Documente Academic

Documente Profesional

Documente Cultură

Northern Stamping Improves Efficiency

Încărcat de

api-298163557Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Northern Stamping Improves Efficiency

Încărcat de

api-298163557Drepturi de autor:

Formate disponibile

CASE STUDY

NORTHERN STAMPING, INC. - CLEVELAND, OH

Northern Stamping Improves Efficiency in

Automated Tube Manufacturing System

The Situation

Northern Stamping Inc. (NSI), a designer,

developer and manufacturer of complex

structural components and welded

assemblies for the global automotive

market, was tasked with building

heavy-duty trailer hitches. In their efforts

to fulfill their customers requirements, NSI

encountered problems with tube bending

equipment that was frequently failing and

costing several hours per day in repair time.

Wayne Trail not only resolved the

frequent equipment failures and

resulting down-time at NSI, but also

enhanced the overall system by opening

up options for future processing needs.

NORTHERN STAMPING, INC. - CLEVELAND, OH

CASE STUDY

The Solution

NSI contacted Wayne Trail, a Lincoln Electric company, for

advice about how to fix the issues with their existing tube bender.

After further discussion and review of their bending process,

Wayne Trail explained that replacement of the automated tube

manufacturing cell was only part of what needed to happen to fix

their manufacturing process. They recommended replacement of

the weld fixture into which the bent trailer hitch fit, and educated

NSI about the importance of ensuring that the bent materials were

meeting required tolerances. The previous bender had been unable

to withstand the forces required to bend the large-diameter,

thick-wall tube, which caused problems with maintaining the

necessary tolerances.

The fitting of parts into a weld fixture is important, as it enables

the tube assembly to be welded correctly, said Mike Bollheimer,

product manager at Wayne Trail. Our team that built the

bending equipment worked hand in hand with the team that built

the weld fixture. This was a benefit to Northern Stamping since the

Wayne Trail equipment could now assume sole responsibility for

how the tube was formed and how it fit in the weld fixture. The

previous system had been built by two separate contractors one

for the bender and one for the weld fixtures.

In the end, Wayne Trail not only resolved the frequent equipment

failures and resulting down-time in the tube bending process, but

they also enhanced the overall system by opening up options for

future processing needs. Wayne Trail looked into the entire process

and what NSI needed to be successful in the industry.

Wayne Trail worked closely with NSI in the handling of several

design changes over the course of the project build, said Jeff Baxter,

automation engineer, NSI. When there was a change, and sample

parts were required to do further testing, Wayne Trail helped by

providing prototypes.

Within weeks after the system installation was complete, NSI

experienced improved efficiency with the new bending system

built by Wayne Trail. The system performed exactly as needed, and

the need for repairs was greatly diminished.

Built-in Flexibility

NSI has only begun to reap the full benefit of its partnership with

Wayne Trail. Thanks to the newly installed manufacturing cell, NSI

now has the flexibility to install additional manufacturing modules

that could perform other tasks as needed, such as end forming, hole

piercing and part separation. When the current trailer hitch program

is complete, the system will be re-tooled to enable the manufacture

of additional tube configurations. A variety of functions will continue

to be performed at high efficiency for years to come.

MC14-36 05/14 Lincoln Global, Inc. All Rights Reserved.

UNITED STATES

22221 Saint Clair Ave.

Cleveland, Ohio 44117-2552

Phone: +1.888.935.3878

CANADA

939 Gana Court

Mississauga, Ontario L5S 1N9

Phone: +1.905.565.5600

MEXICO

Calzada Azcapotzalco-La Villa 869

Industrial Vallejo, Mexico DF CP 02330

Phone: +52.55.5063.0330

Email: Automation@lincolnelectric.com

www.lincolnelectric.com/automated-solutions

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Heroic Tales Core Rules 1.1.0Document33 paginiHeroic Tales Core Rules 1.1.0Melobajoya MelobajoyaÎncă nu există evaluări

- Syllabus ClinPhar143Document2 paginiSyllabus ClinPhar143Angel GoÎncă nu există evaluări

- JIS-G3455 - Carbon Steel Pipes For High Pressure ServiceDocument27 paginiJIS-G3455 - Carbon Steel Pipes For High Pressure ServiceHoang Tan100% (1)

