Documente Academic

Documente Profesional

Documente Cultură

F-100 Hoja de Datos de Separador Rev A

Încărcat de

IsmaelCruzDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

F-100 Hoja de Datos de Separador Rev A

Încărcat de

IsmaelCruzDrepturi de autor:

Formate disponibile

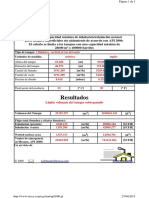

Pgina:

De:

10/24/2003

Emisin para aprobacin

MM

EC

EC

Rev.

Fecha

Descripcin

Por

Revis

Aprob

Proyecto:

DENOMINACIN DEL PROYECTO

Ttulo del documento:

SEPARADOR DE ENTRADA

Nmero de documento:

2003/X-V-HD-XXX

Rev.

F-100: Hoja De Datos Separador Rev A.xls, Trabajo Profesional de Ingeniera Qumica, Facultad de Ingeniera de la Universidad de Buenos Aires

Document Number:

Page:

2003/X-V-HD-XXX

Revision:

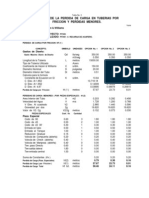

SEPARATOR DATASHEET

1 Project:

2

Of:

V-XXX

DENOMINACIN DEL PROYECTO

GENERAL

MECHANICAL DESIGN DATA

4 Service:

INLET SEPARATOR

Design Pressure:

5 Type:

VERTICAL TWO PHASE

Max/Min Design Temperature:

6 Internal Paint:

NO

Corrosion Allowance:

101.3 barg

-29/ 100 C

3 mm

7 External Paint: YES, AS PER SPEC XXXXXXX

Design Code:

8 Insulation:

MINERAL WOOL - 2"

Code Stamp Required:

9 Fireproof:

NO

Stress Relieve Required:

AS PER CODE

R-X Required:

AS PER CODE

10

11

ASME SEC VIII DIV 1

NO

PROCESS DATA

12 Operating pressure:

93.0 barg

CO2/H2S Content at OUTLET GAS

13 Operating Temperature:

50.0 C

NACE MR-01-75 Required:

14 Gas:

Mass Flow rate:

15

Act. Volum. Flow rate:

16

Density:

17

Viscosity:

18 Light Liquid:

Mass Flow rate:

19

Act. Volum. Flow rate:

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

Density:

Viscosity:

Surface Tension:

Light Liquid:

Mass Flow rate:

Act. Volum. Flow rate:

Density:

Viscosity:

Surface Tension:

Flow rates operation range:

Heads:

Shell:

Pipes:

Forgings:

Studs:

Nuts:

35000.0 kg/hr

583.3 m3/hr

60.0 kg/m3

0.010 cP

4000.0 kg/hr

4.0 m3/hr

ASTM A 516 GR 70 (SE 2:1)

ASTM A 516 GR 70

ASTM A 106 GR B

ASTM A 105

ASTM A 193 B7

ASTM A 194 2H

SPIRAL WOUNDS SS NON ASBESTOS

37 Saddles/Skirt:

ASTM A 516 GR 70 / A 36

38

NO

Slug Flow:

NO

Foaming:

NIL

Solids:

NIL

K (Vessel):

0.15 m/s

Light Liquid Residence Time:

5.0 min.

Heavy Liquid Residence Time:

N/A min.

1000.0 kg/m3

Demister:

Type:

0.800 cP

Size (Dia. or LXW):

30.0 Dyn/cm

Thickness:

0.0 kg/hr

Flow Dist. Assembly:

0.0 m3/hr

Material:

0.0 kg/m3

Coalescer:

Type:

0.000 cP

Size (H X Dia.):

0.0 Dyn/cm

Thickness:

50 - 120 %

Material:

CONSTRUCTION MATERIALS

Antiwave Baffle:

CARBON STEEL

Inlet Baffle:

CARBON STEEL

Vortex Breaker:

CARBON STEEL

Weir Baffle:

CARBON STEEL

Other:

36 Gaskets:

0.1/ 0.1 % mole

WIRE-MESH

600

152

NO

SS 316 L

NONE

N/A

N/A

N/A

mm

mm

mm

mm

NOZZLES DATA

39

TAG

Qty

Dia. (in)

Type

Rating (#)

Sch.

