Documente Academic

Documente Profesional

Documente Cultură

Erlife Valve PDF

Încărcat de

jr110livecomDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Erlife Valve PDF

Încărcat de

jr110livecomDrepturi de autor:

Formate disponibile

#124

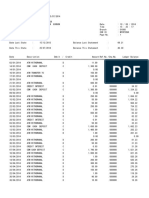

RELIEF VALVES VS. RUPTURE DISCS

Relief valves and rupture discs protect the condenser shell from over pressurization. They are

designed to trip or rupture when the condenser shell pressure rises above the set pressure. This

phenomenon normally occurs due to loss of circulating water flow to the condenser. . .

RELIEF VALVE

RUPTURE DISC

Capital Cost

Higher Initial Cost

Lower Initial Cost

Reliability

Excellent

Good for numerous open and close cycles.

Moderate

Good for single use.

Must have spare on site in case of rupture.

Design

Valve supports must handle valve weight and

trust loads.

Valve hangers may be required if not mounted

directly to the condenser shell.

Personnel protection must be considered.

Water seal around valve disc is required.

Manual lifting device is required.

Designer shall consider erosion and

corrosion when selecting location.

Personnel protection must be considered.

No water seal is required

Installation

No special requirements

Care must be taken during installation to

protect the disc and prevent mechanical

damage.

Please refer to the latest edition of the Heat Exchange Institute Standards for Steam Surface Condensers

for more information.

This Tech Sheet was developed by the members of the Heat Exchange Institutes (HEI) Condenser Section. HEI is a trade association

comprising the leading manufacturers of heat exchange and vacuum equipment. HEI Tech Sheets are information tools and should not

be used as substitutes for instructions from individual manufacturers. Always consult with individual manufacturers for specific

instructions regarding their equipment.

09/14/07 Page 1 of 1

This sheet is reviewed periodically and may be updated. Visit www.heatexchange.org for the latest version.

S-ar putea să vă placă și

- D1 2 Pressure Relief Devices WriteupDocument20 paginiD1 2 Pressure Relief Devices Writeupanurag kumarÎncă nu există evaluări

- IWCF WI - 1 - Well CompletionDocument60 paginiIWCF WI - 1 - Well CompletionAlonso EngrÎncă nu există evaluări

- Installation, Maintenance and Operating Instructions: StorageDocument4 paginiInstallation, Maintenance and Operating Instructions: StorageJAntonio De la CruzÎncă nu există evaluări

- Installation, Maintenance and Operating Instructions Cast Iron, Malleable Iron, Brass and Bronze Gate ValvesDocument4 paginiInstallation, Maintenance and Operating Instructions Cast Iron, Malleable Iron, Brass and Bronze Gate ValvesModassir ZaheenÎncă nu există evaluări

- Packer PDFDocument76 paginiPacker PDFMansur Ermila100% (1)

- Installation, Maintenance and Operating Instructions Cast Iron, Malleable Iron and Bronze Globe ValvesDocument4 paginiInstallation, Maintenance and Operating Instructions Cast Iron, Malleable Iron and Bronze Globe ValvesmahmadwasiÎncă nu există evaluări

- Pressure VesselDocument34 paginiPressure VesselakitakiaÎncă nu există evaluări

- Fundamentals of ValvesDocument35 paginiFundamentals of Valvesmajmor-1100% (1)

- Halliburton Packer Information PDFDocument76 paginiHalliburton Packer Information PDFrlk2806100% (4)

- Topic 1 Well Surface EquipmentsDocument126 paginiTopic 1 Well Surface EquipmentsAjay Suri100% (1)

- Slickline - Lectures. Tools. OperationsDocument44 paginiSlickline - Lectures. Tools. OperationsOmer Abuzeid100% (1)

- Introduction Offshore EngineeringDocument58 paginiIntroduction Offshore EngineeringJerome LIKIBIÎncă nu există evaluări

- Intro and CompletionDocument31 paginiIntro and CompletionKhalid ZaeemÎncă nu există evaluări

- Topic 1: Well Equipment: Prof. Ajay Suri Dept. of Petroleum Engineering IIT (ISM) DhanbadDocument126 paginiTopic 1: Well Equipment: Prof. Ajay Suri Dept. of Petroleum Engineering IIT (ISM) DhanbadAnand aashishÎncă nu există evaluări

- Lecture 2 2023Document29 paginiLecture 2 2023kelvinmsemo33Încă nu există evaluări

