Documente Academic

Documente Profesional

Documente Cultură

SL92-291 B&W Service Letter 2 Stroke Engines

Încărcat de

kamal0 evaluări0% au considerat acest document util (0 voturi)

16 vizualizări3 paginiB&W Service letter 2 Stroke Engines

Titlu original

SL92-291 B&W Service letter 2 Stroke Engines

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentB&W Service letter 2 Stroke Engines

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

16 vizualizări3 paginiSL92-291 B&W Service Letter 2 Stroke Engines

Încărcat de

kamalB&W Service letter 2 Stroke Engines

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 3

MAN B&W Diesel A/S Baw

Service Letter No: SL92-291/UM

March 1992

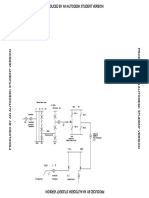

S/K/L50-60-70-80-90MC

Exhaust Valve Lifting Gear Arrangement

Dear Sirs,

With nearly 2000 MC engines in service, we have got reports

about a few cases of breakage of the lifting gear for the

exhaust valve actuator. The reason for breakage was a lack

of clearance between the lifting gear arm (pos. 2 on the

enclosed drawing) and the roller guide in its bottom

position, owing to incorrect tightening. As a result, the

lifting gear arm was hit by the bottom of the roller guide

at each stroke.

As the lifting gear arrangement is seldom used, and only in

connection with emergency running, a possible breakage will

not normally be recognised until the bottom tray of the cam-

shaft housing is inspected. In the reported cases, breakage

of the spindle end was not discovered until the lifting arm

was found broken.

However, recently we learned about one single case of a

breakage which led to severe camshaft damage. The broken-off

lifting arm was, due to heavy rolling of the ship, caught

between the exhaust cam and the housing.

Against this background, we recommend that, at the first

opportunity, the clearance is checked between the lifting

gear arm and the exhaust roller guide in its bottom posi-

tion. The clearance should be min. 3 mm, except for the

S/L50MC for which 2.5 mm is permitted, as will appear from

the enclosed drawing.

HEAD OFFICE (& posta ederess) DIESEL SERVICE FORWARONG & RECEIVING MAN 28W Diesel A/S

‘Staromer Tel Stemhoimen Yo ‘Teghermagece 35 Toginamagade 35 Benmark

DK:2650 rwidove (Copenhagen) DX 2680 Hedowre (Copenhagen) Die2450 Copenhagen SV DIC2a80 Copernagen SV Reg No 24234

hone 453400 2501 ‘olephone: 40314925 01° Telephone: 48 313) 44°93 Telephone: tae 331 4439,

len manbano ‘elo 19028 ontonw de

"97 man {9002 ber de

opy! 45314043 97 opy #48 9317920

‘etecopy = asa 493066

Totscopy 245 31 43.4172

‘0023 onfore ak

py #48 31395 22

The check should be carried out in the following manner:

0.0 Stop the engine.

1.0 Check the correct tightening of the locking device of

the lifting gear in its neutral position.

1.1 Check that the stop block (pos. 12) is in the

blocking position.

1.2 Loosen the nut (pos. 7) completely and ensure that

the lifting gear is resting in the lower position

(pos. 11).

1.3 Retighten the screw (pos. 13) of the stop block in

accordance with the enclosed drawing.

2.0 With the roller guide in the bottom position, check the

clearance between lifting arm and exhaust roller guide,

through the inspection cover in the cam housing. If the

clearance is too small, the correct clearance is esta-

blished by filing off the top of the pin on the lifting

gear arm.

3.0 Now tighten the nut (pos. 7) lightly with 10 Nm (1 kpm

only).

4.0 Finally, check that the clearance between arm and

roller guide is correct.

Yours faithfully,

MAN B&W Diesel A/S

n

{

Encl.