- How Plants SurviveDocument16 paginiHow Plants SurviveGilbertÎncă nu există evaluări

- Mooka Panchsati Arya SatakamDocument18 paginiMooka Panchsati Arya SatakamPrasad Raviprolu100% (1)

- Characteristics of Victorian BritainDocument3 paginiCharacteristics of Victorian BritainmwaqasenggÎncă nu există evaluări

- Annex A2 - CS Form 100 - Revised 2023 - CSESP - A1 - Edited - A1Document2 paginiAnnex A2 - CS Form 100 - Revised 2023 - CSESP - A1 - Edited - A1obs.obando2022Încă nu există evaluări

- Chapter 3Document26 paginiChapter 3Francis Anthony CataniagÎncă nu există evaluări

- Robe Draft Geotechnical Report - Edited by k2nDocument43 paginiRobe Draft Geotechnical Report - Edited by k2nASAMNEW GULILATÎncă nu există evaluări

- Shaheed Suhrawardy Medical College HospitalDocument3 paginiShaheed Suhrawardy Medical College HospitalDr. Mohammad Nazrul IslamÎncă nu există evaluări

- Principles of Marketing: Strategic Planning and The Marketing ProcessDocument16 paginiPrinciples of Marketing: Strategic Planning and The Marketing ProcessAneel ZiaÎncă nu există evaluări

- Transfer CaseDocument46 paginiTransfer Casebantuan.dtÎncă nu există evaluări

- 08 - Chapter 1Document48 pagini08 - Chapter 1danfm97Încă nu există evaluări

- File Server Resource ManagerDocument9 paginiFile Server Resource ManagerBùi Đình NhuÎncă nu există evaluări

- 1st Quarter 2016 Lesson 5 Powerpoint With Tagalog NotesDocument25 pagini1st Quarter 2016 Lesson 5 Powerpoint With Tagalog NotesRitchie FamarinÎncă nu există evaluări

- Light Design by Anil ValiaDocument10 paginiLight Design by Anil ValiaMili Jain0% (1)

- Good Data Won't Guarantee Good DecisionsDocument3 paginiGood Data Won't Guarantee Good DecisionsAditya SharmaÎncă nu există evaluări

- Ellis Lived ExperiencesDocument31 paginiEllis Lived ExperiencesJeanny Mae PesebreÎncă nu există evaluări

- Eps 400 New Notes Dec 15-1Document47 paginiEps 400 New Notes Dec 15-1BRIAN MWANGIÎncă nu există evaluări

- 61-Article Text-180-1-10-20170303 PDFDocument25 pagini61-Article Text-180-1-10-20170303 PDFSOUMYA GOPAVARAPUÎncă nu există evaluări

- Apache Nifi Tutorial - What Is - Architecture - InstallationDocument5 paginiApache Nifi Tutorial - What Is - Architecture - InstallationMario SoaresÎncă nu există evaluări

- POLAR BEARS-Biology ProjectDocument16 paginiPOLAR BEARS-Biology Projectserwaa21Încă nu există evaluări

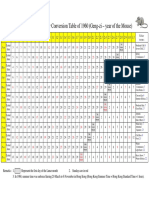

- Gregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Document1 paginăGregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Anomali SahamÎncă nu există evaluări

- Culture Performance and Economic Return of Brown ShrimpDocument8 paginiCulture Performance and Economic Return of Brown ShrimpLuã OliveiraÎncă nu există evaluări

- Vacuum Braking SystemDocument20 paginiVacuum Braking SystemPrashant RaiÎncă nu există evaluări

- Worship Aid - May Crowning 2020Document5 paginiWorship Aid - May Crowning 2020Kevin RyanÎncă nu există evaluări

- IBDP Physics Oxford David - Homer Course Ebook 4th Edition-2014 CH-1Document27 paginiIBDP Physics Oxford David - Homer Course Ebook 4th Edition-2014 CH-1Milek Anil KumarÎncă nu există evaluări

- Acute Conditions of The NewbornDocument46 paginiAcute Conditions of The NewbornCamille Joy BaliliÎncă nu există evaluări

- Concept of ConstitutionDocument32 paginiConcept of ConstitutionDorepe Icon0% (1)

- Lier Upper Secondary SchoolDocument8 paginiLier Upper Secondary SchoolIES Río CabeÎncă nu există evaluări