- Large Above Ground Water Tank Installation GuidelinesDocument2 paginiLarge Above Ground Water Tank Installation Guidelinesemanuel775Încă nu există evaluări

- PackerDocument76 paginiPackerRafael100% (1)

- The Humble Check Valve: Selection of Check Valves For Pumped SystemsDocument36 paginiThe Humble Check Valve: Selection of Check Valves For Pumped SystemsSamuelÎncă nu există evaluări

- Casing Design WorkshopDocument52 paginiCasing Design WorkshopNikita Axyonov100% (1)

- ValvesDocument40 paginiValvesMizta KunaÎncă nu există evaluări

- Basic of Oil & Gas Production and Surface FacilitiesDocument50 paginiBasic of Oil & Gas Production and Surface FacilitiesIlhamÎncă nu există evaluări

- 409 - 8 RO Plant Deck MCDocument18 pagini409 - 8 RO Plant Deck MCisrat jahanÎncă nu există evaluări

- Lecture - 9 RO Plant & Deck MCDocument32 paginiLecture - 9 RO Plant & Deck MCSakib RafeeÎncă nu există evaluări

- Double Disc Check Valve: Job NameDocument10 paginiDouble Disc Check Valve: Job NameAditya RochmansyahÎncă nu există evaluări

- New Packer - 001 PDFDocument76 paginiNew Packer - 001 PDFNagarjunSHÎncă nu există evaluări

- Globe ValveDocument17 paginiGlobe Valveachmad firmanyahÎncă nu există evaluări

- Hatch Covers - Function, Inspection, Tests, Precautions, Operation, MaintenanceDocument25 paginiHatch Covers - Function, Inspection, Tests, Precautions, Operation, MaintenanceGiorgi KandelakiÎncă nu există evaluări

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDe la EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingEvaluare: 5 din 5 stele5/5 (3)

- Inflatable Packers 30apr2013-Spe NeDocument27 paginiInflatable Packers 30apr2013-Spe NeLeonan CostaÎncă nu există evaluări

- Installation & Maintenance of Forcemain Air Relief ValvesDocument31 paginiInstallation & Maintenance of Forcemain Air Relief ValvesManik KandanÎncă nu există evaluări

- Relief Valves - NCCDocument26 paginiRelief Valves - NCCNour HÎncă nu există evaluări

- Inspection, Maintenance, and Troubleshooting of De-Icer BootsDocument13 paginiInspection, Maintenance, and Troubleshooting of De-Icer BootsPatrick dela rosaÎncă nu există evaluări

- Inspection, Maintenance, and Troubleshooting of De-Icer BootsDocument13 paginiInspection, Maintenance, and Troubleshooting of De-Icer BootsPatrick dela rosaÎncă nu există evaluări

- 5 6339170067296551364Document162 pagini5 6339170067296551364Helna joseph JOSEÎncă nu există evaluări

- BVAMA - AEA Technology: Beginner's Guide To Valves and ActuatorsDocument91 paginiBVAMA - AEA Technology: Beginner's Guide To Valves and ActuatorsDoan Van TienÎncă nu există evaluări

- Marine Fuild PowerDocument23 paginiMarine Fuild PowerOladokun Sulaiman OlanrewajuÎncă nu există evaluări

- L6 Hatch CoversDocument62 paginiL6 Hatch CoversRecca Pirrip100% (4)

- 08-INSTALLATION - (A) Ball ValvesDocument4 pagini08-INSTALLATION - (A) Ball ValvesModassir ZaheenÎncă nu există evaluări

- Codeline User Guide 80S and HDocument46 paginiCodeline User Guide 80S and HThiago PessoaÎncă nu există evaluări

- Getting The Most Out of Your Rupture Disc: March 2009Document4 paginiGetting The Most Out of Your Rupture Disc: March 2009madbakingÎncă nu există evaluări

- Workover - 10Document34 paginiWorkover - 10chemkumar16Încă nu există evaluări

- Valves PresentationDocument36 paginiValves PresentationFareedee100% (1)

- Pressure Vacuum Breaker Backflow Prevention Assembly (PVB) (Standard ASSE 1020)Document2 paginiPressure Vacuum Breaker Backflow Prevention Assembly (PVB) (Standard ASSE 1020)RoÎncă nu există evaluări

- Check Valves With Hydrolic DampersDocument9 paginiCheck Valves With Hydrolic DampersJoy BhattacharyaÎncă nu există evaluări