40

10"

WNRF

900

Proj. (mm)

INLET

Service

41

10"

WNRF

900

GAS OUTLET

42

2"

WNRF

900

LIGHT LIQUID OUTLET

43

2"

WNRF

900

DRAIN

44

2"

WNRF

900

PSV

45

2"

WNRF

900

LEVEL TRANSMITTER

46

2"

WNRF

900

LEVEL GAUGE

47

20"

WNRF

900

MANWAY

48

P1/2

2"

WNRF

900

PRESSURE INST.

49

2"

WNRF

900

CHEMICAL INJECTION

50

T1/2

2"

WNRF

900

TEMP. INST.

Notes

51

52

53

54 Notes:

(1): Internals shall be removable type.

55

56

F-100: Hoja De Datos Separador Rev A.xls, Trabajo Profesional de Ingeniera Qumica, Facultad de Ingeniera de la Universidad de Buenos Aires

Document Number:

Page:

2003/X-V-HD-XXX

Revision:

SEPARATOR DATASHEET

57 Project:

58

Of:

V-XXX

DENOMINACIN DEL PROYECTO

59

VESSEL DIMENSIONS

OTHER REQUIREMENTS

60 Shell (OD x Ltt):

600 x 3500 mm

Instruments Clips Required:

61 Boot (OD x Ltt):

YES

- mm

Ladder / Platform Clips Required:

YES

62 Dome (OD x Ltt):

- mm

Other:

63 Saddles/Skirt (H):

1000 mm

64

65

SKETCH

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110 Notes:

111

112

F-100: Hoja De Datos Separador Rev A.xls, Trabajo Profesional de Ingeniera Qumica, Facultad de Ingeniera de la Universidad de Buenos Aires

S-ar putea să vă placă și

- Materiales y técnicas de moldeo y vaciado aplicados a obras de arteDe la EverandMateriales y técnicas de moldeo y vaciado aplicados a obras de arteÎncă nu există evaluări

- Hoja de Datos APIDocument20 paginiHoja de Datos APIdjcafÎncă nu există evaluări

- Hoja de DatosDocument14 paginiHoja de DatosHerrera Jorge AgustínÎncă nu există evaluări

- Calculo de Flare.1Document75 paginiCalculo de Flare.1Alba Duaneth Rocabado Mendieta100% (1)

- Cálculo de Vent - API STD 2000Document7 paginiCálculo de Vent - API STD 2000leslieÎncă nu există evaluări

- Diseño de Separador Horizontal Con BotaDocument16 paginiDiseño de Separador Horizontal Con BotaAnddy AÎncă nu există evaluări

- Calculo Tee EnvolventeDocument4 paginiCalculo Tee Envolventeluiscalderas1Încă nu există evaluări

- Memoria DescriptivaDocument19 paginiMemoria DescriptivarigoalfonzoÎncă nu există evaluări

- Calculos EvaporadoresDocument17 paginiCalculos EvaporadoresOliver Henry CamonesÎncă nu există evaluări

- Memoria de Calcculo de Proceso Filtro Coalescente PDFDocument9 paginiMemoria de Calcculo de Proceso Filtro Coalescente PDFyoselin Ayala RamosÎncă nu există evaluări

- Bombas C1Document34 paginiBombas C1mrpt2015Încă nu există evaluări

- MC Tanque Completo - Skimmer PDFDocument16 paginiMC Tanque Completo - Skimmer PDFRobertoAvilaÎncă nu există evaluări

- Diseño Sep. Trifasico (PDVSA)Document16 paginiDiseño Sep. Trifasico (PDVSA)Irene OjaraÎncă nu există evaluări

