Documente Academic

Documente Profesional

Documente Cultură

Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization Project

Încărcat de

wentropremDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization Project

Încărcat de

wentropremDrepturi de autor:

Formate disponibile

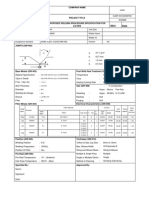

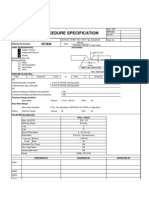

AZZAWIYA CONTROL SYSTEM MODERNIZATION PROJECT

WELDING PROCEDURE SPECIFICATION

JOINT VENTURE

(SECTION IX, ASME BOILER AND PRESSURE VESSEL CODE)

Contract No .

Company Name

Welding Process (es)

: 10/2008

: ABB GEMMO JV

: GTAW & SMAW

PQR No.

Date

: Gemmo Spa / Lloyd's 04

: 22/01/2006

Type (s)

: Manual / Automatic

WPS No.

: 10-08-0000-Q93-PR-00

JOINT

JOINT DETAILS

Joint Design

: Single V Butt Joint

Backing

: N/A

Backing Material

: N/A

6.02 mm

2.5 TO 4 mm

No. of layers according to material wall thicknes

FILLER METAL (QW-404)

BASE METALS (QW-403)

P Number

: P No. 1 To

P No.1

Specification (SFA)

: 5.18 , 5.1

Specification Type &Grade

: ASTM A 106 Gr.B

AWS classification

: ER-70 SG , E 70

F No.

:6,4

Pipe Dia & Size

Wall Thickness

QUALIFIED RANGE

: 6" NB

: Sch. 40 (6.02 mm)

Size of Electrode

: 2.4 mm dia , 2.5

Material Qualified

: ASTM A 106 Gr.B

Welding position

: 6G

DIA Qualified

: 2.5" NB & Above

Progression

: Up hill

Tickness Qualified

: 1.5 To 12.04

Position of fillet

: N/A

Groove Position

Fillet

PRE HEAT (QW-406

: All

: All

Pre-heat Temp.

: Min. 10 C

Temperature

: N/A

Interpass Temp.

: max. 250 C

Time

: N/A

Other

: When ambient temperature is below

5 C, preheat to at least 50 C

Heat rate

: N/A

Heating method

: N/A

ELECTRICAL CHARACTERISTICS (QW-409)

Shielding gas

: Argon

Current

: DC

% Composition

: 99.9 %

Polarity GTAW

: DCEN

Trailing

: N/A

Polarity SMAW

: DCEP

Backing

TECHNIQUE (QW-410)

: N/A

POSITION (QW-405)

POST WELD HEAT TREATMENT (QW-407)

SHIELDING GAS (QW-408)

Sting or Weave Bead

: String for root and other pass Weave (Max 2.5 times of dia

of electrodes)

Cleaning

: Grinding / Brushing, as required

Multiple/Single pass

: Multiple pass

Multiple/Single Electrode

: Single

Peening

: N/A

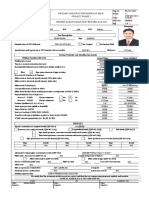

Weld Layer

Process

Filler Metal

Current

Class

Dia mm

Polarity

Amps Range

Volts Range

Travel Sp

(mm)/m

Root Pass

GTAW

ER 70 SG

2.0/2.4

DCEN

93-97

19-21

50-80

Hot Pass

GTAW

ER 70 SG

2.0/2.4

DCEN

93-97

19-21

50-80

Filling

SMAW

E-7018

2.5/3.15

DCEP

72-77

20-21

50-10

Capping

SMAW

E-7018

2.5

DCEP

76-79

18-26

70-10

PREPARED BY : ABB GEMMO JV QC

ABB GEMMO APPROVED

CLIENT

Name

Name

Name

Signature

Signature

Signature

Date

Date

Date

IYA CONTROL SYSTEM MODERNIZATION PROJECT

WELDING PROCEDURE SPECIFICATION

SECTION IX, ASME BOILER AND PRESSURE VESSEL CODE)

: Gemmo Spa / Lloyd's 04/05

: 10-08-0000-Q93-PR-00003

37.5 2.5

1.6 0.8 mm

2.5 TO 4 mm

No. of layers according to material wall thickness

: ER-70 SG , E 7018

: 2.4 mm dia , 2.5/3.15

Travel Speed

(mm)/min.

