Documente Academic

Documente Profesional

Documente Cultură

03 Using ATail Crane C

Încărcat de

demidover0 evaluări0% au considerat acest document util (0 voturi)

2 vizualizări2 paginiUsing Tail Crane C

Titlu original

03UsingATailCraneC

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentUsing Tail Crane C

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

2 vizualizări2 pagini03 Using ATail Crane C

Încărcat de

demidoverUsing Tail Crane C

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 2

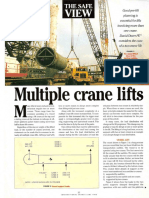

‘The subject of this article Isa pressure vessel of

520 tonnes which has tobe erected by means of

‘ovo main it cranes and one alerane. The pres

sure vessels as shown in Figure L

‘Weewill make use ofthe technique which we

learned in the previous alleles and which can

be summarised as:

"8 Taibloads can be reduced by olseting the

tating ug.

1 TalHloads ean be reduced by positioning the

‘main ling trunnions close to the column's

centre gravity (C.of6).

ENORMOUS CRANE

‘The eno:mous weight and lengt of the column

‘mean that avery large crane would be needed

toereetitinasinge lit.

An alternative method would be the erecton

ofthls column by means ofa mast gantry system

(or Gin Poles), The use of suct a liting gantry is

though time consuming and occuples a large

area of the construction site due to guywires

‘which are in any cases neaded Gules iting

gantcies are avalable as wall but they stil

equire arather big crane t assist inthe erection

‘ofthe gantry itsll. Another disadvantage ofthe

‘act gantry system fs the high pln load under-

eat the legs of the gantry, which must be

bgorbed by specally constructed foundations.

Depending. the location othe jobsite, use

‘of two main Ht eranes and one talleane offers

In general afar more efficient, econamical and

luster erection method than the use of hiting

gantres, Remote areas are really the only

‘exception to this

OVERLOAD DANGER!

Inti antici we wil iit ourselves tothe erec-

tion of 520 tonnes pressure vessel by means of

‘we man if cranes and oe tallerene. The main

consideration whieh we have o observes: low

‘4a we onitor the lsd in exch main lit rane A

and B duringthe erection procedure?

‘Aseach main lit cranes connected directly

to the main liting trunnion (See Fig), and not

‘through an equaling spreader beam, the danger

exists that one ofthe cranes coud be overloaded

Ifthey donot the column atthe same spd.

‘The solution is rather simple: We have to

tse a device which accurately measures the

position of each liting trunnion in relation to

the horizon during the entire erection proce

dur, so that we can adjust the bltng speed of

‘the main lt eranes accordingly. Whea both If

Jngtrunnions are keptin a horizontal plane dur

THE SAFE VIEW

Inge li, then there willbene overload in any

ofthe two main it eranes,

However, {crane A Wis faster then crane B,

Ut will result in an overload of crane A

Depending on the distance ofthe main liting

{runnion to the Cot G, this overload could be

Insigntiant or could be dangerous. iis thus

necessary to calculate these conditions belore

starting the lift. tis also important te keep both

‘main iting trunnions ina horizontal plane dur

Ing the Lit. Following are sore caleulations of

the overload on "A" or“B° when both trunnions

arenot kept horizontal.

‘Suppose tha our pressure vessel is not lied

correctly and that crane 7A" lis faster than

crane “B" resulting in at degree angle with the

torizon. Due to this incline with the horizon the

load in crane A willbe : 27009 tonnes wile tn

crane B it will be: 248.1 tonnes.

‘This overload i calculated when

the column is supported by both

cranes in vertical position. I is

proportionally less before the col

urna reachesits vertical sition

Tne larger the distance

between the C. of G. and the lit.

Ing trunnions, the greater the

Influence of an incline on loads

‘on erane A and B willbe. These

loads are calculated below. (See Table L.)

