Documente Academic

Documente Profesional

Documente Cultură

JSA Fitting and Welding Work For Pipe Trench Instalation

Încărcat de

Azmi FauziTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

JSA Fitting and Welding Work For Pipe Trench Instalation

Încărcat de

Azmi FauziDrepturi de autor:

Formate disponibile

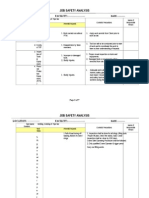

JOB HAZARD ANALYSIS

PT TECHNIC (M) SDN. BHD.

HOW TO USE THIS FORM :

1) Crew performing task reviews ALL generic JHA considerations.

2) Review previous JHA update(s) for useful information which will help this task.

3) Create new JHA update with generic form and ALL considerations for this task.

4) Carry out task as per plan. If any conditions change ---STOP & RE-ASSESS.

5) File JHA update for future reference.

WORK ACTIVITY

FITTING AND WELDING WORK

HOT WORK

Job

Step

1.

Description of

Job Step

Prepare PTW

Potential

Hazards

a. Failure will

cause

damage to

equipment

and

personnel.

OF PIPE AND PIPE

SUPPORT ON UREA PIPE TRENCH.

Potential

Impact

a. Unauthorized and

incompetent

personnel to do

work.

b. Unorganized and

unplanned work

will expose

personnel to

hazard.

1.1

2

1.2

1.3

a. Obstruction.

b. Collision with

Mobilization of

Personnel

a. Personal Injury

equipment and

and

b. Damage to

piping material

equipment.

equipment.

to installation

c. Lost control of

area.

vehicle due

to poor

accessibility.

2.2

2

2.3

2.4

2.5

2.6

2.7

UREA

Pipe

HW

-

JHA Cross-Reference Number

Recovery

Measures

.

a. PTW to be

display at

Applicant, authorizing, approval signatories

work site.

be familiar with the job.

b. Method

Competent personnel to perform the task

statement of

being identified.

work to be

Ensure PTW are applied and valid prior to

approved

work.

before

commencing

of work.

Toolbox meeting to be conducted prior start a. Ensure the

of work.

access way

Ensure vehicle and equipment are certified

to area is

with sticker from consortium.

accessible

Driver to observe speed limits.

for the prior

Park vehicle at designated location.

mobilization.

Neat and proper arrangement of equipment. b. Remove any

Moved cylinders via carriage and valve must

objects

be shut while transporting.

obstructing

Personnel to be vigilant and alert during

the path (if

driving.

applicable)

Control Measures

2.1

2.

Installation/Facility

Location

Associated Work Permit Type

Associated Work Permit Number

Electrical Isolation Certificate Number

Physical Isolation Certificate Number

Result

Tolerable

2

Acceptable

Page 1 of 6

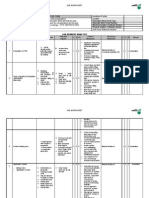

JOB HAZARD ANALYSIS

PT TECHNIC (M) SDN. BHD.

Job

Step

Description of

Job Step

Potential

Hazards

Potential

Impact

3.

a. Manual lifting of

heavy object.

b.

Long

hours of

Manual handling

a. Back ache /

repetition

of equipment

injury /Slip disc

movement.

and materials.

b. Slip and trip

c. Protruding

Hazard.

d. Pinch point

4.

Fitting of

welding cable,

hose

connection,

cutting torch,

grinding,

gouging

equipment and

hand tools.

a. Cylinder under

pressure

b. Spark and

flame

c. Electric shock

d. Defective

welding

equipment.

Entering Pipe

trench

a. Slip and fall

inside pipe

trench.

5.

a. Personnel Injured

b. Fire and explosion

c. Gas leaking out

d. Fire and explosion

a. Personnel injured

Control Measures

Recovery

Measures

3.1 Make sure work area and access way is free

from obstruction.

3.2 To do use mechanical aid to lift heavy tools a. All trip hazard

and materials.

to be

3.3 Do not manually lift heavy object alone, use

eliminate or

buddy to lift.

to be clearly

3.4 Use suitable and correct PPE (Hand glove)

marked with

3.5 Personnel to be vigilant and alert during

signage.

work.

b. To cascade

3.6 Walk on even ground or path.

JSA to all

3.7 Vision of sight must not be blocked by carried

worker

materials.

during TBM.