- Memoria de CalculoDocument23 paginiMemoria de CalculoAlfredo Bautista Hernández100% (1)

- Calculo de Un Recipiente Horizontal A PresionDocument4 paginiCalculo de Un Recipiente Horizontal A PresionJaime Ernesto ChitacapaÎncă nu există evaluări

- Flare Design Data Sheet SpanishDocument2 paginiFlare Design Data Sheet SpanishCarlos Salas Latos100% (1)

- Cálculo de VenteoDocument1 paginăCálculo de Venteo20040384iÎncă nu există evaluări

- 310920524DM42101 Memoria de Calculos de Refuerzos en Tuberias y Espesor Rev 0 ACT01Document37 pagini310920524DM42101 Memoria de Calculos de Refuerzos en Tuberias y Espesor Rev 0 ACT01DanielEstebanAlfonzoFermenal100% (2)

- Cálculo VenteoDocument3 paginiCálculo VenteofedericomoriÎncă nu există evaluări

- Calculos Segun Metodo Bell-DelawareDocument8 paginiCalculos Segun Metodo Bell-DelawareAnonymous HdENZfR100% (1)

- Copia de ASME Pressure Vessel Design-ADocument190 paginiCopia de ASME Pressure Vessel Design-Aebracho2002Încă nu există evaluări

- Separador Trifásico Hosizontal-EmilianoDocument19 paginiSeparador Trifásico Hosizontal-EmilianoEmiliano RodriguezÎncă nu există evaluări

- Catalogo Strainer (Filtros) de FundicionaDocument2 paginiCatalogo Strainer (Filtros) de FundicionaGabotecna67% (3)

- ING DETALLE GUN BARREL 301 FASE 1 Rev.0Document17 paginiING DETALLE GUN BARREL 301 FASE 1 Rev.0proyectos 20180% (1)

- Tea Ko Drum T-MBD-101Document19 paginiTea Ko Drum T-MBD-101carloslimasanchezÎncă nu există evaluări

- Calculo de SeparadoresDocument35 paginiCalculo de SeparadoresMario Avalos SalazarÎncă nu există evaluări

- Memoria de Calculo Torre de EnfriamientoDocument4 paginiMemoria de Calculo Torre de EnfriamientoEstuardo Javier Gan RodríguezÎncă nu există evaluări

- Diseño de Un Depurador de GasDocument31 paginiDiseño de Un Depurador de GasgadaywenÎncă nu există evaluări

- 3.diseño Techo Flotante S.DDocument40 pagini3.diseño Techo Flotante S.DFelix GomezÎncă nu există evaluări

- Cimentacion de Trampa de DiablosDocument43 paginiCimentacion de Trampa de DiablosRamos Javier100% (1)

- OT-0815-17-MCS-1 - Memoria de Calculo Separador Trifasico Rev. 0Document14 paginiOT-0815-17-MCS-1 - Memoria de Calculo Separador Trifasico Rev. 0NicandroGonzalesÎncă nu există evaluări

- Hoja de Datos Del FiltroDocument20 paginiHoja de Datos Del FiltroLU1228Încă nu există evaluări

- Flujo de Fluidos en Dos FasesDocument5 paginiFlujo de Fluidos en Dos FasesCarlos Alvarado C100% (1)

- KOD SizingDocument5 paginiKOD Sizingintania66Încă nu există evaluări

- Venteos API 2000 7th EditionDocument5 paginiVenteos API 2000 7th EditionRicardo LópezÎncă nu există evaluări

- Norma API Fondo de TanqueDocument7 paginiNorma API Fondo de TanqueHns Kvn ChavezÎncă nu există evaluări

- Mechurrio (Calculo de Radiacion)Document1 paginăMechurrio (Calculo de Radiacion)dani8887Încă nu există evaluări

- 0816 Precios UnitariosDocument361 pagini0816 Precios UnitariosMAEBÎncă nu există evaluări