Remarks

50-80

.----------

50-80

.----------

50-100

.----------

70-100

.-----------

CLIENT APPROVED

:

:

S-ar putea să vă placă și

- Ami-003 WPSDocument2 paginiAmi-003 WPSBenjamin BrownÎncă nu există evaluări

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 paginiWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- WPS FormatDocument1 paginăWPS FormatAbdullah AnsariÎncă nu există evaluări

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 paginiQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- WPS GTAW pipe welding procedureDocument2 paginiWPS GTAW pipe welding procedureRichard PeriyanayagamÎncă nu există evaluări

- WPS TITLEDocument2 paginiWPS TITLERichard Periyanayagam86% (14)

- Wps Gmaw SawDocument2 paginiWps Gmaw Sawupedro26Încă nu există evaluări

- WOPQ Form English1Document2 paginiWOPQ Form English1oaperuchenaÎncă nu există evaluări

- WPS PQR A36.20Document5 paginiWPS PQR A36.20gchaves504100% (2)

- Fcaw 16 THKDocument5 paginiFcaw 16 THKparesh2387Încă nu există evaluări

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 paginiWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadÎncă nu există evaluări

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pagini(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WPQR Welding Procedure Qualification RecordsDocument3 paginiWPQR Welding Procedure Qualification Recordsramesh rajaÎncă nu există evaluări

- PQR & WPQ Standard Testing Parameter WorksheetDocument4 paginiPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyÎncă nu există evaluări

- PT Kuwera Karya Me: PanduDocument2 paginiPT Kuwera Karya Me: PanduGalang Pratama PutraÎncă nu există evaluări

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 paginiWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberÎncă nu există evaluări

- PQR WPQ Witness Report LatestDocument1 paginăPQR WPQ Witness Report LatestSatish KeskarÎncă nu există evaluări

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 paginiWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielÎncă nu există evaluări

- WPS 2014-002 006 - 6G PipeDocument3 paginiWPS 2014-002 006 - 6G PipejeswinÎncă nu există evaluări

- Draft WPSDocument32 paginiDraft WPSAnilkumar G NairÎncă nu există evaluări

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 paginiASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaÎncă nu există evaluări

- WPS FormatDocument2 paginiWPS FormatAmit SarkarÎncă nu există evaluări

- LBW WOPQ REV. 2010a Interactive FormDocument1 paginăLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- WPQ Template (Asme Ix) No LogoDocument4 paginiWPQ Template (Asme Ix) No LogorcpretoriusÎncă nu există evaluări

- WELDER QUALIFICATION REPORTDocument2 paginiWELDER QUALIFICATION REPORTAkash Singh TomarÎncă nu există evaluări

- WPQR Welding Procedure QualificationDocument3 paginiWPQR Welding Procedure QualificationThanasis KyrgiazoglouÎncă nu există evaluări

- Proposed WPSDocument2 paginiProposed WPSChisom Ikengwu100% (2)

- WPSDocument3 paginiWPSKhurram Burjees100% (1)

- WpsDocument3 paginiWpsPankaj KumarÎncă nu există evaluări

- WQTDocument1 paginăWQTRamkunwar YadavÎncă nu există evaluări

- WQT Record for Pipeline Welder QualificationDocument99 paginiWQT Record for Pipeline Welder QualificationVivek Jadhav100% (1)

- WPQT FormatDocument176 paginiWPQT FormatRafiqKu50% (2)

- Manufacturer'S Welding Procedure Specification Wps Wpsno: Rev No: Date: Page NoDocument2 paginiManufacturer'S Welding Procedure Specification Wps Wpsno: Rev No: Date: Page NoAMIT SHAHÎncă nu există evaluări

- WPS for 316L Pipe WeldingDocument3 paginiWPS for 316L Pipe WeldingRichard Periyanayagam100% (3)

- Wps - Asme Ix - Gtaw - Plat SteDocument6 paginiWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- WPS MigDocument3 paginiWPS MigAJOJOY00960% (5)

- Welder ID Card BRE KarahaDocument5 paginiWelder ID Card BRE KarahaHerruSetiawan100% (1)

- WPS-46 - Gtaw & Smaw Tig + SmawDocument8 paginiWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaÎncă nu există evaluări

- WPS 316 LDocument4 paginiWPS 316 Llaz_k100% (2)

- WELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENTDocument1 paginăWELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENTAhmed LepdaÎncă nu există evaluări

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Document3 paginiWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- Welding Procedure Specification and Procedure Qualification RecordDocument2 paginiWelding Procedure Specification and Procedure Qualification RecordNatdanai NorawanÎncă nu există evaluări

- Welding Procedure Specification For 24'' PipeDocument2 paginiWelding Procedure Specification For 24'' Pipeenels77100% (2)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 paginăWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pagini163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 paginiWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusÎncă nu există evaluări

- WPS and PQRDocument4 paginiWPS and PQRdandiar1Încă nu există evaluări

- Welding Consumable Baking Register PDFDocument1 paginăWelding Consumable Baking Register PDFKandula Raju100% (1)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 paginiWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaÎncă nu există evaluări

- WPS GTAW Stainless SteelDocument4 paginiWPS GTAW Stainless SteelAnand NarayananÎncă nu există evaluări