3.8 Do not walk on wet and slippery surface

while carrying materials.

4.1 Regular inspection of hose, connection and

leak test to be done prior to start working.

4.2 All cylinders bottle to be positioned upright

a. All flammable,

and secured.

combustible

4.3 Wear welding face shield and glove.

materials are

4.4 Ensure cable, joint and gauge meter in good

removed

condition prior start.

prior to

4.5 Welding machine to be a securely earth.

working.

4.6 All electrodes holder to be insulated.

b. Fire

4.7 Welding machine to be a securely earthed.

extinguisher

4.8 All cylinders regulator to be shut during break

is in place.

hours.

4.9 Welding equipment to be checked and

inspected for safe use.

a. All flammable,

combustible

materials are

5.1 Provide proper access inside pipe trench.

removed

5.2 Hard barricade all around pipe trench.

prior to

5.3 Only authorized personnel to enter pipe

working.

trench.

b. Fire

extinguisher

is in place.

Result

Acceptable

Page 2 of 6

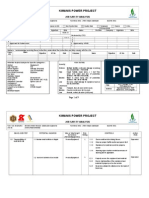

JOB HAZARD ANALYSIS

PT TECHNIC (M) SDN. BHD.

Job

Step

Description of

Job Step

Potential

Hazards

Potential

Impact

6.

a. Personal injury

a. Cylinder under

b. Fire explosion.

pressure.

c. Gas leaking out.

b. Hoses rupture

d. Health hazards

c. Spark and

(inhalation)

flame.

Commencing of

e. Body scald

d. Exposure to

welding, cutting

f. Body injury.

toxic fume.

and grinding

g. Pinching.

e. Hot surface.

work for piping

h. Personal injury,

f. Excessive

and pipe

i. Falling from height

overheating.

support inside

j. Expose to illness

g. Sharp cutting

trench.

risk for long

blades.

hours exposure

h. Exposure to

of mineral dust.

Biological

k. Expose to

and dust

poisonous critter

hazard.

and insect bite.

7.

a. Polluted

area

b. Tripping

a. Fall and Slip

hazard due

b. Protruding hazard.

to material

c. Minor injury.

and

equipment

on working

platform.

Housekeeping

Recovery

Measures

a. Engine must

be stopped

once gas

6.1 Wear welding face shield and glove

break is

6.2 Ensure area is well ventilated

detected.

6.3 Use correct classification of PPE

b. Fire

6.4 Used qualified welder.

extinguisher

6.5 Install fire blanket as barrier to avoid spark

and fire

and flame contact with personnel working

watcher

below scaffold

standby at

6.6 Use correct PPE

welding

6.7 Cordon off the working area.

area.

6.8 Certified and validated scaffold.

c. All personnel

6.9 Display proper warning signage

to familiarize

6.10 To provide ventilation / air blower at trench

work site

depth more than 1.5 meter.

assemble

point.

d. First aid and

first aider.

e. Activate ERP.

7.1 Remove all materials from access way.

7.2 Wear hand gloves.

a. All personnel

7.3 Cleaning up all oil spills.

to familiarize

7.4 Barricade work area.

work site

7.5 Do not leave equipments, uninstalled

assemble

materials and residue of materials in working

point.

platform.

b. First aid and

7.6 Arrange all materials neatly.

first aider.

7.7 Area cleaning before and after work.

c. Activate ERP.

7.8 Wear proper PPE.

Control Measures

Result

Acceptable

Acceptable

Page 3 of 6

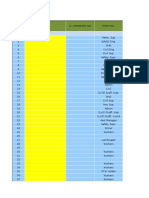

JOB HAZARD ANALYSIS

PT TECHNIC (M) SDN. BHD.

JHA Number: PTTM-HW-1/5

TASK SAFETY MANAGEMENT OUTLINE

Date This JHA Created : 23.10.2013

Page 4 of 6

JOB HAZARD ANALYSIS

PT TECHNIC (M) SDN. BHD.

