Documente Academic

Documente Profesional

Documente Cultură

Rrs Unit 3

Încărcat de

api-297121029Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Rrs Unit 3

Încărcat de

api-297121029Drepturi de autor:

Formate disponibile

SEMBODAI RUKMANI VARATHARAJAN

ENGINEERING COLLEGE

DEPARTMENT OF CIVIL ENGINEERING

Repair & Rehabilitation of structures

BY

KARTHIVELU

Prepared by S.Karthivelu AP CIVIL

Concrete

made with OPC shrinks while

setting due to loss of free water.

Concrete also shrinks continuously for long

time. This is known as dry shrinkage.

The Expansive cement which will expand

while hardening.

It

has been developed by using an expanding

agent & a stabiliser very carefully.

8-20

part of the sulpho-aluminate clinker are

mixed with 100 parts of the Portland cement

and 15part of Prepared

thebystabiliser

S.Karthivelu AP CIVIL

2

The

expansive cement used for grouting

anchor bolts or grouting machine

foundation.

The expansive cement used in grouting the

pre-stressed concrete duck

Expansion takes place only so long as

concrete is moist, curing must be

controlled.

The use of expanding cement requires

skilled and experiences.

One type of expanding cement is known as

shrinkage compensating cement.

Prepared by S.Karthivelu AP CIVIL

Sulphur

is heated to bring it into molten

condition to which coarse and fine aggregate are

poured and mixed together.

Sulphur

of purity 99.9% are used.

A large number of trial mix are mode to determine

the best mix proportion.

The water cement ration of 0.7 or over as been

adopted in all the trial.

After 24 hours of moist curing the specimen is dried

in heating cabinate for 24 hours in 1210c.

Then the dried specimen are placed in a container

0c AP

Prepared

S.Karthivelu

CIVIL

of molten sulphur

atby121

for

3 hours

4

Sulphur

having strength impregnation as

shown great improvement in strength.

Physical properties improve by several

100% and large improvement in water impermeability.

Improved Resistance to corrosion

Sulphur can also be used as a binding

material instead of cement.

Better acid and chemical resistance.

It is costlier than ordinary cement concrete.

Prepared by S.Karthivelu AP CIVIL

The

quantity of sulphur used is also

comparatively less and the process is made

economical.

Its compressive strength of about 100mpa

could be achieved in about 2 days.

It is used in precast industries (Not in cast in

situ) to produce roofing element, fencing

post, sewer pipes and railway sleeper.

Sulphur infiltrated precast concrete unit is

cheaper than commercial concrete.

The techniques are simple effective and in

expansive Prepared by S.Karthivelu AP CIVIL

The

plain concrete possesses a very low

tensile strength limited ductility and little

resistance to cracking. It is because of micro

cracks (few microns width) & its

propagation.

In plain concrete structural cracks develop

even before loading (due to self weight).

Tensile property of concrete members is

improved by using reinforced steel bar.

This method provide tensile strength to the

Prepared by S.Karthivelu AP CIVIL

concrete member.

It

has been recognised that the addition of

small, discontinuous, closely spaced and

uniformly dispersed fibres to mortar or

concrete would act as crack arrestee and

would substantially improve its static and

dynamics properties

The

mixture of cement, aggregate, water

and small, discontinuous, closely spaced

and uniformly dispersed fibres is called

Preparedconcrete.

by S.Karthivelu AP CIVIL

fibre reinforced

Prepared by S.Karthivelu AP CIVIL

Prepared by S.Karthivelu AP CIVIL

10

Continuous

research by concrete

technologist to understand, improve and

develop the properties of the concrete.

It is concaved by many research workers

that reduction of porosity results in increase

of strength of concrete.

The porosity is due to air voids, water voids

due to porosity of gel structure itself.

The process like vibration, pressure

application spinning etc., has been

Prepared by S.Karthivelu

AP CIVIL

practiced mainly

to reduce

porosity.

11

Polymerisation

is the latest technique

adopts to reduce the porosity of the

concrete & to improve the strength and

other properties of the concrete.