MAN B&W DIESEL,

@

oT

Bottom dead centre.

yeaa B lleteonane | x(a cone uNeiem (aoe 13)

K9OMC-C_L/S90MC 3 525

L/S80MG 310

L/S70Mq 165

K60MC _L/S60MC 165 _

L/S50Mq 2.5 65

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- OTL R12 ImplementationDocument288 paginiOTL R12 ImplementationSarah Kay MortelÎncă nu există evaluări

- Basement Masonry Wall Design Based On TMS 402-16/13: Input Data & Design SummaryDocument2 paginiBasement Masonry Wall Design Based On TMS 402-16/13: Input Data & Design SummaryRidho ZiskaÎncă nu există evaluări

- Chemical Process Plant SafetyDocument37 paginiChemical Process Plant Safetyvenky437Încă nu există evaluări

- How To Restring An Acoustic Guitar Nicholas OngkowijayaDocument9 paginiHow To Restring An Acoustic Guitar Nicholas Ongkowijayaplebeius31Încă nu există evaluări

- ITP For Pipeline (Sampel)Document5 paginiITP For Pipeline (Sampel)Reza RkndÎncă nu există evaluări

- Solucionario Statistics For Business and Economics - David R. Anderson, Dennis J. Sweeney - 8edDocument8 paginiSolucionario Statistics For Business and Economics - David R. Anderson, Dennis J. Sweeney - 8edTukumaneriko Filiponditoniko0% (1)

- SL98-356 B&W Service LetterDocument14 paginiSL98-356 B&W Service LetterkamalÎncă nu există evaluări

- SL96-339 B&W Service LetterDocument5 paginiSL96-339 B&W Service LetterkamalÎncă nu există evaluări

- How To Calculate Floor Load CapacityDocument3 paginiHow To Calculate Floor Load CapacityNatarajan KrishnanÎncă nu există evaluări

- Fallout New OrleansDocument44 paginiFallout New Orleansender000Încă nu există evaluări

- SL97-345 B&W Service LetterDocument5 paginiSL97-345 B&W Service Letterkamal100% (1)

- SL97-348 B&W Service LetterDocument1 paginăSL97-348 B&W Service LetterkamalÎncă nu există evaluări

- Process Simulation in Refineries SamplerDocument30 paginiProcess Simulation in Refineries SamplerNagendra HÎncă nu există evaluări

- SL99-370 - B&W Service LetterDocument1 paginăSL99-370 - B&W Service LetterkamalÎncă nu există evaluări

- SL99-366 B&W Service LetterDocument3 paginiSL99-366 B&W Service LetterkamalÎncă nu există evaluări

- SL99-373 B&W Service LetterDocument2 paginiSL99-373 B&W Service LetterkamalÎncă nu există evaluări

- SL99-374 B&W Service Letter 2 Stroke EnginesDocument2 paginiSL99-374 B&W Service Letter 2 Stroke Engineskamal100% (1)

- SL99-372 B&W Service LetterDocument2 paginiSL99-372 B&W Service LetterkamalÎncă nu există evaluări

- SL99-369 B&W Service LetterDocument2 paginiSL99-369 B&W Service LetterkamalÎncă nu există evaluări

- SL98-359 B&W Service LetterDocument1 paginăSL98-359 B&W Service LetterkamalÎncă nu există evaluări

- SL98-358 B&W Service LetterDocument3 paginiSL98-358 B&W Service LetterkamalÎncă nu există evaluări

- SL99-368 B&W Service LetterDocument5 paginiSL99-368 B&W Service Letterkamal100% (1)

- SL98-355 B&W Service LetterDocument4 paginiSL98-355 B&W Service LetterkamalÎncă nu există evaluări

- SL95-332 B&W Service LetterDocument6 paginiSL95-332 B&W Service LetterkamalÎncă nu există evaluări

- SL97-352 B&W Service LetterDocument2 paginiSL97-352 B&W Service LetterkamalÎncă nu există evaluări

- SL97-344 B&W Service LetterDocument2 paginiSL97-344 B&W Service LetterkamalÎncă nu există evaluări

- SL96-342 B&W Service LetterDocument5 paginiSL96-342 B&W Service LetterkamalÎncă nu există evaluări

- SL96-341 B&W Service LetterDocument4 paginiSL96-341 B&W Service LetterkamalÎncă nu există evaluări

- SL95-327 B&W Service LetterDocument4 paginiSL95-327 B&W Service LetterkamalÎncă nu există evaluări

- SL95-328 B&W Service LetterDocument4 paginiSL95-328 B&W Service Letterkamal100% (1)