Date JHA Last Revised : 24.5.2014

WORK ACTIVITY EQUIPMENT

Manufacturer

Type of Equipment

Chain Block

Welding machine

Welding machine

Grinder

Acetylene gas x 2 unit

Oxygen Gas x 2 unit

As per attach list

Airman

Airman

OKATZ

-

Tag. No.

As per attach list

AIT+ELEC 001

AIT+ELEC 002

AIT 1323 / AIT 1324

-

WORK ACTIVITY PARTICIPANTS

Name

Discipline

Position

Precise Work Site

Urea Pipe Trench

Urea Pipe Trench

Urea Pipe Trench

Urea Pipe Trench

Urea Pipe Trench

Urea Pipe Trench

THIS JHA CREATED BY

Performed

Job Before?

Name

Discipline/Position

Tham Chew Toong

Construction

Supervisor

Yes

Azmi Fauzi

Safety / HSEM

Hoo Chee Onn

Construction

Foreman

Yes

Mohd Azril Azli

Engineering / PE

William A/K Jamili

Construction

Fitter

Yes

Sodrie Bin Said

Construction

Welder

Yes

Jasmil Bin Arif

Construction

Welder

Yes

Boniface A/K Unang

Construction

Semi skill

Yes

Rehim Bin Gaiber

Construction

Semi skill

Yes

Sign

Page 5 of 6

JOB HAZARD ANALYSIS

PT TECHNIC (M) SDN. BHD.

JHA SUBMITTED BY SUBCONTRACTOR

WORK LEADER

JHA REVIEW BY CONSORTIUM

HSE DEPT.

HSE DEPT.

RECEIVING AUTHORITY

ENDORSED BY

APPROVING AUTHORITY

Name :- Tham Chew Tong

Name :- Azmi Fauzi

Name :-

Signature :-

Signature :-

Signature :-

Signature :-

Signature :-

Date :-

Date :-

Date :-

Date :-

Date :-

Time :-

Time :-

Time :-

Time :-

Time :-

Name :-

Name :-

Page 6 of 6

S-ar putea să vă placă și

- JSA For Welding GrindingDocument7 paginiJSA For Welding GrindingBabar78% (9)

- JHA Civil WorksDocument2 paginiJHA Civil Worksethelchudi100% (11)

- JSA Shut Down and Tie in Work PDFDocument6 paginiJSA Shut Down and Tie in Work PDFpjosesm80% (5)

- JSA For Cutting, Grinding and WeldingDocument4 paginiJSA For Cutting, Grinding and Weldingyc safety100% (3)

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocument9 paginiHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- SGD SAIPEM CAMP LOADING AND UNLOADINGDocument2 paginiSGD SAIPEM CAMP LOADING AND UNLOADINGsubhanmusadiq82% (55)

- Aboveground Piping Installation Works 2016Document7 paginiAboveground Piping Installation Works 2016Aldrin75% (4)

- JSA Welding Confined SpaceDocument2 paginiJSA Welding Confined Spacegkmlal100% (4)

- Jsa For Piping and Erection RevisedDocument1 paginăJsa For Piping and Erection RevisedAlvin Smith77% (26)

- Jsa For Lifting (Crane) 016Document6 paginiJsa For Lifting (Crane) 016aliraza572270% (27)

- Jsa-Jha For Using of Hand ToolsDocument2 paginiJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- JSA G20 Scaffolding (Erection, Dismantling)Document4 paginiJSA G20 Scaffolding (Erection, Dismantling)Kanchalida Champathong92% (12)

- Jsa CraneDocument3 paginiJsa Cranenattwa201075% (24)

- Jsa ExcavationDocument33 paginiJsa Excavationlal5012002390782% (17)

- JSA HandToolsDocument2 paginiJSA HandToolsCristina Rican100% (3)

- Jsa Grinding Welding Gas CuttingDocument3 paginiJsa Grinding Welding Gas CuttingRana Waseem Khan82% (78)

- 1installation of Steel Structures JHA 1 (06!06!2015)Document33 pagini1installation of Steel Structures JHA 1 (06!06!2015)Karthik babu100% (2)

