginiS-0000-1360-0005 - TECHNICAL SPECIFICATION FOR PipesPaul NieÎncă nu există evaluări

- Cs MaterialDocument12 paginiCs MaterialrajBÎncă nu există evaluări

- 61502YDocument9 pagini61502YbalajivangaruÎncă nu există evaluări

- TRACER Press Release Final ENDocument1 paginăTRACER Press Release Final ENVedran KosanovicÎncă nu există evaluări

- BS 5306 0 2011, Fire ProtectionDocument72 paginiBS 5306 0 2011, Fire ProtectionVedran KosanovicÎncă nu există evaluări

- Epic For CNG Stations in Rlic and Mic: PROJECT/CONTRACT NO: 4091/GC18104500 Contract TitleDocument19 paginiEpic For CNG Stations in Rlic and Mic: PROJECT/CONTRACT NO: 4091/GC18104500 Contract TitleVedran KosanovicÎncă nu există evaluări

- Epic For CNG Stations in Rlic and Mic: PROJECT/CONTRACT NO: 4091/GC18104500 Contract TitleDocument38 paginiEpic For CNG Stations in Rlic and Mic: PROJECT/CONTRACT NO: 4091/GC18104500 Contract TitleVedran KosanovicÎncă nu există evaluări

- Energy LawDocument237 paginiEnergy LawVedran KosanovicÎncă nu există evaluări

- Hazop Close Out Report V-8701 Flare Ko Drum Draining Facilities at Ngl-4Document79 paginiHazop Close Out Report V-8701 Flare Ko Drum Draining Facilities at Ngl-4Vedran KosanovicÎncă nu există evaluări

- ANNEX 1 - LIST of Applicable Standards: Standard TitleDocument2 paginiANNEX 1 - LIST of Applicable Standards: Standard TitleVedran KosanovicÎncă nu există evaluări

- Pipe Stress Analysis Vol IDocument278 paginiPipe Stress Analysis Vol IVedran KosanovicÎncă nu există evaluări

- LT11100300 TB No. 3 - Attachments PDFDocument67 paginiLT11100300 TB No. 3 - Attachments PDFVedran KosanovicÎncă nu există evaluări

- Windows Keyboard ShortcutsDocument3 paginiWindows Keyboard ShortcutsVedran KosanovicÎncă nu există evaluări

- Piping SpecificationsDocument67 paginiPiping SpecificationsVedran Kosanovic100% (3)

- ErrEnvironmental Risk RegisterDocument3 paginiErrEnvironmental Risk RegisterVedran KosanovicÎncă nu există evaluări

- QLS-DT-039 - QP PVLDocument50 paginiQLS-DT-039 - QP PVLVedran KosanovicÎncă nu există evaluări

- Solubility Product ConstantsDocument6 paginiSolubility Product ConstantsBilal AhmedÎncă nu există evaluări

- Seabank Statement 20220726Document4 paginiSeabank Statement 20220726Alesa WahabappÎncă nu există evaluări

- 레벨 테스트Document2 pagini레벨 테스트BÎncă nu există evaluări

- Concrete Repair Manual (2017)Document59 paginiConcrete Repair Manual (2017)Fernando EscriváÎncă nu există evaluări

- Dreaded Attack - Voyages Community Map Rules v1Document2 paginiDreaded Attack - Voyages Community Map Rules v1jÎncă nu există evaluări

- This Study Resource Was: For The Next 6 ItemsDocument9 paginiThis Study Resource Was: For The Next 6 ItemsJames CastañedaÎncă nu există evaluări

- Draft JV Agreement (La Mesa Gardens Condominiums - Amparo Property)Document13 paginiDraft JV Agreement (La Mesa Gardens Condominiums - Amparo Property)Patrick PenachosÎncă nu există evaluări

- Ritesh Agarwal: Presented By: Bhavik Patel (Iu1981810008) ABHISHEK SHARMA (IU1981810001) VISHAL RATHI (IU1981810064)Document19 paginiRitesh Agarwal: Presented By: Bhavik Patel (Iu1981810008) ABHISHEK SHARMA (IU1981810001) VISHAL RATHI (IU1981810064)Abhi SharmaÎncă nu există evaluări

- 82686b - LOAD SHARING MODULEDocument2 pagini82686b - LOAD SHARING MODULENguyễn Đình ĐứcÎncă nu există evaluări

- Syllabus: What Is Artificial Intelligence? ProblemsDocument66 paginiSyllabus: What Is Artificial Intelligence? ProblemsUdupiSri groupÎncă nu există evaluări

- Question Answers of Chapter 13 Class 5Document6 paginiQuestion Answers of Chapter 13 Class 5SuvashreePradhanÎncă nu există evaluări

- Bacacay South Hris1Document7.327 paginiBacacay South Hris1Lito ObstaculoÎncă nu există evaluări

- Biological Assets Sample ProblemsDocument4 paginiBiological Assets Sample ProblemsKathleenÎncă nu există evaluări

- Modern and Nonlinear OpticsDocument181 paginiModern and Nonlinear Opticssoma_venuÎncă nu există evaluări

- VMP 930 Veterinary Parasitology: Paragonimus KellicottiDocument63 paginiVMP 930 Veterinary Parasitology: Paragonimus KellicottiRenien Khim BahayaÎncă nu există evaluări

- IcarosDesktop ManualDocument151 paginiIcarosDesktop ManualAsztal TavoliÎncă nu există evaluări

- Bajaj Vs Hero HondaDocument63 paginiBajaj Vs Hero HondaHansini Premi100% (1)

- Chinese Paper Cutting Work SheetDocument4 paginiChinese Paper Cutting Work Sheet黃梓Încă nu există evaluări

- Colorfastness of Zippers To Light: Standard Test Method ForDocument2 paginiColorfastness of Zippers To Light: Standard Test Method ForShaker QaidiÎncă nu există evaluări

- Prospekt Puk U5 en Mail 1185Document8 paginiProspekt Puk U5 en Mail 1185sakthivelÎncă nu există evaluări

- Retail Banking Black BookDocument95 paginiRetail Banking Black Bookomprakash shindeÎncă nu există evaluări

- Binge Eating Disorder ANNADocument12 paginiBinge Eating Disorder ANNAloloasbÎncă nu există evaluări

- 385C Waw1-Up PDFDocument4 pagini385C Waw1-Up PDFJUNA RUSANDI SÎncă nu există evaluări

- Hydro Electric Fire HistoryDocument3 paginiHydro Electric Fire HistorygdmurfÎncă nu există evaluări

- Electronic Spin Inversion: A Danger To Your HealthDocument4 paginiElectronic Spin Inversion: A Danger To Your Healthambertje12Încă nu există evaluări

- List of Some Common Surgical TermsDocument5 paginiList of Some Common Surgical TermsShakil MahmodÎncă nu există evaluări

- EAC Inquiry SDCDocument9 paginiEAC Inquiry SDCThe Sustainable Development Commission (UK, 2000-2011)Încă nu există evaluări

- Maritta Koch-Weser, Scott Guggenheim - Social Development in The World Bank - Essays in Honor of Michael M. Cernea-Springer (2021)Document374 paginiMaritta Koch-Weser, Scott Guggenheim - Social Development in The World Bank - Essays in Honor of Michael M. Cernea-Springer (2021)IacobÎncă nu există evaluări

- Antibiotic Zone Interpretation Guide PDFDocument2 paginiAntibiotic Zone Interpretation Guide PDFFarandy Insan Sejati100% (2)

- Biology Key Stage 4 Lesson PDFDocument4 paginiBiology Key Stage 4 Lesson PDFAleesha AshrafÎncă nu există evaluări