- C 7Document183 paginiC 7Liza Cabalquinto LorejoÎncă nu există evaluări

- Av-Tek VRX Plunger REV-GDocument12 paginiAv-Tek VRX Plunger REV-GwaqasÎncă nu există evaluări

- Codeline User Guide 80UDocument41 paginiCodeline User Guide 80Udwi yuliantoÎncă nu există evaluări

- Vacuum Breaker ValveDocument2 paginiVacuum Breaker ValveRaghunath YeturiÎncă nu există evaluări

- 23-022 Installation Procedures ValvesDocument6 pagini23-022 Installation Procedures ValvesAli Khalid QureshiÎncă nu există evaluări

- Well Integrity in Production Operation: Didit Achmad BaritoDocument33 paginiWell Integrity in Production Operation: Didit Achmad BaritoaminÎncă nu există evaluări

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!De la EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Evaluare: 5 din 5 stele5/5 (2)

- Oil and Gas Artificial Fluid Lifting TechniquesDe la EverandOil and Gas Artificial Fluid Lifting TechniquesEvaluare: 5 din 5 stele5/5 (1)

- Simple Plumbing Repairs for the Home and FarmsteadDe la EverandSimple Plumbing Repairs for the Home and FarmsteadÎncă nu există evaluări

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingDe la EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingÎncă nu există evaluări

- Maintain and Improve Your Powerboat: 100 Ways to Make Your Boat BetterDe la EverandMaintain and Improve Your Powerboat: 100 Ways to Make Your Boat BetterÎncă nu există evaluări

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDe la EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryÎncă nu există evaluări

- Introduction to Yacht Design: For boat owners, buyers, students & novice designersDe la EverandIntroduction to Yacht Design: For boat owners, buyers, students & novice designersÎncă nu există evaluări

- Sewage Disposal Works: Their Design and ConstructionDe la EverandSewage Disposal Works: Their Design and ConstructionÎncă nu există evaluări

- Skipper & Crew Companions: Cockpit & New Crew CompanionsDe la EverandSkipper & Crew Companions: Cockpit & New Crew CompanionsÎncă nu există evaluări

- Preliminary Radial Flow TurbineDocument10 paginiPreliminary Radial Flow Turbinejr110livecomÎncă nu există evaluări

- V002t06a020 97 GT 149Document9 paginiV002t06a020 97 GT 149jr110livecomÎncă nu există evaluări

- 300 KW Ceramic TurbineDocument6 pagini300 KW Ceramic Turbinejr110livecomÎncă nu există evaluări

- Fundamentals of Soot Formation in Gas Turbine CombustorsDocument18 paginiFundamentals of Soot Formation in Gas Turbine Combustorsjr110livecomÎncă nu există evaluări

- Particle Formation in Aircraft Engines: Deutsches Zentrum Für Luft - Und Raumfahrt. (DLR-Stuttgart)Document2 paginiParticle Formation in Aircraft Engines: Deutsches Zentrum Für Luft - Und Raumfahrt. (DLR-Stuttgart)jr110livecomÎncă nu există evaluări

- Tube Saport PDFDocument4 paginiTube Saport PDFjr110livecomÎncă nu există evaluări

- Heavy-Duty OH2 Process Pump To ISO 13709 / API 610: Our Technology. Your SuccessDocument2 paginiHeavy-Duty OH2 Process Pump To ISO 13709 / API 610: Our Technology. Your Successjr110livecomÎncă nu există evaluări

- Advanced Gas Turbine CombustionDocument7 paginiAdvanced Gas Turbine Combustionjr110livecomÎncă nu există evaluări

- Fuel Nozzle ModificationDocument1 paginăFuel Nozzle Modificationjr110livecomÎncă nu există evaluări

- GEA Ibxrica Surface Condensers EN R0 PDFDocument8 paginiGEA Ibxrica Surface Condensers EN R0 PDFjr110livecom0% (1)

- Torsional Vibration Analysis-BasicsDocument34 paginiTorsional Vibration Analysis-BasicsVarun Das100% (3)

- 8C Throttle Trip ValvesDocument4 pagini8C Throttle Trip Valvesjr110livecom100% (1)

- Marley Product Catalogue Brochure Grease TrapsDocument1 paginăMarley Product Catalogue Brochure Grease TrapsKushalKallychurnÎncă nu există evaluări

- Introduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions ManualDocument12 paginiIntroduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions Manualethelbertsangffz100% (34)

- Dynamics of Interest Rate and Equity VolatilityDocument9 paginiDynamics of Interest Rate and Equity VolatilityZhenhuan SongÎncă nu există evaluări

- Pilot'S Operating Handbook: Robinson Helicopter CoDocument200 paginiPilot'S Operating Handbook: Robinson Helicopter CoJoseph BensonÎncă nu există evaluări

- Quality in CRDocument10 paginiQuality in CRkaushikcrÎncă nu există evaluări

- B.ST Case Study Class 12Document214 paginiB.ST Case Study Class 12Anishka Rathor100% (1)

- Braga - 2016 - On Standing's A Precariat Charter - Confronting The Precaritisation of Labour in Brazil and PortugalDocument12 paginiBraga - 2016 - On Standing's A Precariat Charter - Confronting The Precaritisation of Labour in Brazil and PortugalLiam MurciaÎncă nu există evaluări

- RCC Design of Toe-Slab: Input DataDocument2 paginiRCC Design of Toe-Slab: Input DataAnkitaÎncă nu există evaluări

- Capsule Research ProposalDocument4 paginiCapsule Research ProposalAilyn Ursal80% (5)

- ATLAS HONDA Internship ReportDocument83 paginiATLAS HONDA Internship ReportAhmed Aitsam93% (14)

- Portfolio Report Zarin Tasnim Tazin 1920143 8Document6 paginiPortfolio Report Zarin Tasnim Tazin 1920143 8Fahad AlfiÎncă nu există evaluări

- GATE General Aptitude GA Syllabus Common To AllDocument2 paginiGATE General Aptitude GA Syllabus Common To AllAbiramiAbiÎncă nu există evaluări

- The Finley ReportDocument46 paginiThe Finley ReportToronto StarÎncă nu există evaluări

- TOEFLDocument6 paginiTOEFLSekar InnayahÎncă nu există evaluări

- Mobile Based IVR SystemDocument17 paginiMobile Based IVR SystemIndraysh Vijay [EC - 76]Încă nu există evaluări

- A CMOS Current-Mode Operational Amplifier: Thomas KaulbergDocument4 paginiA CMOS Current-Mode Operational Amplifier: Thomas KaulbergAbesamis RanmaÎncă nu există evaluări

- YeetDocument8 paginiYeetBeLoopersÎncă nu există evaluări

- Lec # 26 NustDocument18 paginiLec # 26 NustFor CheggÎncă nu există evaluări

- Automatic Stair Climbing Wheelchair: Professional Trends in Industrial and Systems Engineering (PTISE)Document7 paginiAutomatic Stair Climbing Wheelchair: Professional Trends in Industrial and Systems Engineering (PTISE)Abdelrahman MahmoudÎncă nu există evaluări

- Heat Exchanger Designing Using Aspen PlusDocument6 paginiHeat Exchanger Designing Using Aspen PlusMeethiPotterÎncă nu există evaluări

- Beam Deflection by Double Integration MethodDocument21 paginiBeam Deflection by Double Integration MethodDanielle Ruthie GalitÎncă nu există evaluări

- Outage Analysis of Wireless CommunicationDocument28 paginiOutage Analysis of Wireless CommunicationTarunav SahaÎncă nu există evaluări

- CEA 4.0 2022 - Current Draft AgendaDocument10 paginiCEA 4.0 2022 - Current Draft AgendaThi TranÎncă nu există evaluări

- Home Guaranty Corp. v. Manlapaz - PunzalanDocument3 paginiHome Guaranty Corp. v. Manlapaz - PunzalanPrincess Aliyah Punzalan100% (1)

- HP Sustainability Impact Report 2018Document147 paginiHP Sustainability Impact Report 2018Rinaldo loboÎncă nu există evaluări

- Bank Statement SampleDocument6 paginiBank Statement SampleRovern Keith Oro CuencaÎncă nu există evaluări

- 1grade 9 Daily Lesson Log For Demo 1 4Document5 pagini1grade 9 Daily Lesson Log For Demo 1 4cristy olivaÎncă nu există evaluări

- Communication On The Telephone InfoDocument30 paginiCommunication On The Telephone Infomelese100% (1)

- Caso Kola RealDocument17 paginiCaso Kola RealEvelyn Dayhanna Escobar PalomequeÎncă nu există evaluări