- KOD SizingDocument6 paginiKOD SizingAris PurniawanÎncă nu există evaluări

- Hoja de Cálculo para KO DRUMDocument28 paginiHoja de Cálculo para KO DRUMFranklin SucllaÎncă nu există evaluări

- API 620 PrologoDocument15 paginiAPI 620 PrologoMariela Angeles RodriguezÎncă nu există evaluări

- MC Tanque SciDocument16 paginiMC Tanque Scihoke-14Încă nu există evaluări

- Calculo Tanque Segun API 650Document4 paginiCalculo Tanque Segun API 650lissettejimenezÎncă nu există evaluări

- Venas de VaporDocument17 paginiVenas de Vaporxela0100Încă nu există evaluări

- 3 - Criterios de Velocidad Caida de Presión TuberíasDocument5 pagini3 - Criterios de Velocidad Caida de Presión Tuberíasfructora100% (1)

- Ejemplo de Calculo de Espesores Requeridos Según ASME B31.8Document11 paginiEjemplo de Calculo de Espesores Requeridos Según ASME B31.8Daniel Arnez AhenkeÎncă nu există evaluări

- Dimensionamiento de PSVDocument18 paginiDimensionamiento de PSVAdrian LemosÎncă nu există evaluări

- Calculo de Tanque de AceiteDocument52 paginiCalculo de Tanque de AceiteEnrique Cvs100% (2)

- AeroenfriadorDocument3 paginiAeroenfriadorJosé AlanizÎncă nu există evaluări

- PEMEX CIMENTACIONES de Estructuras y EquiposDocument30 paginiPEMEX CIMENTACIONES de Estructuras y EquiposMagda ArriolaÎncă nu există evaluări

- 0500 Seleccion de Valvulas de Alivio de Presion-VacioDocument20 pagini0500 Seleccion de Valvulas de Alivio de Presion-VacioAbel Lopez JoachinÎncă nu există evaluări

- Data Sheet TanquesDocument28 paginiData Sheet TanquesWilmar100% (1)

- PI-SUP-55ANEXO6.4 Clases de ValvulasDocument69 paginiPI-SUP-55ANEXO6.4 Clases de ValvulasfrankcengelÎncă nu există evaluări

- Memoria de Calculo TK DecantadorDocument6 paginiMemoria de Calculo TK DecantadorAndres Fernando Cano UrreaÎncă nu există evaluări

- Intercambiadores de PlacasDocument7 paginiIntercambiadores de PlacasMB GustavoÎncă nu există evaluări

- Catalogo Valvulas BrayDocument8 paginiCatalogo Valvulas BrayVladimir SepulvedaÎncă nu există evaluări

- Acido SulfuricoDocument37 paginiAcido SulfuricoJose Luis Sosa LopezÎncă nu există evaluări

- Ipso Dr25 GH - LitesDocument8 paginiIpso Dr25 GH - LitesgiovannichavezÎncă nu există evaluări

- ARA Ejemplo de Calculo de Estanques Segun API 650Document13 paginiARA Ejemplo de Calculo de Estanques Segun API 650Marcelo Elgueta89% (9)

- Planilla de Cálculo de Estanques Según API 650Document13 paginiPlanilla de Cálculo de Estanques Según API 650roconero80100% (1)

- Adherencias Peritoneales - SACDDocument8 paginiAdherencias Peritoneales - SACDR4pT0r666Încă nu există evaluări

- MI6112 Clase6aDocument10 paginiMI6112 Clase6aIsmaelCruzÎncă nu există evaluări

- Calculo de La Presion de Alta P Arranque de MolinosDocument3 paginiCalculo de La Presion de Alta P Arranque de MolinosVolney Quispe AyalaÎncă nu există evaluări

- Prototipo de CeldaDocument5 paginiPrototipo de CeldaAlvaro Contreras VildoÎncă nu există evaluări