- SS312 Type310Document4 paginiSS312 Type310Vimin PrakashÎncă nu există evaluări

- Wps p91 - BhelDocument2 paginiWps p91 - BhelAshish Gupta100% (4)

- Welding Procedure Specification: Page 1 of 1Document2 paginiWelding Procedure Specification: Page 1 of 1Harshad100% (1)

- WPS GTAW Stainless SteelDocument2 paginiWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- Loading Unloading Temperature Welding ProgressionDocument5 paginiLoading Unloading Temperature Welding ProgressionRajesh Owaiyar71% (7)

- Wps Gtaw Monel b127 b164Document2 paginiWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- GTAW Welding Procedure SpecificationDocument3 paginiGTAW Welding Procedure SpecificationVimin Prakash100% (1)

- p22MNVMB MN Gtaw+Smaw (Pipe)Document2 paginip22MNVMB MN Gtaw+Smaw (Pipe)abidaliabid1Încă nu există evaluări

- PQR FormatDocument2 paginiPQR Formatravi0009880% (5)

- MRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDocument5 paginiMRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDeepak100% (1)

- Production and ME Confilicts AssessDocument18 paginiProduction and ME Confilicts AssesswentropremÎncă nu există evaluări

- 2.5 SLMTA Receipt Checklist v1Document2 pagini2.5 SLMTA Receipt Checklist v1wentropremÎncă nu există evaluări

- Solidworks K-Factors Sheet for Bending CalculationsDocument9 paginiSolidworks K-Factors Sheet for Bending CalculationsashkansoheylÎncă nu există evaluări

- Bend AllowanceDocument2 paginiBend AllowancewentropremÎncă nu există evaluări

- Metric FastenersDocument5 paginiMetric FastenerswentropremÎncă nu există evaluări

- What Is The Best Way To Clean Aluminum Before WeldingDocument1 paginăWhat Is The Best Way To Clean Aluminum Before WeldingwentropremÎncă nu există evaluări

- Bolt torque sequences and specifications for flangesDocument2 paginiBolt torque sequences and specifications for flangeswentropremÎncă nu există evaluări

- Internal Audit Checksheet EMS-OHSASDocument32 paginiInternal Audit Checksheet EMS-OHSASwentropremÎncă nu există evaluări

- Declare Medical Device ConformityDocument1 paginăDeclare Medical Device ConformityIstu PataiÎncă nu există evaluări

- Al 3-26-12Document9 paginiAl 3-26-12wentropremÎncă nu există evaluări

- A Comparison of Ultrasonics and Radiography For Weld InspectionDocument8 paginiA Comparison of Ultrasonics and Radiography For Weld InspectionwentropremÎncă nu există evaluări

- Astm b210mDocument13 paginiAstm b210mwentropremÎncă nu există evaluări

- 7c FumigationManualDocument18 pagini7c FumigationManualBryanTamaraBarusÎncă nu există evaluări

- Bolting Procedures: The Following Is A Sample Bolting Procedure Using A Manual or Hydraulic Torque WrenchDocument4 paginiBolting Procedures: The Following Is A Sample Bolting Procedure Using A Manual or Hydraulic Torque WrenchKyaw Kyaw AungÎncă nu există evaluări

- A Short Guide To Metric Nuts and BoltsDocument10 paginiA Short Guide To Metric Nuts and BoltsSandra FerrellÎncă nu există evaluări

- Bolt Torque SpecsDocument2 paginiBolt Torque SpecswentropremÎncă nu există evaluări

- 409 Data SheetDocument2 pagini409 Data SheetMatthieuÎncă nu există evaluări

- Bolt Torque SpecsDocument2 paginiBolt Torque SpecswentropremÎncă nu există evaluări

- Your Company Name: Suggestion SheetDocument2 paginiYour Company Name: Suggestion Sheetwentroprem100% (1)

- IMOA Shop Sheet 104Document2 paginiIMOA Shop Sheet 104Aneesh JoseÎncă nu există evaluări

- New Drug UpdateDocument16 paginiNew Drug UpdateDhaivat JoshiÎncă nu există evaluări

- Ultrasonic Testing FormulasDocument4 paginiUltrasonic Testing FormulasNavneet Singh100% (1)

- Self Regulating ArcDocument1 paginăSelf Regulating ArcwentropremÎncă nu există evaluări

- Staff Suggestion FormDocument1 paginăStaff Suggestion FormwentropremÎncă nu există evaluări

- ISO9001ChkDemo (Element)Document3 paginiISO9001ChkDemo (Element)wentropremÎncă nu există evaluări

- Checklist OHSAS AuditDocument3 paginiChecklist OHSAS AuditwentropremÎncă nu există evaluări

- ISO Standards On WeldingDocument6 paginiISO Standards On WeldingwentropremÎncă nu există evaluări