- Civil JSA Form Block WorkDocument3 paginiCivil JSA Form Block Workdrmuhsin86% (7)

- JSA Steel Erection ManliftsDocument1 paginăJSA Steel Erection Manliftsrudygoot100% (1)

- JSA G17 Lift Container With CraneDocument4 paginiJSA G17 Lift Container With CraneYosep Sapto Rahyudi100% (3)

- Jsa For Weld and GrindingDocument6 paginiJsa For Weld and GrindingTanzeel LiaqatÎncă nu există evaluări

- Jha New Format-Painting Revision)Document8 paginiJha New Format-Painting Revision)Kenny Hassan100% (1)

- Crane JSADocument5 paginiCrane JSAKritsada Tiwutanon100% (1)

- Jsa For Civil Confined Space EntryDocument11 paginiJsa For Civil Confined Space EntryKhuda BukshÎncă nu există evaluări

- Job Safety Analysis For Pipeline WeldingDocument4 paginiJob Safety Analysis For Pipeline WeldingImranuddin Syed83% (6)

- Welding and Grinding HazardsDocument6 paginiWelding and Grinding HazardsJeremia Samosir100% (2)

- Job Safety Analysis: 1 Confined Space Entry JSA ExampleDocument7 paginiJob Safety Analysis: 1 Confined Space Entry JSA Examplerashid zamanÎncă nu există evaluări

- Jsa For Piping and Erection RevisedDocument1 paginăJsa For Piping and Erection RevisedDr AnwarÎncă nu există evaluări

- Lifting Bridge JSADocument8 paginiLifting Bridge JSAeslamÎncă nu există evaluări

- Welding, Cutting and GrindingDocument6 paginiWelding, Cutting and GrindingMohammed MinhajÎncă nu există evaluări

- Jsa Installation of Supports and Cable Racks1Document16 paginiJsa Installation of Supports and Cable Racks1loveson709100% (3)

- Jsa For Air Flushin & Mech. Cleaning of PipesDocument17 paginiJsa For Air Flushin & Mech. Cleaning of PipesKhuda Buksh100% (2)

- Al - Osais Contracting Company Haradh Area Power Reliability EnhancementDocument3 paginiAl - Osais Contracting Company Haradh Area Power Reliability EnhancementREHAN IQBAL100% (3)

- Job Safety Analysis for Concrete WorksDocument8 paginiJob Safety Analysis for Concrete Worksfrancis_e_tan93% (27)

- Column Erection JSA AnalysisDocument6 paginiColumn Erection JSA AnalysisRaghava Richhu100% (2)

- Jsa For Lifting Crane 016Document6 paginiJsa For Lifting Crane 016kiran kumar100% (1)

- JsaDocument39 paginiJsajithin shankar100% (3)

- JHA - Handrails and GratingsDocument10 paginiJHA - Handrails and GratingsVidyesh Nair67% (3)

- Manual Tig Welding (RRC) - Job ProcedureDocument3 paginiManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- Crane Lifting Materials SafelyDocument4 paginiCrane Lifting Materials SafelyAbu MaazÎncă nu există evaluări

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEDocument12 paginiRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- DOCUMENT Loop Checking Activities JHADocument8 paginiDOCUMENT Loop Checking Activities JHAFrancis Enriquez Tan83% (6)

- Refueling JSA 4 08 2019 Rev.03 Near WaterDocument9 paginiRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariÎncă nu există evaluări

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocument4 paginiJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- 3-REV.1 - Hot Work - Risk Assessment JHADocument16 pagini3-REV.1 - Hot Work - Risk Assessment JHAnaiyar100% (1)

- 1.SW-JSA - Piping-1 - Fabrication and Erection of Piping ActivityDocument5 pagini1.SW-JSA - Piping-1 - Fabrication and Erection of Piping ActivityAnwar AliÎncă nu există evaluări

- JHA For Electrical Works - Rev. 01.Document16 paginiJHA For Electrical Works - Rev. 01.SreekumarÎncă nu există evaluări

- Erect Steel Structures SafelyDocument9 paginiErect Steel Structures SafelyLuqman Osman77% (13)