- SL95-329 B&W Service LetterDocument2 paginiSL95-329 B&W Service LetterkamalÎncă nu există evaluări

- SL94-318 B&W Service LetterDocument8 paginiSL94-318 B&W Service LetterkamalÎncă nu există evaluări

- SL95-326 B&W Service LetterDocument3 paginiSL95-326 B&W Service LetterkamalÎncă nu există evaluări

- SL93-313 B&W Service Letter 2 Stroke EnginesDocument6 paginiSL93-313 B&W Service Letter 2 Stroke EngineskamalÎncă nu există evaluări

- SL94-316 B&W Service Letter 2 Stroke EnginesDocument3 paginiSL94-316 B&W Service Letter 2 Stroke EngineskamalÎncă nu există evaluări

- SL91-277 B&W Service Letter 2 Stroke EnginesDocument3 paginiSL91-277 B&W Service Letter 2 Stroke EngineskamalÎncă nu există evaluări

- SL91-286 B&W Service Letter 2 Stroke EnginesDocument10 paginiSL91-286 B&W Service Letter 2 Stroke EngineskamalÎncă nu există evaluări

- Mouse 200Document2 paginiMouse 200Amjad AliÎncă nu există evaluări

- The Impact of Greed On Academic Medicine and Patient CareDocument5 paginiThe Impact of Greed On Academic Medicine and Patient CareBhawana Prashant AgrawalÎncă nu există evaluări

- Ne40 Ne80 PDFDocument192 paginiNe40 Ne80 PDFณัชชา ธนปัญจาภรณ์Încă nu există evaluări

- Stock Market Lesson PlanDocument4 paginiStock Market Lesson PlanWilliam BaileyÎncă nu există evaluări

- Sony CR1220 PDFDocument2 paginiSony CR1220 PDFdiego742000Încă nu există evaluări

- Reynolds EqnDocument27 paginiReynolds EqnSuman KhanalÎncă nu există evaluări

- E 321 - 96 - Rtmymq - PDFDocument9 paginiE 321 - 96 - Rtmymq - PDFPrakash MakadiaÎncă nu există evaluări

- Gym Mega ForceDocument3 paginiGym Mega ForceAnonymous iKb87OIÎncă nu există evaluări

- HydroAir™ Variable Radius Turbine - Dresser-RandDocument2 paginiHydroAir™ Variable Radius Turbine - Dresser-RandLeoPérezÎncă nu există evaluări

- TCE BE EEE RulesandRegulationsDocument509 paginiTCE BE EEE RulesandRegulationsAplieÎncă nu există evaluări

- 01 SQL ErrorsDocument2.085 pagini01 SQL ErrorsM. temÎncă nu există evaluări

- 11kv BB1Document1 pagină11kv BB1Hammadiqbal12Încă nu există evaluări

- Blinx01's Ultimate DVD Subbing GuideDocument12 paginiBlinx01's Ultimate DVD Subbing GuideloscanÎncă nu există evaluări

- Toshiba NB520 Compal LA-6859PDocument38 paginiToshiba NB520 Compal LA-6859Pash thonÎncă nu există evaluări

- Lighting Lighting: Smartbright Direct Panel G2Document2 paginiLighting Lighting: Smartbright Direct Panel G2Devin Yhojan Viafara MancillaÎncă nu există evaluări

- The Role of Social Media and Its Implication On Economic Growth On Society in IndiaDocument3 paginiThe Role of Social Media and Its Implication On Economic Growth On Society in IndiaSara EmamiÎncă nu există evaluări

- Unit 4 SoftwareDocument16 paginiUnit 4 Softwareapi-293630155Încă nu există evaluări

- REA 101 Proteccion de Arco EléctricoDocument64 paginiREA 101 Proteccion de Arco EléctricoIngJGMÎncă nu există evaluări

- Yaskawa TM.J7.01Document96 paginiYaskawa TM.J7.01Salvador CrisantosÎncă nu există evaluări

- Installation of Water HeatersDocument5 paginiInstallation of Water HeatersLaura KurniawanÎncă nu există evaluări

- k2601 enDocument12 paginik2601 enRobert MasaÎncă nu există evaluări