- Internal Audit Checksheet ReviewDocument32 paginiInternal Audit Checksheet ReviewRambir KaushikÎncă nu există evaluări

- On Site Assessment TemplateDocument8 paginiOn Site Assessment TemplatewentropremÎncă nu există evaluări

- Quality Management System Audit Checklist: Department: Email: Locations Sampled: Phone: Fax: NameDocument7 paginiQuality Management System Audit Checklist: Department: Email: Locations Sampled: Phone: Fax: NamewentropremÎncă nu există evaluări

- Internship-Report Fahad NewDocument50 paginiInternship-Report Fahad NewAbdullah LiaqatÎncă nu există evaluări

- Guage CockDocument17 paginiGuage CockomkarvadlooriÎncă nu există evaluări

- Narrow - Gap - TIG - 2P R0 2018 11 19Document2 paginiNarrow - Gap - TIG - 2P R0 2018 11 19gikkederkiÎncă nu există evaluări

- Arc Welding MachineDocument29 paginiArc Welding Machinejevz101-1Încă nu există evaluări

- Welder Question PaperDocument22 paginiWelder Question PaperDevraj VermaÎncă nu există evaluări

- Introduction To WeldingDocument192 paginiIntroduction To WeldingMirtunjay Kumar88% (8)

- 686 Electromedical Technology 2nd SemDocument24 pagini686 Electromedical Technology 2nd Semmaymonamou 2001Încă nu există evaluări

- Steps of Making WPSDocument51 paginiSteps of Making WPSDavid Macatangay100% (7)

- Arc Welding: (Soldadura Por Arco) Profesor: Dr. Jorge Álvarez Díaz Materia: Procesos de ManufacturaDocument19 paginiArc Welding: (Soldadura Por Arco) Profesor: Dr. Jorge Álvarez Díaz Materia: Procesos de ManufacturaRicky VillalobosÎncă nu există evaluări

- 6 77 0001 Rev - 4 PDFDocument40 pagini6 77 0001 Rev - 4 PDFRam Kadam0% (1)

- Al-All Ss Pressure GaugeDocument5 paginiAl-All Ss Pressure Gaugepankaj doshiÎncă nu există evaluări

- Asme Sec Ix - Short NotesDocument20 paginiAsme Sec Ix - Short NotesParvee K NakwalÎncă nu există evaluări

- Question 9Document31 paginiQuestion 9Ehsan KhanÎncă nu există evaluări

- ASME P Material Numbers ExplainedDocument6 paginiASME P Material Numbers Explainedsagar1503100% (1)

- A Study On Sustainability Assessment of Welding Processes: Jaber Jamal, Basil Darras and Hossam KishawyDocument12 paginiA Study On Sustainability Assessment of Welding Processes: Jaber Jamal, Basil Darras and Hossam Kishawyfaqqkecee05Încă nu există evaluări

- Foldable Elcetric BicycleDocument10 paginiFoldable Elcetric BicycleAkash KsÎncă nu există evaluări

- Deepak 2021Document6 paginiDeepak 2021CHONKARN CHIABLAMÎncă nu există evaluări

- Welding Fundamentals GuideDocument163 paginiWelding Fundamentals Guideharoub_nas100% (2)

- BSEN ISO-2553 Standard Symbols For WeldingDocument16 paginiBSEN ISO-2553 Standard Symbols For Weldingاحمد عمر حديد100% (1)

- Repair ProceduresDocument5 paginiRepair Proceduresmohd as shahiddin jafriÎncă nu există evaluări

- Orbital WeldingDocument6 paginiOrbital WeldingPramodPradhanÎncă nu există evaluări

- International Organization For Standardization (ISO) StandardsDocument3 paginiInternational Organization For Standardization (ISO) StandardsDileep100% (3)

- Model - 5Document26 paginiModel - 5PrabuÎncă nu există evaluări

- Microstructural Development and Solidification CrackingDocument12 paginiMicrostructural Development and Solidification CrackingMarjan SubanÎncă nu există evaluări

- Viking STPDocument20 paginiViking STPLee Nagle0% (1)

- SuperGlaze® 5356 TIGDocument1 paginăSuperGlaze® 5356 TIGMichael ClaphamÎncă nu există evaluări

- Cast-iron welding guide covers standardsDocument10 paginiCast-iron welding guide covers standardsclnÎncă nu există evaluări

- Ficha Tecnica - Termos O2Document20 paginiFicha Tecnica - Termos O2funefoÎncă nu există evaluări

- PQR FormatDocument2 paginiPQR Formatravi0009880% (5)

- Fabrication of HASTELLOY Corrosion Resistant AlloysDocument40 paginiFabrication of HASTELLOY Corrosion Resistant AlloysjosemiguelzuÎncă nu există evaluări