Which

is done by combining the ancient

technology of cement with the Morden

technology of polymer chemistry

Prepared by S.Karthivelu AP CIVIL

12

Polymer

impregnated concrete(PIC)

Polymer

cement concrete (PCC)

Polymer

concrete (PC)

Partially

impregnated and surface coated

polymer concrete

Prepared by S.Karthivelu AP CIVIL

13

PIC

is one of the widely used polymer

composite.

types

of monomer used

Methyl-metha-cry late

Styrene, acrylo nitrate, T-butyl styrene

Other thermo plastic monomer

Prepared by S.Karthivelu AP CIVIL

14

The

amount of monomer into a concrete

specimen is limited by total(water & air)

voids space.

The

vacuum or thermal drying is used for

rapid removal of water.

The

specimen prior to soaking in

monomer the application of the pressure is

another technique to reduce monomer

loading time.Prepared by S.Karthivelu AP CIVIL

15

PCC

is made by mixing cement,

aggregate, water and monomer such

plastic mixture is cast in mould, cured,

dried and polymerised.

Monomer used (polyester styrene, epoxy

styrene, furnus, vinylidene chloride)

It

have

shown

relatively

modest

improvement of strength and durability.

Pcc+furly alcohol and aniline hydro

chloride in the wet mix to have high

Prepared by S.Karthivelu AP CIVIL

corrosion resistance.

16

PC

is an aggregate bond with a polymer

binder instead of Portland cement.

The main technique is producing PC is to

minimum voids volume in aggregate.

Proper grading and mixing the

aggregate attain the maximum density

and min voids volume and hence reduce

the quantity of polymer needed for

binding the aggregate.

Prepared by S.Karthivelu AP CIVIL

17

silence coupling agent is added to the

monomer to improve the bond strength

between polymer and aggregate.

PC tends to the brittle and it is reported

that dispersion of fibre reinforcement

would improve the toughness and tensile

strength of the material.

PC has high resistance to chemical attack.

The strength obtained PC can be as high

140Mpa with a short curing period.

Prepared by S.Karthivelu AP CIVIL

18

The

specimen is applied by liquid monomer

like methyl cry late minimise loss due to

evaporation.

The

depth of monomer penetration is

dependent upon

I. Pore structure of harden and dried

concrete

II. The duration of soaking

III. The viscosity of the monomer.

Prepared by S.Karthivelu AP CIVIL

19

The

potential application of polymer

impregnated concrete surface treatment

is in improving the durability of concrete

bridge deck.

It

gives increases in the tensile &

compressive strength, modulus of

elasticity and resistance to acid attack

have been achieved

Prepared by S.Karthivelu AP CIVIL

20

Prepared by S.Karthivelu AP CIVIL

21

Cement

mortar matrix is reinforced with

many layers of continuous and relatively

small diameter wire mesh.

The Ferro cement composite is arch cement

water matrix of 10-60mm thick.

The

wire mesh imparts tensile strength and

ductility to the material & also the

engineering properties such as toughness,

fatigue resistance, Impermeable etc., are

by S.Karthivelu AP CIVIL

considerablyPrepared

improved.

22

Portland

cement and fine aggregate matrix is

used in Ferro cement.

The choice of cement depends on the service

condition to maintain the quality of cement, in

should be fresh of uniform consistency and

free lumps.

Cement should be stored under dry condition

and used as for as short duration as possible.

Plasticizer and other admixture may also be

added for achieving increase in strength,

reduction in permeability, water proofing,

increasing durability prevent galvanic

Prepared by S.Karthivelu APsteel.

CIVIL

corrosion of galvanised

23

The

reinforcement used in Ferro cement

is of two types skeleton steel and wire

mesh.

Welded wire fabric of 3 to 4mm dia wire

welded 80 100m c/c.

The reinforcement should be free from

dust loose rust coating of paint oil or

similar undesirable substance.

Reinforcing bars may be used in

combination with wire messes for

Prepared by

S.Karthivelu AP

CIVIL

relatively thick

Ferro

cement

element.

24

Prepared by S.Karthivelu AP CIVIL

25

Ferro

cement structures are thin and light.

Considerable reduction in the self-weight of

structure.

Precast unit which can be easily transported.

Does not require skilled labour.

Partially or complete elimination of form

work in possible.

Ferro cement construction is easily

amenable to repair in case of local damage

due to abnormal load.