- Job Hazard Analysis Welding Operations: Job Title: Work Place LocationDocument18 paginiJob Hazard Analysis Welding Operations: Job Title: Work Place Locationmuhammad imtiaz100% (1)

- Jsa Grinding W Angle GrinderDocument2 paginiJsa Grinding W Angle GrinderMichael Angelo SanteÎncă nu există evaluări

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Document1 paginăJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- BYDP-JHA-05 Erection of ScaffoldingDocument4 paginiBYDP-JHA-05 Erection of ScaffoldingAhmad Shauqi100% (6)

- JHA Valve Leak Test and RepairDocument16 paginiJHA Valve Leak Test and Repairrosevelvet100% (1)

- Construction Risk Assesment For Riser Top Ring InstallationsDocument11 paginiConstruction Risk Assesment For Riser Top Ring Installationssaifulnizam86gmailcom100% (1)

- JHA To Rectify Platform at v-1605 & v-1506Document6 paginiJHA To Rectify Platform at v-1605 & v-1506firdausÎncă nu există evaluări

- Abrasive Blasting Works at WTF - 3 Construction Site 2018Document3 paginiAbrasive Blasting Works at WTF - 3 Construction Site 2018AldrinÎncă nu există evaluări

- Interal Safety Audit . Shutdown Date: - / - / - Department: FM MechanicalDocument3 paginiInteral Safety Audit . Shutdown Date: - / - / - Department: FM MechanicalchandankrdumkaÎncă nu există evaluări

- Method of Painting WorksDocument43 paginiMethod of Painting WorksIkram Syed50% (2)

- S-PCM Minutes of Meeting: Fire Water Tank BDocument3 paginiS-PCM Minutes of Meeting: Fire Water Tank Bsudeesh kumarÎncă nu există evaluări

- Competency & Training Masterlist 2017. Rev2Document65 paginiCompetency & Training Masterlist 2017. Rev2Azmi FauziÎncă nu există evaluări

- SINGAPORE CIVIL DEFENCE FORCE GUIDELINES FOR COMPANY EMERGENCY RESPONSE PLANDocument29 paginiSINGAPORE CIVIL DEFENCE FORCE GUIDELINES FOR COMPANY EMERGENCY RESPONSE PLANMaey AkimÎncă nu există evaluări

- Behavioural Gap AnalysisDocument2 paginiBehavioural Gap AnalysisAzmi FauziÎncă nu există evaluări

- Method Statement Water StorageDocument2 paginiMethod Statement Water StorageAzmi Fauzi100% (5)

- JHA For PWHT WorkDocument2 paginiJHA For PWHT WorkAzmi Fauzi77% (13)

- In-House Training Muster DrillDocument3 paginiIn-House Training Muster DrillAzmi FauziÎncă nu există evaluări

- Hse Accident NotificationDocument4 paginiHse Accident NotificationAzmi FauziÎncă nu există evaluări

- Land ClearingDocument9 paginiLand ClearingAzmi Fauzi100% (2)

- Inventory Control Spreadsheet: OTC & Medicine Inventory Control Spreadsheet: OTC & MedicineDocument221 paginiInventory Control Spreadsheet: OTC & Medicine Inventory Control Spreadsheet: OTC & MedicineAzmi FauziÎncă nu există evaluări

- Samonte Vs CADocument7 paginiSamonte Vs CAMaricel Caranto FriasÎncă nu există evaluări

- Sar Oumad Zemestoun v01b Music Score سر اومد زمستون، نت موسیقیDocument1 paginăSar Oumad Zemestoun v01b Music Score سر اومد زمستون، نت موسیقیPayman Akhlaghi (پیمان اخلاقی)100% (3)

- CAE-NUST College Aeronautical Engineering AssignmentDocument3 paginiCAE-NUST College Aeronautical Engineering AssignmentBahram TahirÎncă nu există evaluări

- 2017 Climate Survey ReportDocument11 pagini2017 Climate Survey ReportRob PortÎncă nu există evaluări

- Fernández Kelly - Death in Mexican Folk CultureDocument21 paginiFernández Kelly - Death in Mexican Folk CultureantoniadelateÎncă nu există evaluări