When the distarce of the matn lifting run-

ions is inreased to twice the orignal dis

tance, the averload will increase to twice the

‘magnitude aswell See Table 2 beloe where the

distance ofthe main lifting trunnions has been

Increased to I2 metres

What have we learned from this exercise?”

First ofall try to install the main lifting trun-

Electronic inelinometer

Richard Krabbendam* continues his 4-article series on multiple crane

lifts with a project involving two main lift cranes and a tailcrane.

USING A TAILCRANE

sions as close as possible tothe C. of G. ofthe

pressure vessel. Be aware that we should

always keep the mai illing trunnions a least 2

rmettes above the C. of G and nat any closer.

"The reason fr this thatthe main iting sings

are placed around the elreumference of the

trunnions and the freon thus ereated could

prevent the trunnions rotating in the slings as

‘the columo ls ited I this hapoens, the slings

‘will eventually tur. However, a the end ofthe

‘operation, one may find thatthe colemn will

‘not completely turn into the vertical psition =

{his wil hinder the lowering down over the

Foundation bolts.

To counter this problem I would recom

mond the following

"Place a 2 milimetre thick steel strip between

te trunnions an the Uiting slings and grease

Sit. This wil allow the siings to

tum better around the trun-

rlons’ surface and at the same

time protec the sling from wear

and tear. SeeFigured)

1 Place steel guides om a least 3

foundation boks. These guides

‘wll eelate the postioning of

‘the column's base rine aver the

Joundation boli. Its also ads-

ale to connect 4 chain tees or

{frst the base ring during the loveringproce-

‘cure. These tools wll be of great help n guicing

the base tng and will avold possible damage to

the thread ofthe foundation bats.

VITAL MONITORING

We sll have net discussed the main issue of tis

‘operation: how da we accurately moaiter eich

Tiking teunnio to ensue that Ht stays i a el- be

7 TABLE 1

Distance to GofG.: 6m

‘Angle with horizon e r = ¥ a

Teadincrane “8 zauor | 200m | ze07e: | 20281 | s00407

Teadncane peoor | sar | asa | 2as7er | Der

Heghtdicencebawen NES | oem | gen | isan | 2Bem | sem

TABLE 2

Distance to GofG: 12m

‘Angle with horizon e r = = e

loadin "5 pevor | zai | souast | s20s6r | sA0eDr

Teadincane poor | seas | aiaesr | WsBaa | 17820

Heghtdficerabawen XE | ven | sen | an | 2Ben | Seen

33

THE SAFE VIEW

Toierone “C"

Wain Ltt Crane “8

i i 160 ras Sane“

<4 zontal plane during the entire iting procedure?

During @ large number of tandem lis of big

columns, I have successfully used the same

‘method over and over again. During my first

tandem lift back in 1976, used two methods to

‘monitor possible overload of each crane. Load

Indicators, which were installed in the dead

fend of the lifting tackle and an electronic

Inclino meter, which measured the angle of the

Imaginary line between both liting trunions

‘andthe horizon (Se Figure 4.)

‘Imust admit thatthe load indicators were of

‘no use at al, Due to the friction of the sheaves of

‘oth iting tackles, the variations in the dead end

ofthe tackle ofeach erane were In no way are

able measure from which to monitor the opers-

tion, The incino meter, which we installed on a

ssivelplate a the basering of the column, was far

‘more reliable and proved to bea very good too.

‘The inclinometer is fitted on a multiplex

board with a swivel and can be clamped to the

top of the basering or atthe bottom. See Figure

4.As an extra precaution we attached a normal

spirit level on the same swivel plate so that

even fthere were an electronic failure we could

sii monitor the operation. As the tables show,

tls very important to keep both Ifting trun-

ions horizontal during the entire lifting proce-

dure and thus avotd any overloading of any of

the main lit cranes. Normally, one would! post

tion both main lft cranes and tailerane as

shown in figure 2. By calculating the decrease

ofthe taiLioad in relation to the angle with the

vertical we can establish the most economical

Position of tailcrane“C". Let's now look at how

the talHload decreases in relation to the angle

with the vertical See Table3.)