Prepared by S.Karthivelu AP CIVIL

26

Prepared by S.Karthivelu AP CIVIL

27

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- How To Start An Oil and Gas CompanyDocument8 paginiHow To Start An Oil and Gas CompanyNk Novia100% (2)

- Kerala Sea Plane Project - Detailed Project Report (DPR)Document38 paginiKerala Sea Plane Project - Detailed Project Report (DPR)Shajit KumarÎncă nu există evaluări

- Supply Chain ManagementDocument15 paginiSupply Chain ManagementKarthik Arumugham100% (2)

- Course ProposalDocument4 paginiCourse Proposalapi-297121029Încă nu există evaluări

- On Regid PavementsDocument38 paginiOn Regid PavementsramireddyÎncă nu există evaluări

- Unit II Geometric Design of HighwaysDocument30 paginiUnit II Geometric Design of Highwaysapi-297121029Încă nu există evaluări

- 5 Question Bank RrsDocument7 pagini5 Question Bank Rrsapi-297121029Încă nu există evaluări

- 1 ContentDocument12 pagini1 Contentapi-297121029Încă nu există evaluări

- 12 Assignment Ques PaperDocument3 pagini12 Assignment Ques Paperapi-297121029Încă nu există evaluări

- 5 Question BankDocument11 pagini5 Question Bankapi-297121029Încă nu există evaluări

- Unit-I Highway Planning and AlignmentDocument64 paginiUnit-I Highway Planning and Alignmentapi-297121029Încă nu există evaluări

- 4 Lesson Plan RrsDocument2 pagini4 Lesson Plan Rrsapi-297121029Încă nu există evaluări

- 4 1 Syllabus DRCDocument2 pagini4 1 Syllabus DRCapi-297121029Încă nu există evaluări

- 12 Assignment Ques Paper RrsDocument2 pagini12 Assignment Ques Paper Rrsapi-297121029Încă nu există evaluări

- Innovative Ideas For Manufacturing of The Green Concrete by Utilizing The Used Foundry Sand and PozzocreteDocument5 paginiInnovative Ideas For Manufacturing of The Green Concrete by Utilizing The Used Foundry Sand and Pozzocreteapi-297121029Încă nu există evaluări

- 4 1 SyllabusDocument2 pagini4 1 Syllabusapi-297121029Încă nu există evaluări

- 4 1 SyllabusDocument2 pagini4 1 Syllabusapi-297121029Încă nu există evaluări

- 12 Assignment Ques Paper RrsDocument2 pagini12 Assignment Ques Paper Rrsapi-297121029Încă nu există evaluări

- 5 Question BankDocument8 pagini5 Question Bankapi-297121029Încă nu există evaluări

- 4 Lesson Plan DRCDocument2 pagini4 Lesson Plan DRCapi-297121029Încă nu există evaluări

- Green Concrete For Sustainable ConstructionDocument5 paginiGreen Concrete For Sustainable ConstructionInternational Journal of Research in Engineering and TechnologyÎncă nu există evaluări

- 4 Experimental Investigation On Strength Characteristics of Shear Strength of Metakaolin Blended Glass Fibre Reinforced ConcreteDocument6 pagini4 Experimental Investigation On Strength Characteristics of Shear Strength of Metakaolin Blended Glass Fibre Reinforced Concreteapi-297121029Încă nu există evaluări

- 5 Question Bank DRCDocument8 pagini5 Question Bank DRCapi-297121029Încă nu există evaluări

- CEN032015 Binder Record PDFDocument3 paginiCEN032015 Binder Record PDFAnonymous i8hifn7Încă nu există evaluări

- Watretank 4Document40 paginiWatretank 4api-297121029Încă nu există evaluări

- Nano Particles in HighDocument5 paginiNano Particles in Highapi-297121029Încă nu există evaluări

- 12 Assignment Ques PaperDocument3 pagini12 Assignment Ques Paperapi-297121029Încă nu există evaluări

- Watertank 5Document64 paginiWatertank 5api-297121029Încă nu există evaluări

- RetainingwallDocument59 paginiRetainingwallapi-297121029Încă nu există evaluări

- SyllabusDocument16 paginiSyllabusapi-297121029Încă nu există evaluări

- NotificationDocument14 paginiNotificationapi-297121029Încă nu există evaluări

- Watertank 3Document38 paginiWatertank 3api-297121029Încă nu există evaluări

- Cen 03 2015 NTPC GDocument10 paginiCen 03 2015 NTPC GTusharr AhujaÎncă nu există evaluări

