Documente Academic

Documente Profesional

Documente Cultură

Deep Drawn - Deep Drawing Process - Sheet Drawing Metal

Încărcat de

Sanjeev ParasharTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Deep Drawn - Deep Drawing Process - Sheet Drawing Metal

Încărcat de

Sanjeev ParasharDrepturi de autor:

Formate disponibile

9/11/2015

deepdrawn|deepdrawingprocess|sheetdrawingmetal|

|Metalstamping|Tooldiedesignbook|Graphicdesigntutorial|

|JoinourMailinglist|ContactUs|ToolDesignservice|

SheetmetalDeepdrawingtechnologyisoneofthemostchallenging

processinmanufacturing.Successfuldeepdrawingprocessdependson

manyfactors.

AdsbyGoogle HowtoDrawDeepDrawnSheetMetalDrawDesign

Tool&DieMaking

Articles

BendRadius

DeepDrawn

FineBlanking

Formular

Progressionstriplayout

Slugpullingprevention

TooldieDesign

Tooldiedesignbook

TechnicalBookStore

JigandFixture

JigsandFixtureDesign

Materialstreatment

Annealingmetal

Casehardening

Density

ElectricalConductivity

heattreatmentprocess

heattreatingsteel

ThermalExpansion

http://www.wisetool.com/deepdraw.htm

Commentproblems

Drawcomputation

Reductionpercentage

Thesheetmetaldeepdrawntechnologyisoneofthemostchallengingprocessin

manufacturing.Thesizes,shapes,thicknessanddeepdrawnmetalusedtoproduces

sheetmetaldeepdrawnpartscoveradiverserangeofvariables.Individualvariables

shouldbeevaluatedcarefullytodeterminetheoptimummanufacturingmethod.

Regardlessofthemanyfactorsinvolvedaffectingthedrawquality,

themostimportantelementtoasuccessfulsheetmetaldeepdrawingoperationisthe

smoothnessofsheetmetalflow.Thefollowingarekeyelementsaffectingmetalflow

duringdeepdrawingprocessandeachofthemshouldbeconsideredwhendesigningor

troubleshootingsheetmetaldeepdrawingstampingtools:

Typeofmaterialusedanditsthickness.=Indeepdrawingprocess,thickermaterialsarestiffer,

theycanbegrippedbetterduringdeepdrawing.Thickermaterialsalsohavemorevolume,sotheycan

stretchlongerdistancesduringdeepdrawingprocess(deeperdraw).

Toolsurfacefinish&typeofLubricantused=Diesurfacefinishesandlubricantsareimportantto

reducesthefrictionbetweentoolsurfacesandmetalbeendrawn,itallowingmaterialstoflowthrough

toolsmoreeasily.Dietemperaturescanaffecttheviscosityoflubricants.Slowerdeepdrawingspeed

givesbettermetalflow.

Blanksizeandshape=Blanksizesandshapesthataretoolargecanrestrictmetalflow,andthe

1/5

9/11/2015

deepdrawn|deepdrawingprocess|sheetdrawingmetal|

geometryofpartsaffectstheabilityofmetaltoflowduringdeepdrawingprocess.

Material

Aluminum

Alucomparisontable

AluminumTempering

CarbonSteel

Copperalloy

Lowalloys

Materialnations&

Equivalents

Nickelalloys

StainlessSteel

StainlessSteel

comparisontable

ToolSteelequivalent

TungstenCarbide

WroughtstainlessSteel

Manufacturing

ConversionCharts

DrillAngle

Drillsize

EnergyEfficiency

MathArea

MachiningCuttingTime

Technicalarticles

WorkDone

Velocity

Punchingspeed=sufficientpunchingspeedallowstimeformaterialstoflowthroughthetool.Corner

crackingwillalwaysoccurifpressspeedistoolfastindeepdrawingprocess.

Drawradii=Radiusonthedrawdiewherethematerialflowthrough,toobigtheradiiwillresult

wrinklingwheretoosmallwillcreatescrackingatbottomradiusofdrawnpart.

Drawratio=Referstotheabilityofamaterialtoflowordraw.Affectingthedrawdepthandsizeper

anysingledraw.

Drawbeadheightandshape=Tocontrolmetalflowandgrippingpressureindeepdrawingprocess,

drawbeadheightandshapecancausematerialstobendandunbendtocreatesrestrictiveforcesgoing

intoatool.Increasingpressurewillexertsmoreforceonamaterial,creatingmorerestraintonmaterial

goingintothetool.

Causesofcommonproblemsinthedeepdrawing.

highspeedpress

bestmachinerysupplierinChinagoodquality,performanceequmen

Metalfractureduringdeepdrawingprocess

1.Deepdrawingradiitoosmall,creatingresistancetometalflowtocauseunduethinningorfracture.