‘With the results of this table we can now

establish the optimum position ofthe ai-erane.

‘The tallerane should a least have a capacity of

about 80 tonnes at aradlus ofabout 14 metres. A

Liebherr LTM-1400 with Spanlit system has

capacity of 87 tonnes at 14 metres radius with

5355 metres booenlength. It seems that this tele-

scopic crane would have sufficient capacity to

handle the talload of our column, We now have

to position the Liebherr atthe side of the column

between the tabiug and the main it eranes, in

such a way that we can really prove that the

‘rane can guide the tat point ofthe column until

thas reached its vertial position.

ig. 3 the position of each crane is clearly

TABLE 3 ANGLE TO THE VERTICAL

Identified. As main lit cranes we have selected

two mobile Demag TC3000 cranes with

‘Superlift attachment. Each crane is positioned

at 10 metres radius with 54 metres main boom

and has a rated liting capacity of 340 tonnes

with 100 tonnes Superiit counterweight. The

deal positions with each crane placed perpen-

dicular tothe column's longitudinal centreline.

In our case, both lifting trunnions protrude 650

millimetres outside the column's shell, which

Just gives a theoretical clearance of about 150

millimetres (this depends on the physical

«dimensions ofthe erane boombeads)

‘The rated liting capacity for both cranes in

tandem is 2340 = 680 tonnes. With a weight of

4520 tonnes, tis liting capacity Is 520/680 = 75

per cent ofthe maximum allowable iting capac-

ity, which we considered safe, provided the pre-

cautions aretakenas described inthis article. We

could even accept a smaller safety margin, which

‘means that these crane types could even erect

columns close to the 600 tonnes weight category.

‘The concluding part of this article, dealing

with the erection procedures and alignment of

the vessel, wil be published inthe March issue

of terationat Cranes,

“Richard Krabbendan Vee resident fume

cine ae Toe a aes

cel ooirsa | ea Rael few eed ae rds bor sacar oe

oat,

| Taderane“c* reo] ran] raat] rat] o8.ar| eror] ssat] aaa] oo ‘directa of itrec BV Holland, He!

| ae

S-ar putea să vă placă și

- Guia Parafusos, Arruelas E Porcas 1Document156 paginiGuia Parafusos, Arruelas E Porcas 1Adrian VerattiÎncă nu există evaluări

- User SettingsDocument3 paginiUser SettingserdemÎncă nu există evaluări

- Torrent Downloaded From RARBGDocument1 paginăTorrent Downloaded From RARBGdemidoverÎncă nu există evaluări

- Guidelines For Lifting Operations by Floating Vessels CranesDocument36 paginiGuidelines For Lifting Operations by Floating Vessels CranesKin Lai KongÎncă nu există evaluări

- Vagabond Volume 02.Cbr - Inoue TakehikiDocument225 paginiVagabond Volume 02.Cbr - Inoue TakehikiThiago MilitãoÎncă nu există evaluări

- Mulitiple Crane Lifts David DuerrC PDFDocument2 paginiMulitiple Crane Lifts David DuerrC PDFdemidoverÎncă nu există evaluări

- Technical Policy Board Guidelines For Marine Lifting OperationsDocument42 paginiTechnical Policy Board Guidelines For Marine Lifting Operationscostantin2100% (1)

- Hyundai Diesel Forklift Trucks Environmental-Friendly Performance GuideDocument16 paginiHyundai Diesel Forklift Trucks Environmental-Friendly Performance Guidedemidover100% (1)

- Technical Policy Board Guidelines For Marine Lifting OperationsDocument42 paginiTechnical Policy Board Guidelines For Marine Lifting Operationscostantin2100% (1)

- Eslingas Dobradas Fator de ReduçãoDocument2 paginiEslingas Dobradas Fator de ReduçãoDonizete TavaresÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)