- KPI - Port of LADocument28 paginiKPI - Port of LAsambitpandaÎncă nu există evaluări

- Amateur-Built Fabrication and Assembly Checklist (2011) (Helicopter)Document9 paginiAmateur-Built Fabrication and Assembly Checklist (2011) (Helicopter)Bowtie41Încă nu există evaluări

- Structural Civil Engineer - Sample CV 1Document5 paginiStructural Civil Engineer - Sample CV 1ArnabÎncă nu există evaluări

- Pre-Engineered Buildings and Geodesic Structures (4B - Grou 1Document35 paginiPre-Engineered Buildings and Geodesic Structures (4B - Grou 1Chrisel DyÎncă nu există evaluări

- Bridge CourseDocument2 paginiBridge CourseferÎncă nu există evaluări

- Asphalt Concrete PavingDocument16 paginiAsphalt Concrete Pavingprobook450_ehsanÎncă nu există evaluări

- IDA-Internal Telecommunication WiringDocument32 paginiIDA-Internal Telecommunication WiringZhu Qi WangÎncă nu există evaluări

- Metro Railway BookletDocument12 paginiMetro Railway BookletNikhil FutaneÎncă nu există evaluări

- Standard Specification FOR Shop AND Field PaintingDocument5 paginiStandard Specification FOR Shop AND Field PaintingRanjan KumarÎncă nu există evaluări

- Civil Engineering Ramses A Larabel Lee High SchoolDocument5 paginiCivil Engineering Ramses A Larabel Lee High Schoolapi-355173776Încă nu există evaluări

- Norris Pro-Rod Coiled RodDocument8 paginiNorris Pro-Rod Coiled RodMohamed GhareebÎncă nu există evaluări

- A Beginners Guide To Choosing Your Private JetDocument5 paginiA Beginners Guide To Choosing Your Private JetAnish ShakyaÎncă nu există evaluări

- Supply Chain McdonaldsDocument9 paginiSupply Chain McdonaldsAditya MayekarÎncă nu există evaluări

- Land Value Capture Case Study PDFDocument45 paginiLand Value Capture Case Study PDFSamir SharmaÎncă nu există evaluări

- Article On 'Composite Materials in Construction Industry' by Chaitanya Raj GoyalDocument5 paginiArticle On 'Composite Materials in Construction Industry' by Chaitanya Raj GoyalChaitanya Raj GoyalÎncă nu există evaluări

- China Rising PharmaceuticalsDocument4 paginiChina Rising PharmaceuticalsKarthik PitaniÎncă nu există evaluări

- Excavators:: Mohammad Suhail SiddiquiDocument20 paginiExcavators:: Mohammad Suhail SiddiquiTalha SiddiquiÎncă nu există evaluări

- High Feed Milling by SECODocument48 paginiHigh Feed Milling by SECObangash1975Încă nu există evaluări

- Packaging MaterialsDocument15 paginiPackaging MaterialsShraddha Ghag100% (1)

- FM Buying Cycle AssignmentDocument13 paginiFM Buying Cycle AssignmentKartik SinghÎncă nu există evaluări

- Shikhar Insurance Company LTDDocument2 paginiShikhar Insurance Company LTDSamsher AliÎncă nu există evaluări

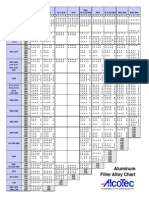

- Aluminum Filler Alloy Selection ChartDocument2 paginiAluminum Filler Alloy Selection Chartbtgottlieb100% (2)

- Edited Excavation, Shoring, Dewatering & Construction MsDocument6 paginiEdited Excavation, Shoring, Dewatering & Construction MsArun Chandra Babu100% (1)

- CastingDocument21 paginiCastingVinitJoryÎncă nu există evaluări

- Asme Section II A-2 Sa-645 Sa-645mDocument6 paginiAsme Section II A-2 Sa-645 Sa-645mAnonymous GhPzn1xÎncă nu există evaluări

- Future Concepts: Core CompetencyDocument3 paginiFuture Concepts: Core CompetencyPrashanthÎncă nu există evaluări

- Material Data Sheet: Material Number Country DesignationsDocument29 paginiMaterial Data Sheet: Material Number Country Designationsdandan29Încă nu există evaluări