- MI6112 Clase6aDocument10 paginiMI6112 Clase6aIsmaelCruzÎncă nu există evaluări

- MI6112 Clase5Document12 paginiMI6112 Clase5IsmaelCruzÎncă nu există evaluări

- Vymsa2012 UCDocument6 paginiVymsa2012 UCTania Maiz CespedesÎncă nu există evaluări

- RedesDocument4 paginiRedesMolly ChaseÎncă nu există evaluări

- MI52E - Guia de Laboratorio 20010-02Document5 paginiMI52E - Guia de Laboratorio 20010-02IsmaelCruzÎncă nu există evaluări

- Hazw Pitar 2 3Document2 paginiHazw Pitar 2 3radacoÎncă nu există evaluări

- Factor de FriccionDocument2 paginiFactor de FriccionIsmaelCruzÎncă nu există evaluări

- Clases de CaneriasDocument45 paginiClases de CaneriasIsmaelCruzÎncă nu există evaluări

- Lista LineasDocument7 paginiLista LineasIsmaelCruzÎncă nu există evaluări

- Lista de Documentos - BaseDocument9 paginiLista de Documentos - BaseIsmaelCruzÎncă nu există evaluări

- ET - AislacionDocument6 paginiET - Aislacionjonito87Încă nu există evaluări

- Diagrama Bloques - TipoDocument1 paginăDiagrama Bloques - TipoIsmaelCruzÎncă nu există evaluări

- Informe Final PipingDocument51 paginiInforme Final Pipingseloso01Încă nu există evaluări

- Informe CorreasDocument45 paginiInforme CorreasPedro Pablo Fernández FernándezÎncă nu există evaluări

- Depuratori A Ciclone PR Scheda TecnicaDocument8 paginiDepuratori A Ciclone PR Scheda TecnicaIsmaelCruzÎncă nu există evaluări

- Documentos Tecnicos Del Proyecto (Piping)Document49 paginiDocumentos Tecnicos Del Proyecto (Piping)Franciscus Xaverius Noval100% (3)

- Calculos PSVDocument12 paginiCalculos PSVAndres100% (1)

- Control de ProcesoDocument24 paginiControl de ProcesoPiruloSanchezÎncă nu există evaluări

- Diseno de Sistema de AntorchaDocument16 paginiDiseno de Sistema de AntorchaBernardo Escalante Higuera100% (1)

- Principios de Valvulas de SeguridadDocument19 paginiPrincipios de Valvulas de SeguridadHARBJA100% (1)

- Capitulos+PFC/4 +equipos+auxiliaresDocument15 paginiCapitulos+PFC/4 +equipos+auxiliaresluiasnadradeÎncă nu există evaluări

- Calculos PSVDocument12 paginiCalculos PSVAndres100% (1)

- Clase Teorica Lay OutDocument43 paginiClase Teorica Lay OutbismarckandresÎncă nu există evaluări

- Casos de Control AutomaticoDocument34 paginiCasos de Control AutomaticoIsmaelCruzÎncă nu există evaluări

- Consumo Servicios Auxiliares - IndiceDocument4 paginiConsumo Servicios Auxiliares - IndiceIsmaelCruzÎncă nu există evaluări

- Cuestionario Inicial 4 Laboratorio de Fundamentos de Mecánica FES AragonDocument8 paginiCuestionario Inicial 4 Laboratorio de Fundamentos de Mecánica FES AragonJosué González MacíasÎncă nu există evaluări

- ManualUsuario MEP V4.0Document15 paginiManualUsuario MEP V4.0CLAUDIO TOSOLINIÎncă nu există evaluări

- Google MapsDocument31 paginiGoogle MapsJosé lenin López Pérez 3AÎncă nu există evaluări

- LENGUAJE - El Sustantivo - Tipos de Sustantivos ' ('1ero de Secundaria') 'Document80 paginiLENGUAJE - El Sustantivo - Tipos de Sustantivos ' ('1ero de Secundaria') 'Mía Frías LaosÎncă nu există evaluări