- Best Practices in Implementing A Secure Microservices ArchitectureDocument85 paginiBest Practices in Implementing A Secure Microservices Architecturewenapo100% (1)

- MICROHARDNESS TESTER HMV-2 - SeriesDocument9 paginiMICROHARDNESS TESTER HMV-2 - SeriesRicoÎncă nu există evaluări

- 268 General Knowledge Set ADocument48 pagini268 General Knowledge Set Aguru prasadÎncă nu există evaluări

- Kristy Gallazin Edte 431 - Assignment 2 Newsletter pdf12Document4 paginiKristy Gallazin Edte 431 - Assignment 2 Newsletter pdf12api-301047467Încă nu există evaluări

- Csd88584Q5Dc 40-V Half-Bridge Nexfet Power Block: 1 Features 3 DescriptionDocument26 paginiCsd88584Q5Dc 40-V Half-Bridge Nexfet Power Block: 1 Features 3 DescriptionJ. Carlos RGÎncă nu există evaluări

- The Cult of Demeter On Andros and The HDocument14 paginiThe Cult of Demeter On Andros and The HSanÎncă nu există evaluări

- Specification For Corrugated Bitumen Roofing Sheets: Indian StandardDocument10 paginiSpecification For Corrugated Bitumen Roofing Sheets: Indian StandardAmanulla KhanÎncă nu există evaluări

- FINAL Conflicts 2019 Official Guidelines PDFDocument48 paginiFINAL Conflicts 2019 Official Guidelines PDFxsar_xÎncă nu există evaluări

- Integrating Force - Com With MicrosoftDocument11 paginiIntegrating Force - Com With MicrosoftSurajAluruÎncă nu există evaluări

- Kamencak D Dip LiteraturaDocument2 paginiKamencak D Dip Literaturaprodaja47Încă nu există evaluări

- Miles and Snow's Organizational StrategiesDocument15 paginiMiles and Snow's Organizational StrategiesVirat SahÎncă nu există evaluări

- Handouts - Entity Relationship DiagramDocument8 paginiHandouts - Entity Relationship Diagramsecret studetÎncă nu există evaluări

- Tentative Quotation For Corporate Video (5 Minutes)Document2 paginiTentative Quotation For Corporate Video (5 Minutes)Lekha JauhariÎncă nu există evaluări

- Artificial IntelligenceDocument1 paginăArtificial IntelligenceTeresaÎncă nu există evaluări

- Economic Globalization: Actors, Categories, and StagesDocument28 paginiEconomic Globalization: Actors, Categories, and StagesJoshua PunganÎncă nu există evaluări

- Firewalker Spell and Ability GuideDocument2 paginiFirewalker Spell and Ability GuideRon Van 't VeerÎncă nu există evaluări

- Urbanization As A Transformative Force: Quick FactsDocument20 paginiUrbanization As A Transformative Force: Quick FactsJulio CovarrubiasÎncă nu există evaluări

- Bill of QuantitiesDocument25 paginiBill of QuantitiesOrnelAsperas100% (2)

- Choi, J H - Augustinian Interiority-The Teleological Deification of The Soul Through Divine Grace PDFDocument253 paginiChoi, J H - Augustinian Interiority-The Teleological Deification of The Soul Through Divine Grace PDFed_colenÎncă nu există evaluări

- Suntay V CojuancoDocument2 paginiSuntay V CojuancoJushiÎncă nu există evaluări

- MATHS UNDERSTANDINGDocument15 paginiMATHS UNDERSTANDINGNurul IzzaÎncă nu există evaluări

- Labor DoctrinesDocument22 paginiLabor DoctrinesAngemeir Chloe FranciscoÎncă nu există evaluări

- Deep Work Book - English ResumoDocument9 paginiDeep Work Book - English ResumoJoão Pedro OnozatoÎncă nu există evaluări

- Quantitative Techniques For Business DecisionsDocument8 paginiQuantitative Techniques For Business DecisionsArumairaja0% (1)

- Station 6 Part 1 2Document4 paginiStation 6 Part 1 2api-292196043Încă nu există evaluări