Correctbyincreasingdieradiusorbychangingdieentrancetoconicalorellipticalshape.

2.Clearancebetweenpunchanddietoolittle,toogreatoruneven.

GeometricTolerancing 3.Blankholderpressuretoogreat.

4.Lubricantinadequateorunsuitable.

GDT

5.Punchnoseradiustoosmall.

TolerancechartISO

SurfaceRoughness

Wrinklesontopedgeorflange

SurfaceTexture

1.Blankholderpressuretootight.

2.Drawradiustoolarge.

3.Punchnoseradiustoolarge.

QualityControl

4.Wrinklesonthesideofcuporflangecausedbyburronblankorbyanunbalancedblankholder

AQL

ProcessCapabilityCPK pressure.

Samplingplan

LevelI,II,III

http://www.wisetool.com/deepdraw.htm

Uneventoprimorflange

1.Nicksorburralongtheperipheryoftheblank.

2/5

9/11/2015

deepdrawn|deepdrawingprocess|sheetdrawingmetal|

EngineeringPlastic

Machiningofplastic

Selectionofplastic

2.Punchdieorblanklocatornotconcentric.Toomuchmaterialpulledintothediebyoffcenterforming

punchpreventingformingofanevencupdepthorflange.

3.Blankholderexertinganunbalancedforceontheblank,permittingthematerialflowunevenlyintothe

die.

Flangewrinkled,Puckered.

1.Blankthicknesswrongoroutoftolerance.

2.Drawradiustoolarge.

3.Clearancebetweenpunch&Dietoolargeforthestockthickness.

3.Depthofpreviousdrawntooshortorredrawoperationtoodeep.Orsidewallofdrawncupbeingtinned

down.

Fractureaybottomofredrawncup

1.Drawradiusandblankholdingsurfacescratched,nickedorgalled.Restrictingmetalflowintothedie.

2.Punchnoseanddrawradiustoosmall.

3.DiameterReductiontoogreat.

FractureinoratFlangeofdrawncup.

1.Punchanddieclearancetoosmall.

Excessmaterialattopofdeepdrawnshell

1.Materialthicknesstoogreatorpunchdieclearancetoosmalloruneven.

2.Punchnoseradiuslargerthancupbottomradius,causesexcess

sheetmetaltoflowupsidewall.

3.Drawradiustoolarge,permittingwrinklestostartthatenlargeduringredrawofcup.

Deepdrawnprocesscomputation

Bydefinition,adrawpiecepartwhichrequiresonly

onedrawoperationisconsideredtobeashallow

draw,andadrawpiecepartwhichrequiremore

http://www.wisetool.com/deepdraw.htm

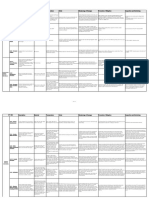

TableAnumberofdraw

H/D

<0.75

0.751.5

1.53.0

3.04.7

3/5

9/11/2015

deepdrawn|deepdrawingprocess|sheetdrawingmetal|

Catheter

Tip

Moulds

thanonedrawingoperationisconsidertobedeep

draw.Inthenutshell,thenumberofdrawsindeep

drawingprocesscanbeestimatedbytableA.

Nickelforms,

Machined

Stainless

HighQuality,

FastService

H=Insideheight

D=meanDiameter

N>4Thickness

P=Numberofdraws

Deepdrawnreductionpercentages

Whenasheetmetalpartsdrawpieceisdrawnfromaflatblank,thediameterofthedrawpieceis

smallerthanthediameteroftheflatblank.Thedifferenceindiametercanbeexpressasapercentage

oftheoriginal1stblankdiameter.

Material=Steel

Sheetmetal

Thickness

1stdraw

2nddraw

3rddraw

4thdraw

(inch)

<0.063

4048

2025

1820

1618

0.0630.125

4048

1518

1415

1314

0.1250.187

4048

1215

1112

1011

0.1870.25

4048

1013

910

89

>0.25

4048

810

78

67

Material=Brass

<0.063

4450

2029

1823

1820

0.0630.125

4450

1623

1517

1215

0.1250.187

4450

1417

1214

1113

0.1870.25

4450

1014

911

810

>0.25

4450

911

89

78

http://www.wisetool.com/deepdraw.htm

4/5

9/11/2015

deepdrawn|deepdrawingprocess|sheetdrawingmetal|

WiseToolallrightsreserved

|Tooldiedesign|JoinOurMailinglist|Usefulformula|Progressionlayout|ContactUs|MaterialDensity|Materialnations&

Equivalents|ThermalExpansion|ElectricalConductivity|SamplingprocedureAQL||

http://www.wisetool.com/deepdraw.htm

5/5

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Salt Analysis-Vi Aluminum SulphateDocument3 paginiSalt Analysis-Vi Aluminum SulphateNANÎncă nu există evaluări