- Aplicación de Técnicas PreventivasDocument95 paginiAplicación de Técnicas PreventivasPipe CastroÎncă nu există evaluări

- Conceptos Fundamentales Del Derecho InternacionalDocument25 paginiConceptos Fundamentales Del Derecho InternacionalIsrael ChavarriaÎncă nu există evaluări

- Grupo 6 - Caso Abb S.ADocument4 paginiGrupo 6 - Caso Abb S.AnickÎncă nu există evaluări

- Ensayo TabacoDocument13 paginiEnsayo TabacoNanci EsquivelÎncă nu există evaluări

- E. T. A. Hoffmann - Cuadros NocturnosDocument129 paginiE. T. A. Hoffmann - Cuadros NocturnosRaúl ValenciaÎncă nu există evaluări

- Pa3 Gesti N ProfesionalDocument8 paginiPa3 Gesti N ProfesionalGerardo QuezadaÎncă nu există evaluări

- Bobinas o InductoresDocument7 paginiBobinas o Inductoresmartin lili cobosÎncă nu există evaluări

- A1 Aplicacion Planeacion Estrategica MICROEMPRESADocument130 paginiA1 Aplicacion Planeacion Estrategica MICROEMPRESADarlenis RodriguezÎncă nu există evaluări

- Un Curso de Milagros para NiñosDocument173 paginiUn Curso de Milagros para Niñosmariasoledadflores32Încă nu există evaluări

- Hodelpe Plataforma de Homologacion CmssDocument3 paginiHodelpe Plataforma de Homologacion CmssOssWissÎncă nu există evaluări

- Trigonometria Cuzcan 91020 Downloadable 3971038Document36 paginiTrigonometria Cuzcan 91020 Downloadable 3971038caleb pÎncă nu există evaluări

- Características de Los EmprendedoresDocument2 paginiCaracterísticas de Los EmprendedoresAlfredoÎncă nu există evaluări

- Leccion 1Document2 paginiLeccion 1leonel21Încă nu există evaluări

- Enzimas de RestricciónDocument3 paginiEnzimas de RestricciónMarco Osuna100% (1)

- Autocontrol Emocional Ce 2021Document17 paginiAutocontrol Emocional Ce 2021JuanCarbajalRondonÎncă nu există evaluări

- 1 Respuestas Prueba Análisis de RiesgoDocument2 pagini1 Respuestas Prueba Análisis de RiesgoArans AckÎncă nu există evaluări

- Cromosomas de Los AnimalesDocument15 paginiCromosomas de Los Animalescheleon_7Încă nu există evaluări

- Fuenmayor 1975-Slogans Divorcistas PDFDocument32 paginiFuenmayor 1975-Slogans Divorcistas PDFAnonymous LnTsz7cpÎncă nu există evaluări

- Preguntas Examen MantenimientoDocument8 paginiPreguntas Examen MantenimientoBorja CerraÎncă nu există evaluări

- Funciones y Modelos MatemáticosDocument25 paginiFunciones y Modelos MatemáticosMario LÎncă nu există evaluări

- El Libre ArbitrioDocument22 paginiEl Libre ArbitrioWillianfilosofoÎncă nu există evaluări

- MezclasDocument2 paginiMezclasLluvia de Otoño100% (1)

- Informe CognitivaDocument10 paginiInforme CognitivaLougi GiraldoÎncă nu există evaluări

- Bibliografia de Isaac NewtonDocument2 paginiBibliografia de Isaac NewtonCindel FloresÎncă nu există evaluări

- Cuadro de Niveles de Comprensión Lectora y Preguntas: Equipo: Nombre de Los Estudiantes: William Olssen Gómez GonzálezDocument3 paginiCuadro de Niveles de Comprensión Lectora y Preguntas: Equipo: Nombre de Los Estudiantes: William Olssen Gómez GonzálezManuelÎncă nu există evaluări

- Guia de RadioDocument17 paginiGuia de RadioJiskah BastiÎncă nu există evaluări