- Nsejs2014 Js 505Document13 paginiNsejs2014 Js 505ChiruhaasÎncă nu există evaluări

- Manganese DioxideDocument5 paginiManganese Dioxidemartinusteddy2114Încă nu există evaluări

- Metrology NOTEDocument90 paginiMetrology NOTERyan Goh Chuang HongÎncă nu există evaluări

- Becogur enDocument2 paginiBecogur enRui Felizardo0% (1)

- Molten Salt Storage Systems For Solar Thermal Prower PlantsDocument8 paginiMolten Salt Storage Systems For Solar Thermal Prower PlantsSaul RamÎncă nu există evaluări

- Concrete ExamDocument26 paginiConcrete ExamKyra AlesonÎncă nu există evaluări

- Alchemy The Treasure of Alchemists by Jaques SadoulDocument5 paginiAlchemy The Treasure of Alchemists by Jaques SadoulVladimir VergunÎncă nu există evaluări

- Manual de Parte Bomba Gorman RuppDocument38 paginiManual de Parte Bomba Gorman RuppLuis Fernando Arias FlorezÎncă nu există evaluări

- NIA Graduate Program: Fall 2016: Full Course ListDocument12 paginiNIA Graduate Program: Fall 2016: Full Course ListMarsala NistoÎncă nu există evaluări

- Atomic PhysicsDocument58 paginiAtomic PhysicsBasitÎncă nu există evaluări

- Environmentally Friendly Cooling With Heat: Ecoo 2.0: The Classic of Adsorption RefrigerationDocument3 paginiEnvironmentally Friendly Cooling With Heat: Ecoo 2.0: The Classic of Adsorption RefrigerationGokulSubramanianÎncă nu există evaluări

- Polymer SyllabusDocument6 paginiPolymer SyllabusJOSEPH HERBERT MABELÎncă nu există evaluări

- Rxn10 - FEMLAB-Fixed Bed ReactorDocument15 paginiRxn10 - FEMLAB-Fixed Bed ReactorvijendranbÎncă nu există evaluări

- Gate 2001Document61 paginiGate 2001api-26818774Încă nu există evaluări

- Vacuum Super Insulated Heat Storage Up To 400 °C: January 2015Document11 paginiVacuum Super Insulated Heat Storage Up To 400 °C: January 2015Arvin SlayerÎncă nu există evaluări

- 12 - Effect of Blanching On TextureDocument9 pagini12 - Effect of Blanching On TexturevishalÎncă nu există evaluări

- Model Paper Engg - Chemistry 1 1 r16Document1 paginăModel Paper Engg - Chemistry 1 1 r16vrkoradaÎncă nu există evaluări

- 5990 7413enDocument20 pagini5990 7413enG_ASantosÎncă nu există evaluări

- A Review On Techniques To Enhance Electrochemical Remediation of Contaminated SoilsDocument19 paginiA Review On Techniques To Enhance Electrochemical Remediation of Contaminated SoilsAdelina96Încă nu există evaluări

- Fta Oil+gasdistilcolumn PDFDocument7 paginiFta Oil+gasdistilcolumn PDFPrasanna GÎncă nu există evaluări

- 571 SummaryDocument3 pagini571 SummarySimbu Arasan100% (1)

- Service Boom Inspection and Repair PDFDocument60 paginiService Boom Inspection and Repair PDFYadi Kusmayadi100% (1)

- HIRAI LTCC Design GuidelineDocument19 paginiHIRAI LTCC Design GuidelineAkanksha BhutaniÎncă nu există evaluări

- 14 List of Products For Cert of Fitness (1) DNVDocument23 pagini14 List of Products For Cert of Fitness (1) DNVCrywul Suitswitt FazhÎncă nu există evaluări

- RSM 2008 RevisionDocument51 paginiRSM 2008 RevisionphanthanhhungÎncă nu există evaluări

- Comparative Investigation of Traditional and Modern Passive Design Strategies To Reduce The Energy Use in Residential Building of West-Maharashtra RegionDocument17 paginiComparative Investigation of Traditional and Modern Passive Design Strategies To Reduce The Energy Use in Residential Building of West-Maharashtra RegionAnonymous CwJeBCAXp100% (1)

- 16 PTIRecommendationsforStayCableDesignTestingandInstallationDocument23 pagini16 PTIRecommendationsforStayCableDesignTestingandInstallationBeratErtekin100% (1)

- Planck's Law - WikipediaDocument88 paginiPlanck's Law - Wikipedia朱岳宸Încă nu există evaluări

- Els&CommunicationDocument145 paginiEls&Communicationapi-3827000100% (1)